Professional Documents

Culture Documents

Spiral PNR PDF

Uploaded by

Robin SanjayaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spiral PNR PDF

Uploaded by

Robin SanjayaCopyright:

Available Formats

24

www.pnr-nozzles.com

FULL CONE NOZZLES

E

RG

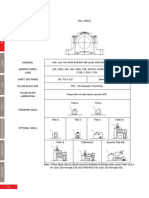

SPIRAL NOZZLES

Spiral nozzles work on the impact principle. The stream of liquid is

deflected onto a surface which is engineered into a spiral profile

creating the desired spray angle. The spray angle value is

maintained even at low pressure and also when spraying high

viscosity liquids.

While the droplet spray distribution is not comparable to that of a

standard full cone nozzle, the fact that an internal vane is not

present makes them virtually clog-free in most cases.

Please note that spray coverage is not as uniform as that from a

standard full cone nozzle with the internal vane. The capacity

values provided on the grey background in the table below should

be attributed to metal nozzles only, as plastic materials can be too

weak to assure structural resistance in the nozzle. See next page

for materials, applications and assembly fittings.

H1

WS

H

Materials

B31

T1

AISI 316L Stainless steel

Brass

The two above materials are usually available in stock, while several

other materials, as listed on page 25, can be offered on request.

Code

60

90

EBQ 1550 xx

EBQ 2156 xx

ECQ 2230 xx

ECQ 2410 xx

ECQ 2640 xx

EDQ 2940 xx

EDQ 3128 xx

EEQ 3165 xx

EFQ 3260 xx

EHQ 3507 xx

EBU 1550 xx

EBU 2100 xx

EBU 2156 xx

ECU 2230 xx

ECU 2317 xx

ECU 2410 xx

ECU 2640 xx

EDU 2940 xx

EDU 3128 xx

EEU 3165 xx

EFU 3260 xx

EFU 3372 xx

EKU 4109 xx

EMU 4204 xx

EMU 4267 xx

RG

D

inch mm

1/4

3/8

1/2

3/4

1

1 1/2

1/4

3/8

1/2

3/4

1

2

3

D1

mm

Capacity

at different pressure values

lpm

bar

Dimensions

mm

0.7

1.0

2.0

3.0

5.0

7.0

10

H1

WS

4.49

12.7

19.2

33.9

52.7

77.1

105

135

212

414

5.50

15.6

23.5

41.5

64.6

94.4

128

165

260

507

7.10

20.1

30.3

53.6

83.4

122

165

213

336

655

8.40

23.8

35.9

63.4

99.0

144

196

252

397

774

10.0

28.5

42.9

75.8

118

172

234

301

475

926

45

12

14

48

14

19

64

18

22

70

92

111

19

26

27

27

34

50

7.10 8.40

12.9 15.3

20.1 23.8

30.3 35.9

40.9 48.4

53.6 63.4

83.4 99.0

122 144

165 196

213 252

336 397

480 568

1407 1665

2633 3116

3447 4078

10.0

18.3

28.5

42.9

57.9

75.8

118

172

234

301

475

679

1990

3724

4874

45

12

14

48

14

19

64

18

22

70

92

19

26

27

34

149

219

31

42

65

89

2.4

4.0

4.8

6.4

7.9

9.5

11.1

12.7

15.9

22.2

2.4

3.2

3.2

3.2

3.2

4.7

4.7

4.7

6.3

7.9

2.66

7.54

11.4

20.0

31.2

45.6

61.8

79.7

126

245

3.18

9.01

13.6

24.0

37.3

54.5

73.9

95.3

150

293

2.4

3.2

4.0

4.8

5.6

6.4

7.9

9.5

11.1

12.7

19.0

23.0

34.9

44.5

50.8

2.4

3.2

3.2

3.2

3.9

4.8

5.5

3.3

3.7

4.7

6.3

6.3

11.1

14.3

2.66

4.83

7.54

11.4

15.3

20.0

31.2

45.6

61.8

79.7

126

180

527

985

1290

3.18 4.49 5.50

5.77 8.16 10.0

9.01 12.7 15.6

13.6 19.2 23.5

18.3 25.9 31.7

24.0 33.9 41.5

37.3 52.7 64.6

54.5 77.1 94.4

73.9 105

128

95.3 135

165

150 212

260

215 304

372

629 890 1090

1178 1666 2040

1541 2180 2670

Pressure values and capacities shown here on the grey background are recommended for cast or machined metal

nozzles only.

The picture shows the inside of a

spiral nozzle with a completely

free passage, without any

internal vane.

www.pnr-nozzles.com

FULL CONE NOZZLES

E

SPIRAL NOZZLES

Code

120

150

180

EBW 1550 xx

EBW 2100 xx

EBW 2156 xx

ECW 2156 xx

ECW 2230 xx

ECW 2317 xx

ECW 2410 xx

ECW 2640 xx

EDW 2940 xx

EDW 3104 xx

EDW 3128 xx

EEW 3165 xx

EFW 3260 xx

EFW 3372 xx

EHW 3507 xx

EHW 3663 xx

EHW 3747 xx

EKW 4109 xx

EKW 4139 xx

EMW 4204 xx

EMW 4265 xx

EPW 4412 xx

ECX 2230 xx

ECX 2317 xx

ECX 2410 xx

ECX 2640 xx

EDX 2940 xx

EDX 3128 xx

EEX 3165 xx

EFX 3260 xx

EFX 3372 xx

EHX 3507 xx

EHX 3663 xx

EHX 3747 xx

EKX 4109 xx

EKX 4139 xx

EBZ 2156 xx

ECZ 2230 xx

ECZ 2317 xx

ECZ 2410 xx

ECZ 2640 xx

EDZ 2940 xx

EDZ 3128 xx

EEZ 3165 xx

EFZ 3260 xx

EFZ 3372 xx

EHZ 3507 xx

EHZ 3663 xx

EHZ 3747 xx

EKZ 4109 xx

EKZ 4139 xx

RG

D

inch mm

1/4

3/8

1/2

3/4

1

1 1/2

2

3

4

3/8

1/2

3/4

1

1 1/2

1/4

3/8

1/2

3/4

1

1 1/2

2.4

3.2

4.0

4.0

4.8

5.6

6.4

7.9

9.5

9.7

11.1

12.7

15.9

19.0

22.2

25.4

28.6

34.9

38.1

44.5

51.0

63.5

4.8

5.6

6.4

7.9

9.5

11.1

12.7

15.9

19.0

22.2

25.4

28.6

34.9

38.1

4.0

4.8

5.6

6.4

7.9

9.5

11.1

12.7

15.9

19.0

22.2

25.4

28.6

34.9

38.1

D1

mm

2.4

3.2

3.2

3.2

3.2

4.0

4.0

4.0

4.8

4.8

4.8

4.8

6.3

7.9

11.1

14.3

15.9

3.2

4.0

4.8

4.8

6.3

7.9

11.1

2.5

3.2

4.0

3.3

4.8

4.7

6.3

7.9

11.1

Capacity

at different pressure values

lpm

bar

Dimensions

mm

0.7

1.0

2.0

3.0

5.0

7.0

10

H1

WS

2.66

4.83

7.54

7.54

11.4

15.3

20.0

31.2

45.6

50.2

61.8

79.7

126

180

245

320

361

527

671

985

1280

1990

3.18

5.77

9.01

9.01

13.6

18.3

24.0

37.3

54.5

60.0

73.9

95.3

150

215

293

383

431

629

803

1178

1530

2379

4.49

8.16

12.7

12.7

19.2

25.9

33.9

52.7

77.1

84.9

105

135

212

304

414

541

610

890

1136

1666

2164

3364

5.50

10.0

15.6

15.6

23.5

31.7

41.5

64.6

94.4

104

128

165

260

372

507

663

747

1090

1391

2040

2650

4120

7.10

12.9

20.1

20.1

30.3

40.9

53.6

83.4

122

134

165

213

336

480

655

856

964

1407

1796

2634

3421

5318

8.40

15.3

23.8

23.8

35.9

48.4

63.4

98.7

144

159

196

252

397

568

774

1013

1141

1665

2125

3116

4048

6293

10.0

18.3

28.5

28.5

42.9

57.9

75.8

118

172

190

234

301

475

679

926

1210

1364

1990

2540

3725

4838

7522

45

12

14

48

14

19

64

18

22

70

92

19

26

27

34

111

27

50

149

31

65

203

35

90

230

40

127

11.4

15.3

20.0

31.2

45.6

61.8

79.7

126

180

245

320

361

527

671

13.6

18.3

24.0

37.3

54.5

73.9

95.3

150

215

293

383

431

629

803

19.2 23.5

25.9 31.7

33.9 41.5

52.7 64.6

77.1 94.4

105

128

135

165

212

260

304

372

414

507

541

663

610

747

890 1090

1136 1391

30.3

40.9

53.6

83.4

122

165

213

336

480

655

856

964

1407

1796

35.9

48.4

63.4

98.7

144

196

252

397

568

774

1013

1141

1665

2125

42.9

57.9

75.8

118

172

234

301

475

679

926

1210

1364

1990

2540

48

14

19

64

18

22

70

92

19

26

27

34

111

27

50

149

31

65

7.54

11.4

15.3

20.0

31.2

45.6

61.8

79.7

126

180

245

320

361

527

671

9.01

13.6

18.3

24.0

37.3

54.5

73.9

95.3

150

215

293

383

431

629

803

12.7 15.6

19.2 23.5

25.9 31.7

33.9 41.5

52.7 64.6

77.1 94.4

105

128

135

165

212

260

304

372

414

507

541

663

610

747

890 1090

1136 1391

20.1

30.3

40.9

53.6

83.4

122

165

213

336

480

655

856

964

1407

1796

23.8

35.9

48.4

63.4

99.0

144

196

252

397

568

774

1013

1141

1665

2125

28.5

42.9

57.9

75.8

118

172

234

301

475

679

926

1210

1364

1990

2540

45

48

12

14

14

19

64

18

22

70

92

19

25

27

36

111

27

50

149

31

63

Pressure values and capacities shown here on the grey background are recommended for cast or machined metal

nozzles only.

Spiral nozzles can be delivered in brass and in all the plastic

materials from the opposite list. Most types are also

available from stock or with a short delivery if in cast 316

stainless steel. Please contact our sales offices for delivery

time in a given material.

Materials

B31

D1

D2

D8

E1

L8

T1

AISI 316L Stainless steel

PVC

Polypropylene

PVDF

PTFE

Hastelloy C 276

Brass

25

You might also like

- Series 406NRSRW Specification SheetDocument2 pagesSeries 406NRSRW Specification SheetWattsNo ratings yet

- Globe ValvesDocument12 pagesGlobe ValvesVivekanandan VaiyapuriNo ratings yet

- Valves Reference PDFDocument35 pagesValves Reference PDFJulio RodriguezNo ratings yet

- Welding Consumables For Pipeline ConstructionDocument32 pagesWelding Consumables For Pipeline ConstructionElias KapaNo ratings yet

- Butterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetDocument2 pagesButterfly Valves Series BF-03-M2 Full Lug and BF-04-M2 Wafer Specification SheetWattsNo ratings yet

- Wireway Spec Sec GDocument22 pagesWireway Spec Sec Grieza_fNo ratings yet

- Iso 9001 CertifiedDocument4 pagesIso 9001 CertifiedLuis R. Salas SotoNo ratings yet

- Full Lift Spring Loaded Open PDFDocument4 pagesFull Lift Spring Loaded Open PDFVenkatespatange RaoNo ratings yet

- PIPING - VALVES - American Flow Control (Gate Valves) (8 PAGES)Document8 pagesPIPING - VALVES - American Flow Control (Gate Valves) (8 PAGES)fkhajehNo ratings yet

- Faslt 0020 enDocument6 pagesFaslt 0020 enshashikanth79No ratings yet

- Gate Valve CataogueDocument4 pagesGate Valve CataogueAditya B. RyantoNo ratings yet

- Válvulas Bola SegmentadaDocument12 pagesVálvulas Bola SegmentadarehynaldoNo ratings yet

- 16620YDocument17 pages16620YbalajivangaruNo ratings yet

- MasterSeries 876V Specification SheetDocument4 pagesMasterSeries 876V Specification SheetFEBCONo ratings yet

- Catalogo Accesorios BpeDocument4 pagesCatalogo Accesorios Bpejuan1215No ratings yet

- Gruvlok Stainless SteelDocument16 pagesGruvlok Stainless Steellink2u_007No ratings yet

- SREBRSuperH Plug ValvesDocument39 pagesSREBRSuperH Plug ValvesFAZUL412100% (1)

- CAST STEEL GATE VALVES UNDER 40 CHARACTERSDocument4 pagesCAST STEEL GATE VALVES UNDER 40 CHARACTERSsghinausNo ratings yet

- KVC 01Document35 pagesKVC 01hamidreza_m85No ratings yet

- Piping ComponentDocument19 pagesPiping Componentreach_arindomNo ratings yet

- BB1-Catalogue 2015Document8 pagesBB1-Catalogue 2015nima hasanzadehNo ratings yet

- Bonetti WBY CatalogueDocument16 pagesBonetti WBY CatalogueisluqueNo ratings yet

- MasterSeries 850 Specification SheetDocument2 pagesMasterSeries 850 Specification SheetFEBCONo ratings yet

- Ergozone New Oct PricelistDocument9 pagesErgozone New Oct PricelistSaurabh BhopleNo ratings yet

- Asa FlangesDocument15 pagesAsa Flangesash.josephite9658No ratings yet

- Saint Gobain Sluice ValvesDocument2 pagesSaint Gobain Sluice ValveskibzeamNo ratings yet

- Victaulic PDFDocument10 pagesVictaulic PDFLim PaNo ratings yet

- Goodwin CatalogDocument56 pagesGoodwin Catalogcavillalobosb8167No ratings yet

- MasterSeries 860 Specification SheetDocument2 pagesMasterSeries 860 Specification SheetFEBCONo ratings yet

- TRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFDocument8 pagesTRIPLE OFFSET BUTTERFLY VALVE TX Literature PDFjdietz4No ratings yet

- Hammer Unions by KemperDocument20 pagesHammer Unions by Kemperjahehe2000100% (2)

- NW FlangeDocument11 pagesNW FlangeStanley PeterNo ratings yet

- MAKO Piping Library Catalogue - Rev CDocument28 pagesMAKO Piping Library Catalogue - Rev Celmfp7774676No ratings yet

- Virgo Welded Valve BrochureDocument8 pagesVirgo Welded Valve BrochureHerrera Jorge AgustínNo ratings yet

- Mip Bohler PipelineDocument32 pagesMip Bohler PipelineDaniel StuparekNo ratings yet

- Bosch Rexroth Fusos EsferasDocument164 pagesBosch Rexroth Fusos EsferasjomiseferNo ratings yet

- Fire Hose and Nozzle Catalog /TITLEDocument30 pagesFire Hose and Nozzle Catalog /TITLEHeru Agung SetyantoNo ratings yet

- Ferulok Flareless Bite Type FittingsDocument14 pagesFerulok Flareless Bite Type FittingsPartsGopher.comNo ratings yet

- 43.11 Series 4360 4380 BrochureDocument4 pages43.11 Series 4360 4380 BrochureGregory DouglassNo ratings yet

- Material Compliance Sheet ValvesDocument10 pagesMaterial Compliance Sheet ValvesindikumaNo ratings yet

- Tool HoldersDocument35 pagesTool HoldersCarlos Santos Ramirez MarañonNo ratings yet

- FMC Weco Wing Union CatalogDocument16 pagesFMC Weco Wing Union CatalogSargunam Sankaravadivel100% (2)

- Needle ValvesDocument18 pagesNeedle ValvesPablo RodriguezNo ratings yet

- Ball ValveDocument12 pagesBall ValveIdabaNo ratings yet

- 5EH Steam Jet EjectorsDocument18 pages5EH Steam Jet Ejectorsbijan1350No ratings yet

- Legrand Swiftrack Channel Support System Framework Brackets TechnicalDocument1 pageLegrand Swiftrack Channel Support System Framework Brackets TechnicalMikaela MihaNo ratings yet

- Swagelok Tubing SpecificationsDocument8 pagesSwagelok Tubing SpecificationsAugustine Owo UkpongNo ratings yet

- Victaulic W07 Rigid Cplg.20.02Document4 pagesVictaulic W07 Rigid Cplg.20.02dan_capitanNo ratings yet

- SpecDocument2 pagesSpecneversigNo ratings yet

- X156 Product PagesDocument2 pagesX156 Product PagesykanchanamNo ratings yet

- SKF Pillow Block HousingsDocument64 pagesSKF Pillow Block HousingsJulio Deyvis Ayala Gutierrez100% (1)

- KUKMC-0394-US Valv Seg KunkleDocument12 pagesKUKMC-0394-US Valv Seg Kunklejose_cadNo ratings yet

- Hep CatalogueDocument8 pagesHep CatalogueleonardsiregarNo ratings yet

- STP CatalogueDocument37 pagesSTP CataloguemmkattaNo ratings yet

- Valves Pipe Fittings DimensionsDocument37 pagesValves Pipe Fittings DimensionstsoheilNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- High-Performance GM LS-Series Cylinder Head GuideFrom EverandHigh-Performance GM LS-Series Cylinder Head GuideRating: 4.5 out of 5 stars4.5/5 (2)

- Alloy 6063 General InformationDocument60 pagesAlloy 6063 General InformationKi Joko BodoNo ratings yet

- Bosch Power Tools Product Catalogue 2014-2015 ID-id PDFDocument67 pagesBosch Power Tools Product Catalogue 2014-2015 ID-id PDFRobin SanjayaNo ratings yet

- Spiral PNR PDFDocument2 pagesSpiral PNR PDFRobin SanjayaNo ratings yet

- 141 Audio Amplifier ConfigurationsDocument26 pages141 Audio Amplifier ConfigurationsRobin SanjayaNo ratings yet

- Turbo TDocument3 pagesTurbo TjeffturboNo ratings yet

- 131 - 1.9.1.2-04T Babbitt WireDocument4 pages131 - 1.9.1.2-04T Babbitt WireRobin SanjayaNo ratings yet

- Solidworks Tutorial 07nov06Document13 pagesSolidworks Tutorial 07nov06Robin SanjayaNo ratings yet

- 8830 Arc Spray System 1.1.8.1Document5 pages8830 Arc Spray System 1.1.8.1Robin SanjayaNo ratings yet

- Capstone - PCB Artist TutorialDocument31 pagesCapstone - PCB Artist TutorialRobin SanjayaNo ratings yet

- Repair Procedures: Connection Field Repair (Refacing)Document5 pagesRepair Procedures: Connection Field Repair (Refacing)islam atif100% (1)

- EnclosurecatalogueDocument153 pagesEnclosurecatalogueTomuta StefanNo ratings yet

- Press Tool Design GuideDocument30 pagesPress Tool Design Guideਹਰਪ੍ਰੀਤ ਸਿੰਘNo ratings yet

- Class 125 Iron Y-StrainerDocument1 pageClass 125 Iron Y-StrainerNarendra Reddy BhumaNo ratings yet

- A Guide To Welding Electrodes On ShipsDocument7 pagesA Guide To Welding Electrodes On ShipsRicardoNo ratings yet

- E 252 - 84 R99 - Rti1mgDocument4 pagesE 252 - 84 R99 - Rti1mgmercab15No ratings yet

- Astm A 297 HU HK HTDocument4 pagesAstm A 297 HU HK HTSama UmateNo ratings yet

- Heat Treating Music Wire for Model Aircraft PartsDocument2 pagesHeat Treating Music Wire for Model Aircraft PartsCiprian MaiorNo ratings yet

- Balance The Equations Below:: Chapter 7 Worksheet #1 Balancing Chemical EquationsDocument4 pagesBalance The Equations Below:: Chapter 7 Worksheet #1 Balancing Chemical EquationsPharawee KrajanglokNo ratings yet

- Standard Internal Circlips - DIN 472 MetricDocument5 pagesStandard Internal Circlips - DIN 472 MetricAbhinav KumarNo ratings yet

- Automobile Engineering Diploma Third Semester Workshop PracticeDocument2 pagesAutomobile Engineering Diploma Third Semester Workshop PracticeSachi MensiNo ratings yet

- MCQ Metallurgy Question PaperDocument11 pagesMCQ Metallurgy Question PaperAshutosh AvasekarNo ratings yet

- AWS - Welding of Cast Iron - Papers PDFDocument365 pagesAWS - Welding of Cast Iron - Papers PDFCarlos Guanipa100% (5)

- F998Document7 pagesF998Jacildo Soares Cavalcante CavalcanteNo ratings yet

- 8 Science (Super Quiz) Formatted Sample Test Ans KeyDocument7 pages8 Science (Super Quiz) Formatted Sample Test Ans KeyVenus Tumampil AlvarezNo ratings yet

- 2006 ChainDocument48 pages2006 Chainhalder_kalyan9216No ratings yet

- PSM InternshipDocument30 pagesPSM InternshipAsad Alamgir Shaikh100% (1)

- Heat Treatment Processes for Different MaterialsDocument31 pagesHeat Treatment Processes for Different MaterialsvinayakNo ratings yet

- How To Control Kiln Shell CorrosionDocument72 pagesHow To Control Kiln Shell CorrosionNael100% (5)

- 03 04 Faradays Laws of Electrolysis and ApplicationsDocument12 pages03 04 Faradays Laws of Electrolysis and ApplicationsPavan ReddyNo ratings yet

- Arbor Press Drawings PDFDocument16 pagesArbor Press Drawings PDFSaul Fernando Cujaban AceroNo ratings yet

- Heat treatment and steel processes guideDocument12 pagesHeat treatment and steel processes guidevjtiitNo ratings yet

- Kyocera Turning CatalogDocument593 pagesKyocera Turning CatalogthyskieNo ratings yet

- M15 PDFDocument2 pagesM15 PDFkinjalpatel12345No ratings yet

- Why Alloy 625 Is Beneficial To Use As Buttering MaterialDocument3 pagesWhy Alloy 625 Is Beneficial To Use As Buttering Materialtan yahyaNo ratings yet

- Earth MagnetismDocument7 pagesEarth Magnetismisa_diogo8170No ratings yet

- CL Masafi PowertechDocument16 pagesCL Masafi PowertechPradeep PooNoorNo ratings yet

- Formwork ManualDocument20 pagesFormwork ManualYo Soy MasriNo ratings yet

- Astm A671 2004 PDFDocument9 pagesAstm A671 2004 PDFDevarajanRamasamyNo ratings yet

- Underground Cable Rev4 15oct09Document16 pagesUnderground Cable Rev4 15oct09najiruddinshaikNo ratings yet