Professional Documents

Culture Documents

Chapter 2

Uploaded by

Haiqal AzizCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter 2

Uploaded by

Haiqal AzizCopyright:

Available Formats

CHAPTER II

PROCESS MODELING AND FLOWSHEETING

2.1

INTRODUCTION

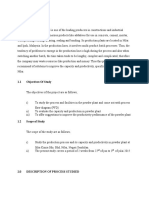

The process flow diagram (Figure 2.1) illustrates the urea plant process design.

This diagram is a layout of all units operation, which are needed in proper sequence to

convert the raw material to desired product, urea.

The plant is to produce a total amount of 200,000 metric ton urea per annum. The

operating day for this plant is 315 days per year and 24 hours a day. The minimum purity

of the urea in the market is 99% with not more than 1% biuret (Ullmanns Encyclopedia

of Industrial Chemistry, Volome, A27).

In this urea plant design, the urea is produced by interaction between ammonia

and carbon dioxide. The process can be represented schematically as essentially

constituting four sections, which are:

o Urea synthesis

o Urea purification

o Unconverted ammonia and carbon dioxide recovery and recycle

o Urea crystallization

Process Modeling & Flowsheeting

2- 2

-1352. kj/hr (condenser)

NH3 & CO2 Recovery

29

26

25

26

28

-1352. kj/hr (condenser)

14

M-11

C-18

3

1

C-21

2

M-1

C-2

X-3

10

R-4

C-16

12

R-

17

13

M-1

26

X-3

C-2

C-16

X-8

F-7

15

E-6

6 C-18

16

C-22

X-15

X-10

18

8

F-9

323

X-1

5

R-4

C-2

M-1

C-19

C-16

T-5

10

X-3

6

21

11

F-14

C-19

X-15

24

M-12

19

20

29

T-5

31

22

X-20

T-13

Urea

purification

Figure 2.1: Urea Production Process Flow Diagram

C-19

27

11

X-20

Vacuum

Crystallizer

Urea

Synthesis

X-17

30

Urea

Crystallization

Storage Tank

Process Modeling & Flowsheeting

2.2

2- 3

PROCESS DESCRIPTION

Referring to Figure 2.1, a great part of the carbamate [SC=Eff. (H2O + NH3 +

CO2] included in the urea solution coming out of the reactor (R-4) and part of the

free ammonia, NH3 present are stripped and recycled into the reactor, while a urea

solution leaves the stripper having a relatively low content of residual carbon

dioxide, CO2. This solution is treated in a purification column (T-13). And, the

obtained vapors from stripper (T-5) and purification column (T-13) are sent to a

series of flash column (F-7, F-9, F-14) to be treated and recycled to further reactions.

Finally, the urea-product solution is solidified based on crystallization concept. Such

a process, as are most of the urea processes used actually on industrial scale, is of the

total recycling type, which means that unreacted NH3 and CO2 coming out of the

reactor are recycled to the reactor.

2.2.1

Urea Synthesis

2.2.1.1 Pre Synthesis: Mixer, M-1; Compressor, C-2 and C-16; Heat Exchanger,

X-3

The fresh ammonia gas through line 1 is compressed and mixed with the

carbamate recycle stream (line 26) in the mixer, M-1. The recycle stream mainly

consists of ammonia, carbon dioxide and water vapor. Urea only occurs in this

recycle stream in minute quantities. The mixture is then compressed using

compressor, C-2 to a very high synthesis pressure at 175 bar. The feed to the reactor

are mainly cooled by heat exchanger, X-3 to synthesis temperature at 190C.

2.2.1.2 Urea Synthesis Reactor, R-4

The manufacture of urea which based on reaction of ammonia with carbon

dioxide occurs in a reactor, R-4 at elevated temperature (190C) and pressure of 175

bar. The outlet temperature of the reactor is same as the feed inlet temperature as the

reactor is isothermal type reactor.

Apparently the reaction takes place in two steps, the first is

Process Modeling & Flowsheeting

2NH3 (l)

Ammonia

2- 4

CO2 (l)

NH2COONH4 (l)

Carbon

Dioxide

Ammonium

Carbamate

H = -117KJ/mol

And the second step in the reaction is

NH2COONH4 (l)

NH2CONH2 (aq) + H2O (l)

Ammonium

Carbamate

Urea

H + +15.5KJ/mol

Water

In the first reaction, carbon dioxide and ammonia are converted to

ammonium carbamate: the reaction is fast and exothermic. In the second reaction,

which is slow and endothermic, ammonium carbamate dehydrates to produce urea

and water. Since more heat is produced in the first reaction than consumed in the

second, the overall reaction is exothermic (Ullmanns Encyclopedia of Industrial

Chemistry, Vol. A27).

The rate of formation of carbamate is highly dependent upon the pressure.

When all other factors are constant the rate of formation increases proportionally to

the square root of the pressure. The rate of formation also increase with temperature,

until a maximum is reached, at which point the rate decreases sharply to zero at a

temperature where the dissociation pressure is equal to the reaction pressure

(www.keele.ac.uk/depts/ch/resources/urea/ureahome.html). The dissociation pressure

of pure carbamate has been investigated quite extensively and the average value of

all the investigations is shown in Table 2.1.

Table 2.1: Dissociation Pressure of Pure Carbamate

Temperature, C

Ammonium

Carbamate Vapor

Pressure, atm absolute

40

60

80

100

120

140 160

0.31

1.05

3.1

8.5

21

46

98

180

200

150,190*

200,360*

Source: Encyclopedia of Chemical Technology, vol. 21

*

Obtained from extrapolation. Above 170C the rate of reaction 2 rapidly increases and exact

carbamate vapor pressure determinations are very difficult to perform due to the formation of water

and urea and the consequent lowering of the carbamate partial pressure.

Process Modeling & Flowsheeting

2- 5

From this information, therefore, it is advisable in industrial urea production

to operate at the highest pressure and at the highest temperature compatible with this

pressure. As the synthesis temperature and pressure have been chosen at 190C and

175 bar respectively, the effluent from the reactor, R-4 contains no ammonium

carbamate instead of carbamate included in the urea solution which consists H2O,

NH3, CO2 and urea.

The synthesis reaction in the reaction space, R-4 is carried out in accordance

with the following process parameters:

NH3/CO2mol

3.5

H2O/CO2mol

0.5

CO2 conversion yield

75%

Urea processes differ mainly in the conditions (composition, temperature and

pressure) at which these reactions are carried out. Traditionally, excess NH3 is used to

react with CO2. This is to minimize the biruet formation in the reaction space.

Biuret formation from urea:

2CO(NH2)2

NH2CONHCONH2 + NH3

Biuret is impurity which has been shown to be toxic to crops, thus the levels of this

must be kept low in the marketed urea product. The high NH3 concentration in the

reactor shifts the biuret formation reaction to the left, such that only a small amount

of, or no biuret is formed in the reactor. In downstream sections of the plant, NH3is

removed from the urea solution, thereby creating a driving force for biuret formation.

The effluent from reactor, R-4 which consists of carbamate included in urea

solution is then cooled down to 170C using a heat exchanger, X-15 before entering

purification section.

Process Modeling & Flowsheeting

2.2.2

2- 6

Urea Purification

2.2.2.1 CO2 Stripping Column, T-5

The stripping equipment, T-5 is subjecting the reaction mixture leaving

reactor R-4 to a treatment of separation of the free ammonia in aqueous solution

present in the mixture. In this column, at synthesis pressure, a considerable part of

free ammonia present in the urea solution is stripped off by the effect of stripping

CO2 which rises through the column in countercurrent after being fed through line 9.

Since the CO2 feed used as stripping agent need to be in gas form, thus, the feed

through line 8 has to be compressed using compressor, C-19.

From the to of T-5, a vapor mixture is obtained composed of carbamate

mixture at temperature of 188.38C, and is fed through the line 10 to the flash drum

zone. An expander, E-6 is used to reduce the high pressure effluent from the top

column to 12 bar before entering flash drum, F-7. From the bottom of T-5, a urea

solution is obtained at a higher temperature of 349.26C, comprising low

concentrations of both NH3 and CO2, water and urea, and is mixed with the bottom

effluent from flash drum zone (line 18) before going into the second stage of urea

purification through line 20.

2.2.2.2 Mixer, M-12

Urea solution with small portion of NH3 and CO2 from line 11, and flash drum

zone (line 18) are mixed in the mixer, M-12 for further urea purification. The

solution is preheated through a heat exchanger, X-17 to 150C and the vapor and

liquid mixture is fed into the purification column, T-13 through line 20 at pressure of

5 bar.

2.2.2.3 Urea Purification Column, T-13

The main objective of this distillation column is to get rid of the NH3 and CO2

that included in the urea solution in order to obtain higher purity and concentration

urea solution.

Process Modeling & Flowsheeting

2- 7

A negligible amount of NH3 and CO2 are present in the bottom product of T13. The urea concentration, so-called urea melt is normally set to be greater than

99%mol at this stage. This concentrate is fed through line 22 to solidification section

where crystallization takes place. The vapors produced in this purification stage are

fed through line 21 to a flash drum in order to get ammonia and carbon dioxide to be

recycled.

2.2.3

Ammonia And Carbon Dioxide Recovery And Recycle

2.2.3.1 Flash Drum: F-7, F-9, and F-14

The recovery of free ammonia begins in the stripper, T-5 where the ammonia

is stripped by fresh stream of carbon dioxide through line 9. The main objective of

this series of flash drum is to recover mainly ammonia and carbon dioxide from the

carbamate solution (SC). The feeds to the flash drums are heated (X-8, X-10) or

depressurized (E-6) before accessing the separation. The top vapors from the flash

drum zone recycled through the line 14, 17-28, and 23-29 is mixed in the mixer, M11 before going back the reactor, R-4. Compressors, C-21 and C-22 are used to raise

the outlet pressure of F-9 and F-14 in order to have same pressure of the three top

stream of the flash drums which entering mixer.

2.2.3.2 Heat Exchanger: X-8, and X-10

A total amount of four heat exchangers are used in the recovery and recycle

section. Both heat exchanger X-8 and x-10 are used to increase the temperature.

2.2.3.3 Mixer, M-11; Compressor, C-18

The multiple input streams from the flash drums through line 14, 17, and 23

are mixed before they are being sent out. The effluent from the mixer is compressed

by the compressor, C-18 before mixing with fresh feed ammonia (line 2) and

entering the reactor, R-4 for urea synthesis.

Process Modeling & Flowsheeting

2.2.4

2- 8

Urea Crystallization

Urea is normally obtained from the synthesis section as a concentrated

solution and is usually further processed to solid urea, which is more economical for

shipping and distribution. The solid form in which urea may appear include crystals,

flake, prills and granules. Here, urea crystallization is chosen as it presents a

relatively pure and quite well suited for both agricultural and industrial uses.

The urea-product solution containing more than 99% urea from the bottom of

urea purification column, T-13 is cooled using heat exchanger, X-20 to 140C and is

then fed through line 22 to a vacuum crystallizer. Water evaporates and leaves

crystallizer as water vapor (line 31). The crystals separated from the water vapor are

then sent to storage tank (line 29) and ready for final handling.

2.2.5

The Mond Index

The Mond Index is a rapid hazard assessment method for use on chemical

plant or in plant design. It produces a numerical ranking for each section of the plant

based upon the properties of materials present, quantity, operating conditions and

type of process. Scales are provided to convert the rankings into qualitative

descriptions of the hazard potential of each unit. The index is primarily concerned

with fire and explosion problems. Toxicity is considered only as a possible

complicating factor. The method gives credits for plant safety features associated

with both the hardware and the software.

The overall aim of the index is to provide a rapid means of identifying and

assessing those sections of the plant having a significant fire or explosion potential.

Uses of the index include assessments of operational plants and the initial

examination of new designs, where it can be used as an aid to inherently safe design

and to help with plant layout.

Total Material Factor, B

Reactive combinations of materials key material in reactor has a reaction which is

more exothermic than combustion then the material factor should be based on the

Process Modeling & Flowsheeting

2- 9

exothermicity of this reaction, B = 1.8 x Hr where Hr is the heat of reaction in

kcal/g.

Total Special Material Hazards, M

Liquefied flammable gases - this refers to materials with boiling points below 30C,

stored as liquids under pressure. A release of such a liquid gives a cooled vapour/mist

cloud due to flashing which is normally denser than air.

Total General Process Hazards, P

Reaction stages where a reactor is used for several purposes and contamination by

one product could affect a subsequent reaction. The factor selected should depend on

the extent of contamination and possible consequences.

Material transfer where flexible or removable pipe work is involved and additional

pipe connections for simultaneous venting or inert gas purging are required.

Special Process Hazards, S

High pressure, p a factor for units operating at above atm. Pressure to allow for the

enhanced fire and explosion risks. Its range between 1000 to 10000 psig.

Quantity Hazards, Q

Quantity of material should be entered in tonnes and the quantity factor, Q

determined which a minimum value of Q = 1 for quantities of less than 100 kg.

Total Acute Health Hazards, T

Skin effects - the material is rapidly harmful by skin contact, either by skin

absorptions

Inhalation effects the rate of vapour generation from the released material and the

concentration which can be tolerated for a few minutes without

causing an immediate threat to life or risk of permanent damage.

Fire Index, F

The Fire Index concentrates on the amounts of flammable material in the unit,

its energy release potential and the area unit.

Process Modeling & Flowsheeting

2- 10

The expression is:

F = (B*K)/N

And description categories can be derived from the table below:

F

FIRE INDEX

CATEGORY

Light

Low

Moderate

High

Very high

Intensive

Extreme

Very extreme

02

25

5 10

10 20

20 50

50 100

100 - 250

> 250

Internal Explosion Index, E

This is expressed as:

E = 1 + ( M + P + S )/100

And gives a measure of the potential for explosion within the unit.

Corresponding descriptive categories are given below.

INTERNAL EXPLOSION INDEX

0 1.5

1.5 2.5

2.5 4

46

Above 6

CATEGORY

Light

Low

Moderate

High

Very high

Aerial Explosion Index, A

Important features in assessing aerial explosion risk include the quantity of

material available and its heat of combustion, the likelihood of release, the rate and

height of release and the mixing characteristics of the gas. All of these factors have

been evaluated during the Mond Index assessment and based upon study of a number

of large flammable releases, the individual terms have been combined to give an

aerial explosion index according to the expression.

A = B ( 1 + M /100 )( QHE / 1000 ) ( t + 273/300 )( 1 + p )

Process Modeling & Flowsheeting

2- 11

Corresponding descriptive categories are given below:

AERIAL EXPLOSION INDEX

0 10

10 30

30 100

100 400

400 1700

Above 1700

CATEGORY

Light

Low

Moderate

High

Very high

Extreme

Overall Hazard Rating, R

As it is often necessary to compare units having different types of hazard, an

overall hazard index has been developed based upon the indices described above.

The combination adopted is:

OVERALL HAZARD RATING

0 20

20 100

100 500

500 1100

1100 2500

2500 12500

12500 65000

> 65000

CATEGORY

Mild

Low

Moderate

High (Group 1)

High (Group 2)

Very High

Extreme

Very Extreme

Equivalent Dow Index, D

This is calculated using the expression

D = B ( 1 + M / 100 )( 1 + P/100 )[ 1 + ( S + Q + L + T ) /100 )]

Experience of using the original Dow Index showed that units giving similar

Dow Index values could have different types of hazard potential, with fire risk

dominant in one case and explosion risk in another. To distinguish between these

cases a separate Fire Index and two explosion indices have been developed. With the

availability of these separate indices it is not necessary to convert Dow Index values

into descriptive ratings or to use it to compare units. However it is retained as a basic

element of the Overall hazard Index.

Process Modeling & Flowsheeting

2- 12

2.2.5.1 Mond Index At Reactor

Score

Material Factor

Reactive combination of materials

Total Material Factor, B

Special Material Hazards

none

Mixing and Dispersion Characteristic, m

Total Special Material Hazards, M

General Process Hazards

Handling and physical changes only

Reaction stages

Material transfer

Total General Process Hazards, P

Special Process Hazards

none

High Pressure, p

Category

1.5

1.5

0

30

0

60

50

110

30

Total Special Process Hazards, S

Quantity Hazards

Quantity of Material

30

Total Quantity Hazards, Q

Layout hazards

Height (H)

Normal working are (N)

Structure Design

Other features

Total layout Hazards, L

Acute Health Hazards

Skin effect

Total Acute Health Hazards, T

Dow Index, D = B (1+ M/100) (1 + P/100) (1 + (S + Q + L +

T)/100)

Fire Index, F = (B * K) / N

Internal Explosion Index, E = 1 + (M + P + S)/100

Aerial Explosion Index, A = B (1 + m/100) (QHE/1000)

(t+273/300) (1+p)

Overall Hazard Rating, R = D {1+ [0.2 * E * (AF)1/2]}

50

50

5

5

2

10

5

5

50

25

8.60

0.30

2.70

0.00

13.24

Light

Moderate

Light

Mild

From the table, all the Fire, Internal Explosion, Aerial Explosion and Overall

Hazard Index are presented either in LIGHT or MODERATE category. For this, the

reactor as well as the materials is conducted in the safe manner.

Process Modeling & Flowsheeting

2- 13

2.2.5.2 Mond Index At Distillation Column

Score Category

Material Factor

Reactive combination of materials

0.5

Total Material Factor, B

Special Material Hazards

none

Mixing and Dispersion Characteristic, m

Total Special Material Hazards, M

General Process Hazards

Handling and physical changes only

0.5

Total General Process Hazards, P

Special Process Hazards

40

High pressure, p and temperature

60

Total Special Process Hazards, S

Quantity Hazards

Quantity of Material

60

Total Quantity Hazards, Q

Layout hazards

Height (H)

Normal working are (N)

Structure Design

Other features

Total layout Hazards, L

Acute Health Hazards

Skin effect

Total Acute Health Hazards, T

Dow Index, D = B (1+ M/100) (1 + P/100) (1 + (S + Q + L +

T)/100)

Fire Index, F = (B * K) / N

50

Internal Explosion Index, E = 1 + (M + P + S)/100

Aerial Explosion Index, A = B (1 + m/100) (QHE/1000)

(t+273/300) (1+p)

Overall Hazard Rating, R = D {1+ [0.2 * E * (AF)1/2]}

0

50

40

50

8

14

55

75

152

5

50

50

4.33

0.04

2.50

0.00

6.49

Light

Moderat

e

Light

Mild

Refer to the table, the Fire, Internal Explosion, Aerial Explosion and Overall

Hazard Index are in the category of LIGHT/MODERATE. Materials in distillation

column are not hazardous but these materials are normally toxicity because its

inhalation effects are 50.

Process Modeling & Flowsheeting

2- 14

2.2.5.3 Mond Index At Stripper

Score Category

Material Factor

Reactive combination of materials

1.8

Total Material Factor, B

Special Material Hazards

none

Mixing and Dispersion Characteristic, m

Total Special Material Hazards, M

General Process Hazards

Handling and physical changes only

Reaction stages

Material transfer

Total General Process Hazards, P

Special Process Hazards

none

High Pressure, p

1.8

Total Special Process Hazards, S

Quantity Hazards

Quantity of Material

40

Total Quantity Hazards, Q

Layout hazards

Height (H)

Normal working are (N)

Structure Design

Other features

Total layout Hazards, L

Acute Health Hazards

Skin effect

Total Acute Health Hazards, T

Dow Index, D = B (1+ M/100) (1 + P/100) (1 + (S + Q + L +

T)/100)

Fire Index, F = (B * K) / N

Internal Explosion Index, E = 1 + (M + P + S)/100

Aerial Explosion Index, A = B (1 + m/100) (QHE/1000)

(t+273/300) (1+p)

Overall Hazard Rating, R = D {1+ [0.2 * E * (AF)1/2]}

50

0

30

0

20

20

40

40

50

5

5

5

5

20

20

20

7.53

0.36

2.10

0.00

10.70

Light

Low

Light

Mild

The table shows that materials in stripper are not hazardous material refers to

overall hazard rating, R where below HIGH category. Similarly, the stripper Fire,

Process Modeling & Flowsheeting

2- 15

Internal Explosion, Aerial Explosion and Overall Hazard Index are within the

category of LOW or LIGHT.

2.2.5.4 Mond Index At Flash Drum

Score Category

Material Factor

Reactive combination of materials

1.2

Total Material Factor, B

Special Material Hazards

none

Mixing and Dispersion Characteristic, m

Total Special Material Hazards, M

General Process Hazards

Handling and physical changes only

Reaction stages

Material transfer

Total General Process Hazards, P

Special Process Hazards

none

High Pressure, p

1.2

Total Special Process Hazards, S

Quantity Hazards

Quantity of Material

40

Total Quantity Hazards, Q

Layout hazards

Height (H)

Normal working are (N)

Structure Design

Other features

Total layout Hazards, L

Acute Health Hazards

Skin effect

Total Acute Health Hazards, T

Dow Index, D = B (1+ M/100) (1 + P/100) (1 + (S + Q + L +

T)/100)

Fire Index, F = (B * K) / N

50

Internal Explosion Index, E = 1 + (M + P + S)/100

Aerial Explosion Index, A = B (1 + m/100) (QHE/1000)

(t+273/300) (1+p)

Overall Hazard Rating, R = D {1+ [0.2 * E * (AF)1/2]}

0

50

0

30

30

60

40

50

8

8

10

10

36

10

10

6.80

0.15

Light

Moderat

2.50

e

Light

0.00

10.20

Mild

Process Modeling & Flowsheeting

2- 16

For the condition we have chosen for the three flash drums, they are operated

in safe condition if we referred to the analysis above. All the indices are classified

below hazardous category, that is, below HIGH category.

2.2.5.5 Conclusion

The most important index is the overall hazard rating, R. Experience from

applying the full method to operating plants has shown that is uncommon for a unit,

after a complete assessment, to have an overall hazard category below MILD, and it

is reasonable to assume that a unit assessed at this level can be operated in a

satisfactory manner given full regard to the hazards indicated by the assessment. As

offsetting usually reduces the overall hazard category by one or two levels then it

could argued that there is no need to continue beyond the initial assessment when the

initial category is at or below HIGH (Group 2). However, there are important gains

from the offsetting analysis since it identifies the benefits deriving from the safety

hardware and software and indicates the relative importance of the various measures

being taken, and in most cases it should be completed.

In addition to examining the category of the overall hazard rating it is

necessary to consider the other indices, even in those cases where the overall hazard

rating is not above HIGH(2). The Fire Index relates directly to Fire Load, as set out

in the table, and so can be used to estimate fire durations. Categories up to intensive

are often found for this index, particularly for stock tanks. For the internal explosion

and aerial explosion indices a level of moderate or below should be sought after

offsetting. Hence levels of high or above in the initial assessment indicate that the

review and offsetting stages should definitely be carried out and show where

offsetting features are most needed.

From the safety assessment we have done on the units exist in our urea

production flowsheet, it is convinced that this plant fulfills the basic safety

requirements. This plant is expected to be operating in safe manner all the way since

Process Modeling & Flowsheeting

2- 17

the overall hazard rating for all the equipments are categorized as MILD. This urea

plant will not face any explosion problem due to our non-explosive materials. It can

be assured through the results of our Mond Index analyses above. As a conclusion,

the plant is under control without any hazardous wastes which cannot give any effect

for plant operating.

2.3

EQUIPMENT SELECTION

2.3.1

Urea Synthesis Reactor

Reactor is the place where the process synthesis occurred (raw materials are

converted into products). The design of an industrial chemical reactor must satisfy

the requirement of the chemical, mass and heat transfer factors. Any catalytic reactor

(packed bed reactors, fixed bed or fluidized bed catalytic reactors) is not suitable for

the synthesis since urea synthesis is a non-catalytic reaction. The manufacture of urea

occurs in a reactor at elevated temperature and pressure and it can be considered as a

heterogeneous reaction where two phases exist: gaseous reactants (mainly NH3 and

CO2) and liquid products (mainly urea and water).

Stirred-tank reactors become unfavorable due to high temperature and

pressure needed in urea synthesis (Smith, 1995). Under high pressure conditions, a

small diameter cylinder requires a thinner wall than a large diameter cylinder. Under

high pressure conditions, use of a tubular reactor is preferred, although mixing

problems with heterogeneous reactions and other factors may prevent this. Besides,

heating has been shown to cause, by decomposition in series, the formation of

impurity in urea synthesis. Such reactors should be avoided for all systems in which

byproduct formation is via series reactions. Another important factor to the

disadvantages of the stirred-tank reactor is that for a given conversion it requires a

large inventory of material relative to tubular reactor. This is not desirable for safety

reasons if the reactants or products are particularly hazardous.

Viewing from the above pros and cons of the stirred-tank and tubular

reactors, it is wise to select tubular reactor to convert ammonia and carbon dioxide to

Process Modeling & Flowsheeting

2- 18

urea. It consists of a cylindrical pipe and is normally operates at steady state.

Although tubular reactors often take the actual form of a tube, they can be any reactor

in which there is steady movement in one direction only. Because the characteristic

of tubular reactors approximates plug-flow, they are used if careful control of

residence time is important, as in this case where there are multiple reactions in

series. It is relatively easy to maintain (no moving part), and it usually produces the

highest conversion per reactor volume. High surface area to volume ratio is possible,

which is an advantage if high rates of heat transfer are required. It is sometimes

possible to approach isothermal conditions or a predetermined temperature profile by

careful design of the heat transfer arrangements

Tubular reactors, as previously stated, are also advantageous for high pressure

reactions where smaller diameter cylindrical vessels can be used to allow thinner

vessel walls.

2.3.2

Urea Melt Crystallizer

Crystallization is a method of purification and also serves to provide

crystalline materials in the desired size range. Crystallization cannot occur without

supersaturation. A classification of crystallizing equipment can be made based on the

methods used to bring about supersaturation as follow: (1) supersaturation produced

by cooling the solution with negligible evaporation tank and batch crystallizers; (2)

supersaturation produced by evaporation of the solvent with little or no cooling

evaporator-crystallizer and crystallizing evaporators; (3) supersaturation by

combined cooling and evaporation in adiabatic evaporator vacuum crystallizers

(Geankoplis, 1993).

In crystallizers producing supersaturation by cooling the substances must

have a solubility curve that decreases markedly with temperature. When the

solubility curve changes little with temperature, evaporation of the solvent (water in

the case of urea solution) to produce supersaturation is often used. The solubility

curve of urea (Figure 2.2) shows that it decreases but changes little with temperature.

It is clear that cooling and evaporation are needed to bring about supersaturation in

urea crystallization process, that is, using vacuum crystallizer.

-1

Process Modeling & Flowsheeting

2- 19

In the method of cooling adiabatically in a vacuum, a hot solution (line 22) is

introduced into a vacuum, where the solvent flashes or evaporates and the solution is

cooling adiabatically. This method to produce supersaturation is the most important

Solubility in water

(g urea/100g solution)

one for large-scale production (200,000 MT/annum urea) (Geankoplis, 1993).

120

100

80

60

40

20

0

0

20

40

60

80

100

120

140

Temperature ( C)

Source: Encyclopedia of Chemical Technology, vol. 21

Figure 2.2: Solubility of Urea in Water

2.3.3

Operating Conditions Summary

25

26

Equipment

5

R-4

C-2 26

M-1

X-3

6

C-18

Operating Condition

M-11

C-18 Synthesis Reactor, R-4

Urea

Objective: To convert NH3 and14CO2 to urea

Type

: Isothermal17reactor

Catalyst

: Nil

7

Temperature

: 190C

13

10

12

25

Pressure

: 175 bar

X-15

Reactor

Fraction

Conversion

: 75%

M-11

E-6

X-8

F-7

14

15

R-4

10

C-2

X-3

6

7

X-15

C-19

9

T-5

C-19

17

CO2 Stripping Column,

T-5

Objective: To strip off free NH3

13

12

Type

-1352. kj/hr (condenser)

E-6

X-8 Feed F-7

Vapor Fraction 18

23

Stripping

Agent16

15

X-10Pressure

F-9 (T

Temperature,

7, P7)

-1352. kj/hr (condenser)

T-5

(T9, P9)

11

(T10, P10)

18

(T11, P11)

M-12

Urea Purity 21

X-10

Urea Purification Column, T-13

19

24

Objective: To recover >99%

urea

F-14

20

19

20

X-17

22

X-17

22

T-13

T-13

F-9

: Partial condenser

: 0.0

: Gas CO2

: 170.00C, 175 bar

21

: 463.42C,

155 bar

: 188.38C, 151 bar

: 349.26C, 152 bar

F-14

: 38.635%

11

M-12

23

16

24

15

23

16

X-10

F-9

5

-1352. kj/hr (condenser)

Process Modeling & Flowsheeting

2- 20

18

T-5

11

21

Type

Feed Vapor Fraction

24

Temperature,

Pressure (T20, P20)

(T21, P21)

(T22, P22)

Reflux Ratio

Urea Purity

F-14

M-12

19

20

X-17

: Partial condenser; Total

reboiler

: 0.13854

: 150.00C, 5 bar

: 118.46C, 2 bar

: 228.88C, 3 bar

: 99.5%

22

T-13

Flash Drum

Objective: To recover ammonia to be recycled

F-7

Type

Stream In

Stream Out (Top, Bottom)

Temperature, Pressure (T13, P13)

(T14, P14)

(T15, P15)

: Adiabatic

: 13

: 14, 15

: 100.00C, 12 bar

: 95.89C, 10 bar

: 95.89C, 10 bar

F-9

Type

Stream In

Stream Out (Top, Bottom)

Temperature, Pressure (T16, P16)

(T17, P17)

(T18, P18)

: Adiabatic

: 16

: 17, 18

: 145.00C, 10 bar

: 126.43C, 5 bar

: 126.43C, 5 bar

F-14

Type

Stream In

Stream Out (Top, Bottom)

Temperature, Pressure (T21, P21)

(T23, P23)

(T24, P24)

: Isothermal

: 21

: 23, 24

: 118.49C, 2 bar

: 94.00C, 1 bar

: 94.00C, 1 bar

Mixer

Objective: To mix 2 or more similar streams to form a

homogenous phase stream

M-1

Stream In

Stream Out

Temperature, Pressure (T2, P2)

(T3, P3)

(T26, P26)

: 2, 26

:3

: 594.98C, 50 bar

: 596.25C, 50 bar

: 596.53C, 50 bar

M-11

Stream In

Stream Out

Temperature, Pressure (T14, P14)

(T17, P17)

(T23, P23)

(T25, P25)

M-12

: 14, 17, 23

: 25

: 95.89C, 10 bar

: 126.43C, 5 bar

: 94.00C, 1 bar

: 87.52C, 1 bar

Process Modeling & Flowsheeting

Stream In

Stream Out

Temperature, Pressure (T11, P11)

(T18, P18)

(T19, P19)

2- 21

: 11, 18

: 19

: 349.26C, 152 bar

: 126.43C, 5 bar

: 191.33C, 5 bar

Compressor

Objective: (i) To increase the stream pressure

(ii) To pump the feed into the following unit

operation

C-2

Stream In

Stream Out

Temperature, Pressure (T3, P3)

(T4, P4)

:3

:4

: 596.25C, 50 bar

: 822.45C, 175 bar

C-16

Stream In

Stream Out

Temperature, Pressure (T1, P1)

(T2, P2)

:1

:2

: 30.00C, 1 bar

: 594.98C, 50 bar

C-18

Stream In

Stream Out

Temperature, Pressure (T25, P25)

(T26, P26)

: 25

: 26

: 87.52C, 1 bar

: 596.53C, 50 bar

C-19

Stream In

Stream Out

Temperature, Pressure (T25, P25)

(T26, P26)

:8

:9

: 30C, 5 bar

: 463.42C, 15.5 bar

C-21

Stream In

Stream Out

Temperature, Pressure (T17, P17)

(T28, P28)

: 17

: 28

: 126.43C, 5 bar

: 218C, 10 bar

C-22

Stream In

Stream Out

Temperature, Pressure (T23, P23)

(T29, P29)

: 23

: 29

: 94C, 1 bar

: 469.49C, 10 bar

Expander, E-6

Objective: To decrease the stream pressure

25

M-11

C-18

Process Modeling & Flowsheeting

2- 22

14

17

Valve, V-7

R-4

10

13

12

X-8

7

E-6

Stream In

Stream Out

Temperature,

Pressure (T10, P10)

F-7

(T12, P12)

15

X-10

Heat Exchanger

X-15

-1352. kj/hr (condenser)

9

T-5

X-1

11

16

: 10

: 12

: 188.38C, 151 bar

: 68.02C, 12 bar

23

F-9

Objective: To increase/decrease stream temperature

X-3

X-8

Decrease

temperature

Increase temperature

218

Stream In

:4

Stream In

: 12

Stream Out

:5

Stream Out

: 13

Temperature In : 822.45C

Temperature In : 68.02C

21

Temperature Out: 190.00C

Temperature Out: 100C

X-10

X-15

Increase temperature

Decrease temperature

F-14

Stream

In

:

15

Stream

In

:6

M-12

24 Out

Stream Out

: 16

Stream

:7

Temperature In : 95.89C

Temperature In : 190.00C

Temperature

Out:

145.00C

Temperature Out: 170.00C

19

X-17

X-20

20

Decreased temperature

Decreased temperature

Stream In

: 19

Stream In

: 22

Stream Out

: 20

Stream Out

: 27

X-17

Temperature In22 : 191.33C

Temperature In : 228.88C

Temperature Out: 150.00C

Temperature Out: 140.00C

T-13

2.4

MASS AND ENERGY BALANCES

2.4.1

Introduction

This plant is designed to produce 200,000 metric ton per annum of urea. In

order to evaluate the conceptual flowsheet presented in the previous section, we need

to consider the detailed of mass and energy balances. This precedes the later tasks of

plant equipment sizing and economic evaluation. Using DESIGN II version 8.35

simulator has carried out the mass balance for this plant.

Mass balance is the basic of process design where the quantities of raw

material required and products produced can be determined. Also, the purpose of

developing the mass balance is to establish energy balances and opportunities for

heat integration. The design of a new process is not complete until it is established

that the inputs and outputs of the entire process and each individual unit satisfy

Process Modeling & Flowsheeting

2- 23

balance equations applied to each process material. All the manual calculations

obtained are compared with the simulation results. A balance on a material in a

system (a single process unit, a collection of units, or an entire process) may be

written in the following general way (Rousseau, 1986):

Input

+

(enters

through

system

boundaries)

Generation - Output (leaves

(produced

through

within system)

system

boundaries)

Consumption = accumulation

(buildup

(consumed

within system)

within system)

In both manual calculation and simulation, some important assumptions are

made:

1.

The basis of the design is based on 200,000 metric ton per annum

urea production.

2.

The plant operates at 315 days per year with 24 hours a day.

3.

The system is steady state.

4.

The composition of the reactants used and the specification of the

urea product are based on what available in the market.

It is very important to know the vapor pressure and volatility for each single

component present in each stream during mass balance calculation. It is a common to

calculate vapor pressure from Antoine equation. Besides, other equations for each

particular component can also be used to predict the vapor pressure for all range of

temperatures, such as below:

Urea

*

: ln P (kPa) C1

C2

C4 ln T C5T C 6

T C3

(2.1)

where, T in Kelvin

Ammonia

P * (kPa) Pc 10 C5 * Tr 1 / Tr

(2.2)

Carbon Dioxide

: P ( kPa) Pc 10

*

C5 * Tr 1 / Tr

(2.3)

Water

C2

C

*

C 3 ln T C 4 ln T 5

: P ( Pa) exp C1

T

where, T in Kelvin; Tmin= 273.15K.

(2.4)

Process Modeling & Flowsheeting

2- 24

The equation constants are shown in the table below:

Table 2.2: The Equation Constant

Component

C1

C2

C3

NH2CONH2* 2.13316e+1 -1.05011e+4

0

#

NH3

0

1.5714

0.48316

CO2#

0

1.732

0.56907

**

H2O

73.649

-7258.2

-7.3037

C4

9.7941e-2

0

0

4.17e-06

C5

C6

6.34741e-9 2.0

2.9562

0

3.3097

0

2.0

0

Sources:

* HYSIS Component Library Databank

** Chemical Engineering Volume 6

# DESIGN II Component Library Databank

In evaluating energy balances, we assume ideal properties for all of the

process streams. Moreover, we neglect kinetic and potential energies and consider

only enthalpy changes. The standard reference state for enthalpy, where H=0, are

set to be T=298 K and P =1 atm. And finally, for these preliminary calculations, we

assume no H of mixing or pressure effect on H (Biegler et al., 1997).

To calculate enthalpies of vapor phase mixtures, the general formula we use

is:

T2

H v (T , y ) H f H T k y k H f ,k (T1 ) y k C p , k (T )dT

k

T1

where H f , k (T1 ) is the heat of formation for component k at T1 and

temperature dependent heat capacities for the component k are represented by

C p , k (T ) ; whereas the enthalpies for liquid mixtures can be estimated by:

H L (T , x) H f H T k xk H f , k

k

C p , k ( ) d H vap

(T )

(2.6)

k

where H vap is heat of vaporization of specific component.

(2.5)

Process Modeling & Flowsheeting

2- 25

k

k

H vap

(T ) H vap

(Tb ) Tck T / Tck Tb

(2.7)

The essential parameter used to calculate the enthalpies in both streams is

heat capacities, C p , k (J/mole.K) at specific temperature, as below:

T2

T1

C p ,k (T ) dT Ak (T T )

Bk (T 2 T ) C k (T 3 T ) Dk (T 4 T )

2

3

4

(2.8)

The enthalpy constants are tabulated as followed:

Table 2.3: Enthalpy Constant

Comp

Ak

Bk

Ck

Dk

Urea#

NH3*

CO2*

H2O*

0.287231

27.313

19.795

32.243

3.8597e-3

2.383e-2

7.343e-2

1.923e-3

1.3e-6

1.707e-5

5.601e-5

1.055e-5

-1.184e-8

1.715e-8

-3.596e-9

Hf

(kJ/mol)

-2.4559e+5

-45.72

-393.77

-242.00

Hv

(J/mol)

54574.57

23362

17166

40683

Tkc

(K)

705

405.6

304.2

647.3

Sources:

# HYSIS Component Library Databank

* Chemical Engineering Volume 6

2.4.2

Pre Calculation

Urea production

200,000 MT 1000kg

1 yr

1day

1kmol

yr

1MT

315day 24hr 60.06kg

= 440.4766kmol urea solution/hr

The detail manual mass and energy calculation are included in

Appendix Chapter 2.

Tkb

(K)

465

239.65

194.65

373.15

Process Modeling & Flowsheeting

2- 26

Table 2.4: Manual Calculation Stream Summary

S1

S2

NH3

881.07

881.07

CO2

0.00

Urea

S3

S4

S5

S6

S7

S8

S9

S10

S11

2055.56 2055.56 2055.56 1174.59 1174.59

0.00

0.00

1172.77

1.83

1172.77 1172.77 1164.21

8.561

0.00

587.29

587.29

587.29

146.82

146.82

441.1

441.1

500.99

87.00

500.99

500.99

500.243

0.751

0.00

0.00

2.94

2.94

2.94

443.41

443.41

0.00

0.00

1.02

442.40

1.0162

1.02

3.44E-5

1.016

Water

0.00

0.00

293.65

293.65

293.65

734.12

734.12

0.00

0.00

205.06

532.00

205.06

205.06

138.05

67.01

Total

881.07

881.07

2939.44 2939.44 2939.44 2498.94 2498.94

441.1

441.1

S16

S17

S18

S19

S20

S21

S22

S23

S24

1879.84 1063.23 1879.84 1879.84 1802.51

S28

S29

S25

S26

S27

77.34

S30

S31

NH3

8.56

7.36

1.20

3.03

3.03

3.31

0.00

2.92

0.11

1174.50 1174.50

CO2

0.75

0.72

0.03

87.02

87.02

87.02

8.70E-11

86.37

0.65

587.34

Urea

1.02

9.69E-6

1.02

443.41

443.41

0.00

Water

67.01

8.99

58.02

590.03

590.03

589.19

0.84

149.95

Total

77.34

17.07

60.26

1123.49 1123.49

679.51

444.25

239.24

443.41 1.71E-24 4.43E-19

S12

0.00

587.34 8.70E-11

S13

S14

S15

7.36

2.92

0.00

0.00

0.72

86.37

0.00

8.70E-11

9.69E-6 1.71E-24 443.41

0.00

2.94

2.94

443.41

439.24

293.65

293.65

0.84

8.99

149.95

0.00

0.84

440.00

2058.42 2058.42

444.25

17.07

239.24

443.41

0.84

Process Modeling & Flowsheeting

2- 27

Table 2.5: Comparison of Molar Flow Rate Between Manual and Simulation

Results

Stream

S1

S2

S3

S4

S5

S6

S7

S8

S9

S10

S11

S12

S13

S14

S15

S16

S17

S18

S19

S20

S21

S22

S23

S24

S25

S26

S27

S28

S29

S30

S31

*

Manual

881.065

881.065

2939.44

2939.44

2939.44

2498.941

2498.941

441.10

441.10

1879.840

1063.227

1879.840

1879.840

1802.507

77.335

77.335

17.0728

60.2636

1123.491

1123.491

679.512

444.253

239.240

440.002

2058.423

2058.423

444.253

17.0728

239.240

443.41

0.84

Simulation

888.00

888.00

2966.95

2966.95

2966.95

2526.456

2526.456

440.50

440.50

1879.852

1087.096

1879.852

1879.852

1802.151

77.6996

77.6996

17.4061

60.2929

1147.390

1147.390

704.6808

442.709

263.682

440.998

2083.239

2083.239

442.709

17.4061

263.682

-*

-

Error (%)

0.7810

0.7810

0.9273

0.9273

0.9273

1.0891

1.0891

-0.1362

-0.1362

0.0007

2.1956

0.0007

0.0007

-0.0198

0.4692

0.4692

1.9153

0.0487

2.0829

2.0829

3.5717

-0.3487

9.2696

0.2260

1.1912

1.1912

-0.3487

1.9153

9.2696

-

Note: Since there is lack of solid handling in DESIGN II version 8.35

simulator, the urea crystallization section of the urea production

process will only be calculated manually.

Process Modeling & Flowsheeting

2- 28

2.5 INDIVIDUAL EQUIPMENT OPTIMIZATION

2.5.1

Introduction To Optimization

At a practical level, the term optimization is defined as follows:

Given a system or process, find the best solution to this process

within constraints.

The process of optimization is carried out to determine the optimum operating

condition and physical design that could achieve best process performance of each unit

operation without compromising all the constraints that are predetermined. The reason

for optimization is reduced capital cost and operating cost without violating the

constraints that are predetermined.

Firstly, we need objective function that serves as a quantitative indicator of

goodness of particular solution so that we can quantify the best solution. Capital and

operating cost, product yield and overall profit are the most typical process design

objectives.

According to Biegler (1997), the values of objective function are determine by

manipulation of the problem variables which can physically represent equipment sizes

and operating conditions such as pressure, temperature and feed flow rates.

Finally, the limits of process operation, product purity, validity of the model,

and relationships among the problem variables need to be considered as constraints in

the process. Similarly, the variable values must be adjusted to satisfy these constraints.

Robin Smith in his book, Chemical Process Design, has cited two forms of

optimization employed in chemical process design. Structural Optimization, the first

form that represent a model of our process structure is simulated and evaluated all over

again so as to compare with previous data. Alternatively, each structure can be subjected

to parameter optimization by changing operating conditions within that structure.

Process Modeling & Flowsheeting

2.5.2

2- 29

Parameter Optimization For Individual Equipment

After designing the process flow diagram, the next important task of a designer is

to seek optimum solution to a design problem. The task of formally optimizing the

design of a complex processing plant involving several hundred variables. The main

objective of this chapter has been the optimization of the individual equipment of the

integrated urea plant to produce 200,000 MT / annum of urea. But the task can be

divided into more manageable units, identifying the key variables and concentrating

work where the effort involved will give the greatest benefit. In this case, we planned to

optimize the reactant recovery separator (flash separator), urea purification distillation

column and carbon dioxide-stripper.

In this preliminary optimization, the best solution usually results in economic or

technical incentives. Examples of economic incentives are maximum profit and

maximum costs, whereas technical incentives are increased yield and reactor conversion.

Individual equipment optimization usually has been limited to parameter optimizations

of individual (stand-alone) equipment only, which mean that the equipment to be

optimized is firstly disconnected from other plant structure. Next, we set an objective

function and the objective function is evaluated through altering the operating conditions

of the specific equipment.

Basically, optimization of urea process involves its economic performance and

trade-off. Target for optimization is to maximize the profit and minimize wastes bounded

by the constraints of operation feasibilities. But, as a balancing between engineering and

business world, it is unpractical to achieve a product purity of 100% at skyrocketing

costs, when the customer could do with a product purity of 99%. Trade-off between

operating and capital cost also an important factor in plant optimization. For example, in

order to increase the purity or higher recovery of reactant ammonia in stripper, we could

very well increase the number of trays in the stripper column. However, we should never

forget that we have to pay more for capital investment and operating cost. So, achieving

a trade-off between the question how many trays and their costs?

Process Modeling & Flowsheeting

2- 30

In order to obtain the optimum operating parameter for the plant, an optimization

has been done on the following equipment, using simulator Design II version 8.35.

(1)

Flash Separator, F-14

(2)

CO2 Stripper Column, T-5

(3)

Urea Purification Column, T-13

We concentrating on the last flash separator (F-14) among the three flash

separators because the two previous separators (F-7 and F-9) are mainly use to moderate

the pressure drop and prevent tremendous pressure decrease. Product losses, top and

bottom products purity not so being concern in this two separators compare to F-14. By

the way, we have left out the optimization of the reactors. The reason has been the

absence and lacking of information, especially the reaction rate constant for the

reactions. The conversion that we have set in simulator is fix and cannot be vary.

The procedure of doing the optimization is by varying the selected parameters

of the equipment and observing the output value given by simulator.

2.5.3

Flash Separator (Ammonia Recovery), F-14 Optimization

The objective of this flash drum is to achieve highest recovery of the unreacted

ammonia and carbon dioxide from water and trace of urea after two reactants recovery

section. It also ensures high purity water discharge, which contains low percentage of

ammonia. The purposes of optimization are:

To reduce duty of flash column.

To increase the reactant recovery.

To reduce the products losses.

Among the few design and operating parameters for optimise the flash operating

efficiency, flash temperature and pressure has been chosen as two main optimization

parameters.

Process Modeling & Flowsheeting

2- 31

2.5.3.1 Effect Of the Operating Pressure

In this part of optimization, ranges of pressure have been used at constant

temperature of 94oC. The Design II simulation results are shown in Table 2.6 below.

Table 2.6: The Effects of The Operating Pressure on Urea Losses and

Ammonia, Carbon Dioxide Recovery

Pressure

1.0

1.5

2.0

2.5

3.0

Duty (-kJ/hr)

x E-07

1.9036E+07

2.4770E+07

1.9036E+07

2.6302E+07

2.6550E+07

NH3 Recovery CO2 Recovery

0.865

0.9997

0.602

0.9985

0.865

0.9997

0.369

0.9961

0.3091

0.9949

Urea loss (kgmole/hr)

X E+02

0.342

0.3531

0.342

0.3553

0.3556

3.0000E+07

1.2

2.5000E+07

2.0000E+07

0.8

1.5000E+07

0.6

1.0000E+07

0.4

Reactant Recover Fraction

Duty (-kJ/hr)

Effect Of Operating Pressure On Reactant Recovery , Product

Losses & Flash Duty

Duty (-kJ/hr) x E-07

NH3 Recovery

CO2 Recovery

Urea loss (KGMOLE/HR) X E+02

5.0000E+06

0.2

0.0000E+00

0.5

1.0

1.5

2.0

Pressure (bar)

2.5

3.0

3.5

Figure 2.3: Duty of Flash and Fraction Vs Pressure

From the graph above, it is obvious that flash-operating pressure has a significant

effect on the ammonia recovery. For pressure higher than 2 bars, ammonia recovery

Process Modeling & Flowsheeting

2- 32

fraction starts reducing. As the pressure increases, the relative volatility may be will

decrease, hence will lower the flash separation efficiency in term of ammonia recovery.

After the point at 2 bar, the flash duty also increases rapidly.

As a conclusion, we observe that the flash reaches its optimum point at pressure

= 2 bar which achieve minimize duty and high recovery fraction.

The operating pressure does not make a significant change on the carbon dioxide

recover and urea losses.

2.5.3.2 Effect Of Operating Temperature

By varying the operating temperature of flash drum at constant pressure of 2 bar,

the effect on flash duty, reactant recovery and product losses has been obtained. Table

2.7 and Figure 2.4 Show the simulated result for this optimization.

Table 2.7: The Effect of Operating Temperature on Flash Duty, Reactant Recovery

and Product Losses

0.8

2.0000E+07

0.6

1.5000E+07

0.4

1.0000E+07

NH3 Recovery

CO2 Recovery

0.2

5.0000E+06

Duty (-kJ/hr)

0

0.0000E+00

80

85

90

95

100

Tem perature (oC)

105

110

118

Duty (-kJ/hr)

Fraction

Temperature

Urea loss (kgmole/hr)

(oC)

Duty (-kJ/hr) NH3 Recovery CO2 Recovery

80

2.7451E+07

0.2934

0.997

0.003559

85

2.6963E+07

0.3450

0.9965

0.003556

90

2.6393E+07

0.4040

0.997

0.003552

95

2.5695E+07

0.4129

0.9974

0.003545

Effect Of Operating Temperature On Reactant Recover, Duty And Product

100

2.4779E+07

0.5532

0.9979

0.003534

Losses

1.2

3.0000E+07

105

2.3443E+07

0.6470

0.9984

0.003514

110

2.1133E+07

0.7590

0.999

0.00347

1

2.5000E+07

118

4.5307E+06

0.9820

0.9999

0.002296

Process Modeling & Flowsheeting

2- 33

Figure 2.4: Effect of Operating Temperature on Reactant Recovery and Flash Duty

Urea Losses (kgmole/hr)

x E+02

Effect Of Operating Temperature On Urea Losses

0.004

0.0035

0.003

0.0025

0.002

0.0015

0.001

0.0005

0

Urea loss (KGMOLE/HR) X E+02

80

85

90

95

100

105

110

118

Temperature (oC)

Figure 2.5: Effect of Operating Temperature on Product Losses

From the graph shown above, with the increasing of operating temperature until

about the same with feed temperature at 118oC, the ammonia recovery is the highest and

at this point also given minimum urea losses. Besides, condenser duty also decreases in

this case. So, we can know that the optimum operating temperature is nearly about the

feed temperature.

Process Modeling & Flowsheeting

2.5.4

2- 34

Distillation Column Optimization

Optimization of distillation can be practice based on many parameters,

such as pressure, temperature, reflux ratio, number of tray and location of feed.

For example, as the pressure in distillation column raised, will cause:

Relative volatility decreases effect the degree of separation, hence more number of

plates are required.

Condenser and reboiler duty decrease due to reduction in latent heat of vaporization.

Higher vapour density given smaller column diameter.

Reboiler temperature increases with a limit often set by thermal decomposition of

the material being vaporised, causing excessive fouling.

Increase in condenser temperature.

As the pressure is lowered, the effects will obviously reverse. The lower limit is

often set by desire to avoid vacuum operation and refrigerant in condenser. Both

conditions involve capital and operating cost penalties and increase the complexity of

the design.

Column optimization can be done also by varying the reflux ratio. There is a

capital energy trade-off for a stand-alone column. As the reflux ratio increase from it

minimum value, the capital cost will decrease initially as the number of tray reduced.

But, the utility costs increase as reboiling and condensation required. Generally, the

operating cost is indicated by the condenser and reboiler duty. Capital cost is showed by

the size of distillation column (size and number of trays). In order to minimize the

capital cost within operating specification, minimum columns diameter and minimum

number of tray should be used. With the help of Design-II simulator, the optimization

seems to be achieved.

2.5.4.1 Urea Purification Column, T-17 Optimization

The main purpose of this column is to concentrate the urea solution to become

urea melt and so purify the urea produced. Optimization of this column mainly to

Process Modeling & Flowsheeting

2- 35

minimum the reboiler and condenser duty by varying different process variables like

pressure, number of tray, and location of feed, reflux ratio and temperature. The

operating costs will decreases when the reboiler and condenser duty reduce.

Optimized

parameter

Minimum number

of tray

Reflux ratio

Consequence

1. Reduce condenser

and reboiler duty

2. Reduce column

height (h)

1. Depend on feed

composition and

vapor fraction

Pressure

1. Optimum pressure

giving a best

separation

Temperature

1. Optimum

temperature giving

a best separation

Location Of Feed

1. Depend on the

vapor fraction of

feed

Gain

Loss

1. Use less energy 1. Unable to

2. Reduce cost of

achieve

column

product

specification

1. Reduce usage

of energy

2. Increase

product purity

3. Operating cost

will be

minimize

1. Reduce energy

needed

2. Give a easy

separation

1. Reduce energy

needed

2. Give a easy

separation

1. Minimize

reboiler and

condenser duty.

2.5.4.2 Effect Of The Reflux Ratio

Figure 2.6 and Table 2.8 shows the optimization results condenser and reboiler

duty within a range of reflux ratio. For this case, temperature, location of feed and

pressure become control variables to achieve the objective function minimizing the

condenser and reboiler duty, hence reduce operating costs.

Process Modeling & Flowsheeting

2- 36

Table 2.8: Effect of Reflux Ratio on Condenser and Reboiler Duty

Reflux Ratio Condenser Duty (-kJ/hr) x E-07 Reboiler Duty (kJ/hr) x E-07

2.0

5.807

8.313

2.5

7.259

9.765

3.0

8.700

11.22

3.5

10.16

12.67

4.0

11.61

14.12

4.5

13.07

15.57

5.0

14.52

17.02

5.5

15.97

18.47

18

20

16

18

14

16

14

12

12

10

10

Condenser Duty (-kJ/hr) x E-07

6

4

Reboiler Duty (kJ/hr) x E-07

Reboiler Duty (kJ/hr) x E-07

Condenser Duty (-kJ/hr) x E07

Effect of Reflux Ratio On Reboiler & Condenser Duty

0

1

10

Reflux Ratio

Figure 2.6: Effect of Reflux Ratio on Reboiler and Condenser Duty

As showed above, as reflux ratio is decreased, heat duty is also decreased, thus

minimise operating cost. The minimum reflux ratio is around 0.5. Energy consumption

will be decreased if the heat duty is decreased. From the same graph, reboiler duty

increases linearly with condenser duty. In order to minimise the total consumption of

energy, other parameter such as number of tray should be included together in order to

get the optimum condition for the operation.

This will give the reduction in total consumption of energy thus decrease the

operating cost. Low reflux ratio will increase the number of tray need for separation. The

optimum reflux ratio occurs at the point where the sum of fixed charges and operating

Process Modeling & Flowsheeting

2- 37

cost is minimum, which is approximate 0.5. As a rough approximation, the optimum

reflux ratio falls in the range 1.1 1.3 times reflux minimum. (Max S. Peters, Kalus D.

Timmerhaus, Plant Design And Economics For Chemical Engineers, 3rd Edition).

2.5.4.3 Effect Of The Number Of Tray

During optimization using simulator, ranges of number of tray have been with

constant pressure, temperature and fixed feed tray. The purity of urea have been set at

99.5%. The result stated below in Table 2.9 and also Figure 2.7 and 2.8.

Table 2.9: Effect of Number of Tray on Reflux Ratio, Column Diameter, Reboiler

and Condenser

Condenser Duty

(-kJ/hr) x E-07

40.65

34.84

29.03

23.23

17.42

Tray Num Reflux Ratio Diameter (m)

6

6

5.790

7

8

5.392

8

10

4.961

9

12

4.487

10

14

3.955

Reboiler Duty (kJ/hr)

x E-07

43.15

37.35

31.54

25.73

19.93

1.2682

1.4

1.268

1.2

1

0.8

1.2678

1.2676

0.6

0.4

Condenser Duty (-kJ/hr) x E-07

1.2674

Reboiler Duty (kJ/hr) x E-07

1.2672

1.267

0.2

0

1.2668

4

4.5

5.5

6.5

7.5

8.5

Num ber of Tray

Figure 2.7: Effect of Number of Tray on Reboiler and Condenser

Duty (kJ/hr) x E-07

Urea Losses

(kgm ole/hr) x E+02

Effect Number of Tray On Reboiler & Condenser Duty

Process Modeling & Flowsheeting

2- 38

Diameter

Reflux

Diameter (m)

Reflux

Effect of the number of tray on the reflux ratio and column diameter

0

7

10

Number of tray

Figure 2.8: Effect of The Number of Tray on The Reflux Ratio and Column Diameter

From Figure 2.7, we have seen that as the number of tray increase, the condenser

duty becomes smaller but not much significant effect on reboiler duty. At this point, the

condenser and reboiler duty is minimized and minimum losses of desired urea

production capacity obtained. These will reduce the operating cost. To ensure the

optimum point affected by the number of tray, we observe also the changes of column

diameter and reflux ratio. The results are shown in Figure 2.8. As the number of tray

increases, reflux ratio and diameter also increase but in different rate, thus increase the

capital costs. These shows inverse effect if compare to the reboiler and condenser duty.

If combining two graphs, we found that the optimum point around 7-8 number of tray to

balance the trade-off between capital and operating costs.

Process Modeling & Flowsheeting

2- 39

2.5.4.4 Effect Of Operating Pressure

At constant reflux ratio, temperature, feed location and purity at 99.5%.

Optimization has been done within a range of column operating pressure from 1.5 bar to

9.5 bar. Changes profile of column diameter, reboiler and condenser duty has been

observed as stated below.

Table 2.10: Effect of Operating Pressure on Column Diameter, Reboiler and

Condenser Duty

Pressure

(bar)

1.5

2.5

3.5

4.5

5.5

6.5

7.5

8.5

9.5

Condenser Duty (-kJ/hr) Reboiler Duty (kJ/hr)

x E-07

x E-07

10.42

12.76

10.16

12.67

9.991

12.62

9.857

12.58

9.744

12.61

9.645

12.69

9.556

12.72

9.476

12.73

9.401

12.74

Diameter

(m)

3.369

3.161

3.032

2.941

2.880

2.838

2.801

2.771

2.744

12.8

12

12.75

10

12.7

Reboiler Duty (kJ /hr) x E-07

12.65

Condenser Duty (-kJ /hr) x

E-07

Diameter

12.6

12.55

8

6

4

Diameter (m)

Duty (kJ/hr)xE-07

Effect of Operating Pressure On Reboiler , Condenser Duty &

Column Diameter

12.5

12.45

0

1.5

2.5

3.5

4.5

5.5

6.5

7.5

8.5

9.5

Pressure (bar)

Figure 2.9: Effect of Operating Pressure on Column Diameter, Reboiler and

Condenser Duty

Process Modeling & Flowsheeting

2- 40

The optimum operating pressure around 4.5 bar. The higher value of pressure

will make the condenser duty to increase. Optimum operating pressure will ensure the

operating costs minimized and balancing the capital costs with the reasonable column

diameter. It is unwise to operate the column at too high pressure because the pump work

will be increase too.

2.5.4.5 Effect Of Operating Temperature

Table 2.11 and Figure 2.10 represent the results in optimising the operating

temperature and its effect on product losses, reboiler and condenser duty.

Table 2.11: Effect Of Operating Temperature On Product Losses, Reboiler and

Condenser Duty

Temperature

(oC)

100

125

150

175

200

Condenser Duty

(-kJ/hr) x E-07

10.16

10.16

10.16

10.16

10.16

Reboiler Duty (kJ/hr)

x E-07

13.66

13.28

12.67

11.08

9.43

Product Loss

(kgmole/hr) x E+02

3.131

3.242

3.592

6.629

16.363

10.2

10.18

18

10.16

10.14

14

16

12

10.12

10.1

10.08

Condenser Duty (-kJ/hr) x E-07

10

Reboiler Duty (kJ/hr) x E-07

Product Loss (kgmole/hr) x E+02

10.06

10.04

10.02

10

Duty (kJ/hr)x E-07

Losses (kgmole/hr)

xE+02

Effect of operating Temperature On Reboiler & Condenser Duty

0

100

125

150

175

200

Temperature ( C)

Figure 2.10: Effect of Operating Temperature on Product Losses, Reboiler and

Condenser Duty

Process Modeling & Flowsheeting

2- 41

As the operating temperature increases, the product losses increase while the

reboiler duty decreases. The optimum operating temperature is about 150C. Although

after this optimum point, the operating costs will minimized due to tremendous reduce in

reboiler duty. But, in other way, maximum product loss is occurred.

2.5.4.6 Effect Of Feed Tray Location

Normally, location of feed tray also to get the maximum product purity. In this

optimization, different location of feed tray have been tried and stated in the figure and

table below.

Table 2.12: Effect of Feed Tray Location Product Purity, Reboiler and Condenser

Duty

Feed

Tray

2

3

4

5

6

Reboiler Duty (kJ/hr) x E-07

10.18

10.17

10.17

10.17

10.17

Condenser Duty (-kJ/hr) x

E-07

12.690

12.69

12.68

12.68

12.68

Product Purity (%)

99.62

99.65

99.66

99.66

99.66

Effect of Feed Tray On Product Purity, Reboiler & Condenser Duty

Duty (kJ/hr)

12.5

99.68

12

99.66

11.5

Reboiler Duty (kJ/hr) x E-07

11

99.64

Condenser Duty (-kJ/hr) x E-07

99.62

Product Purity

10.5

10

99.6

2

4

Feed Tray

Figure 2.11: Effect of Feed Tray Location Product Purity, Reboiler and

Condenser Duty

Product Purity

99.7

13

Process Modeling & Flowsheeting

2- 42

Feed tray location has the negligible effect on the heat duty, but strong effect

observed on the final product purity. The suitable feed tray location will ensure the

higher quality of final product and produces high-grade urea. Start from tray 4, the

product purity achieves 99.66%.

2.5.5

CO2 Stripping Column, T-5 Optimization

The main objective of this stripping column is to strip out the unreacted ammonia

from reactor product stream which containing mixture of urea, water, ammonia and

carbon dioxide. The vapor stream from stripper recycles back to reactor to improve the

product yield. Thus, the major concern in this stripper optimization is to determine

various optimum points for several parameters to obtain highest ammonia recovery with

minimum capital costs such as reduce column diameter.

However, we have tested on several problem variables number of tray, stripping

agent flow rate, operating pressure and temperature in this optimization process. But, we

found that most of these variables do not have significant impact on the certain variables

like urea product losses. Besides, constraint of the parameters changes also occurred

because convergence for this column only limited in small variables change.

2.5.5.1 Effect Of The Number Of Tray

Table 2.13: Effect of The Number of Tray on The Urea Purity

Figure 2.12:

Tray Number

3

4

5

6

7

8

9

10

of Tray on The Urea Purity

Product Purity

0.370

0.395

0.4113

0.422

0.429

0.436

0.380

0.380

Effect of The Number

Process Modeling & Flowsheeting

2- 43

Because of the simulator convergence factor, the variation on the column tray

number only shows significant impact on the bottom urea purity. Because this product

stream not the final product stream, the urea content is not require present in high purity.

At constant operating temperature and stripping agent flow, the product purity reaches

its optimum point at tray number 8 as shown in Figure 2.12.

2.5.5.2 Effect On Stripping Agent Flow

Stripping agent, CO2 in gases phase is needed to strip out the ammonia from the

liquid phase inlet. Hence, the flow rates of stripping agent play an important role in

determining the ammonia recovery and the design parameter of this stripper such as

diameter.

Table 2.14: Effect of The CO2 Flow Rate on The Ammonia Recovery and Column

Diameter

Carbon Dioxide Flow Rate

(kgmole/hr)

439.0

439.5

440.5

441.0

441.5

Ammonia Recovery Diameter (m)

0.9914

1.622

0.9913

1.629

0.9914

1.622

0.9915

1.625

0.9916

1.672

Process Modeling & Flowsheeting

2- 44

Effect Of Stripping Agent Flow Rate On Ammonia Recovery And Column

Diameter

0.99165

Ammonia Recovery

Fraction

1.67

1.66

Diameter (m)

0.9916

Ammonia Recovery

0.99155

0.9915

1.65

0.99145

1.64

0.9914

1.63

0.99135

1.62

0.9913

1.61

438.5

Diameter (m)

1.68

0.99125

439.0

439.5

440.0

440.5

441.0

441.5

442.0

CO2 Flow Rate (kgmole/hr)

Figure 2.13: Effect of The CO2 Flow Rate on The Ammonia Recovery

and Column Diameter