Professional Documents

Culture Documents

TRA 047 Field Weld, Erection, Loading, Unloading, Transportation, Punch List Modification & Hydrotesting.

Uploaded by

arunmirandaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

TRA 047 Field Weld, Erection, Loading, Unloading, Transportation, Punch List Modification & Hydrotesting.

Uploaded by

arunmirandaCopyright:

Available Formats

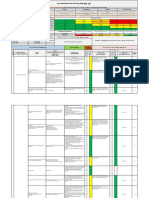

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

TRA Ref No:

TRA Member /Team

Leader

ADCOs Team

Members

Signature

Team

Members

Contractor

Names

Signature

TRA Team Leader

Signature

(All pages)

TRA Member / A.A.

TRA Member/HSE

...th .... 2011

TRA Member / J.O.

TRA Member/I.A

Construction Team

PIL

Date :

HSE

1

JI-193/PIL/SC/0.....

Construction Team

Job Performer

Job Performer

______________________

High Risk Authorisation

Signature

(First page Only)

_______________________

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 1 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

TRA Ref No:

Work

Location :

JI-193/PIL/SC/0.....

Date :

Zone 2

Zone 0/1

...th .... 2011

Unclassified Zone

Activity

Tools &

equipment

Used

Reference

s:

Method statement for

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

Travel

Vehicle

1 and

Movement.

mobilizat

ion

Unsafe

Driving.

Fatigue

#

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Vehicle

Crash.

Collision.

Working for

Long hours.

Over loads.

Consequen

ces

(The harm

which could

possibly

occur).

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

Fatality.

Injury.

Property

Damage.

Fire/Expl

osion.

Environmen

tal impact

TRA Team Leader

Signature

(All pages)

______________________

High Risk Authorisation

Signature

(First page Only)

Driver should possess Valid

UAE Drivers Licence.

Driver should have a Valid

ADSD Card.

Vehicle should be Equipped

with IVMS and approved by

ADCO.

Driver and passengers should

wear seat belt.

Maintain a Daily maintenance

checklist.

Follow Road Signs and speed

limits.

Deflate tire pressure while

going on sand road.

No Driving while low visibility

condition.

Compliance

to

journey

management system.

Compliance to ADCO road

safety Manual 10/3.

Trained/ competent banks

men must be assigned to

control

vehicle/equipment

_______________________

Recommended Controls

Desert

Safety Box made available

Vehicle.

Spare tire and tools shall be available.

Action By

in

First Aid Box available.

Personnel should be trained

JP /

SUPVR./

SO

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

YES

and aware on

ADCO Emergency Procedure.

Desert box should be periodically inspected

No one allowed to drive under the influence

of alcohol or drugs

Emergency control room no. 02-6044600.

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 2 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Consequen

ces

(The harm

which could

possibly

occur).

JI-193/PIL/SC/0.....

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

Date :

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

movement on site.

Site

2 Survey

using

Auto

level and

Total

station.

Leveling

,Grading

and

compacti

on

Battery

Device

Equipment

Movement.

Equipment

might

hit

worker during

fill/removal of

soil

Lack

of

supervision

Spark

Explosion

Blind spot

Poor

visibility

Dust

generated

from fill

materials/g

atch

Wrong

guidance to

reverse/for

ward

movement

Fire

Person

nel

injury

Propert

y

damag

e

Fatality

TRA Team Leader

Signature

(All pages)

______________________

High Risk Authorisation

Signature

(First page Only)

Use explosion

proof/intrinsically safe

equipment.

Certified and experienced

Technicians shall be

deployed.

Fire extinguisher shall be

available

Valid 3rd party calibration

certificate shall be

available at work site.

Banks man to guide the

equipment movement

All

workmen

to

be

positioned

away

from

operating area

Revolving beacon to be

kept on.

Use warning lights and

back up horn.

Spray water to reduce

dust.

Sign board to be posted

Intrinsically safe equipment/ certificate from

3rd party made available

Compliance to ADCO road safety Manual

10/3.

Proper supervision

JP /

SUPVR./

SO

YES

Only

ADCO

approved

competent/certified

operator to be allowed.

Area to be cordoned and

sign board to be placed

_______________________

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 3 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Consequen

ces

(The harm

which could

possibly

occur).

Heavy Load.

Untrained

worker/New

worker.

Using

Crane./

Hiab,

and

trailer

for

Loading

and

Unloadi

ng and

stackin

g of

Pipes ,

Damage

nearby

structure/existi

ng lines

Suspended load

/ Swinging of

load

Failure of lifting

gears

Crane tips over

TRA Team Leader

Signature

(All pages)

Incompetent

/untrained

operators/

riggers

Falling

materials.

Wrong

Posture

Improper

access

Lack of

training/aw

areness

Defective

Personal

injury

Personal

/unsuitable

equipment

Unstable

ground

condition.

Improper

positioning of

crane.

Caught

inbetween

Unauthorized

entry

Poor/Damage

d

lashing

strap/slings

Inadequate

support.

______________________

Injury

Fatality

Asset

Damage

High Risk Authorisation

Signature

(First page Only)

Date :

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

Manual

3 handling

JI-193/PIL/SC/0.....

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

Do not allow to enter any

unauthorised persons

Operators must worn seat

belt.

Eyes

Conduct TBT on manual

handling before commencing

the

work.

Use proper PPE

on path and remove obstructions

before moving, check for sharp edges and

splinters

JP /

SUPVR./

SO

YES

JP /

SUPVR./

SO

YES

Seek assistance if

required, use correct manual

handling

techniques

(Bending

at

the

knees,

keeping back straight and

lifting with arm and leg

muscles, clear access ways

etc)

Conduct TBT before

commencing the work.

Inspect the crane and ensure

all are suitable and in good

condition.

Check equipment sticker of

ADCO/PIL.

Operator having valid UAE

driving /Operator License.

Check the capacity of crane

& lifting tackles and ADCO

approved TPI certificate.

Proper supervision.

Only certified, trained and

experienced operator and

rigger shall be used.

Swing radius should be

barricaded with warning

_______________________

Any employee, whether supervisor or

craftsman, has the responsibility to stop a lift

operation when it becomes apparent that

something is not safe.

Awareness training on emergency procedure

for working crew.

Not allow to travel anyone on crane or above

the trailer.

Trained Banks man should be stationed to

control the equipment movement

ADCO checklist to be followed

No crane movement

while outriggers

extended

All crane movement should be escorted

All cranes should be travelled by designated

route only.

Color code system should be followed.

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 4 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Consequen

ces

(The harm

which could

possibly

occur).

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

TRA Team Leader

Signature

(All pages)

______________________

High Risk Authorisation

Signature

(First page Only)

JI-193/PIL/SC/0.....

tape and sign board to be

posted.

Use two Tag lines to control

the movement of the load.

Lifting activities shall be

suspended during strong

wind speed 17 knots and

above.

Ensure out riggers are fully

extended.

In case of Fog / poor visibility

/ sand storm / rain etc Job

to be stopped.

Out rigger pad should be 1.2

x 1.2 meter.

Crane hook blocks secured

during travel

Ensure crane is set up within

its capacity (Lifting radius)

Ensure crane is set up as

indicated in the layout plan.

Ensure cranes are not set

close to excavations

Assess the load/ lifting

tackles

not

to

be

overloaded beyond its SWL.

Softeners to be provided at

sharp corners of load to be

lifted.

Load test certificates for all

lifting/rigging devices with

SWLs clearly marked and

available in the crane cabin.

Follow the Lift plan/simple lift

plan/checklist.

_______________________

Date :

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

Lifting perimeter must be barricaded and

provided with warning sign boards place in

conspicuously area.

Use proper stacking and storage techniques.

Support and chock all pipes and fittings.

Leave clearways around stored pipes and

space to adequately rig heavy items so as to

avoid double handling.

Do not bring any excess material at RDSs.

Crane TPI certificate from ADCO 3rd party.

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 5 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

Rigging Heavy Lift

&

Tandem lift

Lifting

of pipes Damage nearby

structure/existi

ng lines

Suspended load

/ Swinging of

load

Failure of lifting

gears

Crane tips over

Incompetent

/untrained

operators/

riggers

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Uncertified

crane and

operator

Defective

crane

Inadequate

ground

compaction /

Soft ground

Wrong

positioning of

cranes

Cranes set up

incorrectly

Consequen

ces

(The harm

which could

possibly

occur).

Serious

injuries

to

personnel

.

Multiple

fatalities

Asset

Damage

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

Falling

materials.

TRA Team Leader

Signature

(All pages)

______________________

High Risk Authorisation

Signature

(First page Only)

JI-193/PIL/SC/0.....

Rigging Supervisor/Project

engineer is responsible to

see that all lifts are

executed in accordance

with this practice and the

Site Specific Rigging

Specifications.

CM is full responsibility for

the site preparation and

safe execution of all heavy

lift/tandem lift operations.

Verify with the Operator

that the crane is set up

correctly and is at the

correct operating radius.

Responsible Personnel

- The crane operator, and

the qualified field rigger,

are jointly responsible for

determination of the load

weight and placement of

the crane so that it is set

up within the operating

radius selected. The

rigging supervisor has

final responsibility for all

operations.

All lifts under eighty (80)

percent of the capacity

chart of the crane for the

boom length and radius

being used or under

ninety (90) percent if the

crane has an operational

load indication device with

an overload cut-off.

Each crane will be

inspected by a competent

person for mechanical

_______________________

Date :

Recommended Controls

Execute all lifts in accordance with the

Site Specific Heavy Lift Dozier

The weight of all auxiliary handling

devices such as hoist blocks, headache

balls, hooks and rigging shall be

considered as part of the total load.

Additionally, the weight of all items added

to the load at the site must be determined

and added to the total weight.

Tools and small materials shall be kept

securely to avoid possible fall and hitting

personnel working below.

Using man basket/man lift (check the TPI

certificate)

Provide separate life line from hook of the

crane

...th .... 2011

Action By

JP /

SUPVR./

SO

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

YES

Any employee, whether supervisor or

craftsman, has the responsibility to

stop a lift operation when it becomes

apparent that something is not safe.

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 6 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Consequen

ces

(The harm

which could

possibly

occur).

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

Transpo

rtation

of

Material

s

Movement

of Vehicle /

Equipment

Unsecured

loads

TRA Team Leader

Signature

(All pages)

Poor

visibility

Sand

Storm

High Wind

Speed

Raining

Fatality

Person

al

Injury

Asset

Damag

e.

Loads

falling off

during

movement

of trailer.

Uneven

road

potholes

______________________

High Risk Authorisation

Signature

(First page Only)

JI-193/PIL/SC/0.....

Date :

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

defects upon its arrival,

before its use on the

project, and Checklist will

be completed.

Tendem lift controlled by

one rigger/Supervisor

Only

trained/authorized

personnel are allowed to

operate boom/man lifts.

A 100% fall protection at all

times while in boom lifts, tie

off only to designed anchor

points.

Secure all loose materials in

basket.

Ensure that the

weight of all material and

occupants does not exceed

the rated capacity of the

man lift.

Red white

barricade tape off work

area.

Ensure personnel involved

in rigging operations are

using full PPE including

hand gloves.

Riggers to be briefed on

potential pinch, crush

points.

Ensure that a visual

inspection is conducted by

the riggers prior to using

the gears to secure the

loads.

Gears used to secure the

loads not to be over

tensioned.

Softeners to be provided

_______________________

Designated route to be followed for the

transportation.

Escort to be provided.

JP /

SUPVR./

SO

YES

Riggers to be provided jacket/vest

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 7 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Consequen

ces

(The harm

which could

possibly

occur).

Scaffold

ing

erection

and

dismant

ling

Working at

height.

Slip/Trip

Collapse

TRA Team Leader

Signature

(All pages)

Improper

access

Falling

object

Person

falling from

height.

Lack of fall

protection.

Instability

Person

nel

injury

Fatality

Propert

y

Damag

e

Over

Loading

lack of

knowledge

of

operational

______________________

High Risk Authorisation

Signature

(First page Only)

Date :

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

JI-193/PIL/SC/0.....

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

at sharp corners of load

which is secured to the

trailer.

Trailer should not be

subjected to negotiate

sharp bends in site.

Route used for travel to be

pre checked to ensure

that the route is safe for

travel

Ensure that all materials

are properly secured

before moving off trailer.

Excavations along the side

of the road in which trailer

travels to have a physical

barricade.

Spotter to accompany

trailer at all times with

red& green flag, whistle.

Obtain ADCO PTW prior to

work start

Conduct TBT before

Commencing the work.

Only

qualified

and

certified ADCO approved

3rd party Scaffolders to

erect scaffolding.

Ensure

the

base

is

compacted and leveled

Scaffolding to be tagged

and scaff tag system to be

strictly followed.

Scaffolding

materials

should be stored properly

in allocated area and

barricaded.

_______________________

Working area should be barricaded and

provide warning sign board

Use proper tools lifting bag, rope & Pulley

etc.

Throwing is not allowed

JP /

SUPVR./

SO

YES

Training should be carried out for all

personnel

Once the scaffold is completed, it will be

inspected by a qualified and competent

person. a green scafftag insert will be

completed by the competent person.

All scaffolders must use the proper access.

Scaffolding register to be maintained.

Scaffolding should be inspected in weekly

basis

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 8 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

SCAFFTAG

system

Consequen

ces

(The harm

which could

possibly

occur).

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

TRA Team Leader

Signature

(All pages)

______________________

High Risk Authorisation

Signature

(First page Only)

JI-193/PIL/SC/0.....

All scaffolding materials

should be as per ADCO

manual volume part 16/BS

1139/2482

Proper

platform

and

access to be made

Scaffolding

to

be

inspected by qualified and

certified supervisor before

starting the work

Scaffolding shall not to be

used to support heavy

loads

Proper platform and all

guards are in place

Ensure that no personnel

are under the area where

scaffold erection takes

place

Personnel

must

have

attended the Work at

heights training.

100% Tie off to be

maintained and double

lanyard to be used

Use

fire

retardant

laminated

scaffolding

planks and must be pre

approved from PIL/ADCO

Use non-sparking hammer

(brass) (For work inside

RDS).

Scaffold shall not obstruct

existing access ways /

ladders.

Provide RED Tag during

erection or when not

_______________________

Date :

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

Provide proper access and egress.

Prior to dismantling a scaffold, the scaffold

shall be inspected and safe procedure for

dismantling established by the foreman or

supervisor

If dismantling has reached the stage at

which a critical members has to be

removed, the stability of the scaffold shall

be ensured by fixing a similar component in

place lower down the scaffold.

During scaffolding erection no other activity

nearby.

In case of bad weather all activities to be

stopped at site & re inspect the scaffold.

Maintain the scaffold clean & dry.

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 9 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Consequen

ces

(The harm

which could

possibly

occur).

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

Fabricat

ion & fit

up

pipes

Welding

,

Grindin

g

and

Gas

cutting.

TRA Team Leader

Signature

(All pages)

Welding

Grinding

Cutting

operations

Working at

height.

Falls.

Falling pipe

spools.

Caught

in

between/cr

ushed

by

pipes.

Shattering

Hot Metal

Slag

High

Intensity

of Light

Flying

of

grinding

particles.

Fumes

Burn

Damage of

Cable.

Electrocuti

ons

______________________

Person

al

injury

Affect

Vision

Fire

/Explosi

on

Fatality

Propert

y

damag

e

High Risk Authorisation

Signature

(First page Only)

JI-193/PIL/SC/0.....

Date :

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

completed scaffold.

Personnel shall not access

a scaffold if the Scaffold

insert has been removed

or if the Scafftag itself is

not in place.

Erect hand rails and mid

rails to prevent persons

fall off the scaffolding

Erect

toe

boards

to

prevent tools fall from a

height.

The erection sequence of

the scaffold shall ensure

that at no time will the

scaffold reach an unstable

condition

All modification to existing

scaffolding shall be carried

out in such a way that the

stability of the scaffolding

is not impaired.

Valid PTW will be obtained

prior to start of work at

site.

Approved

Method

Statement

will

be

followed.

TBT to be conducted and

all the hazards discussed

& each crew member

responsibility

to

be

defined.

Welding area will have a

booth covered by using

Fire Proof Tarpaulin.

Welding Generator will be

_______________________

Inspect all equipment prior to use

especially noting RPM of grinder disc

must have higher rated RPM.

Job Performer will have close monitor on

the activity.

All welding leads to be as short as

possible.

Ensure all equipment is correctly earthed

and that the return lead is clamped as

close as possible to the work piece.

Close valves on all cylinders after use

JP /

SUPVR./

SO

YES

Provide checklist that may be used prior

to work commencing

Cover/seal any drains/catch basin within

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 10 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

of grinding

disc.

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Consequen

ces

(The harm

which could

possibly

occur).

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

Movement

of

Man

lift/equipm

ents.

Unsecured

tools.

Failure of

tie off.

Inadequat

e

pipe

supports.

Unexpecte

d collapse

of

fabricated

pipes

or

supports.

Poor

quality of

Grinding

or cutting

disc.

TRA Team Leader

Signature

(All pages)

______________________

High Risk Authorisation

Signature

(First page Only)

JI-193/PIL/SC/0.....

earthed properly. Check

for cable and insulation

damage,

if

any,

rectification

should be

done immediately.

Only competent person

will be deployed on the

job.

Welding machine installed

with ELCB/GFCI

Fire extinguishers & fire

watchman must be in

place

Ensure

there

are

no

flammables in the vicinity

of the operation, including

flammable liquids (paints

etc)

or

other

waste

materials.

Qualified Welders will be

deployed.

Whilst grinding activity JP

to ensure face shield is

used by the welder for any

slag removal

Double eye protection and

ensure Dead man switch

for grinding machine

Availability of Flash Back

Arrestor on Oxy/Acetylene

cylinder to be ensured by

the User/Job Performer.

Job Performer to ensure

the Cylinders are secured

in proper position before

beveling

operation

commences.

_______________________

Date :

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

a radius of 15 meter from the welding

area

Ensure access is good for men and

materials but also for emergency

purposes

Ensure no other conflicting tasks are

taking place within the vicinity of the

proposed work

Prior to start the work tool box talk to be

conducted emphasizing the hazards

associated with the job as well as the

preventive, precautionary measures to be

taken up

Do not place fingers or hande where it

can be caught in between pipes during fit

up.

Adequate pipe supports & chocks to be

provided.

Only steel pipe supports to be employed.

All grinding tools must have proper

guards correctly fitted. Grinding/cutting

disc must be suitable for the job and the

correct speed rated ginder to be used.

Goggles with face shield to be used.

Never use cutting wheels for grinding.

Trained fire watch must be present at

site.

All welding machines inspected &

certified.

All gas cylinders should be taken put of

RDSs.

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 11 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Consequen

ces

(The harm

which could

possibly

occur).

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

TRA Team Leader

Signature

(All pages)

______________________

High Risk Authorisation

Signature

(First page Only)

JI-193/PIL/SC/0.....

Date :

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

Job Performer will have

close supervision on the

activity.

All

compressed

gas

cylinders should be stored

and handled as per the

procedure and tested for

leakage each time before

use.

All

combustible

and

flammable

products

removed from area.

Ignition of oxy-acetylene

or propane torches must

only be made using the

Gas

Lighters

(flint

lighters)

which

are

supplied for this purpose.

Personnel

engaged

in

welding, cutting, chipping

and grinding operations

must wear the appropriate

protective

clothing/equipment

provided, e.g. goggles,

face

shields,

welding

helmets, welding screens,

gloves, leather chrome

aprons, etc.

Working

area

to

be

Barricaded

to

warn

passerby / workers.

Maximum

weight

a

support can hold will be

displayed.

ADCO

approved

fire

blanket will be installed

properly & adequately to

_______________________

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 12 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Consequen

ces

(The harm

which could

possibly

occur).

JI-193/PIL/SC/0.....

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

Date :

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

contain all welding slag &

grinding sparks in the

work area.

9

PWHT

Electric

power

sources.

Over heat

Burns

Damage

Electrical

wire/ Chord.

High Voltage

Fatality.

Personal

Injury

Fire

Power source Property

Failure.

Improper

method

Personnel

within the

heating area

damage

1

0

Non

Destruc

tive

Test

(NDT)

RT

MPI

PT

TRA Team Leader

Signature

(All pages)

X-Ray

radiation.

Gamma

Ray

Chemicals

Misuse of

radioactive

Source.

Exposure

to X-Ray

radiation.

Chemical

______________________

Acute

health

problem

Personal

injury.

Fire.

Property

High Risk Authorisation

Signature

(First page Only)

All heating elements shall

be thoroughly examined

before use in order to

ensure that the element

wire is not exposed.

Examination to be also

made for broken beads in

both the heater pad and the

element tails.

Twist-lock connection shall

also be examined to ensure

that the insulation is sound

and that a good electrical

joint is made.

All cable connections shall

be properly insulated.

The component surface

shall be free of

contaminants

All PWHT equipment must

have a valid current

calibration certificate.

Working area must be

barricaded off warn

workers/passerby

Comply with ADCO Work

Permit Requirements.

Only ADCO approved NDT

service personnel to

conduct radiographic

tests.

Advance coordination with

_______________________

Before a Heat Treatment is switched on

particular attention shall be paid to the

work area to ensure that there are no

combustible materials present which can

be affected by the heated zone.

Fire watch and Fire extinguishers are

made available.

MSDS to be available on site & follow

precautions.

Barricade the area & sign boards to be

posted.

Certified and trained technicians being

used.

Storage as per Ministry rules.

JP /

SUPVR./

SO

YES

JP /

SUPVR./

SO

YES

Strict control & handling

Before commencing the radiography

supervisor shall ensure that nobody are in

the area of radiation.

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 13 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

exposure

Consequen

ces

(The harm

which could

possibly

occur).

Damage.

Blasting

&

Painting

Operati

ons

Medically

Unfit Persons

Chemicals

Toxic Fumes

Personnel

TRA Team Leader

Signature

(All pages)

unsuitable for

blasting

operations.

Production of

hazardous

dust during

blasting

Blasting

hoses

whiplashes

Poor

breathing

air

Flying

particles

causing

injury.

Toxic

airborne

dust

Excessive

Noise

Failure of

blasting

equipment

______________________

Fire

Fatality

Injury &

Poison.

Irritation

s

Itching

High Risk Authorisation

Signature

(First page Only)

Date :

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

1

1

JI-193/PIL/SC/0.....

Plant Operations required

for X-ray work in the

RDSs.

Radiation area roped off

and manned by

designated watchman.

Safe distance established

with a survey meter.

Radiographers are

wearing pocket dosimeter

and film badge.

Warning notices i.e.

Danger, Radiation Area

to be installed.

Prior coordination with all

affected personnel / other

contractors (if any)

required.

Conduct radiographic

tests after regular hours

or during knock-off time.

Ensure that all personnel

tasked to perform blasting

operations have already

completed a pre

employment check up

including chest x ray and

medically fit.

Personnel involved in

blasting and painting

should undergo the

Respirator Fit Test

program and to complete

the required questionnaire

with the assistance of a

qualified physician.

Ensure that the CO Monitor

_______________________

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

During transportation of radiography

source extreme care shall be taken and

vehicle shall have sign boards.

Radiography source shall only be stored at

designated places.

No person allowed 100 meter surrounding

area.

Barricading & sign boards to be placed.

MSDS to be made available at site &

precautions to be followed.

Ensure that all waste generated from the

blasting and painting activities are

properly segregated and contained.

Ensure that sufficient fire extinguishers

are placed within the vicinity of

painting area.

Dead mans control Switch in working

condition

Waste materials to be disposed off

through the licensed waste collector.

Waste materials to be disposed off in a

separate dedicated skip and should not

be thrown into the main skips provided

on site.

Waste materials should not be left to

JP /

SUPVR./

SO

YES

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 14 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

Static

charges

Slips, trips

and falls

TRA Team Leader

Signature

(All pages)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

causing

hap hazard

operations

Respiratory

Hazard

ENV

Impact

______________________

Consequen

ces

(The harm

which could

possibly

occur).

Potential

Risk

H/M/L

(With no

controls

in place)

High Risk Authorisation

Signature

(First page Only)

JI-193/PIL/SC/0.....

Date :

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

is set to trigger off at 10

PPM and monitors the

quality of air supplied to

the blasting personnel.

Ensure that all open areas

are screened off to prevent

the airborne particles from

coming into contact with

personnel in the vicinity.

Provide adequate

ventilation within the

enclosed area where

blasting activities take

place to ensure a positive

supply of fresh air.

Ensure that all personnel

working near the blasting

area are wearing a proper

pair of ear plugs.

Ensure that all pneumatic

couplings are properly

secure with whiplash

arrestors.

Ensure that all personnel

involved in painting

operations wear a proper

NIOSH certified mask

capable of filtering off the

airborne particulates.

(To refer to MSDS of dust

mask)

Ensure that all personnel

involved in the painting

operation wears proper

PPE including chemical

resistant gloves.

No hot works to be allowed

within the area where

painting works are being

_______________________

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

overflow and should be cleared on a

periodic manner.

Waste disposal area to be properly

barricaded to ensure that personnel are

not allowed into this area.

Signage to the effect of No Smoking No

Hot Works should be provided.

Blasting painting sign boards to be placed

& area barricaded.

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 15 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Consequen

ces

(The harm

which could

possibly

occur).

Potential

Risk

H/M/L

(With no

controls

in place)

JI-193/PIL/SC/0.....

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Date :

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

carried out.

1

2

Working

at height

using

Man lift

or man

basket

Climbing

ladders

with

equipment.

Personnel

leaning

over the

scaffold

platform

structures.

Falling

from

height

Falling

objects

Improper

access

Fatality.

Personal

Injury

TRA Team Leader

Signature

(All pages)

______________________

High Risk Authorisation

Signature

(First page Only)

Personnel to

maintain a three point

contact at all times

when they climb the

ladders.

Personnel on the

structures to ensure

that they are tied off at

all times.

Materials are not to

be hand carried and

should be hoisted up to

the required location.

Materials are to be

placed on proper

containers and

housekeeping must be

maintained at all times

onto the permanent

platforms.

Working area below

the scaffold platforms

to be barricaded with

the red and white tape

to ensure that

unauthorized personnel

are kept out.

Incomplete scaffolds

and permanent

platforms must be

marked out and

communicated to the

night shift work force.

Works are not to be

allowed on incomplete

scaffolds and/or

_______________________

Only trained/authorized personnel are

allowed to operate boom/man lifts.

A 100% fall protection at all times while in

boom lifts, tie off only to designed anchor

points.

Secure all loose materials in basket. Ensure

that the weight of all material and

occupants does not exceed the rated

capacity of the man lift.

Red white

barricade tape off work area.

Those people working from man basket

must

wear and connected with safety

harness to the crane hook.

Ensure the TPI certificate of man lift and

Man basket/check the SWL.

Ensure TPI certificate for man lift/Maan

basket & check SWL.

Two men only allowed to work on man

lift/basket.

Men / materials to be minimized in

restricted / hazardous area.

JP /

SUPVR./

SO

YES

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 16 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Consequen

ces

(The harm

which could

possibly

occur).

Potential

Risk

H/M/L

(With no

controls

in place)

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

1

3

Hydro/

Leak

testing of

lines

TRA Team Leader

Signature

(All pages)

High

Pressure

Liquid /

Chemical

Hose gaveoff

Piping

rupture

Spillage

ENV

Impact

______________________

Personn

el injury

Property

damage

Fatality

High Risk Authorisation

Signature

(First page Only)

JI-193/PIL/SC/0.....

Date :

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

permanent platforms.

Incomplete scaffolds

and permanent

platforms must be

communicated to the

workforce in the daily

toolbox talks.

Personnel are not

allowed to move from

one point to the other

by walking or sliding on

pipes.

Personnel are only

allowed to move on

proper work platforms

and 100 % tie off must

be maintained at all

times.

Provide Safe Work Permit from

ADCO and place in site permit

box

All involved personnel must

be competent and experience

for the work to be carried out.

Prior to hydro-testing, all

personnel involved in the

activity must be inducted.

Hydro-testing equipment

must be in good working

condition and passed

accordance with ADCO safety

standard, and UAE

government rules and

regulations.

All pipes are properly

supported

All fittings, gauges, manifold,

blinds are in rated capacity

_______________________

Closed supervision

Standby vehicle available

First Aider available

JP /

SUPVR./

SO

YES

First Aid Kit available

JP and crews should have awareness

training on Emergency Response Plan /

Procedure

Call ADCO Control Room in case of

emergency

MSDS in place

Emergency Eye wash

Goggles, PVC/Rubber gloves. Etc

Ensure gauges shall be placed at visible

location from where pressure controller

can see the gauges.

Personnel not to work on pipe while it is

under pressure.

On completion of the test, the pressure

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 17 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Consequen

ces

(The harm

which could

possibly

occur).

JI-193/PIL/SC/0.....

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

Recommended Controls

Air compressor

inspected and

relief valve 3 party certified

All hose connections to be

provided with whip lash

arrestor

Activity should be supervised

by a experienced / competent

supervisor

Striking on working

equipment while under

pressure is prohibited

Provide calibrated / certified

pressure gauges with the

proper rating.

Vent the air prior to hydro test

Date :

rd

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

shall be reduced gradually and under

controlled conditions.

When draining equipment, adequate

vents at the highest point must be

opened or other precautions taken to

avoid the possibility of drawing a vacuum.

Consideration must be given to the

possibility of test fluids being trapped

behind non-return valves and it may be

necessary to vent or drain the test fluid

from more than one point

Temporary test piping should

meet the designed test

pressure

Provide bleed valve on test

piping

Pressure during hydro test to

be increased gradually as per

procedure

Provide MPPE to all personnel.

Install physical barrier & sign

board for the hydro-test.

shelter and designate

safe

assembly point.

Provide

All roads leading to the test

TRA Team Leader

Signature

(All pages)

______________________

High Risk Authorisation

Signature

(First page Only)

area to be closed off with

physical barricades.

Air horn to be readily

available to signal emergency

_______________________

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 18 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Consequen

ces

(The harm

which could

possibly

occur).

JI-193/PIL/SC/0.....

Date :

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

to halt test and evacuate

personnel.

Entry & Exit to test area to be

controlled.

Pressure gauges having range

1.5 to 3 times the test

pressure, Relief valve Set to

5% above test pressure,

Do not stand in front of Blind

flanges/Components

Do not use old / used gaskets

Release pressure before

1

4

Cleanin

g&

Flushin

g

Water &

Foam

pumping

Liquid /

Chemical

Contact

with

chemical

Hose

rupture

Spillage

Injury &

Poison.

Irritation

s

Itching

attempting to Tighten the

joints using a Bleed valve.

Only trained personnel to use

pump

ENV

Impact

TRA Team Leader

Signature

(All pages)

______________________

High Risk Authorisation

Signature

(First page Only)

Ensure that all personnel

involved in the cleaning

wear proper PPE including

rubber apron, rubber

boots, gloves, safety glass

and full face shields as per

MSDS recommendation.

Personnel to be briefed

that they are not to

handle the chemicals with

bare hands.

Personnel exposed to

direct contact with the

chemical should be

brought to the Medical

Center for treatment.

Ensure that waste foam

solution and water used to

rinse off chemicals are

_______________________

Ensure that all waste generated from

water/foam pumping activities are

properly segregated and contained.

Waste materials to be disposed off

through the licensed waste collector.

Waste materials should not be left to

overflow and should be cleared on a

periodic manner.

Waste disposal area to be properly

barricaded to ensure that personnel are

not allowed into this area

JP /

SUPVR./

SO

YES

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 19 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

Consequen

ces

(The harm

which could

possibly

occur).

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

1

5

Use of

Hand

Tools

and

Portable

power

electric

al tools.

Electrocution

/ electrical

shock.

Defective

Tools and

Parts.

Improper

Tools

Damage

Electrical

wire/ Chord.

Improper

repairing or

servicing

tools

Tools Failure.

Fatality.

Personal

JI-193/PIL/SC/0.....

Recommended Controls

inspected

prior to use.

Do not use defective Tools.

Only trained and experienced

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

properly contained for

disposal

Ensure that a copy of the

MSDS is readily available

at the storage site to

identify potential harmful

mixtures.

Use of Proper PPE.

Tools should be

Injury

Fire

Date :

to be assigned on electrical

hand Tools i.e. Grinders, Drill

machine etc...

Portable

Electrical

Tools

should have Dead man switch

and properly grounded.

Use Industrial type electrical

connectors.

Tools should be 110 volt.

Emergency Procedures to be followed

Make sure RPM of Grinding/buffing wheel

greater than the Machine

ELCB/GFCI and Double insulated cable to

be used

All power cables and hand tools must be

inspected daily basis and prior to use

JP /

SUPVR./

SO

YES

JP /

SUPVR./

SO

YES

Power

1

6

Working

in

adjacen

t plot

Existing or

undergroun

d or any

other

facility

TRA Team Leader

Signature

(All pages)

Unauthorize

d entry of

personal

and

equipment.

Unaware of

hazard

______________________

Property/

asset

damage

Personal

injury

High Risk Authorisation

Signature

(First page Only)

Generator should be

properly grounded.

Fire extinguisher in place

nearby.

Make sure proper guards are

in

place

for

all

tools/equipments.

No personnel shall enter

any nearby operating

facility without

communicating with the

area supervisor or

obtaining senior

management permission.

_______________________

All site personnel working in the area shall

be fully and constantly familiar with the

specific area and the task.

Individual extra awareness on the basics of

emergency shall be maintained through

TBT.

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 20 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

present

Consequen

ces

(The harm

which could

possibly

occur).

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

Welfare

facilities

Lack of Toilet

Lack of Rest

shelter

General

1

8

TRA Team Leader

Signature

(All pages)

Extreme

Temperature/

Humid

H2S

Non

availability

of toilet

/unhygienic

Non

availability

of rest

shelter

Non use of

MPPE

Heavy

physical

work

Dehydration

______________________

inconven

ience

Personal

illness

Difficulty

or

discomfo

rt

Date :

Recommended Controls

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

Cutting short cuts through

adjacent facility at any one

time is strictly forbidden.

Only designated access

ways shall be used

Materials, tools and

equipment intended for

work in an area shall be

limited to as minimum as

possible.

Only the quantity required

for the particular work day

shall be mobilized in and

stored at the worksite

1

7

JI-193/PIL/SC/0.....

Obtain ADCO PTW prior to

work start

Conduct TBT to brief all the

crews about hazards, and risk

involved in the preparation

activity before commencing

the work.

Use proper MPPE

Toilet facility to be provided and sewage tank

to be emptied regularly

Prior to start of work all vehicles and

equipment inspected and approved by

PIL/ADCO

JP /

SUPVR./

SO

YES

JP /

SUPVR./

SO

YES

All

employees should be

familiar with emergency plan

Rest shelter should be

provided

Assembly point to identified

and

installed

by

the

consideration

of

wind

direction

Wind sock to be installed

Heat

stroke

Heat

stress.

Heat

High Risk Authorisation

Signature

(First page Only)

Personnel awareness

training on Heat stress.

Availability of Cold water

and shaded rest area

Use loose cloths.

_______________________

Standby vehicle available.

Schedule the heavy work during cooler part

of the shift

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 21 of 24

TASK RISK ASSESSMENT

Field/Terminal :

1

9

ASAB

Job

Hazard

Step

The potential to

Sequence

cause harm

of working

(Health, Injury,

activities Property damage,

environment etc)

House

Keeping

and

waste

Disposa

l.

Poor

housekeepi

ng

Slips & Trips

TRA Ref No:

CAUSE

(Possible

causes that will

potentially

release a

hazard)

from

heavy

sweating

Bad

weather

condition

Inhalation

Toxic Gas

Improper

cleaning

Improper

material

placement

Improper

Disposal.

Consequen

ces

(The harm

which could

possibly

occur).

exhausti

on

Poisono

us

Fatality

Existing Barrier / Control

Describe all existing barriers /

controls for each hazard

Potential

Risk

H/M/L

(With no

controls

in place)

Personn

el Injury

Fire

Environ

mental

impact.

TRA Team Leader

Signature

(All pages)

______________________

High Risk Authorisation

Signature

(First page Only)

JI-193/PIL/SC/0.....

Recommended Controls

Continuous water and ice

distribution / replenishment

in the field.

Drink plenty of cool water

to replace the water loss.

Drink about 1 cup (150 ml)

every 15 minutes

H2S personal monitors and

escape hood shall be

available at all the

employees during the

course of work.

Working Area shall be kept

in High standard

housekeeping.

Refuse shall be kept in

designated bins.

Waste Shall be disposed

properly

Waste management

procedure shall be

followed.

Clear the un wanted

materials from the site

time to time

_______________________

Date :

...th .... 2011

Action By

Residu

al Risk

H/M/

L

(with

controls

in place

ALARP Comple

Demon

tion

strated

Date

(Yes /

No)

Follow as per UAE ministerial decree no

587 for 2009.

All crew shall be familiar with emergency

procedure

Close supervision

TBT on waste segregation and

minimization.

Proper signage of waste bin.

JP /

SUPVR./

SO

YES

ENV TBT to be conducted in weekly basis.

All vehicles should carry plastics bags.

JP

________________________

IA

_________________________

Signature

signature

I have checked that all controls stated in the TRA are in place & conducted TBT

Page 22 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

TRA Ref No:

JI-193/PIL/SC/047

Date :

11-11-2010

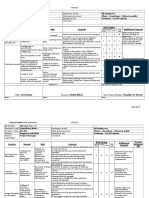

PROBABILITY

SEVERITY

PEOPLE

ASSETS

ENVIRONMENT

REPUTATION

1. Catastrophic

Multiple Fatality

Extensive

damage

Massive effect

International impact

2. Severe

Single Fatality or

Permanent

Disability

Major Injury or

Health Effects

Minor Injury or

health effects

Single injury or

health effects

Major damage

Major effect

National impact

Local damage

Localised effect

Considerable impact

Minor damage

Minor effect

Minor impact

Slight damage

Slight effect

Slight impact

3. Critical

4. Marginal

5. Negligible

Has occurred in

world-wide

industry but not

in ADNOC

Has occurred in

other ADNOC

Group Company

Has occurred in

specific ADCNOC

Group Company

Happens several

times each year

in specific

ADNOC Group

Company

Happens several

times each year in

same location or

operation

HIGH

MEDIUM

(ALARP)

LOW

PROBABILITY

SEVERITY

PEOPLE

ASSETS

ENVIRONMENT

REPUTATION

6. Catastrophic

Multiple Fatality

Massive effect

7. Severe

Single Fatality

or Permanent

Disability

Major Injury or

Health Effects

Minor Injury or

health effects

Single injury or

Extensive

damage

Major damage

International

impact

National impact

Local damage

Localised effect

Minor damage

Slight damage

8. Critical

9. Marginal

10. Negligible

Major effect

Has occurred

in world-wide

industry but not

in ADNOC

Has occurred

in other

ADNOC Group

Company

Has occurred

in specific

ADCNOC

Group

Company

Happens

several times

each year in

specific

ADNOC Group

Company

Happens

several times

each year in

same location

or operation

HIGH

MEDIUM

Minor effect

Considerable

impact

Minor impact

Slight effect

Slight impact

LOW

(ALARP)

TRA Team Leader Signature

(All pages)

Page 23 of 24

TASK RISK ASSESSMENT

Field/Terminal :

ASAB

TRA Ref No:

JI-193/PIL/SC/047

Date :

11-11-2010

health effects

HAZARD CHECKLIST

TRA Team Leader Signature

(All pages)

Page 24 of 24

You might also like

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- GL 28 Material Loading PlatformDocument1 pageGL 28 Material Loading Platformtp101267No ratings yet

- Part-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykeDocument4 pagesPart-A: Jsa Date: 23.11.16 Work Permit No: HW-: Civil Works Inside The Tank DykevivekaramanaNo ratings yet

- Construction Assessment Checklist: Green TagDocument2 pagesConstruction Assessment Checklist: Green TagRyan GillespieNo ratings yet

- MDLZ-RBIPL-MS-01-SITE MOBILIZATION WORK - UptdDocument21 pagesMDLZ-RBIPL-MS-01-SITE MOBILIZATION WORK - Uptdshamshad ahamedNo ratings yet

- Ra02 - Container OffloadingDocument3 pagesRa02 - Container OffloadingSamNo ratings yet

- Ra FormDocument5 pagesRa FormEngrHazrat MaazNo ratings yet

- SBOI Chklist PDFDocument1 pageSBOI Chklist PDFRajanNo ratings yet

- Hazard RegisterDocument1 pageHazard RegisterSamuel Maclean ArthurNo ratings yet

- Tower Crane Work Permit ChecklistDocument1 pageTower Crane Work Permit Checklistfaisal nadeemNo ratings yet

- JHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDocument4 pagesJHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDarmawan OnradNo ratings yet

- Safety management for front loader operationsDocument6 pagesSafety management for front loader operationskoketsoNo ratings yet

- DAR Vol1-2013Document744 pagesDAR Vol1-2013chitransh2002No ratings yet

- HSE Alert - LTI Fall From Heights TBTDocument12 pagesHSE Alert - LTI Fall From Heights TBTrodman823No ratings yet

- JSO Cable Drum (02 Sept.'07)Document2 pagesJSO Cable Drum (02 Sept.'07)Francis Enriquez TanNo ratings yet

- Cable Tray Installation JSADocument5 pagesCable Tray Installation JSAazerNo ratings yet

- Excavator Daily Inspection Check List Rev 0Document1 pageExcavator Daily Inspection Check List Rev 0Zhafran diniyNo ratings yet

- JHA Risk Assesment 1Document6 pagesJHA Risk Assesment 1leonardo GaraisNo ratings yet

- HSE-F-314 Passenger-Material Hoist Monthly ChecklistDocument1 pageHSE-F-314 Passenger-Material Hoist Monthly ChecklistAhmad RazaNo ratings yet

- Monthly HSE Statistics SeptemberDocument2 pagesMonthly HSE Statistics SeptemberRaza Muhammad SoomroNo ratings yet

- HIRA-22 Logistic & Commissioning Activity OKDocument8 pagesHIRA-22 Logistic & Commissioning Activity OKadityajailani19No ratings yet

- RISK ASSESSMENT FOR SWRO PLANT FOUNDATION WORKDocument7 pagesRISK ASSESSMENT FOR SWRO PLANT FOUNDATION WORKabhinav djNo ratings yet

- Confined Space Rescue Plan: Description of The WorkDocument2 pagesConfined Space Rescue Plan: Description of The Workidigiti100% (1)

- Shorebase HSE Walkthrough ScorecardDocument4 pagesShorebase HSE Walkthrough ScorecarddnmuleNo ratings yet

- Safety BoardDocument1 pageSafety BoardsunilNo ratings yet

- Bar Bending Checklist: Contractor NameDocument1 pageBar Bending Checklist: Contractor NameAfroz AlamNo ratings yet