Professional Documents

Culture Documents

Application Note LTARP Q1 2015

Uploaded by

Geert Henk WijnantsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application Note LTARP Q1 2015

Uploaded by

Geert Henk WijnantsCopyright:

Available Formats

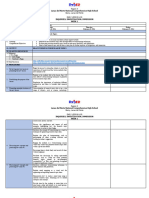

TECHNICAL BULLETIN.

LTARP; Basics guide.

The issue

A query that is commonly

encountered in LTARP projects is:

To what extent do the principles of the

methodology fit in with other

replacement guides?

The query refers to the next issues:

There is an abundance of lifetime

references; to what extent does

this differ with what is already

available.

There are various approaches like

Risk Based Inspections available.

To what extent does this approach

fit in to what is already

implemented.

The LTARP approach

In order to understand the basics with

respect to lifetime assessment, its

helpful to review how lifetime is

incorporated during the design phase.

A well-known phrase that points out

how maintenance and replacement as

well are guided, is: the needs for

maintenance are decided on the

drawing table.

Some examples that illustrate this

sentence are:

> If corrosion is likely to take place,

the effects of that can be accounted

for by incorporating corrosion

allowance. When adequately applied,

this does not only apply to the larger

equipments; also fittings and tubing

should be included in this approach.

An integrated approach in which

besides the larger equipment also all

connected tubing is designed for a

specific lifetime, is rare.

> If an equipment should last for a

specific period, this can be

incorporated in a transparent way in

the design specifications by reference

to predicted deterioration rate and the

way that has been accounted for. In

general only the plant design lifetime

is specified. The lifetime as applicable

to plant components is not traceable.

The LTARP End Of Life (EOL)

approach is in its core an act of

reverse engineering of the original

design assumptions, incorporating the

experience obtained in practice. It can

be characterized as feedback on the

original design calculations on which

the lifetime specification is based.

What does this imply?

Retrofitting the original allowances

and condition acceptance criteria with

the actual End Of Life deterioration

rate to a lifetime that will actually be

attained.

Predicting the asset performance

over time, in accordance with the

reliability requirements as per original

design, taking the actual reliability

characteristics into account.

It differs from generic replacement

guides, since it takes the actual plant

design with its specific built-in

characteristics as a reference.

Modular framework

A query that is commonly

encountered in LTARP project is:

What requirements do apply in order

to implement LTARP effectively?

The main characteristic of an LTARP

project is:

Trending, trending, trending.

In all cases, trends are assessed in

order to determine the specific

changes over time that are decisive

for an exchange or major repair of

equipment.

Commonly, equipment condition is

assessed by:

condition checks, resulting in still

good or need for repair. This

approach is commonly known as

the stoplight approach.

condition assessments. Actual

condition is determined by

reference to quality specifications

that apply for the supply phase.

In service acceptance criteria are

only seldom supplied as an

integrated part of the design.

generic equipment functional

requirements as per supplier.

Plant specific acceptance criteria

based on actual required

performance, are even more rare.

Commonly the performance

requirement refers to the design

specs which usually contains

overcapacity. Minimum

performance requirements are

rare.

LTARP Long Term Asset Replacement Planning

Application note LTARP Basics guide Q1 2015

Knowledge owner: geerthenk.wijnants@stork.com

The LTARP approach in general

results in the definition of default,

plant specific acceptance criteria with

guidelines by which the actual plant &

equipment specific EOL condition

assessment criteria can be

determined.

If trends are commonly assessed by

means of for instance an RBI

approach, the LTARP approach is

merely a plug-in, by which the already

available data are reviewed in order to

select the specific data that pertain to

the actual End Of Life scenario.

In other cases, particularly in the

StopLight LTARP will reveal that due

End Of Life situations are invisible,

since OK will result as long as no

repairs are required.

So here also, criteria for more specific

characterization of the actual

conditions, will be sought for.

Conclusions

As discussed, the core of the LTARP

approach is as follows:

It acts as a plugs-in onto already

available approaches by which

conditional changes are

monitored.

If reveals the Stoplight situations

and will opt for predictive capacity,

since stoplight assessments

commonly lack in predictive

capacity.

It retro-engineers the original

designed lifetime calculation by

incorporating the actual observed

conditional behavior over time.

It reveals the decisive End Of Life

scenarios, which can validate the

original reference as per design or

may reveal as yet hidden

characteristics as per specification

of the decisive scenario.

For transparency and traceability

purposes, LTARP uses the ISO 15686

and the NEN 2767 as a common

framework for End Of Life condition

assessment and documented,

traceable End Of Life calculations.

LTARP acts as a plug-in on already

operational trend-based condition

monitoring programs.

You might also like

- Overall Report WP2 WCM-IP (En)Document12 pagesOverall Report WP2 WCM-IP (En)Geert Henk Wijnants100% (1)

- 2015 Challenges 4 Infra Asset ManagementDocument16 pages2015 Challenges 4 Infra Asset ManagementGeert Henk WijnantsNo ratings yet

- Floating Windfarms For Shallow Offshore Sites: A.R. HendersonDocument8 pagesFloating Windfarms For Shallow Offshore Sites: A.R. HendersonGeert Henk WijnantsNo ratings yet

- Creep and Fatigue Crack Growth in A PipeDocument14 pagesCreep and Fatigue Crack Growth in A PipeGeert Henk WijnantsNo ratings yet

- Measuring of The Reliability of Nde: F. Fücsök, C. Müller, M. ScharmachDocument8 pagesMeasuring of The Reliability of Nde: F. Fücsök, C. Müller, M. ScharmachSabino LaraNo ratings yet

- Organisational Integrity Embedded in Asset Management: A Key Success Factor For Oil and Gas OperatorsDocument3 pagesOrganisational Integrity Embedded in Asset Management: A Key Success Factor For Oil and Gas OperatorsGeert Henk WijnantsNo ratings yet

- Service Life Prediction and Repair of Conc StructuresDocument18 pagesService Life Prediction and Repair of Conc StructuresmpcopeNo ratings yet

- Fiberglass Reinforced Plastic Assets Corrosion Barier Condition and RSLDocument13 pagesFiberglass Reinforced Plastic Assets Corrosion Barier Condition and RSLNadiagdikaNo ratings yet

- CBM & RCM Applied On Nuclear Power PlantsDocument11 pagesCBM & RCM Applied On Nuclear Power PlantsGeert Henk WijnantsNo ratings yet

- International Conference On Port & Maritime R&D and TechnologyDocument8 pagesInternational Conference On Port & Maritime R&D and TechnologyGeert Henk WijnantsNo ratings yet

- Model To Optimize The Design of Fiberglass Reinforced Plastic in Chlorine Dioxide Service 2Document9 pagesModel To Optimize The Design of Fiberglass Reinforced Plastic in Chlorine Dioxide Service 2Geert Henk WijnantsNo ratings yet

- A 398282Document65 pagesA 398282Geert Henk WijnantsNo ratings yet

- Control Strategies For Floating Offshore Wind TurbDocument14 pagesControl Strategies For Floating Offshore Wind TurbGeert Henk WijnantsNo ratings yet

- Condition Assessment of Underground Pipes (April 2015)Document12 pagesCondition Assessment of Underground Pipes (April 2015)Geert Henk WijnantsNo ratings yet

- A Study of Long-Term Strength and Creep Rupture in uPVC Plastic PipesDocument6 pagesA Study of Long-Term Strength and Creep Rupture in uPVC Plastic PipesGeert Henk WijnantsNo ratings yet

- City of Parramatta Fees and Charges ScheduleDocument267 pagesCity of Parramatta Fees and Charges ScheduleGeert Henk WijnantsNo ratings yet

- Peter J. Postma, René J.M. Hermkens, Kiwa Technology, The NetherlandsDocument10 pagesPeter J. Postma, René J.M. Hermkens, Kiwa Technology, The NetherlandsGeert Henk WijnantsNo ratings yet

- Floating Windfarms For Shallow Offshore Sites: A.R. HendersonDocument8 pagesFloating Windfarms For Shallow Offshore Sites: A.R. HendersonGeert Henk WijnantsNo ratings yet

- Life Cycle CostingDocument82 pagesLife Cycle CostingronfrendNo ratings yet

- CBM & RCM Applied On Nuclear Power PlantsDocument11 pagesCBM & RCM Applied On Nuclear Power PlantsGeert Henk WijnantsNo ratings yet

- Corrosion 11Document9 pagesCorrosion 11niqutomoNo ratings yet

- Service Life Prediction and Repair of Conc StructuresDocument18 pagesService Life Prediction and Repair of Conc StructuresmpcopeNo ratings yet

- Managing Spares Inventory Through Life Time Value AssessmentDocument9 pagesManaging Spares Inventory Through Life Time Value AssessmentGeert Henk WijnantsNo ratings yet

- GHD Infrastructure Maintenance PDFDocument112 pagesGHD Infrastructure Maintenance PDFmahsa_ci80No ratings yet

- ISSF Workshop Final Report Benchmarking LCC AnalysesDocument100 pagesISSF Workshop Final Report Benchmarking LCC AnalysesnagaNo ratings yet

- Sap PMDocument93 pagesSap PMprodigious8467% (3)

- LCC A 121405Document30 pagesLCC A 121405Renato GutierrezNo ratings yet

- Sap PMDocument93 pagesSap PMprodigious8467% (3)

- Operations and Maintenance GuideDocument321 pagesOperations and Maintenance GuideNatrajiNo ratings yet

- Ris R 1235Document39 pagesRis R 1235Geert Henk WijnantsNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- English-VI Week 24Document4 pagesEnglish-VI Week 24Rabab ZafarNo ratings yet

- ChedDocument1 pageChedlsanchez3451No ratings yet

- 3is QUARTER 3 WEEK1Document5 pages3is QUARTER 3 WEEK1Monique BusranNo ratings yet

- Revisiting Feminist Approaches To Art Therapy Edited by Susan Hogan (2012) - BreghahnDocument4 pagesRevisiting Feminist Approaches To Art Therapy Edited by Susan Hogan (2012) - Breghahnpaula zorziNo ratings yet

- Types and Providers of InformationDocument27 pagesTypes and Providers of InformationVilla EdlynCrisNo ratings yet

- Kristens Updated Resume 06-21-16Document4 pagesKristens Updated Resume 06-21-16api-323019788No ratings yet

- Soc FallDocument688 pagesSoc Falljpcarter1116No ratings yet

- List of Education and Training Companies in IndonesiaDocument108 pagesList of Education and Training Companies in IndonesiaMelna Monica Apriana0% (1)

- Evidence Based PracticeDocument4 pagesEvidence Based PracticeChandu RajNo ratings yet

- SyllabusDocument1 pageSyllabusapi-265062685No ratings yet

- NCSE-Physical Education (2014) - P1 (Practical) - Teacher's ScriptDocument14 pagesNCSE-Physical Education (2014) - P1 (Practical) - Teacher's Scriptget thosebooksNo ratings yet

- Higher SuperstitionDocument47 pagesHigher SuperstitionsujupsNo ratings yet

- Emerging-Distinguished Rubric for Art SkillsDocument2 pagesEmerging-Distinguished Rubric for Art SkillsCarmela ParadelaNo ratings yet

- Unit 9. Choosing A Career (1) : OpportunityDocument7 pagesUnit 9. Choosing A Career (1) : OpportunityNguyễn ThảoNo ratings yet

- TR - Carpentry NC II PDFDocument161 pagesTR - Carpentry NC II PDFBlueridge Pacific100% (3)

- Materi Elearning Akhlak 031120Document14 pagesMateri Elearning Akhlak 031120clevereto100% (4)

- Corporate and Allied Laws Vol. II (Practice Manual) - g1Document454 pagesCorporate and Allied Laws Vol. II (Practice Manual) - g1caatulgarg6023100% (1)

- Ibrahim Kalin - Islam and Science: Notes On An Ongoing DebateDocument7 pagesIbrahim Kalin - Islam and Science: Notes On An Ongoing DebatezostriNo ratings yet

- Arts 7 Q1 M1Document18 pagesArts 7 Q1 M1SirJo Rios NillosNo ratings yet

- Project Stakeholder Management GuideDocument2 pagesProject Stakeholder Management Guideashunir2001No ratings yet

- 4.10 (Mahanama) Gilayana S s55.54 Piya TanDocument5 pages4.10 (Mahanama) Gilayana S s55.54 Piya TanpancakhandaNo ratings yet

- Sethu Institute of Technology - Wireless Networks and Standards CIA Marks May 2021Document2 pagesSethu Institute of Technology - Wireless Networks and Standards CIA Marks May 2021john pragasamNo ratings yet

- Housing Information: (1) On-Campus DormitoryDocument4 pagesHousing Information: (1) On-Campus DormitoryNico Illarregui HelNo ratings yet

- Wearing School UniformsDocument1 pageWearing School UniformsEmanAbdel-HaqNo ratings yet

- Sample Third Grade LessonsDocument10 pagesSample Third Grade Lessonsapi-214652729No ratings yet

- Cambridge International Examinations: Design and Technology 0445/11 May/June 2017Document4 pagesCambridge International Examinations: Design and Technology 0445/11 May/June 2017knNo ratings yet

- Avaliação Competencias Sociais 7 12Document27 pagesAvaliação Competencias Sociais 7 12Cristina BarreiraNo ratings yet

- Numerical Control of Machine Tools PDFDocument2 pagesNumerical Control of Machine Tools PDFBruce MartinNo ratings yet

- Cambridge iGCSE Design and Technology ST PDFDocument1 pageCambridge iGCSE Design and Technology ST PDFfarihaNo ratings yet

- DyslexiaDocument13 pagesDyslexiabloodythornNo ratings yet