Professional Documents

Culture Documents

ACI For Waterproofing

Uploaded by

Ghayas JawedOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACI For Waterproofing

Uploaded by

Ghayas JawedCopyright:

Available Formats

FM 5.

3 Exhibit 2

page 1 of 7

ACI 515.1 R-79

This document has been a proved for use by agendes of the Department of uefense and for listing in

the DoD Index of Specifications and Standards.

(Revised 1985)

A Guide to the Use of Waterproofing, Dampproofing,

Protective, and Decorative Barrier Systems

for Concrete

Reported by ACI Committee 515

Byron I. Zolin, Chairman

Warner K. Babcock

Arthur E. Blackman, Sr.

Donald E. Brotherson

Robert W. Gaul

Clark R. Gunness

Kenneth A. Heffner

A. L. Hendricks

James E. Kubanick

Dorothy M. Lawrence

Stella L. Marusin

Charles J. Parise

Charles 0. Pratt

Andrew Rossi, Jr.

Donald L. Schlegel

Lawrence E. Schwietz

The revising committee is listed at the end of the document.

This Guide updates and expands the scope of the

committee report "Guide for the Protection of Concrete Against Chemical Attack by Means of Coatings

and Other Corrosion Resistant Materials," which appeared in the December 1996 ACI JOURNAL. The previous Guide has been revised and is found in

Chapter 6 of this Guide entitled "Protective Barrier

Systems." In addition, there are new chapters on

"Waterproofing Barrier Systems," "Dampproofing

Barrier Systems," and "Decorative Barrier Systems."

A separate chapter on conditioning and surface

preparation of concrete is included because it is relevant to all the other chapters.

This Guide is not to be referenced as a complete

unit.

Keywords: abrasive blasting; acid treatment (concrete); acid resistance; adhesion; asphalts; chemical attack; chemical cleaning; coatings; concrete

bricks; concretes; detergents; emulsifying agents; epoxy resins; finishes;

furan resins; glass fibers; inspection; joint sealers; latex (rubber); mortars

[materials); paints; phenolic resins; plastics, polymers, and resins; polyester

resins; polyurethane resins; protective coatings; repairs; sealers; silicates;

sulfur; surfactants; temperature; tests; vaporbarriers; waterproofing.

Foreword

ACI Committee 515 was organized in 1936 and published a report "Guide for the Protection of Concrete

Against Chemical Attack by Means of Coatings and

Other Corrosion Resistant Materials," in the De-

ACl Committee Reports, Guides, Standard Practices, and Commentaries are intended for guidance in designing, planning, executing;

or inspecting construction, and in preparing specifications. Reference to these documents shall not be made in the Project Documents. If items found in these documents are desired to be part of

the Project Documents, they should be incorporated directly into the

Project Documents.

cember 1966 ACI JOURNAL. William H. Kuenning was

chairman when this Guide was published. Albert M.

Levy was chairman from 1974 to 1977 when some of

the information, found in the chapters on "Waterproofing Barrier Systems" and "Dampproofing Barrier Systems," was developed.

CONTENTS

Chapter I-Introduction, page 515.1R-2

1.1-General discussion

1.2-The systems concept for barriers

1.3-Barrier performance difficult to define

1.4-Economic factors for barrier selection

1.5-Inspection during application

1.6-Safety requirements

Chapter 2-Barrier systems: types and

performance requirements, page 515.1R-3

2.1-Definitions of barrier systems

2.2-When waterproofing is used

2.3-When dampproofing is used

2.4-When protective barrier systems are used

2.5-Susceptibility of concrete to attack by chemicals

2.6-When decorative painting barrier systems are used

Chapter 3-Concrete conditioning and surface

preparation, page 515.1R-12

3.1 -General requirements

3.2-Repair of surface defects

3.3-Stopping or rerouting of water

3.4-Surface preparation

Co-pyngFh_ 1986, American Concrete Institute. All rights reserved including rights of reproduction and use in any form or by any means, including

the making of copies by any photo process, or by any electronic or mechanical device, printed or written or oral, or recording for sound or visua1

reproduction or for use in any knowledge or retrieval system or device,

unless permission in writing is obtained from the copyright proprietors

. -,

page 2 of 7

FM 5.3 Exhibit 2

MANUAL OF CONCRETE PRACTICE

515.1R-6

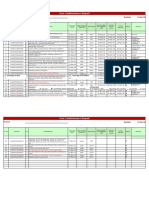

Table 2.5.24ffect of chemicals on concrete ksee end of Table 2.5.2 for special notations)

Material

*Acetic acid, all

Disintegrates slowly

Ashes

Harmful if wet, when sulfides and

sulfates leach out (see sodium sulfate)

Liquid loss by penetration. May

contain acetic acid as impurity (which

see)

Ashes, hot

Cause thermal expansion

Automobile and diesel

exhaust gases (n)

May disintegrate moist concrete by

action of carbonic, nitric, or sulfurous

acid

*Baking soda

See sodium bicarbonate

Barium hydroxide

Not harmful

Bark

See tanning bark

*Beef fat

Solid fat disintegrates slowly, melted fat

concentrations

Acetone

Acid waters (pH of 6.5

or less) (a)

Disintegrates slowly. In porous or

cracked concrete, attacks steel

*Alcohol

See ethyl alcohol, methyl alcohol

Alizarin

Not harmful

*Almond oil

Disintegrates slowly

*Alum

See potassium aluminum sulfate

Aluminum chloride

Disintegrates rapidly. In porous or

cracked concrete, attacks steel

*Aluminum sulfate

*Ammonia, liquid

more rapidly

*Beer

May contain, as fermentation products,

acetic, carbonic, lactic, or tannic acids

(which see)

Disintegrates. In porous or cracked

concrete, attacks steel

Benzol (benzenel

Liquid loss by penetration

Harmful only if it contains harmful

Bleaching solution

See specific chemical, such as

hypochlorous acid, sodium

hypochlorite, sulfurous acid, etc.

*Borax

Not harmful

ammonium salts (see below)

Ammonia vapors

Effect

Material

Effect

May disintegrate moist concrete slowly

or attack steel in porous or cracked

moist concrete

*Boric acid

Negligible effect

Disintegrates. In porous or cracked

concrete, attacks steel

*Brine

See sodium chloride or other salt

Ammonium carbonate

Not harmful

Bromine

*Ammonium chloride

Disintegrates slowly. In porous or

Gaseous bromine disintegrates. Liquid

bromine disintegrates if it contains

hydrobromic acid and moisture

*Buttermilk

Disintegrates slowly

Butyl stearate

Disintegrates slowly

Calcium bisulfite

Disintegrates rapidly

*Calcium chloride

In porous or cracked concrete, attacks

Ammonium bisulfate

cracked concrete, attacks steel

Ammonium cyanide

Disintegrates slowly

Ammonium fluoride

Disintegrates slowly

Ammonium hydroxide

Not harmful

Ammonium nitrate

Disintegrates. In porous or cracked

concrete, attacks steel

Ammonium oxalate

Not harmful

*Calcium hydroxide

Not harmful

*Ammonium sulfate

Disintegrates. In porous or cracked

Calcium nitrate

Not harmful

*Calcium sulfate

Disintegrates concrete of inadequate

steel. (b) Steel corrosion may cause

concrete to spall

concrete, attacks steel

Ammonium sulfide

Disintegrates

Ammonium sulfite

Disintegrates

Carbazole

Not harmful

Ammonium

superphosphate

Disintegrates. In porous or cracked

concrete, attacks steel

Carbolic acid

See phenol

*Carbon dioxide

Gas may cause permanent shrinkage

Ammonium

thiosulfate

Disintegrates

Animal wastes

See slaughter house wastes

Anthracene

Not harmful

Arsenious acid

Not harmful

sulfate resistance

(see also carbonic acid)

*Carbon disulfide

May disintegrate slowly

*Carbon tetrachloride

Liquid loss by penetration of concrete

*Carbonic acid

Disintegrates slowly (c)

1 191

4 -

FM 5.3 Exhibit 2

page 3 of 7

515.1R-7

SURFACE BARRIER SYSTEMS

Table 2.5.2-(Continued)

Material

Effect

Effect

Material

Disintegrates, especially in presence of

air

*Cottonseed oil

Chile saltpeter

See sodium nitrate

Creosote

Phenol present disintegrates slowly

China wood oil

Liquid disintegrates slowly.

Cresol

Phenol present disintegrates slowly

Chlorine gas

Slowly disintegrates moist concrete

Cumol

Liquid loss by penetration

Chrome plating

Disintegrates slowly

Deicing salts

Scaling of non-air-entrained or

insufficiently aged concrete (b)

Chromic acid, all

Attacks steel in porous or cracked

Diesel gases

concentrations

concrete

See automobile and diesel exhaust

gases

*Chrysen

Not harmful

Dinitrophenol

Disintegrates slowly

*Cider

Disintegrates slowly (see acetic acid]

Distiller's slop

Lactic acid causes slow disintegration

Cinders

Harmful if wet, when sulfides and

sulfates leach out (see, for example,

sodium sulfate)

Epsom salt

See magnesium sulfate

*Ethyl alcohol

Liquid loss by penetration

Cinders, hot

Cause thermal expansion

*Ethyl ether

Liquid loss by penetration

Coal

Sulfides leaching from damp coal may

*Ethylene glycol

Disintegrates slowly (d)

oxidize to sulfurous or sulfuric acid, or

ferrous sulfate (which see)

Feces

See manure

*Fermenting fruits,

Industrial fermentation processes

grains, vegetables, or

extracts

produce lactic acid. (e) Disintegrates

slowly (see lactic acid)

Ferric chloride

Disintegrates slowly

sulfate resistance

Ferric nitrate

Not harmful

Disintegrates, especially in presence of

Ferric sulfate

Disintegrates concrete of inadequate

quality

Ferric sulfide

Harmful if it contains ferric sulfate

(which see)

Ferrous chloride

Disintegrates slowly

Ferrous sulfate

Disintegrates concrete of inadequate

sulfate resistance

Fertilizer

See ammonium sulfate, ammonium

superphosphate, manure, potassium,

nitrate, sodium nitrate

Castor oil

Disintegrates, especially in presence of

air

solutions (o)

Coal tar oils

See anthracene, benzol, carbazole,

chrysen, creosote, cresol, cumol,

paraffin, phenanthrene, phenol, toluol,

xylol

Cobalt sulfate

*Cocoa bean oil

Disintegrates concrete of inadequate

air

*Cocoa butter

Disintegrates, especially in presence of

air

Coconut oil

Disintegrates, especially in presence of

air

*Cod liver oil

Disintegrates slowly

Coke

Sulfides leaching from damp coke may

oxidize to sulfurous or sulfuric acid

(which see]

Copper chloride

Disintegrates slowly

Fish liquor

Disintegrates

(0

Copper plating

Not harmful

*Fish oil

Disintegrates slowly

Flue gases

Hot gases (400-1100 F) cause thermal

stresses. Cooled, condensed sulfurous,

hydrochloric acids disintegrate slowly

solutions (p)

Copper sulfate

Disintegrates concrete of inadequate

sulfate resistance

Copper

Harmful if it contains copper sulfate

(which see)

Foot oil

Disintegrates slowly

*Formaldehyde, 37

Formic acid, formed in solution,

*Com syrup

Disintegrates slowly

percent

disintegrates slowly

Corrosive sublimate

See mercuric chloride

Formalin

See formaldehyde

sulfide

1.

0%

I FM 5.3 Exhibit 2

page 4 of 7

MANUAL OF CONCRETE PRACTICE

515.1R-8

Table 2.5.2-(Continued)

*Formic acid, 10

Disintegrates slowly

Lignite oils

If fatty oils are present, disintegrates

slowly

*Linseed oils

Liquid disintegrates slowly. Dried or

percent

*Formic acid, 30

Effect

Material

Effect

Material

Disintegrates slowly

percent

drying films are harmless

*Formic acid, 90

Disintegrates slowly

Locomotive gases (r)

percent

*Fruit juices

Hydrofluoric, other acids, and sugar

cause disintegration (see also

fermenting fruits, grains, vegetables,

extracts)

oil

Lubricating

May disintegrate moist concrete by

action of carbonic, nitric or sulfurous

acids (see also automobile and diesel

exhaust gases)

Fatty oils, if present, disintegrate slowly

Lye

See sodium hydroxide

Machine oil

Fatty oils, if present, disintegrate slowly

*Magnesium chloride

Disintegrates slowly. In porous or

Gas water (g)

Ammonium salts seldom present in

sufficient quantity to disintegrate

Gasoline

Liquid loss by penetration

*Glucose

Disintegrates slowly

*Glycerine

Disintegrates slowly

Magnesium nitrate

Disintegrates slowly

*Grain

See fermenting fruits, grains,

*Magnesium sulfate

Disintegrates concrete of inadequate

cracked concrete, attacks steel

sulfate resistance

vegetables, extracts

*Honey

Not harmful

Manganese

Horse fat

Solid fat disintegrates slowly, melted fat

more rapidly

Manure

Disintegrates slowly

Humic acid

Disintegrates slowly

*Margarine

Solid margarine disintegrates slowly,

*Hydrochloric acid, all

Disintegrates rapidly, including steel

sulfate

Disintegrates concrete of inadequate

sulfate resistance

melted margarine more rapidly

concentrations

Mash, fermenting

Acetic and lactic acids, and sugar

disintegrate slowly

Mercuric chloride

Disintegrates slowly

Hydrofluoric acid, all

concentrations

Disintegrates rapidly, including steel

Hydrogen sulfide

Not harmful dry. In moist, oxidizing

environments converts to sulfurous

acid and disintegrates slowly

Mercurous chloride

Disintegrates slowly

Methyl alcohol

Liquid loss by penetration

Hypochiorous acid, 10

percent

Disintegrates slowly

Methyl ethyl ketone

Liquid loss by penetration

Methyl isobutyl ketone

Liquid loss by penetration

Iodine

Disintegrates slowly

*Milk

Not harmful. However, see sour milk

Kerosene

Liquid loss by penetration of concrete

Mine water, waste

*Lactic acid, 5-25

Disintegrates slowly

Sulfides, sulfates, or acids present

disintegrate concrete and attack steel in

porous-or cracked concrete

*Mineral oil

Fatty oils, if present, disintegrate slowly

Mineral spirits

Liquid loss by penetration

*Molasses

At temperatures >_120 F, disintegrates

percent

*Lamb fat

Solid fat disintegrates slowly, melted fat

more rapidly

*Lard and lard oil

Lard disintegrates slowly, lard oil more

rapidly

slowly

Lead nitrate

Disintegrates slowly

Lead refining solutions

Disintegrates slowly

Muriatic

(q)

acid

*Mustard oil

See hydrochloric acid

Disintegrates, especially in presence of

air

Leuna

saltpeter

See ammonium nitrate and ammonium

sulfate

Nickel plating

solutions (v)

Nickel ammonium sulfate disintegrates

slowly

page 5 of 7

FM 5.3 Exhibit 2

515.1R-9

SURFACE BARRIER SYSTEMS

Table 2.5.2-(Continued)

Effect

Material

Material

Effect

Nickel sulfate

Disintegrates concrete of inadequate

sulfate resistance

Potassium hydroxide,

25 percent or over

Disintegrates concrete

Niter

See potassium nitrate

*Potassium nitrate

Disintegrates slowly

Nitric acid, all

concentrations

Disintegrates rapidly

Potassium

permanganate

Harmless unless potassium sulfate

present (which see)

*Oleic acid, 100

Not harmful

Potassium

Disintegrates concrete of inadequate

sulfate resistance

Oleum

See sulfuric acid, 110 percent

Potassium sulfate

Disintegrates concrete of inadequate

sulfate resistance

*Olive oil

Disintegrates slowly

Potassium sulfide

Ores

Sulfides leaching from damp ores may

oxidize to sulfuric acid or ferrous

sulfate (which see)

Harmless unless potassium sulfate

present (which see)

Pyrites

See ferric sulfide, copper sulfide

Not harmful. Protects tanks against

acetic acid, carbon dioxide, salt water.

Poisonous. Do not use with food or

drinking water

*Rapeseed oil

Disintegrates, especially in presence of

Rock salt

See sodium chloride

Shallow penetration not harmful, but

should not be used on highly porous

surfaces like concrete masonry (u)

Rosin

Not harmful

Rosin oil

Not harmful

*Peanut oil

Disintegrates slowly

Sal ammoniac

See ammonium chloride

Perchloric acid, 10

percent

Disintegrates

Sal soda

See sodium carbonate

Salt for deicing roads

Perchloroethylene

Liquid loss by penetration

See text. Also calcium chloride,

magnesium chloride, sodium chloride

Petroleum oils

Liquid loss by penetration. Fatty oils, if

present, disintegrate slowly

Saltpeter

See potassium nitrate

*Sauerkraut

Flavor impaired by concrete. Lactic

Phenanthrene

Liquid loss by penetration

Phenol, 5-25 percent

Disintegrates slowly

*Phosphoric acid,

Disintegrates slowly

persulfate

percent

Oxalic acid

Paraffin

air

acid may disintegrate slowly

Sea water

Disintegrates concrete of inadequate

sulfate resistance. Attacks steel in

porous or cracked concrete

Sewage

Usually not harmful (see hydrogen

sulfide]

Silage

Acetic, butyric, lactic acids (and

sometimes fermenting agents of

hydrochloric or sulfuric acids)

disintegrate slowly

10-85 percent

*Pickling brine

Attacks steel in porous or cracked

concrete

Pitch

Not harmful

*Poppy seed oil

Disintegrates slowly

*Potassium aluminum

Disintegrates concrete of inadequate

sulfate resistance

Slaughter house

wastes (w)

Organic acids disintegrate

sulfate

*Potassium carbonate

Harmless unless potassium sulfate

Sludge

See sewage, hydrogen sulfide

Soda water

See carbonic acid

steel in porous or cracked concrete

*Sodium bicarbonate

Not harmful

Potassium cyanide

Disintegrates slowly

Sodium bisulfate

Disintegrates

Potassium dichromate

Disintegrates

Sodium bisulfite

Disintegrates

Potassium hydroxide,

15 percent

Not harmful (h)

Sodium bromide

Disintegrates slowly

present (which see)

*Potassium chloride

Magnesium chloride, if present, attacks

I FM 5.3 Exhibit 2

page 6 of 7

MANUAL OF CONCRETE PRACTICE

515.1R-10

Table 2.5.2-(Continued)

Material

Effect

Material

Sodium carbonate

Not harmful, except to calcium

aluminate cement

*Sodium chloride

Magnesium chloride, if present, attacks

steel in porous or cracked concrete. (b)

Steel corrosion may cause concrete to

spall

Sodium cyanide

Disintegrates slowly

Sodium dichromate

Dilute solutions disintegrate slowly

*Sodium hydroxide,

Not harmful (h)

Sulfurous acid

Disintegrates rapidly

Tallow and tallow oil

Disintegrates slowly

Tannic acid

Disintegrates slowly

Tanning bark

May disintegrate slowly if damp (see

tanning liquor)

Tanning

1-10 percent

Effect

liquor

Disintegrates, if acid

*Tartaric acid solution

Not harmful

Tobacco

Organic acids, if present, disintegrate

slowly

Toluol (toluene)

Liquid loss by penetration

*Sodium hydroxide,

20 percent or over

Disintegrates concrete

Sodium hypochlorite

Disintegrates slowly

*Trichloroethylene

Liquid loss by penetration

*Sodium nitrate

Disintegrates slowly

*Trisodium phosphate

Not harmful

Sodium nitrite

Disintegrates slowly

Tung oil

Liquid disintegrates slowly. Dried or

drying films are harmless

Sodium phosphate

(monobasic)

Disintegrates slowly

Turpentine

Mild attack. Liquid loss by penetration

Sodium sulfate

Disintegrates concrete of inadequate

sulfate resistance

*Urea

Not harmful

Urine

Sodium sulfide

Disintegrates slowly

Attacks steel in porous or cracked

concrete

*Sodium sulfite

Sodium sulfate, if present, disintegrates

concrete of inadequate sulfate

resistance

Vegetables

See fermenting fruits, grains,

vegetables, extracts

Vinegar

Disintegrates slowly (see acetic acid)

Sodium thiosulfate

Slowly disintegrates concrete of

inadequate sulfate resistance

Walnut oil

Disintegrates slowly

*Sour milk

Lactic acid disintegrates slowly

*Whey

Disintegrates slowly (see lactic acid)

*Soybean oil

Liquid disintegrates slowly. Dried or

drying films harmless

*Wine

Not harmful. Necessary to prevent

flavor contamination

Strontium chloride

Not harmful

Wood pulp

Not harmful

*Sugar

Disintegrates slowly

Xylol (xylene)

Liquid loss by penetration

Sulfite liquor

Disintegrates

*Zinc chloride

Disintegrates slowly

Sulfite solution

See calcium bisulfite

Zinc nitrate

Not harmful

*Sulfur dioxide

With moisture forms sulfurous acid

(which see)

Zinc refining solutions

(x)

Hydrochloric or sulfuric acids, if

present, disintegrate concrete

*Sulfuric acid, 10-80

percent

Disintegrates rapidly

Zinc slag

Zinc sulfate (which see) sometimes

formed by oxidation

*Sulfuric acid, 80

percent oleum

Disintegrates

Zinc sulfate

Disintegrates slowly

FM 5.3 Exhibit 2

page 7 of 7

SURFACE BARRIER SYSTEMS

515.1R-11

Key to special notations-Table 2.5.2

Sometimes used in food processing or as food or beverage ingredient. Ask for advisory opinion of Food and Drug Administration

regarding coatings for use with food ingredients.

a

Waters of pH higher than 6.5 may be aggressive if they also contain bicarbonates. (Natural waters are usually of pH higher than 7.0

and seldom lower than 6.0, though pH values as low as 0.4 have been reported. For pH values below 3, protect as for dilute acid.)

Frequently used as a deicer for concrete pavements. If the concrete contains too little entrained air or has not been aged more than

one month, repeated application may cause surface scaling. For protection under these conditions, see "deicing salts."

Carbon dioxide dissolves in natural waters to form carbonic acid solutions. When it dissolves to extent of 0.9 to 3 parts per million it

is destructive to concrete.

Frequently used as deicer for airplanes. Heavy spillage on runway pavements containing too little entrained air may cause surface

scaling.

In addition to the intentional fermentation of many raw materials, much unwanted fermentation occurs in the spoiling of foods and

food wastes, also producing lactic acid.

Contains carbonic acid, fish oils, hydrogen sulfide, methyl amine, brine, other potentially reactive materials.

Water used for cleaning coal gas.

However, in those limited areas of the United States where concrete is made with reactive aggregates, disruptive expansion may be

produced.

Composed mostly of nitrogen, oxygen, carbon dioxide, carbon monoxide, and water vapor. Also contains unburned hydrocarbons,

partially burned hydrocarbons, oxides of nitrogen, and oxides of sulfur. Nitrogen dioxide and oxygen in sunlight may produce

ozone, which reacts with some of the organics to produce formaldehyde, peracylnitrates, and other products.

These either contain chromium trioxide and a small amount of sulfate, or ammonium chromic sulfate [nearly saturated) and sodium

sulfate.

Many types of solutions are used, including

(a) Sulfate-Contain copper sulfate and sulfuric acid.

(b) Cyanide-Contain copper and sodium cyanides and sodium carbonate.

(c) Rochelle-Contain these cyanides, sodium carbonate, and potassium sodium tartrate.

(d) Others such as fluoborate, pyrophosphate, amine, or potassium cyanide.

Contains lead fluosilicates and fluosilicic acid.

Reference here is to combustion of coal, which produces carbon dioxide, water vapor, nitrogen, hydrogen, carbon monoxide, carbohydrates, ammonia, nitric acid, sulfur dioxide, hydrogen sulfide, soot, and ashes.

Porous concrete which has absorbed considerable molten paraffin and then been immersed in water after the paraffin has solidified

has been known to disintegrate from sorptive forces.

Contains nickelous chloride, nickelous sulfate, boric acid, and ammonium ion.

May contain various mixtures of blood, fats and oils, bile and other digestive juices, partially digested vegetable matter, urine, and

manure, with varying amounts of water.

Usually contains zinc sulfate in sulfuric acid. Sulfuric acid concentration may be low (about 6 percent in "low current density"

process) or higher (about 22-28 percent in "high current density" process).

You might also like

- 5 Precast in Seismic AreasDocument50 pages5 Precast in Seismic AreasMuhammad Arif RachmanNo ratings yet

- Ultimate Load Capacity of Reinforced Concrete SlabDocument8 pagesUltimate Load Capacity of Reinforced Concrete SlabUmed ADA-ALSATAR100% (1)

- Aluminum Structures FAQ GuideDocument3 pagesAluminum Structures FAQ GuideZebNo ratings yet

- Life-365 - v2.2.3 - Users - Manual (1) - 26-53Document28 pagesLife-365 - v2.2.3 - Users - Manual (1) - 26-53Fernando RosalesNo ratings yet

- Sharma Et Al-2017-Structural Concrete As PublishedDocument9 pagesSharma Et Al-2017-Structural Concrete As PublisheddebiNo ratings yet

- Hilti HCC-B For Concrete Overlays: Fastening Technology ManualDocument39 pagesHilti HCC-B For Concrete Overlays: Fastening Technology ManualPablo Martinez FesserNo ratings yet

- Concrete Exposure Classes Sept2018 PDFDocument5 pagesConcrete Exposure Classes Sept2018 PDFMohd.irfanNo ratings yet

- AISI S230-12-E1Document2 pagesAISI S230-12-E1Jon JacobsNo ratings yet

- Evaluation and Repair of Bridge Truss Gusset PlatesDocument16 pagesEvaluation and Repair of Bridge Truss Gusset PlatesLAM CONo ratings yet

- Astm C 1227 - (Med To Heavy Traffic)Document5 pagesAstm C 1227 - (Med To Heavy Traffic)HaniAminNo ratings yet

- Fluid Loss of Clay Component of Geosynthetic Clay Liners: Standard Test Method ForDocument3 pagesFluid Loss of Clay Component of Geosynthetic Clay Liners: Standard Test Method ForDanZel DanNo ratings yet

- Tek 10-03Document4 pagesTek 10-03Thai DamNo ratings yet

- Notes On Design of Steel Parking Structures IncludDocument42 pagesNotes On Design of Steel Parking Structures IncludSudhakar KrishnamurthyNo ratings yet

- Composite Steel Deck-Slabs With Supplimental Reinforcing BarsDocument4 pagesComposite Steel Deck-Slabs With Supplimental Reinforcing BarsHyunkyoun JinNo ratings yet

- AISI S211-07 (Raffirmed 2012) - E1Document2 pagesAISI S211-07 (Raffirmed 2012) - E1Jon JacobsNo ratings yet

- CDOT 2017 09 Chapter 5 Base MaterialsDocument21 pagesCDOT 2017 09 Chapter 5 Base Materialscarl_orbeNo ratings yet

- JPRCP Manual FullDocument243 pagesJPRCP Manual FullHanuman BuildersNo ratings yet

- ETL 1110-2-321 Reliability of Navigation Structures PDFDocument23 pagesETL 1110-2-321 Reliability of Navigation Structures PDFAnonymous huM1Y0DlLNo ratings yet

- Ga IEBCDocument6 pagesGa IEBCcabalistNo ratings yet

- Cladding Fixation MethodDocument106 pagesCladding Fixation MethodUnited Construction Est. TechnicalNo ratings yet

- Liquid Loads on a Tank Wall using PCA TablesDocument1 pageLiquid Loads on a Tank Wall using PCA TablesKevin YewNo ratings yet

- Aci 330r 92Document1 pageAci 330r 92Sue JinsueNo ratings yet

- XYPEX TESTING SUMMARYDocument18 pagesXYPEX TESTING SUMMARYSamrerng KriengprathanaNo ratings yet

- TB Manual 7 Dec19Document44 pagesTB Manual 7 Dec19Brett RobertsNo ratings yet

- Toe QuestDocument4 pagesToe Questrameshbabu_1979No ratings yet

- GRCA Specification PDFDocument15 pagesGRCA Specification PDFrencydNo ratings yet

- Half Cell Potential PDFDocument11 pagesHalf Cell Potential PDFCitiux CitiuxNo ratings yet

- Tedds Engineering Library (US)Document80 pagesTedds Engineering Library (US)Mallesh NenkatNo ratings yet

- Corporate Circular: Bridge Technical Direction Btd2013/01Document2 pagesCorporate Circular: Bridge Technical Direction Btd2013/01scribdarell100% (1)

- Field Applications of Nano-Engineered UHPC 2.0TM for BridgesDocument10 pagesField Applications of Nano-Engineered UHPC 2.0TM for BridgesAkshay SamadhiyaNo ratings yet

- Astm C-88Document5 pagesAstm C-88Fernanda MenesesNo ratings yet

- Industrial Floors and Pavements in Australia A Critical Overview of Current Design MethodsDocument9 pagesIndustrial Floors and Pavements in Australia A Critical Overview of Current Design Methodsmehdi_hoseineeNo ratings yet

- Aluminum Design Manual 2015Document505 pagesAluminum Design Manual 2015Marcin KrólNo ratings yet

- ASCE 7-22 CH 18 - For PC - SouDocument57 pagesASCE 7-22 CH 18 - For PC - SousharethefilesNo ratings yet

- Guide For The Design and Construction of Fixed Offshore Concrete StructuresDocument23 pagesGuide For The Design and Construction of Fixed Offshore Concrete StructuresINARQ1979No ratings yet

- G - Standards - TMP - Astm c503.c503m 2010Document2 pagesG - Standards - TMP - Astm c503.c503m 2010BALEN KAKLNo ratings yet

- An Overview On Methods For Slope Stability Analysis: Mr. Digvijay P. Salunkhe Assist. Prof. Guruprasd ChvanDocument8 pagesAn Overview On Methods For Slope Stability Analysis: Mr. Digvijay P. Salunkhe Assist. Prof. Guruprasd ChvanAbu AimonNo ratings yet

- Load Assumtions For Buildings PDFDocument25 pagesLoad Assumtions For Buildings PDFJose LuisNo ratings yet

- Flaky Elongated AggregatesDocument7 pagesFlaky Elongated AggregatesAnkur GoyalNo ratings yet

- ASTM B 69 Rolled ZN - 1998Document4 pagesASTM B 69 Rolled ZN - 1998ecsuperalNo ratings yet

- TB Manual 4Document62 pagesTB Manual 4Brett RobertsNo ratings yet

- Lateral Load Test of Drilled Shaft in Clay Reveals Structural FailureDocument110 pagesLateral Load Test of Drilled Shaft in Clay Reveals Structural FailurechrtromNo ratings yet

- Corrosion Evaluation of Geopolymer Concrete Made With Fly Ash and Bottom AshDocument16 pagesCorrosion Evaluation of Geopolymer Concrete Made With Fly Ash and Bottom Ashaboodalshouha1998No ratings yet

- Roberto C. A. Pinto and Kenneth C. Hover Frost and Scaling Resistance of High-Strength ConcreteDocument75 pagesRoberto C. A. Pinto and Kenneth C. Hover Frost and Scaling Resistance of High-Strength ConcreteFaroq MaraqaNo ratings yet

- TEK 03-04C Bracing CMU Walls Under ConstructionDocument12 pagesTEK 03-04C Bracing CMU Walls Under ConstructionAdam JonesNo ratings yet

- Advanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionFrom EverandAdvanced Opensees Algorithms, Volume 1: Probability Analysis Of High Pier Cable-Stayed Bridge Under Multiple-Support Excitations, And LiquefactionNo ratings yet

- Cap 1 - Meredith Mantel (2009) Project ManagementDocument34 pagesCap 1 - Meredith Mantel (2009) Project Managementjohn100% (1)

- Beam Moment Diagram TablesDocument2 pagesBeam Moment Diagram TablesVictor Alejandro Calderón GonzálezNo ratings yet

- Tips For Designers PDFDocument5 pagesTips For Designers PDFSushil DhunganaNo ratings yet

- Slab On GradeDocument57 pagesSlab On GradeGurnam Singh SodhiNo ratings yet

- Booth, Edmund D - Earthquake Design Practice For Buildings-ICE Publishing (2014)Document219 pagesBooth, Edmund D - Earthquake Design Practice For Buildings-ICE Publishing (2014)CRISTIAN OMAR TUCTO ARANDANo ratings yet

- What's New in ASCE 7-16?: The Big ChangesDocument17 pagesWhat's New in ASCE 7-16?: The Big ChangesduckeNo ratings yet

- Concrete Surface Prep Guide for Coatings & RepairsDocument3 pagesConcrete Surface Prep Guide for Coatings & RepairsOmer aliNo ratings yet

- Earthquake Resistant Design and Risk ReductionFrom EverandEarthquake Resistant Design and Risk ReductionRating: 4 out of 5 stars4/5 (1)

- Sustainable Steel Buildings: A Practical Guide for Structures and EnvelopesFrom EverandSustainable Steel Buildings: A Practical Guide for Structures and EnvelopesBernhard HaukeNo ratings yet

- Vendor Performance Service Report SupplierDocument14 pagesVendor Performance Service Report SupplierGhayas JawedNo ratings yet

- Tollerance For Doors Wdma I.S. 1aDocument52 pagesTollerance For Doors Wdma I.S. 1aAdnan JadoonNo ratings yet

- Doctor Referral FormDocument2 pagesDoctor Referral FormGhayas JawedNo ratings yet

- Louvers Schedule - DetailsDocument1 pageLouvers Schedule - DetailsGhayas JawedNo ratings yet

- Plaster Completion ChecklistDocument1 pagePlaster Completion ChecklistGhayas JawedNo ratings yet

- Metal FabricationsDocument10 pagesMetal FabricationsGhayas JawedNo ratings yet

- Internal Wooden Door SnaggingDocument18 pagesInternal Wooden Door SnaggingGhayas JawedNo ratings yet

- Tiling WorksDocument21 pagesTiling WorksGhayas JawedNo ratings yet

- Spare Parts Requirement On Construction ProjectDocument67 pagesSpare Parts Requirement On Construction ProjectGhayas JawedNo ratings yet

- External Finishes DetailsDocument1 pageExternal Finishes DetailsGhayas JawedNo ratings yet

- Louvers Schedule - DetailsDocument1 pageLouvers Schedule - DetailsGhayas JawedNo ratings yet

- Astm c1048 Specification For Heat Treated Flat GlassDocument7 pagesAstm c1048 Specification For Heat Treated Flat GlassWayce C. GabrilloNo ratings yet

- Cladding Specifications - Ifc Material SpecsDocument4 pagesCladding Specifications - Ifc Material SpecsGhayas JawedNo ratings yet

- DEIRA MALL MAIN WORKS BILLS OF QUANTITIES T08Document1 pageDEIRA MALL MAIN WORKS BILLS OF QUANTITIES T08Ghayas JawedNo ratings yet

- Ceramic TilingDocument11 pagesCeramic TilingGhayas JawedNo ratings yet

- Tiles For Stone and Slates ComparisonDocument2 pagesTiles For Stone and Slates ComparisonGhayas JawedNo ratings yet

- Skylight Option Comparison - 190330Document1 pageSkylight Option Comparison - 190330Ghayas JawedNo ratings yet

- Material Description and Specification SummaryDocument2 pagesMaterial Description and Specification SummaryGhayas JawedNo ratings yet

- Retractable Roofing Comparison Sheet: Specs Vol 02.04/3.4.4 Specs Vol 02.01/133457/4.1.L.2 (ASHRAE 90.1)Document2 pagesRetractable Roofing Comparison Sheet: Specs Vol 02.04/3.4.4 Specs Vol 02.01/133457/4.1.L.2 (ASHRAE 90.1)Ghayas JawedNo ratings yet

- Uvalue of PolycarbonateDocument1 pageUvalue of PolycarbonateGhayas JawedNo ratings yet

- Steel Staircase and Cladding DetailsDocument12 pagesSteel Staircase and Cladding DetailsGhayas JawedNo ratings yet

- Gradient Striped Broadloom CarpetDocument5 pagesGradient Striped Broadloom CarpetGhayas JawedNo ratings yet

- Sample Quality MetricsDocument16 pagesSample Quality MetricsGhayas JawedNo ratings yet

- 096723-Resinous Floor SpecsDocument7 pages096723-Resinous Floor SpecsGhayas JawedNo ratings yet

- DCD Material Test Standards - September - 2018Document128 pagesDCD Material Test Standards - September - 2018Ghayas JawedNo ratings yet

- Floor MatsDocument3 pagesFloor MatsGhayas JawedNo ratings yet

- Steel Staircase and Cladding DetailsDocument12 pagesSteel Staircase and Cladding DetailsGhayas JawedNo ratings yet

- External NCR MonitoringDocument7 pagesExternal NCR MonitoringGhayas JawedNo ratings yet

- Claims Responsibility MatrixDocument1 pageClaims Responsibility MatrixGhayas JawedNo ratings yet

- Steel Erection SequenceDocument34 pagesSteel Erection SequenceGhayas JawedNo ratings yet

- Monsal Enzymic Hydrolysis New Developments and Lessons LearntDocument23 pagesMonsal Enzymic Hydrolysis New Developments and Lessons LearntAnonymous MVHQ97KEoPNo ratings yet

- Kandungan Obat Merek Dagang SediaanDocument1 pageKandungan Obat Merek Dagang SediaanRaden Mas Nur HaryonoNo ratings yet

- 4-Procedure Pipe To SoilDocument7 pages4-Procedure Pipe To SoilKhanh DTNo ratings yet

- Presentation 01Document28 pagesPresentation 01Rexona KhanomNo ratings yet

- Effectiveness of Liquid Oxygen BleachDocument4 pagesEffectiveness of Liquid Oxygen BleachSingh GurleenNo ratings yet

- DISINFECTION in Health CareDocument86 pagesDISINFECTION in Health Caretummalapalli venkateswara raoNo ratings yet

- Murex Mig Poster 2008 PDFDocument1 pageMurex Mig Poster 2008 PDFPCNo ratings yet

- AJODO Eliades2006 - Orthodontic Materials Research and Applications Part 1-Current Status and Projected Future Developments in Bonding and Adhesives.Document7 pagesAJODO Eliades2006 - Orthodontic Materials Research and Applications Part 1-Current Status and Projected Future Developments in Bonding and Adhesives.drgeorgejose7818No ratings yet

- Turton - Appb 30 37Document8 pagesTurton - Appb 30 37asadNo ratings yet

- Stereoisomers Part 1Document14 pagesStereoisomers Part 1Mabelle DucusinNo ratings yet

- Clay Mineral Cements in SandstonesDocument3 pagesClay Mineral Cements in Sandstonesandrea.cipagautaNo ratings yet

- Biomaterials As A Pillar of ImplantsDocument5 pagesBiomaterials As A Pillar of ImplantsInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Dental Materials: Metals (Alloys) Non-MetalsDocument32 pagesDental Materials: Metals (Alloys) Non-MetalsShahriar honarmandNo ratings yet

- Maintaining Boiler Water Quality (35 charactersDocument3 pagesMaintaining Boiler Water Quality (35 characterskcp1986No ratings yet

- CHM 1321 Assignment 1 Answers: CN H H H H HDocument10 pagesCHM 1321 Assignment 1 Answers: CN H H H H HSara YuenNo ratings yet

- HPLC ExperimentDocument4 pagesHPLC ExperimentFrances PaulineNo ratings yet

- Heavy Metal Contamination: An Alarming Threat To Environment and Human HealthDocument23 pagesHeavy Metal Contamination: An Alarming Threat To Environment and Human HealthMalik HopeNo ratings yet

- ANSYS Fluent Teory Guide 21R1Document1,072 pagesANSYS Fluent Teory Guide 21R1John Stone0% (3)

- p095 Re Struct 07 PCDocument12 pagesp095 Re Struct 07 PCmidhungbabu88No ratings yet

- Syllabus 30A Fall 2014Document4 pagesSyllabus 30A Fall 2014Gabby TanakaNo ratings yet

- Coconut Shell Based Activated Carbon W No Greeen House Gas EmissionDocument4 pagesCoconut Shell Based Activated Carbon W No Greeen House Gas Emissionmragul22No ratings yet

- PESSAT-Chemistry-Model-PaperDocument12 pagesPESSAT-Chemistry-Model-PaperpullagalkNo ratings yet

- Chemical Injection SkidDocument6 pagesChemical Injection SkidRaheel SultanNo ratings yet

- Introduction to Computational Chemistry for Experimental Chemists... (Part 1/2Document46 pagesIntroduction to Computational Chemistry for Experimental Chemists... (Part 1/2Jennifer Carolina Rosales NoriegaNo ratings yet

- Pharmaceutical Organic Chemistry Unit II: Aromatic AminesDocument20 pagesPharmaceutical Organic Chemistry Unit II: Aromatic AminesSaili SawardekarNo ratings yet

- Elzein M. Fahal, Et Al PDFDocument9 pagesElzein M. Fahal, Et Al PDFNiaz mahmudNo ratings yet

- Laboratory Exercise 4Document3 pagesLaboratory Exercise 4dennise reyesNo ratings yet

- 11 Numerical AnalysisDocument9 pages11 Numerical Analysisعزالدين حسنNo ratings yet

- Fundamental Reservoir Fluid BehaviourDocument20 pagesFundamental Reservoir Fluid BehaviourBrian CbtngnNo ratings yet

- Thermoplastic Gas Pressure Pipe, Tubing, and Fittings: Standard Specification ForDocument20 pagesThermoplastic Gas Pressure Pipe, Tubing, and Fittings: Standard Specification ForAndres Camilo BenitezNo ratings yet