Professional Documents

Culture Documents

8082

Uploaded by

sopian320Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

8082

Uploaded by

sopian320Copyright:

Available Formats

ENGINE COMPONENTS

For complete ATGL engine specifications, see Bulletins 7084 and 7085.

CAMSHAFT Consists of individual segments, one per cylinder, bolted together.

CONNECTING RODS Low alloy, forged, fully machined.

CRANKCASE Single piece, stress relieved, gray iron casting. Main bearing caps are retained with vertical

studs and lateral tie bolts.

CRANKSHAFT Low alloy, forged, fully machined, counterweighted with seven main bearing journals. The

crankshaft is flanged for full power transmission from each end. Bearings are heavy duty, replaceable,

precision aluminum type.

CYLINDER HEAD Twelve interchangeable, bore-cooled with two hard-faced intake and two hard-faced

exhaust valves per head. Includes hardened stainless steel intake and exhaust valve seats and

prechamber fuel control valves.

CYLINDER LINERS Removable wet type with intermediate jacket water guide.

ENGINE INSTRUMENT CONNECTIONS Thermocouples, K-type, for jacket water temperature, lube oil

temperature, individual cylinder exhaust temperatures and pre and post turbocharger temperatures wired to

a common junction box. Pressure taps piped to a common bulkhead for intake manifold pressure,

lube oil pressure, prechamber fuel pressure, main chamber fuel pressure and jacket water

pressure. Instruments and panel are by others. Recommend optional Model 4000 Remote

Engine Instrument Panel (reference WPS Engomatic controls).

ENGINE PROTECTION SHUTDOWN CONTACTS For high water temperature, low oil

pressure, high intake manifold temperature (standard engine mounted thermocouple with

one thermocouple relay shipped loose), overspeed (electronic speed switch shipped

loose), and engine detonation sensing, alarm and shutdown, (see separate description of

Detonation Sensing Module). Two engine mounted emergency shutdown/starter lockout

palm buttons are supplied, one on either side of the engine. Use all of the above in

conjunction with a DC control panel for unit shutdown, (reference WPS Engomatic controls).

NOTE: DC control panel is not supplied as standard.

FLYWHEEL With 291 tooth ring gear. Machined for direct connected, generator shaft or plate

type coupling.

NOTE: Flywheel will be removed for shipment.

INTERCOOLER Air-to-water.

PISTON Single piece, aluminum alloy with integrally cast cooling coils. Four piston rings with

the top two compression rings housed in a Ni-resist ring carrier. 9:1 compression ratio.

TURBOCHARGER Two, water cooled center housing, exhaust driven, with Turbocharger Control Module

(TCM), electronic controlled wastegate and air bypass. 24V DC required.

VIBRATION DAMPER Enclosed, viscous type.

ENGINE SYSTEMS

AIR INLET SYSTEM

Air Inlet Connection Two 14 (356 mm) round tubes.

Air Cleaner - Two, dry panel type for remote mounting (shipped loose).

EXHAUST SYSTEM

Exhaust Manifold Twelve, water cooled.

Exhaust Outlet Two 8 (203 mm) flanged, vertical outlets.

FUEL SYSTEM Carburetor with precombustion circuit. Single fuel inlet connection, mounted main and

prechamber gas supply regulators. Pressure required; 45 60 psig (3.1 4.1 bar). Shipped loose 24V DC

pilot operated main fuel valve. Mounted 24V DC pilot operated prechamber fuel valve. Includes adjustable

speed switch for control of prechamber solenoid valve during start cycle.

IGNITION SYSTEM Waukesha Custom Engine Control Ignition Module with flange mounted coils. Ignition

system meets Canadian Standards Association Class I, Division 2, Group D hazardous location

requirements. Includes fuses for protection against reverse polarity. 24V DC power required.

LUBRICATION SYSTEM Gear driven, externally mounted gear type pump with pressure regulator and

bypass circuit. Discharge side has flange for connection to remote oil cooler. Includes shell and tube type

lube oil cooler sized for connection in series with intercooler. Not mounted. Includes full flow, 45 gallon (170

litre) capacity oil filter. Not mounted. Includes 175 F (79 C) lube oil temperature control valve, mounted

on shipped loose oil cooler. Includes full flow filter strainer. Requires single customer lube oil inlet

connection. Includes electric motor driven pre/post lube pump, 5 hp 230V AC/3ph/50 60 Hz, with motor

starter (other voltages can be specified). Not mounted.

NOTE: External control logic is required to start/stop prelube pump.

STARTING SYSTEM One turbine type pneumatic starter with 24V DC starting valve and strainer. Requires

150 psig (10.3 bar) air/gas supply. Crank termination switch is shipped loose.

NOTE: For starting and/or operation at or below 40 F (5 C) consult S9064 in the Technical Data Book under

Starting.

WATER CIRCULATION SYSTEM

Auxiliary Circuit Includes gear driven water pump with discharge piped to intercooler. Suction side has

single flange for customer connection. Requires single customer outlet connection. Includes auxiliary water

temperature control valve, not mounted.

Engine Jacket Includes gear driven water pump with discharge to engine inlet. Suction side has single

flange for customer outlet connection. Requires single customer outlet connection. Includes 180 F (82 C)

jacket water temperature control valve, not mounted.

(continued on next page)

12V-AT27GL

Gas Enginator

Generating System

2000 - 2330 kW

Model 12V-AT27GL Gas Enginator

SPECIFICATIONS

ENGINE

12V-AT27GL,

Four Cycle,

Overhead Valve

Cylinders

V 12

Piston Displacement

13048 cu. in. (214 L)

Bore & Stroke

10.83 x 11.81

(275 x 300 mm)

Fuel LHV

900 Btu/ft3

(33.5 J/cm 3)

Lube Oil Capacity

252 gal. (955 L)

GENERATOR

Power Factor for

Ratings

0.8

Insulation Material

NEMA Class F

Compression Ratio

9:1

Temperature Rise

Within NEMA (105C)

Jacket Water

Capacity

97.2 gal. (368 L)

Voltage

4160/2400, 3 phase,

6 wire, Wye, 60 Hz*

Aux. Water Capacity

19.4 gal. (74 L)

3300/1905, 3 phase,

6 wire, Wye, 50 Hz*

Starting System

150 psig

(10.3 bar) Air

TIF and Deviation

Factor

Within NEMA, MG 1.22

Fuel Pressure Range

45-60 psi

(3.1-4.1 bar)

*Additional voltages available.

ENGINE ACCESSORIES

GENERATOR AND BASE

BARRING DEVICE Manual.

CRANKCASE PRESSURE RELIEF DOORS Eight mounted on side of

crankcase.

CRANKCASE VENT CONNECTION Single 3 (76.2 mm) round tube.

NOTE: A crankcase ventilation blower is required.

GOVERNOR Woodward UG actuator, mounted, with 701A speed control for

single stand alone unit, shipped loose. Does not include optional generator

load sharing control or portable programmer for 701A speed control.

JUNCTION BOXES Separate AC, DC, and instrument/thermocouple junction

boxes for engine wiring and external connections.

WAUKESHA CUSTOM ENGINE CONTROL DETONATION SENSING

MODULE (DSM) Includes individual cylinder sensors, Detonation

Sensing Module, and filter. Device is compatible with Waukesha CEC

Ignition Module only. Sensors are mounted and wired to DSM filter. Detonation

Sensing Module and filter are mounted. 24V DC power is required. The DSM

meets Canadian Standards Association Class I, Division 2, Group D,

hazardous location requirements.

WAUKESHA CUSTOM ENGINE CONTROL AIR FUEL MODULE (AFM)

Electronic air fuel ratio control. Includes air fuel module, main fuel gas

regulator actuator, intake manifold pressure transducer, exhaust O2 sensor

assembly, junction box, and wiring harness. All equipment is shipped loose

for customer installation. Wiring harness allows connection of all engine

mounted components to junction box. The module must be mounted off

engine. 24V DC power is required. The AFM meets Canadian Standards

Association Class I, Division 2, Group D hazardous location requirements.

GENERATOR Open dripproof, direct connected, fan cooled, 2/3 pitch, A.C.

revolving field type, anti-friction grease lubricated bearing(s), with brushless

PMG type exciter and damper windings. TIF and deviation factor within

NEMA MG1.22. Voltage 4160/2400, 3 phase, 6-wire, WYE, 60 Hz or 3300/

1905, 3 phase, 6-wire, WYE 50 Hz. Other voltages are available, consult

factory. Insulation material NEMA Class F. Temperature rise within NEMA

(105 C) for continuous power duty. All generators are rated at 0.8 power

factor. Includes terminal standoff assembly.

NOTE: Generator is removed after testing and is shipped loose.

VOLTAGE REGULATOR SCR static automatic type, providing 1% regulation

from no load to full load with automatic subsynchronous speed protection.

Single phase sensing. Includes voltage adjustment rheostat. All items are

shipped loose.

BASE Engine and generator are mounted and aligned on a structural steel

fabricated base designed for mounting on an isolated concrete pad and

suitable for lifting. Base must be fully grouted in place according to Waukesha

recommendations.

FLYWHEEL GUARD Fabricated steel guard for protection of the rotating

components is mounted to the engine-generator base.

TESTING Standard Enginator testing.

PAINT/PRESERVATION Oilfield orange paint. Internal preservation treatment

for shortterm storage up to one year.

NOTE: All connections made to Enginator must be flexible.

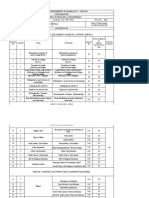

PERFORMANCE DATA: 12V-AT27GL ENGINATOR

I.C. Water Temp.: 90F (32C)

WATER CONNECTION COOLING

Continous Power*

kW Rating

1000 rpm

900 rpm

1000 rpm

60 Hz

50 Hz

60 Hz

50 Hz

2100

Fuel Consumption x 1000 Btu/h (kW)

Jacket Water x 1000 Btu/h (kW)

Intercooler x 1000 Btu/h (kW)

Lube Oil x 1000 Btu/h (kW)

Heat Radiated x 1000 Btu/h (kW)

Exhaust Heat** x 1000 Btu/h (kW)

Exhaust Flow lb/h (kg/h)

Exhaust Temperature F (C)

Induction Air Flow scfm (m3/min)

I.C. Water Temp.: 130F (54C)

900 rpm

19315

3360

1890

746

519

5635

33460

661

7405

(5661)

(985)

(554)

(219)

(152)

(1652)

(15177)

(349)

(210)

2330

21835

3945

2205

888

447

6400

37335

678

8260

2000

(6399)

(1156)

(646)

(260)

(131)

(1876)

(16935)

(359)

(234)

Typical heat balance data is shown. Consult factory for guaranteed data.

18285

3475

1595

604

332

5455

28775

650

7220

(5359)

(1018)

(467)

(177)

(97)

(1599)

(13052)

(343)

(204)

2220

20560

3875

1780

749

381

6200

32240

703

7640

*Continuous Power Rating: The highest electrical power ouput of the Enginator

available for an unlimited number of hours per year, less maintenance. It is

permissible to operate the Enginator with up to 10% overload for two hours in each

24 hour period.

(6026)

(1136)

(522)

(220)

(112)

(1817)

(14624)

(373)

(216)

Rating Standard: The Waukesha Enginator power rating descriptions are in

accordance to ISO 8528, DIN6271 and BS5514. It is also valid for ISO 3046/1-1986

with an engine mechanical efficiency of 90% and auxiliary water temperature Tcra

(clause 10.0) is limited to 10 F (5 C).

**Heat rejection based on cooling exhaust gs to 85 F (29 C).

Cooling Equipment L in (mm) W in (mm)

W.C.

WAUKESHA POWER SYSTEMS

WAUKESHA ENGINE

DRESSER EQUIPMENT GROUP, INC.

1000 West St. Paul Avenue

Waukesha, WI 53188-4999

Phone: (262) 547-3311 Fax: (262) 549-2795

waukeshaengine.dresser.com

WAUKESHA ENGINE

DRESSER INDUSTRIAL PRODUCTS, B.V.

Farmsumerweg 43, Postbus 330

9900 AH Appingedam, The Netherlands

Phone: (31) 596-652222 Fax: (31) 596-628111

300 (7600)

94 (2390)

H in (mm)

Avg. Wt. lb (kg)

132 (3350)

79000 (36000)

Consult your local Waukesha Distributor for system

application assistance. The manufacturer reserves the right

to change or modify without notice, the design or equipment

specifications as herein set forth without incurring any

obligation either with respect to equipment previously sold

or in the process of construction except where otherwise

specifically guaranteed by the manufacturer.

Bulletin 8082 0501

Waukesha, Enginator, Engomatic, TCM, AFM, DSM, CEC and Custom Engine Control are trademarks/registered trademarks of Waukesha Engine, Dresser, Inc.

You might also like

- 6fttall Mini Specs WebsiteDocument4 pages6fttall Mini Specs Websitesopian320No ratings yet

- Cement GroupeCIF UKWebDocument7 pagesCement GroupeCIF UKWebsopian320No ratings yet

- Fig 36 Austenitic Stainless Steel Strainer: DescriptionDocument2 pagesFig 36 Austenitic Stainless Steel Strainer: Descriptionsopian320No ratings yet

- CorelDRAW X7Document699 pagesCorelDRAW X7Naveen Sajja RsaNo ratings yet

- Tool and Material List-Girth Gear InstallDocument2 pagesTool and Material List-Girth Gear InstallPeter RoseNo ratings yet

- Pre-Commissioning Hot Water BoilersDocument2 pagesPre-Commissioning Hot Water Boilerssopian320100% (1)

- Bridas 150 SoDocument1 pageBridas 150 SoJuan OrmacheaNo ratings yet

- Swire Mini Containers Spec SheetDocument2 pagesSwire Mini Containers Spec Sheetsopian320No ratings yet

- Swire Mini Containers Spec SheetDocument2 pagesSwire Mini Containers Spec Sheetsopian320No ratings yet

- Burner CalculationDocument29 pagesBurner Calculationjoshuadelapava100% (1)

- Ansi B16.5 150 BlindDocument1 pageAnsi B16.5 150 Blindnovocaine67No ratings yet

- Alignment of KilnDocument27 pagesAlignment of KilnarafatNo ratings yet

- Ansi B16.5 150 BlindDocument1 pageAnsi B16.5 150 Blindnovocaine67No ratings yet

- Benchmark Commissioning Checklist Effective From 1st April 2014 PDFDocument4 pagesBenchmark Commissioning Checklist Effective From 1st April 2014 PDFsopian320No ratings yet

- Sample - Belt Bucket Elevator DesignDocument7 pagesSample - Belt Bucket Elevator Designmfhasnain100% (1)

- Design - B16.34, OS&Y, BB, THD Per B1.20.1, SW Per B16.11, Flex Wedge, Body Materials - ASTM A351, A494, A890, A990, Others Upon RequestDocument1 pageDesign - B16.34, OS&Y, BB, THD Per B1.20.1, SW Per B16.11, Flex Wedge, Body Materials - ASTM A351, A494, A890, A990, Others Upon Requestsopian320No ratings yet

- Hidrometalurgia PDFDocument123 pagesHidrometalurgia PDFJuan Corcuera Urbina100% (4)

- Central or Girth Gear Drive For Ball Mills - 1Document26 pagesCentral or Girth Gear Drive For Ball Mills - 1Vishnu Vardhan . C100% (3)

- Tool and Material List-Girth Gear InstallDocument2 pagesTool and Material List-Girth Gear InstallPeter RoseNo ratings yet

- Rotary Kilns For Cement PlantsDocument6 pagesRotary Kilns For Cement PlantsAngshuman Dutta100% (3)

- Design - B16.34, OS&Y, BB, THD Per B1.20.1, SW Per B16.11, Flex Wedge, Body Materials - ASTM A351, A494, A890, A990, Others Upon RequestDocument1 pageDesign - B16.34, OS&Y, BB, THD Per B1.20.1, SW Per B16.11, Flex Wedge, Body Materials - ASTM A351, A494, A890, A990, Others Upon Requestsopian320No ratings yet

- Rotary Kilns For Cement PlantsDocument6 pagesRotary Kilns For Cement PlantsAngshuman Dutta100% (3)

- PD BasicsDocument9 pagesPD BasicsUmar DrazNo ratings yet

- Tool and Material List-Girth Gear InstallDocument2 pagesTool and Material List-Girth Gear InstallPeter RoseNo ratings yet

- Alamat Bullet Cleaning AustraliaDocument1 pageAlamat Bullet Cleaning Australiasopian320No ratings yet

- AUCBMPRESENTATIONMarrakish Nov 2014Document29 pagesAUCBMPRESENTATIONMarrakish Nov 2014sopian320100% (1)

- Alamat Bullet Cleaning AustraliaDocument1 pageAlamat Bullet Cleaning Australiasopian320No ratings yet

- Thin Wall TitaniumDocument9 pagesThin Wall Titaniumsopian320No ratings yet

- How-Use-Conco-English (System Conco) PDFDocument4 pagesHow-Use-Conco-English (System Conco) PDFsopian320No ratings yet

- Hot Rolled Steel, Stainless Steel, Aluminum, Brass, Copper Metal GuideDocument188 pagesHot Rolled Steel, Stainless Steel, Aluminum, Brass, Copper Metal Guidesopian320No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Rivera Jerahmae D. NSTP-CWTS Project ProposalDocument8 pagesRivera Jerahmae D. NSTP-CWTS Project ProposalRichard Culaton IIINo ratings yet

- What Is Rogers Ultralam 3850 PCBDocument8 pagesWhat Is Rogers Ultralam 3850 PCBjackNo ratings yet

- Breviar de Calcul - Cos C.R.Document63 pagesBreviar de Calcul - Cos C.R.tulvyNo ratings yet

- Void Content of Reinforced Plastics: Standard Test Methods ForDocument3 pagesVoid Content of Reinforced Plastics: Standard Test Methods ForStéfany Vier SteffenNo ratings yet

- YOKOGAWA Exa Fc400g (Ing)Document91 pagesYOKOGAWA Exa Fc400g (Ing)biotech666No ratings yet

- Correction of Service Manual Si-18 M-11011Document18 pagesCorrection of Service Manual Si-18 M-11011Ahmed AzadNo ratings yet

- EstimatesDocument5 pagesEstimatesRamil S. ArtatesNo ratings yet

- QIS College Engineering & Tech Session Plan Metal CuttingDocument13 pagesQIS College Engineering & Tech Session Plan Metal CuttingKalai ArasanNo ratings yet

- Rotho Peristaltic Pumps PDFDocument40 pagesRotho Peristaltic Pumps PDFxxxxxxxxxxxxNo ratings yet

- CHS Waste Disposal GuideDocument37 pagesCHS Waste Disposal GuideFazal RaheemNo ratings yet

- Kema Ageing Test 5000 Hrs.Document12 pagesKema Ageing Test 5000 Hrs.Tarun AggarwalNo ratings yet

- Kimray 112 SMT (Regulator)Document5 pagesKimray 112 SMT (Regulator)CARLOS SARMIENTONo ratings yet

- Building material thermal properties tableDocument19 pagesBuilding material thermal properties tablehansleyNo ratings yet

- Colt ShadovoltaicLouvreDocument3 pagesColt ShadovoltaicLouvrePutri Astri NafisaNo ratings yet

- TRANSOM TRANSDUCER Installation GuideDocument16 pagesTRANSOM TRANSDUCER Installation GuideFlorin PloscarNo ratings yet

- Motor Spec - IPOWER Rev01Document4 pagesMotor Spec - IPOWER Rev01GAGANNo ratings yet

- Trouble With Paint Blistering of Paint Films On Metal Part 1 Osmotic BlisteringDocument10 pagesTrouble With Paint Blistering of Paint Films On Metal Part 1 Osmotic Blisteringandreathome100% (1)

- Blanco Ku 0099M 13094 DATA 1 PDFDocument96 pagesBlanco Ku 0099M 13094 DATA 1 PDFCm EtcmNo ratings yet

- LG AC Service ManualDocument80 pagesLG AC Service ManualFrengky RmNo ratings yet

- Spark Plasma SinteringDocument24 pagesSpark Plasma Sinteringshrikant tambeNo ratings yet

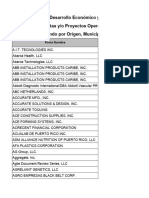

- Directorio de Empresas Operando Noviembre 2021 (Nov 30, 2021) PubDocument238 pagesDirectorio de Empresas Operando Noviembre 2021 (Nov 30, 2021) PubnewprojectsNo ratings yet

- Prelis 2012 MK en BRDocument9 pagesPrelis 2012 MK en BRDana LoreNo ratings yet

- Thermal Cracking:: Stream Number Stream Make SourceDocument3 pagesThermal Cracking:: Stream Number Stream Make SourcejohnNo ratings yet

- GFRC Glass Fibre Reinforced ConcreteDocument9 pagesGFRC Glass Fibre Reinforced ConcreteMohd ShahrizanNo ratings yet

- AQA GCSE Chem Combined End of Topic C1Document9 pagesAQA GCSE Chem Combined End of Topic C1joeNo ratings yet

- Allen - Fordism and The Modern IndustryDocument26 pagesAllen - Fordism and The Modern IndustryANTON MARIE MACASAETNo ratings yet

- UK Gate Valves Brochure High Res 02 - 2017Document20 pagesUK Gate Valves Brochure High Res 02 - 2017Sivasubramanian PalaniappanNo ratings yet

- Fire CraftDocument28 pagesFire CraftLooi Kok HuaNo ratings yet

- Lecture 10 - Recovery Recrystallication and Grain GrowthDocument22 pagesLecture 10 - Recovery Recrystallication and Grain GrowthsimNo ratings yet

- Disclaimer Document Supplier ListDocument30 pagesDisclaimer Document Supplier ListAmin AzadNo ratings yet