Professional Documents

Culture Documents

Stores Proc

Uploaded by

JaspreetSinghCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stores Proc

Uploaded by

JaspreetSinghCopyright:

Available Formats

Title:

Stores Inventory Policy & Procedures

Scope:

This document covers the availability of common use items

through the Store and the correct method of obtaining those

items and assists Stores staff to correctly issue, charge and

maintain accurate store records using the Banner Stores

Inventory system.

Objectives:

To assist University staff to acquire items from Stores.

To ensure Stores staff correctly issue and charge items and

maintain stock records to ensure accurate stocktaking

procedures.

Issues:

Nil.

Policies:

All Stores Issues must be recorded in the Banner Stores

Inventory system within 72 hours of issue of stock.

Stores Inventory purchasing has been centralised to achieve

significant savings in the purchase of high-use. These savings

are directly passed on to each user of the Store.

Procedures:

Completing a Stores Issue Docket /Stock Requisition

To satisfactorily complete a stores issue docket using the

Banner codes, use the hard copy catalogue which is available

from the Admin Office of your School / Section.

Locate the item(s) you require and record the Banner Code,

Item description and quantity on your Stores Issue Docket /

Stock Requisition.

There is NO NEED to enter the price of items onto the Stores

Issue Docket / Stock Requisition.

When this has been completed, please ensure that all other

information is correct, ie. Authorising Officer signature,

Budget Allocation and Delivery Point/Contact.

Send the Completed Document to the Central Store at

Bathurst or Wagga for issuing of your Order.

Return of Store Items for Credit

For return of items incorrectly ordered from Stores, complete

a new Stores Issue Docket /Stock Requisition highlighting that

the goods are for Credit. Complete the necessary details of

Banner Code, Description and Quantity being returned. The

Credit Stores Issue Docket/Stock Requisition will then be

processed and a credit issued to your Ledger codes that were

originally debited.

You MUST also indicate the Stores Issue Docket/Stock

Requisition number for the items that were originally ordered.

Return of items and Issue of items CANNOT be processed on

the same Stores Issue Docket / Stock Requisition.

What the Banner Commodity Codes Mean

The use of commodity coding helps you locate your required

item quickly and easily in the Stores catalogues.

All Wagga Banner Store Codes consist of 5 Letters and 4

Numerals.

The First Letter is always W for items held at Wagga Stores.

The Next 4 Letters indicate the type of item code.

All Bathurst Banner Store Codes consist of 4 Letters and 4

Numerals.

Summary of Codes:

AVTM = Audio Visual, Transparency Materials

CMCL = Cleaning materials, mops, brushes, buckets etc

CMDE = Cleaning materials, Detergents

CMPP = Cleaning materials, paper products, toilet paper,

handtowel etc

FAOS = First Aid Officers Supplies

MSCA = Maintenance Supplies, Carpentry

MSEL = Maintenance Supplies, Electrical

MSFL = Maintenance Supplies, Lighting, Bulbs, Tubes, etc

MSGA = Maintenance Supplies, Grounds

MSPA = Maintenance Supplies, Painting

PCSG = Protective Clothing and Safety Gear

STBA = Stationery, Batteries

STBK = Stationery, Books

STBI = Stationery, Binding

STBG = Stationery, Jiffy Bags

STDI = Stationery, Diaries

STDP = Stationery, Data Processing

STEN = Stationery, Envelopes

STFI = Stationery, Filing

STIN = Stationery, Inks and Pads

STPA = Stationery, Paper

STPE = Stationery, Pens, Pencils

STRI = Stationery, Toners and Ribbons

STST = Stationery, Staples and Staplers

STTA = Stationery, Tapes, Packing and Sticky

STZZ = Stationery, Miscellaneous

The 4 digit number then indicates the actual item.

For example:

Wagga:

A4 Photocopy Paper, Banner code is WSTPA0100,

meaning Wagga Store, Stationery, Paper , Item Number

W

ST

PA

0100

Bathurst:

A4 Photocopy Paper, Banner code is STPA0100,

meaning Bathurst Store, Stationery, Paper, Item Number

ST

PA

0100

Items that have not been able to be placed under an

appropriate code location have been listed in the STZZ code,

for Miscellaneous items. Should you not be able to locate the

item you require in any of the other codes, please check under

STZZ.

Please take the opportunity to look through the CSU Stores

Catalogue to familiarise yourself with the items available

through Stores and the appropriate codes.

Other Matters

All Store Issue Dockets issued by Wagga Stores are prefixed

with the letters WI (Wagga Issues).

Stores Issues for Diaries are prefixed with the letters DI

(Diary Issues).

Each Item on a Stores Issue Docket is individually listed.

The total amount charged against the Stores Issue Docket is

shown in the Accounting Block.

The average price quoted in this catalogue for items will

change as each Purchase Order is processed . Please use it

ONLY as a guide.

It is intended to place the Stores Catalogue onto the Web, once

all necessary changes have been made. This will allow a more

up-to-date catalogue to be available to staff as items are added

or deleted from the Stores.

Stores Personnel Only

General Matters

Under no circumstances are stores items to be issued without a

Stores Requisition or Stores Issue Docket, except for Diary

issues which are specifically covered by an order form.

Stores are to be kept clean, tidy and shelving organised.

Stores orders are not to be placed into the Store until receiving

document is completed.

Purchase Orders:

The Purchasing Officer at Wagga Stores will be responsible

for the placement of Stores Purchase Orders with the at Wagga

Purchasing Office providing backup.

A Purchase Requisition will be completed for each Purchase

Order.

Purchase Orders will be produced using the Banner form

FPAPURR, utilising the NEXT function.

All Purchase orders are to assigned to the relevant Store by

use of ship to code, CSUBS or CSUWS. Each purchase order

must be for only one Store.

Stores purchase orders must reflect the issue of measure as the

stock item, as defined by the commodity description. Ie ea,

box, carton.

Ensure that the correct FOAPAL is specified for each Store.

Commodity codes for Stores items used must be active.

Form FTRINVM (Stores Inventory Maintenance Form) can be

used to check activity of Purchase Order for on hand stock, on

order and receiving.

Receiving

Stores Purchase Orders will be received at Stores and

processed in accordance with form FPARCVD (Receiving

Goods Form).

The Receiving Officer will check that the goods received at

Stores match the Purchase Order and the commodity code

description with due care given to the unit of measure. The

Purchase order UOM must match the commodity code, if a

discrepancy is found, a change order is required to be

completed prior to receiving. Due care must be given to any

pricing and UOM adjustments.

This action moves stock from on order to on hand and permits

issue of stock.

New stock is not to be placed onto the shelves until receiving

has taken place.

Creation of the receiving document permits Accounts Payable

to process payment of the Stores Order without a signed

remittance. The receiving document gives the authority to pay.

Commodity Coding:

Creation of new commodities and maintenance of the existing

commodity table is the responsibility of the Purchasing

Officer.

New commodities will be created using form FTMCOMM

(Commodity Maintenance Form). New commodities will be

setup in accordance with the rules set for commodity

descriptions and with the Account code of 433.

Form FTRINVM (Stores Maintenance Form) will then be

completed with the appropriate codings for Stores Inventory

commodities, using Account code 662 (specific for Stores

Inventory). Particular care is to be taken for the allocation of

unit of measure, as this cannot be changed once created. Unit

of measure should accurately reflect the issue quantity, ie box,

carton, each.

It has been determined by the Executive Director, Financial

Services, that a 10% surcharge will be applied to the sale of all

commodities to cover freight and handling charges. No new

rate will be applied without the express permission of the

Executive Director.

Store Issues:

No stock will be issued without a Stock Requisition or Stores

Issue Docket being presented.

All Stores Requisitions/Dockets are to be stamped with a

numerical filing number upon receiving by Stores and noted in

the Stores manifest. This filing number will be entered onto

the Stores Issue /Return Form.

Form FSAISSU (Stores Issue/Return Form) will be used to

issue stock with due care being taken to ensure that stock on

hand and pricing of the commodity are valid.

Return of stock will be processed using this form, with the

original issue document being a nominated requirement of the

form, Faculties and Divisions returning stock are required to

provide this.

Non Sufficient Funds (NSF) indicator in the Accounting block

maybe checked to allow internal charges to be processed

against Budgets without funds.

On a regular basis, the Issuing Officer will check form

FSIISSU (Issue/Return List Validation Form) using the search

function for incomplete issue documents and correct any

found.

Once completed the Stock Requisition/Docket will be ticked

off in the Stores Manifest and filed by the numerical number

allocated to the docket.

For issues against affiliated bodies, the form FSAISSU will be

completed and then using form FSIISSQ (Stores Issue/Return

Query Form, a screen print of each commodity issued will be

produced. This documentation as well as a copy of the original

Stores Requisition/Docket will be sent to Accounts

Receivable, where an external invoice (Tax Invoice) will be

produced and sent to the relevant body.

Commodity Adjustments:

Where it is identified that an adjustment to a commodity level

or commodity price is required, the Stores Officer will notify

the Finance Manager (Supply) by e-mail to investigate the

adjustment and take appropriate action.

Adjustments to commodity quantity, follow the same

procedure as Stocktake.

Adjustments to price, will use the form FSAADJC (Stores

Adjustment to Unit Cost Form) and all adjustments are posted

to the General Ledger.

Under no circumstances are forms FSASTKQ (Stores Quick

Quantity Entry Form) and FSASTKC (Stores Quick Cost

Entry Form) to be used to make adjustments to either existing

commodities or new commodities.

Both of these forms are only for use when first setting up the

Store system and do not post any transaction to the GL.

Stocktake

Two weeks prior to Stocktake notify University community of

Stores closure by appropriate methods (Whats New message,

internal mail).

Tidy and arrange shelves to make counting easier.

Note any commodity quantities held on bulk areas with a

small quantity on shelf.

Check and ensure all Stock Requisitions/Dockets are

processed and completed, using form FSIISSU.

Check

Store

manifest

and

ensure

all

Requisitions/Dockets have been ticked off and filed.

Check that all Stores Purchase Orders have been received

correctly. No commodities are to be placed on shelves prior to

receiving.

Any Stores Purchase orders received at Stores during the

Stocktake period are to be set aside and not received onto

Banner until Stocktake has been completed.

Stock

No Stock Requisitions/Dockets are to be processed during

Stocktake or commodities physically issued.

Do pre-count of commodities held in Store.

Run report FSRINVL (Inventory Listing Report).

Print FGITBAL (General Ledger Trial Balance) for the Store

Account.

Form FSASYSA (Inventory Adjustment System Control

Form) places the Store into Stocktake mode. Enter the primary

location and page down, tick the Quantity box in the

Adjustment Action Block and save. For individual commodity

adjustments enter the commodity code and follow the standard

procedure.

Run report FSRPIWS (Physical Inventory Worksheet)

Using this report, and working in teams of two, record

commodities held on-hand. Sign each page of worksheet.

Enter commodity records onto Form FSAPHYC (Stores

Physical Inventory Count Recording Form). Sign each page as

to who entered information.

Run report FSRPIDR (Physical Inventory Discrepancy

Report)

Highlight all commodities which differ from system totals.

Recount all commodities which show discrepancy between

physical record and system total. Sign each page of report.

Re-enter new totals for highlighted commodities in Form

FSAPHYC (Stores Physical Inventory Counting Form)

Begin adjustment of commodity records by entering form

FSAADJQ (Adjustment to Quantity/Inventory Reconciliation

Form). Tick select all box and system will access FSCSTKL

(Inventory Reconciliation Location Selection Form). Do a

cross check with data on entered system and records from

report FSRPIDR to ensure data entered is correct. When

satisfied, tick the reconcile all box and save. This will transfer

all entries of the Stocktake to the journal on form FSAADJQ.

Down arrow through all records and save. This requires

posting process.

Enter form FSASYSA (Inventory Adjustment System Control

Form), enter primary location and page down and tick END in

the Adjustment Block, save record.

Run report FSRINVL (Inventory Listing Report)

Check report for any commodities on-hand which do not have

a price listed and adjust using FSASYSA and FSAADJC

( Stores Adjustment to Unit Cost Form)

Using the data report FSRPIDR, arrange for an independent

examiner to do a spot check of commodity counts (2 or 3

items per page or as determined by the examiner).

If necessary, adjust any discrepancies found through form

FSASYSA and FSAPHYC.

Run report FSRINVL (Inventory Listing Report)

Screen-print FGITBAL (General Ledger Trial Balance) for the

Store Account.

Check to ensure all pages of documentation are signed.

Forward all signed Stocktake documentation to the Finance

Manager (Business Services).

Responsibilities:

Budget Managers of Faculties/Divisions:

Ensuring that Budgets are checked to ensure Stock

Requisitions/Dockets are correctly charged and to notify

Stores of any discrepancies.

Ensuring that sufficient funds are available.

Central Store:

Issue and process Stock Requisitions/Dockets in a timely

manner.

File Stock Requisitions/Dockets in such a manner as to permit

easy retrieval of documentation.

Receive Store Purchase Orders correctly and monitor usage of

commodities to ensure available stock is on hand to meet

University requirements.

Maintain a safe and tidy work environment.

Perform Stocktakes as required.

Implementation:

This procedure has been implemented and is subject to regular

review.

Date Submitted:

Originally submitted June 1994. Submitted for review June

2000.

Date Approved:

Prepared by:

Mike Smith, Finance Manager (Supply).

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Goods and Services Tax (GST) KnowledgeDocument8 pagesGoods and Services Tax (GST) KnowledgeJaspreetSinghNo ratings yet

- Local Area Network PlanDocument165 pagesLocal Area Network PlanJaspreetSinghNo ratings yet

- Alphabet Language School Marketing Plan SummaryDocument10 pagesAlphabet Language School Marketing Plan SummaryJaspreetSinghNo ratings yet

- Executive SummaryDocument4 pagesExecutive SummaryJaspreetSinghNo ratings yet

- Muncie Personal License PDFDocument1 pageMuncie Personal License PDFJaspreetSinghNo ratings yet

- Perform Stock Control Procedures - A Strategic GuideDocument35 pagesPerform Stock Control Procedures - A Strategic GuideJaspreetSingh100% (2)

- Muncie Personal License PDFDocument1 pageMuncie Personal License PDFJaspreetSinghNo ratings yet

- NetworkingDocument20 pagesNetworkingJaspreetSinghNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- IiedDocument44 pagesIiedss.pp0077687No ratings yet

- Oriental Despotism in Ancient IndiaDocument4 pagesOriental Despotism in Ancient IndiamishikaNo ratings yet

- Steve Hanke Publications ListDocument49 pagesSteve Hanke Publications Listshanke1No ratings yet

- Derivatives, Money, Finance and Imperialism: A Response To Bryan and RaffertyDocument20 pagesDerivatives, Money, Finance and Imperialism: A Response To Bryan and RaffertyHyeonwoo KimNo ratings yet

- Rural Marketing Notes FullDocument121 pagesRural Marketing Notes Fullpiyu_bhagwat100% (1)

- How Inflation Affects the Financial Status of Juan Dela Cruz BusinessesDocument4 pagesHow Inflation Affects the Financial Status of Juan Dela Cruz BusinessesFrencis A. EsquierdoNo ratings yet

- Vietnam Consumer & Retail ReportDocument49 pagesVietnam Consumer & Retail ReportLương HiếuNo ratings yet

- Digital Labour Virtual WorkDocument342 pagesDigital Labour Virtual WorkventolinNo ratings yet

- Chapter 3 CUSTOMER PERCEPTION DRIVEN PRICINGDocument15 pagesChapter 3 CUSTOMER PERCEPTION DRIVEN PRICINGjoyce serraNo ratings yet

- New Methods of Measuring Marginal Utility 01Document77 pagesNew Methods of Measuring Marginal Utility 01dquartulliarchivos20 QNo ratings yet

- Alfred Sohn-Rethel Am LabernDocument12 pagesAlfred Sohn-Rethel Am LabernNatalie ZementbeisserNo ratings yet

- Islamic Banking User Manual-Bai SalamDocument21 pagesIslamic Banking User Manual-Bai SalamPranay SahuNo ratings yet

- Metrication and decision making in PD ProcessDocument2 pagesMetrication and decision making in PD ProcessROBIN BACCAYNo ratings yet

- Stability in The Banking Industry and Commodity Price Volatility: Perspective From Developing EconomiesDocument25 pagesStability in The Banking Industry and Commodity Price Volatility: Perspective From Developing EconomiesPrasanjit BiswasNo ratings yet

- Chapter 4 - Advanced Risk MGMTDocument68 pagesChapter 4 - Advanced Risk MGMTAli YaqoobNo ratings yet

- Godawari Power & Ispat Limited: A Sustainable Mid-Sized Steel CompanyDocument189 pagesGodawari Power & Ispat Limited: A Sustainable Mid-Sized Steel CompanyrkotichaNo ratings yet

- Derivatives Instruments... by Muhammad Al-Bashir M Al-AmineDocument45 pagesDerivatives Instruments... by Muhammad Al-Bashir M Al-Aminevishvasa11No ratings yet

- Key Causes of Inflation in IndiaDocument6 pagesKey Causes of Inflation in IndiashankarinadarNo ratings yet

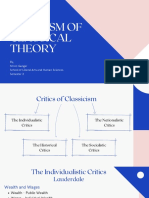

- Criticism of Classical TheoryDocument28 pagesCriticism of Classical TheoryShruti Gangar100% (1)

- Kieran McKeown Auth. Marxist Political Economy and Marxist Urban Sociology A Review and Elaboration of Recent DevelopmentsDocument294 pagesKieran McKeown Auth. Marxist Political Economy and Marxist Urban Sociology A Review and Elaboration of Recent DevelopmentsFelipe Reyes VallejosNo ratings yet

- Agrarian Societies and the Rise of AgricultureDocument5 pagesAgrarian Societies and the Rise of AgricultureEmanuele Giuseppe ScichiloneNo ratings yet

- JPMorgan EuropeanChemicals2024outlookPositioningforanoverduerecovery Dec 03 2023Document111 pagesJPMorgan EuropeanChemicals2024outlookPositioningforanoverduerecovery Dec 03 2023vikrams22No ratings yet

- Comparing pricing strategies of two gasoline stationsDocument2 pagesComparing pricing strategies of two gasoline stationsVanessa GabroninoNo ratings yet

- Product Class PDFDocument19 pagesProduct Class PDFAmir MirNo ratings yet

- L5M4 Lesson PlanDocument69 pagesL5M4 Lesson PlanpoifoonnieNo ratings yet

- Surber 1998 Materialist Critique of CultureDocument37 pagesSurber 1998 Materialist Critique of Culturebilal.salaamNo ratings yet

- BCAS v13n02Document86 pagesBCAS v13n02Len HollowayNo ratings yet

- Writing About Academic Labor: Joss WinnDocument15 pagesWriting About Academic Labor: Joss WinnCheshta AroraNo ratings yet

- Bs. Accountancy (Aklan State University) Bs. Accountancy (Aklan State University)Document9 pagesBs. Accountancy (Aklan State University) Bs. Accountancy (Aklan State University)JANISCHAJEAN RECTONo ratings yet

- Law of Equimarginal UtilityDocument5 pagesLaw of Equimarginal UtilityscribdranijNo ratings yet