Professional Documents

Culture Documents

Cast Iron

Uploaded by

Khin Aung ShweOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cast Iron

Uploaded by

Khin Aung ShweCopyright:

Available Formats

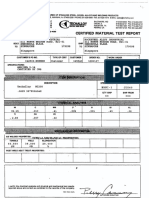

http://www.amfiller.

com

Staineless Steel Wire

Flux Cored Wire

Nickel

QUALITY WELDING ALLOYS

6015 Murphy Street, Houston, TX 77033, USA

(T) 1.713.649.8785 (F) 1.713.644.9628

Real People Real Service Real Fast

Get Your Quality Filler Metal

American Filler Metals

manufacturing capabilities

allow us to provide a wider

variety of options with regards

to cut lengths, spool sizes and

diameter of wires than many

of our competitors.

E71T-1

E71T-GS

STS FCW

STS Wires

Nickel

Made In USA Products

Call us today!

Toll Free: 1.800.394.4550

Telephone: 1.713.649.8785

Fax: 1.713.644.9628

Go Back to Table of Contents

Material

Safety

Data

Sheet

Important Notice for All Users of This Book

The information contained herein is intended for general information only and not for specification purposes.

American Filler Metals Company presents all the technical information, data and applications to permit you

to make your own evaluations and decisions, and is not to be mistaken as expressed or implied warranties for

these or other applications.

American Filler Metals Company assumes no liability for results or damages incurred from the use of any

information contained herein, in whole or in part.

Go Back to Table of Contents

Cast Iron Coated Electrodes & Wires

Coated Electrodes

AFM Product

AWS Classification

Page

AFM NI-55

AWS/SFA A5.15

ENiFe-CI

68

AFM NI-99

AWS/SFA A5.15

ENi-CI

69

Bare Wires

AFM Product

AWS Classification

Page

AFM NI-55

NO AWS/SFA Classification

70

AFM NI-99

AWS/SFA A5.15

ERNi-CI

71

Please contact us

for MSDS

66

Cast Iron Coated Electrodes & Wires

Order of Mandatory Classification Designators

AWS/SFA A5.15

Designates an electrode.

Designates the chemical composition of the filler metal

or undiluted metal.

Designates that these filler metal are intended for

cast iron applications.

E NiFe-CI

Designates an electrode or rod.

Designates the chemical composition of the filler metal

or undiluted metal.

Designates that these filler metal are intended

for cast iron applications.

ERNi-CI

Designates an electrode.

Designates the chemical composition of the filler metal

or undiluted metal.

Designates a tubular electrode.

Designates that the electrode is used primarily

without an external shielding gas.

Designates that these filler metal are intended

or cast iron applications.

E NiFeT3-CI

Go Back to Table of Contents

67

Cast Iron Electrode

AFM NI-55

AWS/SFA A5.11 ENiFe-CI

AC or DC+ (Reverse Polarity)

Description:

AFM NI-55 is designed for welding cast iron, malleable iron and ductile iron to themselves and other

wrought alloys, including nickel alloys.

A core wire chemistry of approximately 55% nickel and 45% iron produces weld deposits with much lower

weld shrinkage stress which in turn reduces the possibility of weld or heat-affected zone cracking.

Applications:

AFM NI-55 is especially suited for welding heavy sections such as motor blocks, housings, machine parts,

frames, defective castings and building up worn sections.

Stringer deposits are generally harder to machine due to the dilution of the weld metal, however heavier beads

and multiple layer welds will exhibit good machinability.

Recommended Amperage (AC or DC+):

Dia. (inch)

Dia. (mm)

Length

AC

DC +

3/32

2.4 mm

12

55 ~ 65

50 ~ 70

1/8

3.2 mm

14

70 ~ 85

70 ~ 95

5/32

3/16

4.0 mm

4.8 mm

14

14

110 ~ 125 135 ~ 150

100 ~ 130 135 ~ 170

Chemical Composition Requirements for Undiluted Weld Metal (%):

C

2.00

Mn

2.50

Si

4.00

S

0.03

Fe

Bal.

Ni*

45 ~ 60

Cu**

1.00

Al

1.00

Total Other

1.00

All values are considered maximum, unless otherwise noted.

* Nickel plus incidental Cobalt.

** Copper plus incidental Silver.

Typical Mechanical Properties of Undiluted Weld Metal:

psi

Tensile Strength

MPa

Elongation

(%)

58,000 ~ 84,000

400 ~ 579

6 ~ 18

AFM NI-55 is also available in

a bare MIG and TIG wire.

See page 71.

Standard Packaging:

All sizes are packaged in 10 Lb containers.

6 containers per 60 Lb Master Carton.

S

M

D

S

Go Back to Table of Contents

68

Cast Iron Electrode

AFM NI-99

AWS/SFA A5.11 ENi-CI

AC or DC+ (Reverse Polarity)

Description:

AFM NI-99 is designed for welding thin sections of cast iron to itself or to low alloy and carbon steels.

This all-position electrode is used where maximum machinability is required.

The weld deposits are soft and can be drilled, tapped, milled or shaped.

Applications:

AFM NI-99 is especially suited for repairing porous or cracked castings and can be used to weld cast iron

to itself or dissimilar metals.

Recommended Amperage (AC or DC+):

Dia. (inch)

Dia. (mm)

Length

AC

DC +

3/32

2.4 mm

12

60 ~ 90

50 ~ 80

1/8

3.2 mm

14

90 ~ 140

80 ~ 130

5/32

3/16

4.0 mm

4.8 mm

14

14

140 ~ 190 150 ~ 200

100 ~ 170 120 ~ 190

Chemical Composition Requirements for Undiluted Weld Metal (%):

C

Mn

Si

Fe

Ni*

Cu**

Al

Total Other

2.00

2.50

4.00

0.03

8.00

85 Min.

2.50

1.00

1.00

All values are considered maximum, unless otherwise noted.

* Nickel plus incidental Cobalt.

** Copper plus incidental Silver.

Typical Mechanical Properties of Undiluted Weld Metal:

Tensile Strength

Elongation

psi

MPa

(%)

40,000 ~ 65,000

276 ~ 488

3~6

AFM NI-99 is also available in

a bare MIG and TIG wire.

See page 72.

Standard Packaging:

All sizes are packaged in 10 Lb containers.

6 containers per 60 Lb Master Carton.

S

M

D

S

Go Back to Table of Contents

69

Cast Iron Wire

AFM NI-55

Description:

AFM NI-55 is a bare MIG and TIG alloy for the welding of cast iron.

It has a harder weld than AFM NI-99, but machining can be accomplished by using carbide tipped tools.

A 350F minimum preheat and interpass temperature is recommended during welding.

Typical Chemical Analysis (%):

C

0.05

Mn

0.25

Si

0.15

Fe

43.60

Ni

55.90

For AFM NI-55 stick electrodes see page 69.

Typical Mechanical Properties:

Tensile Strength

Elongation

psi

MPa

(%)

Standard Sizes:

36 TIG Wire

1/16

1.6 mm

105,000

720

35

30 Lb ~ 33 Lb Spool

0.035

0.9 mm

3/32

2.4 mm

0.045

1.2 mm

1/8

5/32

3.2 mm

4.0 mm

1/16

1.6 mm

S

M

D

S

Go Back to Table of Contents

70

Cast Iron Wire

AFM NI-99

AWS/SFA A5.15 ERNi-CI

Description:

AFM NI-99 is a bare MIG and TIG alloy for the welding of cast iron.

It is a machinable alloy that can also be used for buildup and overlay.

A 350F minimum preheat and interpass temperature is recommended during welding.

Typical Chemical Analysis (%):

C

0.05

Mn

0.22

Si

0.05

Ni

99.60

For AFM NI-99 stick electrodes see page 70.

Typical Mechanical Properties:

Tensile Strength

Elongation

psi

MPa

(%)

Standard Sizes:

36 TIG Wire

1/16

1.6 mm

66,500

450

40

30 Lb ~ 33 Lb Spool

0.035

0.9 mm

3/32

2.4 mm

0.045

1.2 mm

1/8

5/32

3.2 mm

4.0 mm

1/16

1.6 mm

S

M

D

S

Go Back to Table of Contents

71

You might also like

- Special Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresDocument10 pagesSpecial Alloy: Covered Arc Welding Electrodes Submerged Arc Welding Materials Gas Tungsten Arc Welding WiresCarlos PadillaNo ratings yet

- Technical Data & Terms for Welding AlloysDocument32 pagesTechnical Data & Terms for Welding Alloysnarutothunderjet216No ratings yet

- C 18150Document2 pagesC 1815003sri03No ratings yet

- Steel Clasification and WeldabilityDocument32 pagesSteel Clasification and Weldabilitycentaury2013No ratings yet

- Cast-iron welding guide covers standardsDocument10 pagesCast-iron welding guide covers standardsclnNo ratings yet

- Description:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless SteelDocument1 pageDescription:: AWS A5.4 E308-16 JIS Z3221 ES308-16 EN 1600 E 19 9 R 1 2 Covered Electrodes For Stainless Steel13421301508No ratings yet

- CI-500 Cast Iron Repair ElectrodeDocument1 pageCI-500 Cast Iron Repair ElectrodeLasandu WanniarachchiNo ratings yet

- Springwire Xinhua 2006Document10 pagesSpringwire Xinhua 2006teban09No ratings yet

- Metrode E2209 (B-60) ElectrodeDocument6 pagesMetrode E2209 (B-60) ElectrodeClaudia MmsNo ratings yet

- Welding Wires & Rods: MIG/MAG - Low Alloyed Steels: ClassificationDocument6 pagesWelding Wires & Rods: MIG/MAG - Low Alloyed Steels: ClassificationTaufikWibowoNo ratings yet

- 1.smaw All PDFDocument76 pages1.smaw All PDFkaviatchennaiNo ratings yet

- HILCO Stick Electrodes at A GlanceDocument6 pagesHILCO Stick Electrodes at A Glanceziaee950No ratings yet

- Analysis of Tig Welding Weldment and Defect Identification Using Non Destructive Testing NDTDocument48 pagesAnalysis of Tig Welding Weldment and Defect Identification Using Non Destructive Testing NDTRebecca KelleyNo ratings yet

- Electrode SsDocument29 pagesElectrode SsEbrahim Abdelhady ElmekaweyNo ratings yet

- Quality American Filler Metals ManufacturerDocument15 pagesQuality American Filler Metals ManufacturerbrunizzaNo ratings yet

- Welding Cast Iron GuideDocument10 pagesWelding Cast Iron GuideRoberto CordovaNo ratings yet

- Mild Steel Welding Electrodes: Salient FeaturesDocument16 pagesMild Steel Welding Electrodes: Salient FeaturesHandrea Hadi SaputraNo ratings yet

- Welding Electrodes Classification and Selection for Thermal Power PlantsDocument2 pagesWelding Electrodes Classification and Selection for Thermal Power Plantskiki270977No ratings yet

- Welding TrainingDocument87 pagesWelding Trainingeswar100% (1)

- 1.07 TIG Welding Part-2Document79 pages1.07 TIG Welding Part-2rohit mathanker100% (1)

- Welding Consumables For Hydro Power StationsDocument16 pagesWelding Consumables For Hydro Power StationsMohamed FaragNo ratings yet

- A-23 WB36 Rev 03 15NiCuMoNb5 MicrostructureDocument4 pagesA-23 WB36 Rev 03 15NiCuMoNb5 Microstructuremavis16No ratings yet

- Atmospheric Corrosion Resisting SteelDocument10 pagesAtmospheric Corrosion Resisting SteelCarlos PadillaNo ratings yet

- Weld Metal Selector Guide: Effective March, 2000Document28 pagesWeld Metal Selector Guide: Effective March, 2000saghirhassan61No ratings yet

- Select Arc Catalogue Part 1Document10 pagesSelect Arc Catalogue Part 1lionheartedNo ratings yet

- Welding of Ferritic Cryogenic SteelsDocument2 pagesWelding of Ferritic Cryogenic SteelsMuhammed SulfeekNo ratings yet

- How To Weld Fully Austenitic Stainless SteelsDocument20 pagesHow To Weld Fully Austenitic Stainless SteelsCarlos Bermejo AlvarezNo ratings yet

- Recom. de Soldadura XARDocument4 pagesRecom. de Soldadura XARelias667No ratings yet

- MSM Marketing SDN BHD: MIG Welding Electrodes !Document3 pagesMSM Marketing SDN BHD: MIG Welding Electrodes !namasralNo ratings yet

- Catalog ElectrDocument140 pagesCatalog ElectrMocanu Stefan ArtemonNo ratings yet

- Welding Technology Steelconstr - EngDocument32 pagesWelding Technology Steelconstr - EngLukman Tarigan SumatraNo ratings yet

- 65 45 12 Ductile IronDocument2 pages65 45 12 Ductile IronD_D_76100% (1)

- SAF Welding Cutting GuideDocument165 pagesSAF Welding Cutting GuideSelvem0% (1)

- Cast Iron Welding AlloysDocument4 pagesCast Iron Welding AlloysKhin Aung ShweNo ratings yet

- Welding GuideDocument48 pagesWelding Guideedu_canete100% (2)

- Special Metals - Product CatalogDocument65 pagesSpecial Metals - Product Catalogilham_metallurgy6744No ratings yet

- Types of Electric WeldingDocument7 pagesTypes of Electric WeldingSUKhanNo ratings yet

- Elettrodo Per Alluminio e Sue Leghe AWS A5.3 - E4043 (Selectarc - Eurosald Mod. AL105)Document1 pageElettrodo Per Alluminio e Sue Leghe AWS A5.3 - E4043 (Selectarc - Eurosald Mod. AL105)Eraldo MigliavaccaNo ratings yet

- Nickel Alloy Based Filler MetalDocument1 pageNickel Alloy Based Filler MetaljoehodohNo ratings yet

- Fontargen Sales ProgramDocument20 pagesFontargen Sales ProgramCarlos Nombela PalaciosNo ratings yet

- Cu Ni FabricationDocument28 pagesCu Ni FabricationAli Varmazyar100% (1)

- AluminumPresentationIEEE (CompatibilityMode)Document31 pagesAluminumPresentationIEEE (CompatibilityMode)A. HassanNo ratings yet

- Aluminium Alloys: Weldability of Materials: Alloy Designation Chemical Designation Classificatio N Filler ApplicationDocument7 pagesAluminium Alloys: Weldability of Materials: Alloy Designation Chemical Designation Classificatio N Filler ApplicationMuhammad WaseemNo ratings yet

- Welding BasicsDocument37 pagesWelding BasicsSnehal DeshmukhNo ratings yet

- 22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESDocument7 pages22%Cr DUPLEX STAINLESS STEEL WELDING CONSUMABLESNguyen Anh TuanNo ratings yet

- Met 05 Nonferrous WeldingDocument16 pagesMet 05 Nonferrous WeldingRaghu vamshiNo ratings yet

- Metallic-Coated Steel Marcelled Tension Wire For Use With Chain Link FenceDocument3 pagesMetallic-Coated Steel Marcelled Tension Wire For Use With Chain Link FenceJosé Ramón GutierrezNo ratings yet

- Oxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting: Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- The Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20From EverandThe Mechanical and Physical Properties of the British Standard En Steels (B.S. 970 - 1955): En 1 to En 20No ratings yet

- Oxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonFrom EverandOxy-Acetylene Welding and Cutting Electric, Forge and Thermit Welding together with related methods and materials used in metal working and the oxygen process for removal of carbonNo ratings yet

- Die Casting Metallurgy: Butterworths Monographs in MaterialsFrom EverandDie Casting Metallurgy: Butterworths Monographs in MaterialsRating: 3.5 out of 5 stars3.5/5 (2)

- Welding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesFrom EverandWelding Craft Practice: Oxy-Acetylene Gas Welding and Related StudiesNo ratings yet

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- Control and Analysis in Iron and SteelmakingFrom EverandControl and Analysis in Iron and SteelmakingRating: 3 out of 5 stars3/5 (2)

- Microscopy With Light and ElectronsDocument36 pagesMicroscopy With Light and ElectronsCORE Materials100% (1)

- Focus On Proper Weld Size When Developing WPS Parameter Ranges - Fabricating and MetalworkingDocument4 pagesFocus On Proper Weld Size When Developing WPS Parameter Ranges - Fabricating and MetalworkingKhin Aung ShweNo ratings yet

- ERNI-1 Cast Iron ElectrodeDocument1 pageERNI-1 Cast Iron ElectrodeKhin Aung ShweNo ratings yet

- Austenitic Ductile Iron For Low Temperature ApplicationDocument6 pagesAustenitic Ductile Iron For Low Temperature ApplicationKhin Aung ShweNo ratings yet

- Investigation of The Cause of Reinforcing Steel Fracture Induced by Alkali-Silica Reaction and Study On MaintenanceDocument10 pagesInvestigation of The Cause of Reinforcing Steel Fracture Induced by Alkali-Silica Reaction and Study On MaintenanceKhin Aung ShweNo ratings yet

- JK Stereo1Document26 pagesJK Stereo1Yongliang LiuNo ratings yet

- Lab Exericise 3 For MicroscopeDocument9 pagesLab Exericise 3 For MicroscopeKhin Aung ShweNo ratings yet

- Experimental Investigation On Weld Ability of Cast IronDocument5 pagesExperimental Investigation On Weld Ability of Cast IronKhin Aung ShweNo ratings yet

- Fracture and Crack Propagation in WeldmentsDocument66 pagesFracture and Crack Propagation in WeldmentsKhin Aung ShweNo ratings yet

- Effect of Heat Input To Weld Residual StressDocument4 pagesEffect of Heat Input To Weld Residual StressSurya DharmaNo ratings yet

- Mo SteelDocument0 pagesMo SteelSamsi B HanifNo ratings yet

- Safety of Machinery - Principles of Risk AssessmentDocument27 pagesSafety of Machinery - Principles of Risk AssessmentKhin Aung ShweNo ratings yet

- Manual de Servicio Olympus SZ-IIIDocument18 pagesManual de Servicio Olympus SZ-IIIcarlosibaNo ratings yet

- Theweldignofaluminiumcastingsoctober2011 111210001526 Phpapp02Document68 pagesTheweldignofaluminiumcastingsoctober2011 111210001526 Phpapp02Khin Aung ShweNo ratings yet

- DryerDocument80 pagesDryerAaron Paulo Bernardo100% (2)

- အမ်ားသံုး ျမန္မာ-အဂၤလိပ္-ပါဠိ အဘိဓါန္ PDFDocument1,080 pagesအမ်ားသံုး ျမန္မာ-အဂၤလိပ္-ပါဠိ အဘိဓါန္ PDFKo Lin96% (45)

- Lampiran PQR 003Document3 pagesLampiran PQR 003Khin Aung ShweNo ratings yet

- Fundamentals of Metal CastingDocument14 pagesFundamentals of Metal CastingKhin Aung ShweNo ratings yet

- Cast Iron Welding AlloysDocument4 pagesCast Iron Welding AlloysKhin Aung ShweNo ratings yet

- Brazil: "PLANTAR" Project: Sustainable Fuelwood and Charcoal Production and Substitution of Coke in Pig Iron ProductionDocument33 pagesBrazil: "PLANTAR" Project: Sustainable Fuelwood and Charcoal Production and Substitution of Coke in Pig Iron ProductionKhin Aung ShweNo ratings yet

- Welding of Nonferrous Metal and Their AlloysDocument62 pagesWelding of Nonferrous Metal and Their AlloysKhin Aung ShweNo ratings yet

- Braze Cast Iron - Videos, Tips and ProceduresDocument5 pagesBraze Cast Iron - Videos, Tips and ProceduresKhin Aung ShweNo ratings yet

- Boiler Furnace TheoryDocument8 pagesBoiler Furnace TheoryArun YogaNo ratings yet

- The Crucible Arthur Miller Play AllegoryDocument11 pagesThe Crucible Arthur Miller Play AllegoryKhin Aung Shwe100% (1)

- Casting Material WCBDocument8 pagesCasting Material WCBYusri WyeuserieyNo ratings yet

- Material Grade Comparison Chart PDFDocument1 pageMaterial Grade Comparison Chart PDFHelen Kate Saccuan100% (1)

- Effect of Pouring Temperature and Stirring Speed OnDocument6 pagesEffect of Pouring Temperature and Stirring Speed OnInternational Journal of Research in Engineering and TechnologyNo ratings yet

- PNS 49 2020 Rev Std. For Steel Bars For Concrete Reinforcement - SpecificationDocument19 pagesPNS 49 2020 Rev Std. For Steel Bars For Concrete Reinforcement - SpecificationStandpro Testing CenterNo ratings yet

- Oxygen SensorsDocument2 pagesOxygen SensorsVăn Đình NhậtNo ratings yet

- What Is PETDocument7 pagesWhat Is PETAza_AzlinAizri_2765No ratings yet

- Mod 1 ReviewDocument9 pagesMod 1 ReviewGamers GaloreNo ratings yet

- 2009 High Foaming Mild Body Wash (160P, LMB, S1210P, LiquidDC, REACH)Document1 page2009 High Foaming Mild Body Wash (160P, LMB, S1210P, LiquidDC, REACH)Diana BlueseaNo ratings yet

- Carbon compounds and periodic trendsDocument9 pagesCarbon compounds and periodic trendsBilva BabuNo ratings yet

- 2021-2022 S3 AE AnswersDocument12 pages2021-2022 S3 AE AnswersEndi WongNo ratings yet

- Investigatory Project On Metal CouplingDocument24 pagesInvestigatory Project On Metal CouplingDude LukaazNo ratings yet

- Chapter 4. Heat Treatment by InductionDocument1 pageChapter 4. Heat Treatment by InductionKamil IbraNo ratings yet

- Through-Hardening Low Alloy Steel Properties & ApplicationsDocument3 pagesThrough-Hardening Low Alloy Steel Properties & Applicationsl_aguilar_mNo ratings yet

- Chapter 2 Histology PDFDocument43 pagesChapter 2 Histology PDFpizzaNo ratings yet

- Veratherm: High-Temperature Water-Based Drilling FluidDocument8 pagesVeratherm: High-Temperature Water-Based Drilling FluidSupanca Ade Putri100% (1)

- Hazardous Chemical Waste ManagementDocument16 pagesHazardous Chemical Waste ManagementShumank SrivastavaNo ratings yet

- Lipids: Long Term Energy Storage Concentrated EnergyDocument22 pagesLipids: Long Term Energy Storage Concentrated EnergyLoreta Avenido PertosNo ratings yet

- Technical Data Sheet for Dow Dipropylene GlycolDocument2 pagesTechnical Data Sheet for Dow Dipropylene GlycolWidhy LestariNo ratings yet

- Nitobond Ec (Epoxy Adhesive)Document3 pagesNitobond Ec (Epoxy Adhesive)Kris SiregarNo ratings yet

- Geology of Titanium-Mineral Deposit Force1991Document113 pagesGeology of Titanium-Mineral Deposit Force1991Nicouux MagnetiteNo ratings yet

- Exp. 3 Test For The Presence of Carbohydrates Molisch TestDocument4 pagesExp. 3 Test For The Presence of Carbohydrates Molisch TestClarice Catorce100% (2)

- Differences Between WeldingDocument2 pagesDifferences Between WeldingBeing Ban100% (3)

- Extraction (L)Document45 pagesExtraction (L)Praveen yadavNo ratings yet

- Hardness and Surface Roughness of Reline and Denture Base Acrylic Resins After Repeated Disinfection ProceduresDocument8 pagesHardness and Surface Roughness of Reline and Denture Base Acrylic Resins After Repeated Disinfection ProceduresdanielNo ratings yet

- Chapter 9 Organic Chemistry SolomonDocument6 pagesChapter 9 Organic Chemistry SolomonSukhi Sohal0% (1)

- 0654/42/M/J/22 © Ucles 2022Document26 pages0654/42/M/J/22 © Ucles 2022Zenron27No ratings yet

- Preparation of Sulfanilamide Lab ReportDocument3 pagesPreparation of Sulfanilamide Lab ReportKirs EchagueNo ratings yet

- Rubber Product GuideDocument10 pagesRubber Product Guiderensso19605851No ratings yet

- The Lipids, Their Chemistry and - Deuel, Harry James, 1897-1956Document1,016 pagesThe Lipids, Their Chemistry and - Deuel, Harry James, 1897-1956Adrinian100% (2)

- F 1058 - 97 - RjewntgtukveDocument8 pagesF 1058 - 97 - RjewntgtukvePrakash MakadiaNo ratings yet

- TDS - QHXN Xanthan Gum For DrillingDocument1 pageTDS - QHXN Xanthan Gum For DrillingmatiasNo ratings yet

- Forensic Chemistry Gun PowderDocument21 pagesForensic Chemistry Gun PowderMary Joyce Anne ColloNo ratings yet

- Water Treatment Water Treatment: Lecture 7: DisinfectionDocument17 pagesWater Treatment Water Treatment: Lecture 7: DisinfectionAbo-Khaled MohammedNo ratings yet