Professional Documents

Culture Documents

Spe 90455

Uploaded by

loralaraCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Spe 90455

Uploaded by

loralaraCopyright:

Available Formats

SPE 90455

Application of Mini-Falloff Test to Determine Reservoir Parameters

and Optimize Fracture Designs in a Tight Gas Field

T.A. Harting, SPE, BP America Inc; D.L. Cox, SPE, BP America Inc; R. Murillo, SPE, BP America Inc; T.L. Young BP

America Inc; K.A. Adegbola, SPE, Schlumberger; and D. Schupp, SPE, Schlumberger

Copyright 2004, Society of Petroleum Engineers Inc.

This paper was prepared for presentation at the SPE Annual Technical Conference and

Exhibition held in Houston, Texas, U.S.A., 26 29 September 2004.

This paper was selected for presentation by an SPE Program Committee following review of

information contained in an abstract submitted by the author(s). Contents of the paper, as

presented, have not been reviewed by the Society of Petroleum Engineers and are subject to

correction by the author(s). The material, as presented, does not necessarily reflect any

position of the Society of Petroleum Engineers, its officers, or members. Papers presented at

SPE meetings are subject to publication review by Editorial Committees of the Society of

Petroleum Engineers. Electronic reproduction, distribution, or storage of any part of this paper

for commercial purposes without the written consent of the Society of Petroleum Engineers is

prohibited. Permission to reproduce in print is restricted to an abstract of not more than 300

words; illustrations may not be copied. The abstract must contain conspicuous

acknowledgment of where and by whom the paper was presented. Write Librarian, SPE, P.O.

Box 833836, Richardson, TX 75083-3836, U.S.A., fax 01-972-952-9435.

Abstract

This paper provides examples of using small injection tests on

tight gas wells in Jonah field to determine reservoir pressure

and transmissibility.

Prior to Mini-Falloff (MFO) test application in Jonah field,

reservoir pressure and permeability of each sand body were

obtained from log-derived correlations; these correlations in

the presence of depletion have been determined to be invalid.

The incorrect reservoir pressure and permeability will

generally result in wrong fracture geometry and pre-frac rate

prediction. The MFOs were designed as small injection tests

prior to fracture stimulation to correct these anomalies.

The After Closure Period following the MFO injection and

shut-in contain the reservoir pseudo-linear and pseudo-radial

flow periods. Analysis of the pseudo-radial flow period

provides reservoir transmissibility (kh/) and initial reservoir

pressure (Pr) in a manner similar to a Horner analysis. These

two-reservoir parameters play a crucial role in the

optimization of fracture design and rate prediction. For a tight

gas sand, the amount of time required to reach pseudo-radial

flow was thought to be quite large. However over sixty

percent of all the valid tests performed so far reached pseudoradial flow within a shut-in time of 24hrs.

A total of eighteen MFO tests were performed in the Jonah

field Lance formation from April to October 2003. Two of the

tests were invalid due to extremely high depletion and surface

pressure gauge malfunction. The remaining sixteen valid data

sets show various ranges of depletion in twelve sands tested

(0.36 0.52psi/ft) while the two remaining sands were overpressured (> 0.7psi/ft). Permeability results in general ranges

from 0.004 to 0.08md. The Jonah field log-derived

correlations were validated and improved with the MFO

results.

Introduction

The Jonah field is located in Sublette County, WY,

approximately 70 miles north of Rock Springs as shown in

Figure 1. The field is a large, structurally complicated wedge

shaped fault trap located in the northwestern part of the Green

River Basin. Production is primarily from over-pressured and

tight sandstones in the latest Cretaceous Lance Formation. The

Lance formation in Jonah field is composed of a stacked

sequence of fluvial channel sands inter-bedded with associated

over-bank siltstone and floodplain shale deposits as shown in

Figure 2. Gross interval thickness ranges from 2,800 ft to

more than 3,600ft. Within this interval the net-to-gross ratio

varies from 25 to 40%. Sandstone bodies occur as individual

10 to 20ft thick channels and stacked channel sequences

greater than 200ft in thickness in some cases. The main

reservoir issues are low permeability and small pay section

across a large gross interval.

One of the objectives of the Jonah field 2003 infill-drilling

program was to determine whether or not some sand bodies

were depleted. The question was addressed by the use of the

MFO technique. This technique determined the reservoir

pressure and transmissibility of individual sand bodies.

The use of MFO technique to determine reservoir pressure

and transmissibility is not a new idea. Gu et al1 and

Abousleiman et al2 comprehensively covered the after-fracture

closure application of radial flow from impulse fracture

injection. The theory and analysis of impulse fracture are

based on an instantaneous-source solution to the diffusivity

equation. The restriction is that the decline time (shut-in)

should be long enough to apply the impulse solution.

Ken Nolte3 further developed the techniques (field

application and analysis) in 1997 and it is currently known in

the industry as the Mini-Fall Off (MFO) test. The after-closure

pressure behavior is independent of the physical properties

governing fracture propagation and depends only on the

previous spatial and temporal history of the fluid loss, the

fracture length, and the reservoir parameters. The late-time

behavior becomes pseudo-radial flow and provides reservoir

transmissibility (kh/) and initial reservoir pressure (Pr) in a

manner similar to more traditional methods for a well test.

A MFO test consists of:

1. A small-volume water injection to create a short fracture

and

2. A shut-in period (decline time) afterwards to record

pressure falloff.

SPE 90455

A pressure response chronology for a constant rate fracture

injection, shut-in and pressure decline is shown in Figure 33

and described as follows:

1.

Injection period (pumping data): Used to evaluate the

nature of fracture propagation.

2. The fracture closing period: Used to quantify fluid

efficiency, fracture geometry, non-ideal events such as

post injection fracture propagation, pressure dependent

leak-off, height recession during closure and the existence

of a near well-bore choke. Though these non-ideal

fracturing characteristics can sometimes be identified

while the fracture is closing, it is unlikely given the small

fluid volumes, low viscosity fluid, and pump rate used in

these tests.

3. The after closure period (transient reservoir pressure

near well-bore) contains:

i.

Pseudo-linear flow period: Can be used to

determined closure time, spurt loss and fracture

length.

ii.

Pseudo-radial flow period: The presence of this

period depends on the allowed decline time. The late

time pseudo-radial pressure decline can be analyzed in

a manner similar to traditional well test methods to

determine transmissibility and reservoir pressure

(basis of MFO technique).

Literature Review

It is not the objective of this paper to provide a technical

review of the after-closure analysis. The reader is referred to

Gu et al1 and Nolte et al3 for such a review, however a brief

synopsis describing the basic equations associated with the

pseudo-radial flow period will be described in the following

section.

After-Closure Pseudo-Radial Flow

The late-time pressure decline evolves from the pseudolinear flow period to pseudo-radial flow allowing reservoir

pressure and transmissibility to be determined using a method

similar to a Horner analysis. After-closure radial-flow is a

function of the injected volume, reservoir pressure, formation

transmissibility, and closure time. Their relationship is

provided in the following equations using the radial-flow time

function, FR,

p(t ) p r = m R FR (t , t c )

(1)

where tc is the time to closure with time zero set as the

beginning of pumping, pr is the initial reservoir pressure, mR is

functionally equivalent to the Horner slope for conventional

testing, and

FR (t , t c ) =

t c

1

16

, =

ln 1 +

16

.

4 t tc

2

(2)

Thus, a Cartesian plot of pressure versus the radial-flow

time function yields reservoir pressure from the y-intercept

and the slope (mR) that permits determination of

transmissibility.

kh

= 251,000(

Vi

)

mR t c

(3)

with k, h, expressed in oil field units, tc in minutes and Vi is

injected volume (bbl). (Note, all other equations are either

dimensionless or in consistent units.)

Field Application

The primary objective of MFO application in Jonah field is to

assess the current level of depletion, by testing multiple sands

in a series of 20 acres infill-wells. The available open-hole and

cased-hole log correlations could not correctly predict or

determine the presence of depletion. The secondary objective

is to use the technique to determine the permeability to gas

and validate the formation evaluation neural network model

from logs. The technique is also used to estimate stress

profiles and validate the log generated stress profile for

improving fracture design.

Minimum Requirements for Field Application

The following are the minimum requirements that need to

be met for a successful application of MFO technique:

1. Static reservoir condition where reservoir pressure is

greater than hydrostatic pressure is desired. Not

applicable for wells that will not support a full column of

fluid.

2. The wellbore must be free of gas. Otherwise, incorrect

values for hydrostatic pressure and injected volume will

be utilized. After perforating, it is important to ensure that

gun movement does not pull/swab reservoir fluids into the

wellbore.

3. Single known fluid must be present in the wellbore.

4. An estimate of the reservoir pressure should be known

prior to the test for competent interpretation of pseudoradial flow regimes.

Specifying reservoir pressure

eliminates uniqueness considerations from the analysis.

5. In deep, hot reservoirs, bottomhole gauges will be

required because wellbore fluid expansion from

decreasing pressure and heating of the fluid will decrease

the hydrostatic pressure. Excessive expansion of the fluid

may also violate the no-flow condition and could require

bottomhole shut-off.

6. Large zones of varying lithology will reduce the

likelihood of successful application of the technique. The

analysis assumes equal fracture penetration and

communication over the complete interval. Therefore, it

is best suited for relatively thin, or somewhat single

homogeneous zones and not valid for multi-zone reservoir

without proper zonal isolation.

7. Volume has minimal effect on the time for development

of radial-flow (see next guideline). However, a minimum

volume of fluid should be pumped to insure accuracy of

the volume injected through the perforations because the

calculated transmissibility is proportional to volume (Eq.

#3).

8. To attain radial-flow within a reasonable time frame use

a fluid with minimal fluid loss control and adhere to the

following rate criterion:

SPE 90455

q (bpm) 5x10 6

kh

( pc pr )

(4)

If fluid loss is controlled by the reservoir, this guideline

provides a dimensionless time greater than one, i.e., beginning

of radial-flow.

The guideline will also require an estimate of reservoir

permeability for designing an injection test.

For low

permeability reservoirs this necessitates low injection rates.

Mobility greater than 5 to 10 md/cp should be considered as a

guideline to positively obtain radial-flow with a relatively

short monitoring period.

Job Procedure

All the tests performed follow the same job procedure as

follows:

1. Connect surface pressure gauge to casing valve to monitor

well pressure for the minifrac.

2. Rig up wireline. Run in hole with perf guns and frac plug

if isolation is necessary prior to injection.

3. Set frac plug at appropriate depth.

4. Perforate the target sand; perforation should cover the

entire net height.

5. Pull perf gun immediately out of the wellbore after

perforation and begin injection test.

6. Pump the minifrac at a rate of 2.5bpm to breakdown the

formation. Begin counting the fluid volume immediately

after breakdown. Step down the rate at 0.5bpm interval.

Shut down after pumping a total of 10bbl of KCl water.

Monitor decline pressure for 24hrs.

7. Gather pump rate and pressure data for analysis.

Summary of Field Applications

A total of eighteen tests were performed between April

and October 2003. Sixteen of the tests were successful. One of

the tests went on a vacuum immediately after pump-in and the

decline data was invalid, the other test had surface pressure

gauge malfunction.

Depletion was observed in twelve out of the sixteen sands

tested ranging from 0 to 2500psi below original reservoir

pressure. Two pay sands were about 1,000psi above the

expected pressure. In general permeability results ranges from

0.004 to 0.08md. The permeability values from the MFO tests

were not far from the predicted permeability from the

formation evaluation neural network model.

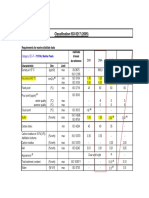

MFO Analysis Example

Application of the mini-falloff analysis is illustrated by

analyzing the pressure monitored following small injection

into the lower lance of one of the test wells in Jonah field. The

log cross-section of the zone of interest is shown in Figure 4.

The injection and 24hr shut-in pressure data are shown in

Figure 5. A total of 8.53bbl of water was injected into the

lower lance pay at the rate of 1.1bpm. The G-function analysis

from pressure decline is shown in Figure 6. Closure pressure

from the G-function analysis is determined to be 8215psi

(0.79psi/ft). The 17-ft zone has a porosity of 9% and contains

gas with a viscosity of 0.022cp. For these values, Eq. 3 with

the slope of the Cartesian radial-flow plot, mR and time to

closure, tc gave permeability of 0.006md and reservoir

pressure of 4913psi (0.474 psi/ft). Summary of the Horners

analysis and pseudo-radial analysis are shown in Figure 7 and

Figure 8 respectively. Figure 9 shows the summary of all the

tests data and analysis results while Figure 10 and 11

graphically illustrate the variation of log derived Reservoir

Pressure and Reservoir Permeability with the MFO results.

Fracture Placement Optimization

The main purpose of MFO application in 20 acres infilldrilling program in Jonah field is to determine the reservoir

pressure of each sand body within Lance formation and assess

the current level of depletion. Each Jonah well consists of a

stacked sequence of 20 to 50 fluvial channel sands interbedded with associated over-bank siltstone and flood plain

shale deposits; a multi-zone induced stress diversion fracture

treatment is the preferred option for cost savings and better

completion efficiency. Each fracture treatment stage consists

of between 2 to 7 sand bodies; one of these sand bodies is

perforated prior to actual fracture treatment and tested for

depletion. Due to the incomplete testing and data gathering of

all the pay sands, the desired fracture design optimization that

was to be done with the multi-layer pseudo3D fracture design

model was excluded. Also the pre-frac gas rate prediction for

all the pay sands could not be performed due to incomplete

pressure and transmissibility data.

The only design change employed by the completion team

was the use of energize fluid whenever depletion was

detected. Having confirmed a varying degrees of depletion in

more than half of the sands tested, the completion team

decided to optimize fracture placement by energizing the

fracturing fluid with Nitrogen. Foam qualities ranging from 35

to 55 were used in most cases.

Conclusions

1. The application of MFO in Jonah field is providing

critical reservoir information to improve the

understanding of reservoir performance and the potential

for infill drilling.

2. Each MFO test took 1.0 1.5 operating days. Earlier

failed techniques were more costly and time consuming.

3. MFO analysis validated Jonahs pre-frac neural network

permeability model. With the exception of one or two

cases, all MFO derived permeabilities agreed with the

permeabilities derived from OH/CH logs.

4. MFO

technology

adds

a

pre-frac

reservoir

characterization tool to the existing tool-kit to assist in the

evaluation of tight gas reservoirs.

5. Full utilization of MFO technology for rate prediction and

fracture optimization will require all the pay sands to be

tested. Future work should look into the logistics and cost

implication of getting all the zones tested effectively.

Acknowledgments

The authors acknowledge their appreciation to our companies

for providing the opportunity to undertake and publish this

study.

SPE 90455

References

1.

2.

3.

4.

He Gu, H., Elbel, J.L., Nolte, K.G., Cheng, A.H-D. and

Abousleiman, Y.: Formation Permeability Determination

Using Impulse Fracture Injection, paper SPE 25425,

1993 Production Operations Symposium, Oklahoma City,

OK, Mar21-23.

Abousleiman, Y., Cheng, A.H-D. and Gu, H.: Formation

Permeability Determination by Micro or Mini-Hydraulic

Fracturing, J. Ener. Res. Tech. (June 1994) 104.

Nolte, K.G., Maniere, J.L. and Owens, K.A.: AfterClosure Analysis of Fracture Calibration Tests, paper

SPE 38676, 1997 SPE Annual Technical Conference and

Exhibition, San Antonio, TX, Oct5-8.

Talley, G. R., Swindell, T. M., Waters, G. A., and Nolte,

K. G.: Field Application of After-Closure Analysis of

Fracture Calibration Tests, SPE 52220, 1999 Mid-Con.

Oper. Symp., Oklahoma City, OK, Mar 28-31.

Figure 2 Cross section of Jonah Lance Formation

Figure 1 Jonah Field Location Map

Figure 3 Bottom hole Fracture Pressure History (Nolte 1988)

SPE 90455

Porosity = 9%, Net Height = 17ft

Perm estimate from logs = 0.0079md

G s l o pe >>

<<P res s u re

P re s s d eriv >>

ps i

ps i

9000

Reservoir Pressure estimate = 6535psi

S p u rt % =0

P * =1 3 5 3

m 3 / 4 =1 3 5 3

m G c =6 6 0 ; fc =1 . 6 3

m G c . fc =1 0 7 5

E ffic ie n c y = 0 . 0 7

P s e u d o _ p o is s o n =0 . 3 4

ISIP

8000

1100

1000

900

800

700

Pclosure = 8215psi

600

7000

500

400

6000

300

200

100

5000

0

10

20

30

40

G fu n c tio n

Figure 6 G-function Analysis

initial reservoir pressure

Figure 4 Jonah Lance Sand Cross section for MFO Treatment

res_press

4940

match range

Rate(bpm)

Pres(psi)

4000

1.2

4920

1.0

3000

0.8

2000

0.6

4900

late-WBS diagnostic:

linearly increasing

values of "res press"

begins at ~ 1000 min

and eff stress ~ 3000 psi

4880

0.4

1000

0.2

0

0.0

0 100 200 300 400 500 600 700 800 900 1000 1100 1200 1300 1400 1500

time (min)

Figure 5 Jonah Lance Sand Pressure Fall-off Data

4860

50

100

150

200

( t- t_c) / t_c

res_pr match

match dp_R

4913

kh /

8851

C_L / C_R

4.6

2.6

Figure 7 MFO Horners Analysis

250

SPE 90455

<<P re s s d i ff

<<P re s s d i ff(T C )

S l o p e (T C ) >>

<<P re s s d e ri v

<<P re s s d e ri v (T C )

S l o p e >>

p s i P g De riv

10000

0.9

Slope = 0.8 approaching unit

slope (radial flow)

0.8

1000

100

Tp

=0 . 0 0 7 4

M a tc h d e r = 6 1 1 0 p s i

P Cl

=8 2 1 5 p s i

P re s

=4 9 1 3 p s i

k h / m u = 4 . 6 0 m d . ft/ c p

M a tc h d e r+ P re s > IS IP !

10

1

0.7

0.6

100

10

f(t) = 1 / F l^2

Figure 8 MFO Radial Flow Analysis

Well Stage

A Zone 1

Zone 2

Zone 3

Zone 4

Log Derived

MFO Analysis

Pay Height for Volume

Pumping Decline

Continuos Sand Pumped

Rate

Time

Time

(ft)

(bbls)

(bpm)

(min)

(min) K (md) Pr (psi) K (md) Pr (psi)

17

8.53

1.1

9.4

1400 0.0079 6535

0.008

4862

21

23.4

3 - 0.75

17

1500 0.0033 5961

0.025

4778

22

8

2 - 0.5

10

1380 0.0102 5282

0.02

5040

19

10

2 - 0.05

12.5

1500 0.0106 4397

0.054

4410

Test Effective

Yes

Yes

Yes - but still in transitional flow

Yes

Zone 1

Zone 2

Zone 3

Zone 4

23

22

8

20

13.46

21

11.8

13

3 - 0.5

1 - 0.5

2.2 - 0.75

3 - 2.1

11.3

10.75

14

12

1300

1400

1400

50

0.0007

0.055

0.017

0.0351

5875

5374

5057

4873

0.006

0.049

0.082

0.057

7076

4443

4860

3025

Yes

Yes

Yes

Yes

Zone 1

Zone 2

Zone 3

Zone 4

26

21

12

26

10.6

17.4

14.5

10

2.5 - 0.75

3 - 0.75

2.5 - 0.6

2.5 - 0.6

12

10

10

10

1450

1250

16

NA

0.0015

0.0144

0.0008

0.0125

6168

5612

5276

4719

0.004

0.031

-

4700

4503

-

Yes

Yes

No - too depleted for effective analysis

No - pressure gauge malfunction

Zone 1

Zone 2

Zone 3

22

28

17

11.7

8.3

16.4

2.5 - 0.6

2 - 0.5

3 - 0.75

10

10

10

1050

80

816

0.0071

0.0062

0.0577

6991

6377

5864

0.0066

0.00885

0.025

7104

3719

3793

Yes

Yes

Yes

Zone 1

Zone 2

Zone 3

22

24

14

7.4

8.8

10.8

2 - 0.5

2 - 0.5

2 - 0.5

12

12

10

1060

550

930

0.0098

0.0115

0.0288

6951

6344

5486

0.006

0.005

0.046

6430

5408

5131

Yes

Yes

Yes

Figure 9 Tests Data and Results

SPE 90455

Pressure vs Depth

0.0

All Data Normalized to top of Trap

Normal Pressure Gradient

Over Pressure Gradient 1.13

Depth below depth at Top of Trap

500.0

1000.0

1500.0

2000.0

2500.0

3000.0

3500.0

-500.0

0.0

500.0

1000.0

1500.0

2000.0

2500.0

3000.0

3500.0

4000.0

4500.0

5000.0

Pressure above hydrostatic at top of Trap

Figure 10 MFO vs Log Reservoir Pressure Variation

Permeability(MFOvsLog)

0.0900

0.0800

0.0700

0.0600

0.0500

0.0400

0.0300

0.0200

0.0100

8124

8296

8431

8959

9107

9143

9353

9772

9783

9794

10285

10372

10580

10647

11587

11647

0.0000

Klogmd

Kmfomd

Figure 11 MFO vs Log Permeability Variation

Klogmd

You might also like

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Res Sim - April 2007 Topic ListDocument1 pageRes Sim - April 2007 Topic ListloralaraNo ratings yet

- Log ResponsesDocument0 pagesLog ResponsesTran Dang SangNo ratings yet

- Project ManagementDocument311 pagesProject Managementloralara100% (3)

- Test PDFDocument1 pageTest PDFloralaraNo ratings yet

- Intro EclipseDocument35 pagesIntro Eclipseloralara100% (2)

- Eclipse AssignmentDocument8 pagesEclipse AssignmentloralaraNo ratings yet

- Saturation Profiles Using FlovizDocument8 pagesSaturation Profiles Using FlovizloralaraNo ratings yet

- Introduction and Case Studies on Reservoir Simulation ModelsDocument57 pagesIntroduction and Case Studies on Reservoir Simulation ModelsMuhammadHafizBaharuddinNo ratings yet

- Exam Possible QuestionsDocument2 pagesExam Possible QuestionsloralaraNo ratings yet

- M2-2 Section 4 Borehole StabilityDocument156 pagesM2-2 Section 4 Borehole StabilityloralaraNo ratings yet

- Eclipse AssignmentDocument6 pagesEclipse AssignmentloralaraNo ratings yet

- Eclipse AssignmentDocument8 pagesEclipse AssignmentloralaraNo ratings yet

- Capillary Pressure and Relative Permeability Behavior Characterized for J1 and J2 ReservoirsDocument105 pagesCapillary Pressure and Relative Permeability Behavior Characterized for J1 and J2 ReservoirsMuzakkir MohamadNo ratings yet

- M2-3 Section 1 The Drill StemDocument59 pagesM2-3 Section 1 The Drill StemloralaraNo ratings yet

- M2-2 Section 6 Borehole Behaviour Under Pressure & Solid ProductionDocument34 pagesM2-2 Section 6 Borehole Behaviour Under Pressure & Solid ProductionloralaraNo ratings yet

- M2-2 Section 7 Surface Effects at Great ScaleDocument14 pagesM2-2 Section 7 Surface Effects at Great ScaleloralaraNo ratings yet

- M2-2 Section 5 Compaction & SubsidenceDocument64 pagesM2-2 Section 5 Compaction & SubsidenceloralaraNo ratings yet

- Spe 90865Document14 pagesSpe 90865loralaraNo ratings yet

- M2-2 Section 2 in Situ States of Stress & Pore Pressure RegimesDocument16 pagesM2-2 Section 2 in Situ States of Stress & Pore Pressure RegimesloralaraNo ratings yet

- Water Frac Vs Regular FracDocument12 pagesWater Frac Vs Regular FracloralaraNo ratings yet

- 1 Sca2001 35Document14 pages1 Sca2001 35loralaraNo ratings yet

- M2-1 Section 1 Introduction To CompletionDocument49 pagesM2-1 Section 1 Introduction To CompletionloralaraNo ratings yet

- SPE90865 BrittDocument14 pagesSPE90865 BrittloralaraNo ratings yet

- Water Frac Provide Cost Effective MeansDocument12 pagesWater Frac Provide Cost Effective MeansloralaraNo ratings yet

- Spe 90002Document15 pagesSpe 90002loralaraNo ratings yet

- Water Frac ApplicationDocument16 pagesWater Frac ApplicationloralaraNo ratings yet

- Rocket Science Behind Water FracDocument14 pagesRocket Science Behind Water FracloralaraNo ratings yet

- Reservoir Quality and Well ResponseDocument9 pagesReservoir Quality and Well ResponseloralaraNo ratings yet

- Fresh Water Injection StimulationDocument14 pagesFresh Water Injection StimulationloralaraNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Two-Phase Flow (Gas-Flow) Line SizingDocument24 pagesTwo-Phase Flow (Gas-Flow) Line SizingvictorvikramNo ratings yet

- Esite Bauer Poseidon Edition VE 300 850 Hengitysilmakompressori enDocument4 pagesEsite Bauer Poseidon Edition VE 300 850 Hengitysilmakompressori enrolandoNo ratings yet

- Resume Dr. R.N.MukerjeeDocument13 pagesResume Dr. R.N.MukerjeeRahul Mukerjee100% (1)

- Solar Refrigerator SpecsDocument4 pagesSolar Refrigerator SpecsFaisal Bin FaheemNo ratings yet

- DC Machine Theory and Transformer PrinciplesDocument32 pagesDC Machine Theory and Transformer PrinciplesPolireddi Gopala KrishnaNo ratings yet

- Cause Effect Analysis of Oil Loss in Edible Oil IndustryDocument60 pagesCause Effect Analysis of Oil Loss in Edible Oil IndustrySaurabh RaiNo ratings yet

- cg-600 p2Document1 pagecg-600 p2mdishong27No ratings yet

- Cwi QuestionsDocument6 pagesCwi QuestionsGokul Thangam75% (4)

- 2563-Wireless Catalogue enDocument151 pages2563-Wireless Catalogue enElafanNo ratings yet

- Hydropower, Development & Poverty Reduction in Laos - Promises Realised or Broken (2020)Document22 pagesHydropower, Development & Poverty Reduction in Laos - Promises Realised or Broken (2020)Thulasidasan JeewaratinamNo ratings yet

- Sungris BrochureDocument8 pagesSungris Brochurechemasi123No ratings yet

- Mechatronics Handbook - 02 - Mechatronic Design Approach PDFDocument16 pagesMechatronics Handbook - 02 - Mechatronic Design Approach PDFJosé Fernando TerronesNo ratings yet

- Chlorosorb Ultra Case StudiesDocument5 pagesChlorosorb Ultra Case StudiesWitta Kartika RestuNo ratings yet

- LT AB Cable GTPsDocument3 pagesLT AB Cable GTPsnishant sainiNo ratings yet

- AC TO AC Write UpsDocument7 pagesAC TO AC Write UpsTin PelingonNo ratings yet

- Measuring Instrument Accuracy LimitsDocument2 pagesMeasuring Instrument Accuracy LimitsDan DanubiusNo ratings yet

- Model AR Ellipse® Annular Flow Meter PDFDocument2 pagesModel AR Ellipse® Annular Flow Meter PDFjhorlanNo ratings yet

- Microcontroller-Based Power Monitoring for COE RoomsDocument8 pagesMicrocontroller-Based Power Monitoring for COE Roomskenneth_molenilla1475No ratings yet

- Marine Chock InstallationDocument48 pagesMarine Chock InstallationSumeet SawantNo ratings yet

- TERAO Presentation August 2022Document48 pagesTERAO Presentation August 2022LuatNguyenNo ratings yet

- Week 6 - Sample Final TestDocument4 pagesWeek 6 - Sample Final TestMai Thúy VyNo ratings yet

- Flamanville France Nuclear Power Plant WallchartDocument1 pageFlamanville France Nuclear Power Plant WallchartArzu AkarNo ratings yet

- Classification ISO 8217 (2005)Document5 pagesClassification ISO 8217 (2005)Salah JallaliNo ratings yet

- Sub Sea Hot Stab (Sub Sea High Pressure Quick Disconnect)Document2 pagesSub Sea Hot Stab (Sub Sea High Pressure Quick Disconnect)estelauNo ratings yet

- Photovoltaic Silicon Wafer - SUMCO CORPORATIONDocument21 pagesPhotovoltaic Silicon Wafer - SUMCO CORPORATIONlawrence_yuen_3No ratings yet

- The Oil Kings Cooper en 15522 - PDFDocument5 pagesThe Oil Kings Cooper en 15522 - PDFNan EatonNo ratings yet

- Valve Material ApplicationDocument16 pagesValve Material Applicationehab8320014413100% (1)

- V. Ganapathy On Calculation of Flue Gas DensityDocument2 pagesV. Ganapathy On Calculation of Flue Gas DensityRi KoNo ratings yet

- Three-Phase Induction MotorDocument21 pagesThree-Phase Induction MotorRajeev ValunjkarNo ratings yet

- Test RDCDocument88 pagesTest RDCWan SahNo ratings yet