Professional Documents

Culture Documents

Steel Ss41p Jis g3101

Uploaded by

mahmoud_allam3Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Steel Ss41p Jis g3101

Uploaded by

mahmoud_allam3Copyright:

Available Formats

Gordon and Breach, Science Publishers Ltd.

Particle Accelerators

1975, Vol. 6, pp.123-129

Printed in the United Kingdom

DESIGN OF EARTHQUAKE-PROOF STRUCTURE FOR

KEK LINEAR ACCELERATOR TANK

S. INAGAKI, J. TANAKA, H. BABA, S. OKUMURA, S. IKEDA,t R. FUJITA,t

J. KISAKlt AND Y. IINOt

National Laboratory for High Energy Physics, Oho-machi, lsukuba-gun, Ibaraki-ken, Japan

(Received September 20, 1974)

In order to avoid the stress due to thermal expansion and to avoid resonance with an earthquake, the KEK proton

linear accelerator tank has as supports a so-called soft-structure.

In this paper we describe the design of the support, i.e. the idea of the structure, the calculation of the mechanical

features (the natural frequency, the endurable acceleration etc.) and experimental results with a brief comment on the

damping factor.

which can endure an acceleration of 0.5 gt in the

horizontal plane.

Secondly through Fourier-analysis of microtremors of the ground, the power spectra in the

KEK building sites were obtained. It was shown

that the natural frequency at the building site

ranges from 2.5 Hz to to Hz. 2 ,3t Therefore resonance will be avoided, if the natural frequency

of the supports is below 2 Hz.

1 INTRODUCTION

The KEKlinac tank is one cavity consisting of six

unit tanks and the total length is 15.5 m. Normally

the linac is operated at a temperature of(27 l)OC.

However, when the machine is shut down and the

air conditioning is stopped, the expansion or the

contraction for the whole length will amount to

several millimeters in a bad case. Further, taking

into account frequent earthquakes in Japan, one of

the authors (J. Tanaka) proposed to design an earthquake-proof structure for the KEK linac supports.

The degree of the damage due to quakes mainly

depends upon the acceleration of the ground and

the resonances of the machine with the vibration.

It also depends upon other unknown factors as the

velocity, the amplitude of the displacement and the

duration of the vibration. In the design of the support, we take the former two factors into consideration.

In Japan the earthquake intensity scale is classified into eight ranks and is called J.M.A. (Japan

Meteorological Agency) seismic scale. For a tremor

of the largest degree,.the acceleration of the ground

exceeds 400 cm/sec 2 (Ref. 1). It is characterized by

the following phenomena: destruction of more than

30 % of buildings, landslides, crumbling of mountain sides and. changes of geographical features

(dislocations, upheavals, subsidences etc.) in a wide

area. Therefore we intended to make supports

tMitsubishi Heavy Industry

Minato-ku, Nagoya-shi, Japan.

Company,

STRUCTURE OF THE SUPPORT

Figure 1 shows the whole view of the KEK linac

tank and Figure 2, the side view of the first unit

tank. It is around three tons in weight, and is

mounted on two supports. The support consists of

a steel plate and two preloaded U-shaped steel

springs (Figure 3). The former has the role of

spring action in the longitudinal direction and the

latter, the transverse direction.

The plate is 1.2 cm in thickness, 78 cm in height

and 75 cm in width, having a rectangular hole of

50 cm x 45 cm. The principle to determine the

dimensions .of the plate is as follows. First, the

height is uniquely determined from the beam line

t g stands for the acceleration of gravity.

The first and the second dominant mode are 5.89 Hz and

3.71 Hz respectively. In the general, the frequency of earthquake

in Japan lies between 2 and 20 Hz.

We use the term "longitudinal" in the sense of beam direction and "transverse", perpendicular to the beam direction in

the horizontal plane.

Oe-machi,

123

s.

124

INAGAKI et af.

and the diameter of the cavity. The thickness hand

the width b are determined to reduce the natural

frequency below 2 Hz, to endure longitudinal

acceleration of more than 0.5 g and to make the

buckling load larger than the weight of the tank.

The structure is shown in Figure 4. The spring

plate is indicated by CD. The height of the cavity

can be finely adjusted with four screws (J).t

The U -shaped spring is 3 cm in thickness,

3.2 cm in width and 47.4 cm in length. It is also

designed to have a natural frequency of 2 Hz. In

order to reduce the frictional force an assembly of

needle bearings and a guiding plate C@) is

inserted between the legs of the tank ~ and the

adjusting screws (J). A pair of mating blocks @

having a groove in the transverse direction is

attached to the legs and the upper end of the spring

plate. Each mating block has a pin hole (J), to

which each end of the U -shaped spring is fixed.

So as not to fail in exact repositioning, the Ushaped spring is pretensioned to 28 kgjmm 2 by the

FIGURE 1 Whole view of KEK linac tank.

t The method to set up the unit-tanks (and the drift tubes)

on the beam-line will be reported elsewhere. We merely mention

here that the tanks are well aligned if the screws can be rotated

with the effective up and down movement of 5 mm.

FIGURE 2 Side view of the first unit-tank.

125

EARTHQUAKE-PROOF LINAC TANK STRUCTURE

FIGURE 3 Structure of the Support I.

screws . This strength corresponds to a transverse acceleration of 0.2 g. The spring has only

leftward restoring force in the case of Figure 4;

spring action occurs for a stretching force which

exceeds the preset value, but does not for any compressive force owing to the clearance of a trackshaped hole . Therefore it can be said that for

the transverse direction, the support is a rigid

structure below the acceleration of 0.2 g, but becomes a soft structure above that value (Figure 5}.

3 PROPERTIES IN THE LONGITUDINAL

DIRECTION

As two guiding blocks are bolted on the upper end

of the support and- two anchor bolts are buried at

the lower end ofthe su.pport, we can take the bound..

ary condition as follows. The upper end of the

plate is free for displacement but restricted in

rotation, meanwhile the lower end is fixed both for

displacement and rotation. Let the x-axis be

FIGURE 4 Structure of the Support II.

Displacement

" ---- 0

-leftward

,"

,,

"

Q2g rightwardAcceleration

,"

/

FIGURE 5 Acceleration-displacement diagram for the transverse movement.

s.

126

INAGAKI et al.

y

FIG URE 6 Coordinate of a plate spring.

( YV2 -yJ

FIGURE 7 Flexible pillar model.

vertical and the Y-axis along the longitudinal

direction (Figure 6). Then

y= 0,

Fs = 0,

oY

-=0

ox

oY

-=0

ox

Then, Eq. (2) becomes

at x = 0

(1a)

at x = 1

(1b)

ay

3

(1':) = 0.

P -..!:. - Y

2

x=l

Y = y(x)cos(wt).

(7)

(2)

ay

= E1 -;-3 + P-,

ux

ax

(3)

where P is the weight of the tank.

(8)

the general solution of which is given

COs(~x) + C Sin(j~ x)

2

We consider the restoring force due to the deflection of the elastic plate. Let the mass on the

upper end be m, and assume the mass of the plate

be negligible. The bending moment exerting at any

point (x, Y) is due to the load P and the force of

inertia F (Figure 7), being expressed as follows.

FG - x) + p(i - y).

a

axy2 + Py = {2(1)

mw 2 - x + iP} ~,

y = C1

Natural Frequency

M =

-2

As the time variation is independent of the position

Y can be written as follows.

'

EI

Fs

)(aotY)

2

- x

From Eqs. (6) and (7), we get

a y2

ox

F s is given by

3.1

uX

+ m(1-

(6)

in which the displacement Y is a function of x and

t, and Fs means the shearing force. If we denote

Young's modulus by E and the geometrical

moment of inertia by 1, then the bending moment

M can be expressed as follows:

M = El

y

EI ~

mw

+ {P

(12- x) +21} ~.

(9)

Using the boundary condition (1), we can determine

C 1 and C 2 to get

~ (mw

-"2

P +1

2

y=

([P)

..j Ei

cos

(4)

where

(5)

{mwP

(I2 ) 21} ,.

+--~-x+-1':

(10)

127

EARTHQUAKE-PROOF LINAC TANK STRUCTURE

Putting y = yzl2 at x = 1/2, we get the natural

frequency f

1

fP

j= 2nymi

j~f}tan(~.D - 1

The maximum bending stress (Jmax at an arbitrary

cross section of a beam is given as follows.

. (11)

(Jmax

(14)

where e is the maximum distance from the neutral

axis and Z, the modulus of section. It is given by

Taking It = 78 cm, E =-2.09 x 106 kg cm- 2 ,

P = 1.5 X 10 3 kg and I = 4.32 cm 4 t, we get

M

M

= T e = Z'

= 1.88 Hz.

If the denominator in Eq. (11) becomes infinite,

the natural frequency f goes to zero. The load Pc at

which this condition is satisfied is called the Euler's

critical buckling load; the lowest mode of which is

given by

(13)

bh 2

bh 3 /12

Z=e=hj2=6

(15)

The bending moment M takes the largest value at

x = 0 and x = 1, neglecting the second term in

Eq. (4). Then Eq. (14) becomes

3Fl

= bh 2

(Jmax

(16)

Using the minimum yield strengtht of SS41P,

= 25 kg/mm 2, we get

(Jmax

(Jmax3~ bh = 4.62

2

With the same values as those in the preceding

section, Pc is evaluated to be 1.47 x 104 kg.

Therefore the safety factor becomes 9.8.

3.2

Longitudinal Critical Force

Due to the vibration of the ground, a forced oscillation is induced to the tank. In this section, however,

we suppose a static model. At the initial time when

the ground moves in one direction suddenly, the

tank is left at the original position due to inertia.

We assume that the period of the vibration is long

enough and do not consider the subsequent reverse

movement of the ground. If the acceleration of the

ground is very large, the bending stress at some

cross section of the support exceeds the yield

strength of the material used. We call the force

corresponding to this acceleration the critical

force. The actual acceleration which the support

can endure will be much larger than that calculated

here, because the tensile strength is about two

times larger than the yield strength.

t Owing to the reinforcement and the installation of the

height-adjusting mechanism, I does not coincide with the real

height of the support.

t The geometrical moment of inertia is given by

bh 3

1=-.

12

(12)

The thickness h of the plate is 1.2 cm. But the width is 75 cm

having a rectangular hole of 45 cm (in width) x 50 cm (in

height). So we tentatively take b = 30 cm.

F =

102 kg,

which corresponds to a horizontal acceleration of

0.31 g.t It can easily be shown that the deflection

is 2.0 cm for this acceleration.

4

4.1

PROPERTIES IN THE TRANSVERSE

DIRECTION

Natural Frequency

We use a simple pendulum model for the calculation of natural frequency.

j=~ fk.

2n~m

(17)

Due to the sequence of two cantilevers in the

U-type blocks, the spring constant k is given

as follows (Figure 8):

k=

3E1'

Eb'h,3

"2 = 8f3.

(18)

t SS41P is rolled steel plate for general structure (JIS G3101).

The yield strength is more than 25 kg/mm 2 and the tensile

strength, 41 ~ 51 kg/mm 2

t If we use the tensile strength of 41 kgjmm 2 for (j max' the

endurable horizontal acceleration becomes 0.51 g.

For a cantilever the boundary condition is given as

follows.

dy

y = 0,

- = 0 atx = 0

(19a)

dx .?

Fs = 0,

M= 0

atx = l'

(19b)

s.

128

INAGAKI et aJ.

FIGURE 8

Coordinate of a U-shaped spring.

When a concentrated load F' is exerted on the one

end of a cantilever, the cross section of which is

rectangular, the maximum bending stress aritax is

given by Eq. (20).

6F'I'

uritax = llh'2

(20)

Corresponding to the pretensioned force F' = 0.2

my, we decided to make uritax = 28 kgjmm 2 ,

which is about half of the yield strength of S45C.t

Substituting f = 2 Hz into Eqs. (17), (18) and (20),

we get relations between h', l' and h'. Using h' = 3

cm for the thickness of the spring, we get h' = 3.2

cm and l' = 47.4 cm. Therefore the deflection b of

the spring, which we give, corresponding to the

initial pretension, is given by

b=

4.2

F'

k =

6.25 mm.

Transverse Critical Force

Just as in Sec. 3.3, the maximum transverse

acceleration can be obtained by substituting the

yield strength or the tensile strength for uritax

in Eq. (20). From this we get 0.36 g and 0.5 g

respectively.

5 EXPERIMENTAL RESULTS

The natural frequency in the longitudinal direction

was measured for the first unit tank. A permanent

t S45C is a carbon steel Jor machine structure use (JIS

G4051). The yield strength and the tensile strength are more

than 50 kg/mm 2 and 70 kg/mo1 2 respectively.

FIGURE 9 Oscillation of the first unit-tank.

magnet was attached to the end flange, after the

completed unit tank had been placed in the correct

location. The oscillations of the magnet against

a Hall probe, which was fixed to the floor, generated

the signal voltage (Figure 9). The measured natural

frequency and the damping factor were 1.72 Hz

and 1.46 sec respectively. The former is 9.3 %

smaller than that calculated in Sec. 3.1, which

coincides rather well in spite of the rough estimation.

As we have lost the opportunity to get any

experimental result about the transverse- oscillation, since the alignment of the whole tanks and

drift tubes has been completed, we are going to

measure the frequency by monitoring real earthquakes.

In the design of earthquake-proof structure, it is

also necessary to make fast damping. We consider

that there is no problem for the transverse

structure because of the nonlinearjty of the righting

force. For the longitudinal structure there is no

intended device for damping. We hope that the

installation of twelve sputter-ion pumps, two rf

feeders and beam transport systems will serve as

dampers to some extent. However, we are also

investigating the possibility of an oil damper.

ACKNOWLEDGEMENT

We express our thanks to Prof. T. Nishikawa and the staff of

the KEK linac group. The members of the linac group in the

Mitsubishi Heavy Industry Company were also very enthusiastic

in the design and the realization.

EARTHQUAKE-PROOF LINAC TANK STRUCTURE

REFERENCES

1. A. Odaka, S. Nasu, M. Takeuchi, J. Sakurai and S. Tani,

Earthquake- and Wind-Proof Structure, Kashima Pub. Co.,

p. 24 (1972) (in Japanese).

2. T. Itoh, H. Watanabe and H. Yanohara, Measurement and

129

Analysis of the Oscillation at National Laboratory for High

Energy Physics, Research Reports of Shimizu Construction

Company, Oct. 20 (1972) (in Japanese).

3. S. Inagaki, J. Tanaka, H. Baba, S. Ikeda, R. Fujita, J. Kisaki,

and Y. lino, Earthquake-proof Structure of KEK Linear

Accelerator Tank, KEK PREPRINT-l (1974).

You might also like

- Shallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceFrom EverandShallow Crack Fracture Mechanics Toughness Tests and Applications: First International ConferenceNo ratings yet

- Compressor Wash Skid Manual (Pages 1-14)Document14 pagesCompressor Wash Skid Manual (Pages 1-14)Anibal QuezadaNo ratings yet

- SurfacingDocument14 pagesSurfacingrahul063No ratings yet

- IIW, IX-H-736-11 DSS Welding DSS - Review of Current Recommendations 2011Document17 pagesIIW, IX-H-736-11 DSS Welding DSS - Review of Current Recommendations 2011Anonymous jlciIdX8q100% (1)

- Brochure For National Skill Competition For Best Welder - 2018 - Rev PDFDocument4 pagesBrochure For National Skill Competition For Best Welder - 2018 - Rev PDFPrakash RajNo ratings yet

- HSE TBT 0018 Head ProtectionDocument1 pageHSE TBT 0018 Head ProtectionniazNo ratings yet

- DNV-RP-H102: Marine Ops During Offshore Installation RemovalDocument1 pageDNV-RP-H102: Marine Ops During Offshore Installation Removalhlaing Thant0% (1)

- Duplex Steels: Carbides and Nitrides Reduce Corrosion ResistanceDocument9 pagesDuplex Steels: Carbides and Nitrides Reduce Corrosion ResistanceKatellin BermudezNo ratings yet

- Topical Outline: Level III NDT BasicDocument1 pageTopical Outline: Level III NDT BasicraofrhanNo ratings yet

- Welding - DIN EN ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and Rotation PDFDocument12 pagesWelding - DIN EN ISO 6947-1997 Welds-Working Positions Definitions of Angles of Slope and Rotation PDFEswaranNo ratings yet

- 234 D7091 344Document7 pages234 D7091 344Ivan AlanizNo ratings yet

- 2005 Stainless SteelsDocument76 pages2005 Stainless SteelsAnonymous 98vSKYTaDgNo ratings yet

- Dynamic and Static Balancing of Rolls - How, Why and WhenDocument2 pagesDynamic and Static Balancing of Rolls - How, Why and WhenAbolfazl KhakiNo ratings yet

- 00 Cover WE Rev2Document5 pages00 Cover WE Rev2ariyonodndiNo ratings yet

- Weldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructuresDocument8 pagesWeldability of Thermo-Mechanically Rolled Steels Used in Oil and Gas Offshore StructurestheijesNo ratings yet

- TWI Paper On Fatigue and GridingDocument42 pagesTWI Paper On Fatigue and GridingKatsaras SotirisNo ratings yet

- FY00 Welding Emissions-Mgmt-AppilicableDocument39 pagesFY00 Welding Emissions-Mgmt-AppilicablePeter's KitchenNo ratings yet

- Welder NIMI Q 2Document30 pagesWelder NIMI Q 2Mahesh SonarNo ratings yet

- Demagnetization: BSS Non Destructive Testing PVT - LTDDocument18 pagesDemagnetization: BSS Non Destructive Testing PVT - LTDSANU100% (1)

- G 14 - 04 (2010) E1Document6 pagesG 14 - 04 (2010) E1jose floresNo ratings yet

- Electroslag & Electrogas PDFDocument5 pagesElectroslag & Electrogas PDFRobin GuNo ratings yet

- Weldeability Offshore SteelDocument12 pagesWeldeability Offshore Steelcarrotiron100% (1)

- GMAW of Creep Resistant SteelsDocument5 pagesGMAW of Creep Resistant SteelsJustin Morse100% (1)

- Astm G 17Document6 pagesAstm G 17DdsNo ratings yet

- Guidelines For Welding: ZERON 100 Super Duplex Stainless SteelDocument16 pagesGuidelines For Welding: ZERON 100 Super Duplex Stainless SteelHrishikesanNo ratings yet

- Temper Embrittlement - J and X FactorDocument2 pagesTemper Embrittlement - J and X Factorgovimano100% (2)

- Catalog Tevi - Van Leeuwend-Slatina PDFDocument62 pagesCatalog Tevi - Van Leeuwend-Slatina PDFBara SebastianNo ratings yet

- Inspection - Spark-Testing PDFDocument3 pagesInspection - Spark-Testing PDFanandtpe1No ratings yet

- Aws WJ 201401 PDFDocument139 pagesAws WJ 201401 PDFeduardo huancaNo ratings yet

- Materials & Their Materials & Their Behavior in Welding Behavior in WeldingDocument56 pagesMaterials & Their Materials & Their Behavior in Welding Behavior in WeldingWahyu Tirta Nugraha100% (1)

- Filler Wires PDFDocument7 pagesFiller Wires PDFJayaram MVNo ratings yet

- dpvc-09 Petrobras PDFDocument47 pagesdpvc-09 Petrobras PDFBilly TanNo ratings yet

- GMAW Guide for Welding Copper-Base AlloysDocument2 pagesGMAW Guide for Welding Copper-Base AlloysMaulana Mufti MuhammadNo ratings yet

- Review of The Performance of High Strength Steels Used OffshoreDocument130 pagesReview of The Performance of High Strength Steels Used OffshoreElias Kapa100% (1)

- Advance StructuresDocument6 pagesAdvance StructuresManju NishaNo ratings yet

- 2015 - KOBELCO - Arc Welding of High Tensile Strength SteelDocument170 pages2015 - KOBELCO - Arc Welding of High Tensile Strength SteelNhan vo vanNo ratings yet

- QT2109958 - ITP For 1T-1201 Buffer Water Tank Itp PDFDocument3 pagesQT2109958 - ITP For 1T-1201 Buffer Water Tank Itp PDFGanesh EswaranNo ratings yet

- Comparison of Preheat Predictive Methods: N. Yurioka Nippon Steel Corporation, Technical Development Bureau (Japan)Document7 pagesComparison of Preheat Predictive Methods: N. Yurioka Nippon Steel Corporation, Technical Development Bureau (Japan)Erijanio Silva100% (1)

- SST (GMAW) Welding Process PDFDocument4 pagesSST (GMAW) Welding Process PDFmudrijasm100% (1)

- September 18, 2000 04:31:29 Information Handling Services, 2000Document32 pagesSeptember 18, 2000 04:31:29 Information Handling Services, 2000Rajoo PrajapatiNo ratings yet

- Steel Construction UKCA Marking v3Document20 pagesSteel Construction UKCA Marking v3ioancNo ratings yet

- List of en Standards: SR No Code/Standard DescriptionDocument4 pagesList of en Standards: SR No Code/Standard DescriptionAnilNo ratings yet

- Integrally Reinforced Forged Branch Outlet Fittings - Socket Welding, Threaded, and Buttwelding EndsDocument22 pagesIntegrally Reinforced Forged Branch Outlet Fittings - Socket Welding, Threaded, and Buttwelding EndsVinoth MechNo ratings yet

- WPQT Schedule Plan Rev.1aDocument1 pageWPQT Schedule Plan Rev.1asaffririzal4237No ratings yet

- A Study On Transverse Weld Cracks PDFDocument8 pagesA Study On Transverse Weld Cracks PDFRifani ImamNo ratings yet

- Fb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischDocument13 pagesFb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischDan DumbravescuNo ratings yet

- Purging Brochure PDFDocument19 pagesPurging Brochure PDFjustinctlNo ratings yet

- Increase Range and Velocity of 122mm HowitzerDocument8 pagesIncrease Range and Velocity of 122mm HowitzerJose Luis RomanNo ratings yet

- 4 Welding Metallurgy-3Document20 pages4 Welding Metallurgy-3Defi Rizki MaulianiNo ratings yet

- Aws WJ 201205Document137 pagesAws WJ 201205doyenofcastleNo ratings yet

- Dilution in Single Pass Arc Welds: As+As,, Asm EtaDocument9 pagesDilution in Single Pass Arc Welds: As+As,, Asm EtadayalramNo ratings yet

- Electrode Converted Into TextDocument14 pagesElectrode Converted Into TextNeha NimbarkNo ratings yet

- Hydro Aluminium - AlSi7Mg0.6Document2 pagesHydro Aluminium - AlSi7Mg0.6Raj PrasanthNo ratings yet

- Shipbuilding Steels Weldability TestsDocument81 pagesShipbuilding Steels Weldability TestsiulianticNo ratings yet

- Welder SyllabusDocument52 pagesWelder Syllabussantosh0% (1)

- GGG40CI WeldingDocument13 pagesGGG40CI WeldingA K NairNo ratings yet

- Proceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987From EverandProceedings of the Metallurgical Society of the Canadian Institute of Mining and Metallurgy: Proceedings of the International Symposium on Fracture Mechanics, Winnipeg, Canada, August 23-26, 1987W. R. TysonNo ratings yet

- A Study of The Static Stiffness of Machine Tool SpindlesDocument18 pagesA Study of The Static Stiffness of Machine Tool SpindlesnounakameliaNo ratings yet

- Dynamic Pressure For Circular Silos Under Seismic ForceDocument10 pagesDynamic Pressure For Circular Silos Under Seismic Forcesebastian9033No ratings yet

- Study of Ductile-Brittle Transition Temperature of 9Cr-1Mo SteelsDocument2 pagesStudy of Ductile-Brittle Transition Temperature of 9Cr-1Mo Steelsmahmoud_allam3No ratings yet

- Engineering, Steel Fabrication and Process Equipment ManufacturerDocument4 pagesEngineering, Steel Fabrication and Process Equipment Manufacturermahmoud_allam3No ratings yet

- Method For Mechanical Properties EvaluationDocument5 pagesMethod For Mechanical Properties Evaluationmahmoud_allam3No ratings yet

- Fracture Toughness of The Heat Affected Zone in Girth WeldsDocument7 pagesFracture Toughness of The Heat Affected Zone in Girth Weldsmahmoud_allam3No ratings yet

- Color Metallurgy of Cast IronDocument13 pagesColor Metallurgy of Cast Ironmahmoud_allam3No ratings yet

- Projects Follow UpDocument1 pageProjects Follow Upmahmoud_allam3No ratings yet

- Furnaces and RefractoriesDocument36 pagesFurnaces and Refractoriesengkassem100% (5)

- Steam Generators 2Document33 pagesSteam Generators 2gbharathreddysNo ratings yet

- 1english Reg Final Nov 2010 PDFDocument367 pages1english Reg Final Nov 2010 PDFmahmoud_allam3No ratings yet

- ASME New Code Case LetterDocument1 pageASME New Code Case Lettermahmoud_allam3No ratings yet

- Passivating Gel For Stainless SteelDocument2 pagesPassivating Gel For Stainless Steelmahmoud_allam3No ratings yet

- Color Metallurgy of Cast IronDocument13 pagesColor Metallurgy of Cast Ironmahmoud_allam3No ratings yet

- PICKLING Gel FOR STAILESS STEEL PdsDocument2 pagesPICKLING Gel FOR STAILESS STEEL Pdsmahmoud_allam3No ratings yet

- Nitrogen Purging For Stainless SteelDocument4 pagesNitrogen Purging For Stainless Steelmahmoud_allam3No ratings yet

- Code Case 2891 U-2 CerDocument1 pageCode Case 2891 U-2 Cermahmoud_allam3No ratings yet

- Request For Code CaseDocument2 pagesRequest For Code Casemahmoud_allam3No ratings yet

- Journal Modified 9% CR Steels For AdvancedDocument6 pagesJournal Modified 9% CR Steels For Advancedmahmoud_allam3No ratings yet

- Code Case 2891 U-2 CerDocument1 pageCode Case 2891 U-2 Cermahmoud_allam3No ratings yet

- Welding CrMo Steels for Power and Petrochemical ApplicationsDocument11 pagesWelding CrMo Steels for Power and Petrochemical Applicationsmahmoud_allam3100% (1)

- Assessment of Welding ConsumablesDocument17 pagesAssessment of Welding Consumablesmahmoud_allam3No ratings yet

- Presentation For WeldingDocument31 pagesPresentation For Weldingmahmoud_allam3No ratings yet

- 16-2819 Welders InterpretationDocument1 page16-2819 Welders Interpretationmahmoud_allam3No ratings yet

- Heat Treatment of 9 CRDocument12 pagesHeat Treatment of 9 CRmahmoud_allam3No ratings yet

- 10 1 1 161 3015Document7 pages10 1 1 161 3015rinshadNo ratings yet

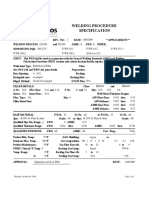

- WPS for GTAW Welding of Aluminum Butt JointsDocument2 pagesWPS for GTAW Welding of Aluminum Butt Jointsmahmoud_allam3No ratings yet

- Welding of P91Document10 pagesWelding of P91mahmoud_allam3No ratings yet

- Aluminim WPSDocument5 pagesAluminim WPSmahmoud_allam3No ratings yet

- WPS for GTAW Welding of Aluminum Butt JointsDocument2 pagesWPS for GTAW Welding of Aluminum Butt Jointsmahmoud_allam3No ratings yet

- Aluminim WPSDocument5 pagesAluminim WPSmahmoud_allam3No ratings yet

- WPS for GTAW Welding of Aluminum Butt JointsDocument2 pagesWPS for GTAW Welding of Aluminum Butt Jointsmahmoud_allam3No ratings yet

- Sri Lanka, CBSLDocument24 pagesSri Lanka, CBSLVyasIRMANo ratings yet

- CMC4 Controller Technical Support DocumentDocument148 pagesCMC4 Controller Technical Support DocumentZurab ChanturiaNo ratings yet

- Materials Science & Engineering A: Alena Kreitcberg, Vladimir Brailovski, Sylvain TurenneDocument10 pagesMaterials Science & Engineering A: Alena Kreitcberg, Vladimir Brailovski, Sylvain TurenneVikrant Saumitra mm20d401No ratings yet

- Endodontic Emergencies GuideDocument27 pagesEndodontic Emergencies GuideJitender Reddy100% (1)

- ATM ReportDocument16 pagesATM Reportsoftware8832100% (1)

- Format For Handout - Comparative Models of EducationDocument5 pagesFormat For Handout - Comparative Models of EducationAdrian AsiNo ratings yet

- Acl Data Analytics EbookDocument14 pagesAcl Data Analytics Ebookcassiemanok01No ratings yet

- Tiger Tales: From Colonial MalayaDocument16 pagesTiger Tales: From Colonial MalayamatarsNo ratings yet

- 2018 Cambridge Lower Second Progression Test Science Stage 8 QP Paper 2 - tcm143-430409Document16 pages2018 Cambridge Lower Second Progression Test Science Stage 8 QP Paper 2 - tcm143-430409AnisahNo ratings yet

- Disk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0Document16 pagesDisk Electrostatic Automatic Coating System - OTSON - DM - OTS - 5000!3!0otsontek9227No ratings yet

- IT Technician CVDocument3 pagesIT Technician CVRavi KumarNo ratings yet

- Learner's Activity Sheet: English (Quarter 4 - Week 5)Document5 pagesLearner's Activity Sheet: English (Quarter 4 - Week 5)Rufaidah AboNo ratings yet

- MUM202001007 - 300 TR Price BOQ ChillerDocument4 pagesMUM202001007 - 300 TR Price BOQ ChillerB DASNo ratings yet

- Curriculum Vitae: Name: Bhupal Shrestha Address: Kamalamai Municipality-12, Sindhuli, Nepal. Email: ObjectiveDocument1 pageCurriculum Vitae: Name: Bhupal Shrestha Address: Kamalamai Municipality-12, Sindhuli, Nepal. Email: Objectivebhupal shresthaNo ratings yet

- Oracle Time and Labor - Data SheetDocument5 pagesOracle Time and Labor - Data Sheetbilaltanoli@gmail.comNo ratings yet

- Manage a micro business with BSB30315Document3 pagesManage a micro business with BSB30315Theo A W JacksonNo ratings yet

- Chapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsDocument10 pagesChapter 1-The Indian Contract Act, 1872, Unit 1-Nature of ContractsALANKRIT TRIPATHINo ratings yet

- Bread Machine Sunbeam 5891Document44 pagesBread Machine Sunbeam 5891Tyler KirklandNo ratings yet

- Radiant Tube BurnersDocument18 pagesRadiant Tube BurnersRajeshNo ratings yet

- Family Culture and Traditions PaperDocument7 pagesFamily Culture and Traditions PaperAmit JindalNo ratings yet

- College Physics Reasoning and Relationships 2nd Edition Nicholas Giordano Solutions ManualDocument36 pagesCollege Physics Reasoning and Relationships 2nd Edition Nicholas Giordano Solutions Manualshippo.mackerels072100% (22)

- Nec TutorialDocument5 pagesNec TutorialbheemasenaNo ratings yet

- Sankalp Sanjeevani NEET: PhysicsDocument11 pagesSankalp Sanjeevani NEET: PhysicsKey RavenNo ratings yet

- Lesson Plan Garbage Gym GameDocument3 pagesLesson Plan Garbage Gym Gameapi-272479731No ratings yet

- Working Capital Management at Padmavathi Co-operative BankDocument53 pagesWorking Capital Management at Padmavathi Co-operative BankMamidishetty Manasa67% (3)

- School newspaper report teaches Present PerfectDocument2 pagesSchool newspaper report teaches Present PerfectMiro MiroNo ratings yet

- Scope of Incubator CentersDocument3 pagesScope of Incubator Centersanon_542600428No ratings yet

- Image Formation in Plane Mirrors: Ray DiagramsDocument3 pagesImage Formation in Plane Mirrors: Ray DiagramsSouvik BanerjeeNo ratings yet

- Iwwusa Final Report IdsDocument216 pagesIwwusa Final Report IdsRituNo ratings yet

- Public Speaking Skills for Career SuccessDocument7 pagesPublic Speaking Skills for Career SuccessAnish John100% (1)