Professional Documents

Culture Documents

All About Steel

Uploaded by

Anurag NairCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

All About Steel

Uploaded by

Anurag NairCopyright:

Available Formats

http://metalsupermarkets.

com/blog/types-of-steel/

http://metalsupermarkets.com/blog/alloy-steel/

http://metalsupermarkets.com/blog/stainless-steel/

http://metalsupermarkets.com/blog/tool-steel/

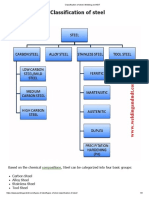

1) Carbon Steels:

Carbon steels contain trace amounts of alloying elements and account for 90% of total steel

production. Carbon steels can be further categorized into three groups depending on their carbon content:

Low Carbon Steels/Mild Steels contain up to 0.3% carbon

Medium Carbon Steels contain 0.3 0.6% carbon

High Carbon Steels contain more than 0.6% carbon

2) Alloy Steels:

Alloy steels contain alloying elements (e.g. manganese,

silicon, nickel, titanium, copper,chromium and aluminum) in varying proportions in order to manipulate the

steel's properties, such as

its hardenability, corrosion resistance, strength, formability, weldabilityor ductility.

Applications for alloys steel include pipelines, auto parts, transformers, power generators and electric

motors.

3) Stainless Steels:

Stainless steels generally contain between 10-20% chromium as the main alloying element and are

valued for high corrosion resistance. With over 11% chromium, steel is about 200 times more resistant to

corrosion than mild steel.

These steels can be divided into three groups based on their crystalline structure:

Austenitic: Austenitic steels are non-magnetic and non heat-treatable, and generally contain 18% chromium,

8% nickel and less than 0.8% carbon. Austenitic steels form the largest portion of the global stainless steel market

and are often used in food processing equipment, kitchen utensils and piping.

Ferritic: Ferritic steels contain trace amounts of nickel, 12-17% chromium, less than 0.1% carbon, along with

other alloying elements, such as molybdenum, aluminum or titanium. These magnetic steels cannot be hardened

with heat treatment, but can be strengthened by cold working.

Martensitic: Martensitic steels contain 11-17% chromium, less than 0.4% nickel and up to 1.2% carbon.

These magnetic and heat-treatable steels are used in knives, cutting tools, as well as dental and surgical equipment.

4) Tool Steels:

Tool steels contain tungsten, molybdenum, cobalt and vanadium in varying quantities to increase heat

resistance and durability, making them ideal for cutting and drilling equipment.

Steel products can also be divided by their shapes and related applications:

Long/Tubular Products include bars and rods, rails, wires, angles, pipes, and shapes and sections. These

products are commonly used in the automotive and construction sectors.

Flat Products include plates, sheets, coils and strips. These materials are mainly used in automotive parts,

appliances, packaging, shipbuilding, and construction.

Other Products include valves, fittings, and flanges and are mainly used as piping materials.

You might also like

- Types of Steel Grades and Their PropertiesDocument2 pagesTypes of Steel Grades and Their PropertiesPriyanathan ThayalanNo ratings yet

- Types of Steel: Carbon, Alloy, Stainless & ToolDocument7 pagesTypes of Steel: Carbon, Alloy, Stainless & ToolSakib RafeeNo ratings yet

- Metals & Material ScienceDocument21 pagesMetals & Material ScienceJaveed A. KhanNo ratings yet

- Different Types of Steel Grades and Their PropertiesDocument9 pagesDifferent Types of Steel Grades and Their PropertiesSyed Shoaib RazaNo ratings yet

- Types of Steel PDFDocument8 pagesTypes of Steel PDFIyappan MuruganNo ratings yet

- MEE 511 Course WorkDocument10 pagesMEE 511 Course WorktornakingstonNo ratings yet

- Designation of The Types of SteelsDocument6 pagesDesignation of The Types of SteelsDavid FernandezNo ratings yet

- Classification of Steel PDFDocument11 pagesClassification of Steel PDFkart_rl100% (2)

- Carbon SteelsDocument7 pagesCarbon SteelsRickle Vincent PilongoNo ratings yet

- Classifying and Understanding Steel GradesDocument8 pagesClassifying and Understanding Steel GradesSandeep PrajapatiNo ratings yet

- Types of Steel-Grades of SteelDocument7 pagesTypes of Steel-Grades of SteelmabroukNo ratings yet

- Types Properties Market Uses Steel ConstructionDocument36 pagesTypes Properties Market Uses Steel ConstructionLikhitaKaranamNo ratings yet

- Classification of Carbon and Low Alloy SteelsDocument4 pagesClassification of Carbon and Low Alloy SteelsmomoitachiNo ratings yet

- Ferrous and Non-Ferrous Alloys GuideDocument22 pagesFerrous and Non-Ferrous Alloys GuideHarsh V Ashok0% (1)

- Page 1 of 16Document16 pagesPage 1 of 16Wilfharry billyNo ratings yet

- Classifying Steels by Carbon Content and Alloying ElementsDocument3 pagesClassifying Steels by Carbon Content and Alloying ElementsHaider EjazNo ratings yet

- Tool SteelsDocument31 pagesTool SteelsMaheswaran MuthuNo ratings yet

- 202 Out1Document5 pages202 Out1professorNo ratings yet

- Ferrous Alloys GuideDocument11 pagesFerrous Alloys Guidekalaivananmek100% (1)

- Classification of Steels for Engineering Materials AssignmentDocument9 pagesClassification of Steels for Engineering Materials AssignmentZarak MirNo ratings yet

- Page 1 of 59Document59 pagesPage 1 of 59Wilfharry billyNo ratings yet

- Properties and applications of carbon and alloy steelsDocument12 pagesProperties and applications of carbon and alloy steelsananda narayananNo ratings yet

- Classification of Steel - Welding and NDTDocument3 pagesClassification of Steel - Welding and NDTAshif Iqubal100% (1)

- The 4 Main Types of Steel: Carbon, Alloy, Tool, and StainlessDocument4 pagesThe 4 Main Types of Steel: Carbon, Alloy, Tool, and StainlessVivek KambleNo ratings yet

- Materials and Processes For Agricultural and Biosystems EngineeringDocument17 pagesMaterials and Processes For Agricultural and Biosystems EngineeringMelanie D. Aquino BaguioNo ratings yet

- Steel in Industrial Construction: Jyoti Chaurasiya Priyanka Siddharth Agarwal Zeenat ParveenDocument14 pagesSteel in Industrial Construction: Jyoti Chaurasiya Priyanka Siddharth Agarwal Zeenat ParveenSanjay SaxenaNo ratings yet

- Manufacturing Materials ColouredDocument20 pagesManufacturing Materials Colouredramu reddyNo ratings yet

- Carbon steelDocument9 pagesCarbon steelArfanAliNo ratings yet

- AdditionalNotesonMaterialScience Tech 3Document27 pagesAdditionalNotesonMaterialScience Tech 3Sumit JainNo ratings yet

- Manufacturing ProcessesDocument17 pagesManufacturing ProcessesasowdiNo ratings yet

- 04 - MetE 414-Steel Designations - Fall 2023Document37 pages04 - MetE 414-Steel Designations - Fall 2023egesenturk2000No ratings yet

- Engineering MaterialsDocument53 pagesEngineering MaterialsRAGINI PASUPULETINo ratings yet

- Ferrous & Non Ferrous Material PropertiesDocument6 pagesFerrous & Non Ferrous Material PropertiesTusharNo ratings yet

- Metallurgy, Properties, and Uses of FerrousDocument37 pagesMetallurgy, Properties, and Uses of FerrousAl DrinNo ratings yet

- Stainless Steel Manufacturing ProcessesDocument27 pagesStainless Steel Manufacturing Processesmaadhesh100% (1)

- M 1.2.8 Carbon, Lowalloyed, Fine Grained, and ThermomechanicalyDocument17 pagesM 1.2.8 Carbon, Lowalloyed, Fine Grained, and Thermomechanicalydokumen qcNo ratings yet

- Chapter 5Document3 pagesChapter 5Dufton MusiliNo ratings yet

- Carbon in SteelDocument8 pagesCarbon in SteelJanice FernandezNo ratings yet

- 202004091956358706brijesh Ojna Engg FERROUS MATERIALS 2Document3 pages202004091956358706brijesh Ojna Engg FERROUS MATERIALS 2vinayak dalviNo ratings yet

- Cast Iron ComposiotionDocument34 pagesCast Iron ComposiotionMubash AbdNo ratings yet

- 7 Engineering MaterialsDocument58 pages7 Engineering MaterialsSOURABH GANGWARNo ratings yet

- Application of Steel AloyDocument2 pagesApplication of Steel AloyTâm QuangNo ratings yet

- Alloy Steel (A Textbook of Machine Design)Document4 pagesAlloy Steel (A Textbook of Machine Design)Muh FarhanNo ratings yet

- General Information About SteelsDocument20 pagesGeneral Information About SteelsilkinNo ratings yet

- Lecture 2 - ECE 2215 PDFDocument24 pagesLecture 2 - ECE 2215 PDFRando ClintonNo ratings yet

- Hss Tools and AppilcationDocument17 pagesHss Tools and AppilcationMeena SivasubramanianNo ratings yet

- Types of Metals and Their Uses (With Pictures)Document10 pagesTypes of Metals and Their Uses (With Pictures)Iman SadeghiNo ratings yet

- 300 Series Austenitic: Austenite Face Centered Cubic Alloys Chromium Nickel Molybdenum NitrogenDocument3 pages300 Series Austenitic: Austenite Face Centered Cubic Alloys Chromium Nickel Molybdenum NitrogenMohamad AzuwanNo ratings yet

- Bme - Part 1Document49 pagesBme - Part 1Sumanth ChallaNo ratings yet

- Classification and properties of carbon and low-alloy steelsDocument15 pagesClassification and properties of carbon and low-alloy steelscal2_uniNo ratings yet

- MSM Unit 4 Chap 2 (Ferrous Materials and Non-Ferrous Materials)Document15 pagesMSM Unit 4 Chap 2 (Ferrous Materials and Non-Ferrous Materials)rakeshpatkar332No ratings yet

- SteelDocument31 pagesSteelumairNo ratings yet

- MZ FS Unit - 1Document27 pagesMZ FS Unit - 1Jai KumarNo ratings yet

- UNIT 2 PPT 1Document42 pagesUNIT 2 PPT 1neha yarrapothuNo ratings yet

- Engineering Materials Classification and Properties GuideDocument53 pagesEngineering Materials Classification and Properties GuideGeno Martinez100% (1)

- Aircraft Material HardwareDocument307 pagesAircraft Material HardwareMorrisNo ratings yet

- Engineering Metallurgy: Misan University-College of EngineeringDocument16 pagesEngineering Metallurgy: Misan University-College of Engineeringbone manNo ratings yet

- Cutting Tool Materials - Properties and List of MaterialsDocument3 pagesCutting Tool Materials - Properties and List of MaterialsarulsivagiriNo ratings yet

- Media Research TermsDocument1 pageMedia Research TermsAnurag NairNo ratings yet

- Top 3 Newspapers in IndiaDocument3 pagesTop 3 Newspapers in IndiaAnurag NairNo ratings yet

- Venn Diagram Logic Problem TutorialDocument9 pagesVenn Diagram Logic Problem TutorialThe-Truth100% (8)

- WatchesDocument2 pagesWatchesAnurag NairNo ratings yet

- Media LinksDocument1 pageMedia LinksAnurag NairNo ratings yet

- Questionaire CBBDocument3 pagesQuestionaire CBBAnurag NairNo ratings yet

- Forex Markets & Risk Management: Deenar KaswaDocument1 pageForex Markets & Risk Management: Deenar KaswaAnurag NairNo ratings yet

- Abhishek Grover Charandeep Singh Navneet KaurDocument9 pagesAbhishek Grover Charandeep Singh Navneet KaurAnurag NairNo ratings yet

- Marketing 2014 - 16 Summer Internship Project AllocationDocument1 pageMarketing 2014 - 16 Summer Internship Project AllocationAnurag NairNo ratings yet

- Current TrendsDocument3 pagesCurrent TrendsAnurag NairNo ratings yet

- Date Feb 24thDocument1 pageDate Feb 24thAnurag NairNo ratings yet

- File FactorsDocument3 pagesFile FactorsSendhilNathanNo ratings yet

- Submitted By:: Shristi Podar 109 Yash Inani 125 Project - Iind SemesterDocument4 pagesSubmitted By:: Shristi Podar 109 Yash Inani 125 Project - Iind SemesterAnurag NairNo ratings yet

- CBDocument1 pageCBAnurag NairNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Management: A Global PerspectiveDocument11 pagesManagement: A Global PerspectiveAnurag NairNo ratings yet

- Indian AutoDocument15 pagesIndian AutoaborhadeNo ratings yet

- Sap kr97Document79 pagesSap kr97tva400% (1)

- Use of Pyroxenite in Place of DolomiteDocument4 pagesUse of Pyroxenite in Place of DolomiteDhirender KapoorNo ratings yet

- Introduction Electrical MotorDocument36 pagesIntroduction Electrical MotorYajidNo ratings yet

- Almex Light Weight BrochureDocument16 pagesAlmex Light Weight BrochureGijoNo ratings yet

- 2008 Nissan Teana J32 Service Manual-ECDocument414 pages2008 Nissan Teana J32 Service Manual-ECMrihex100% (3)

- Stress Corrosion Cracking of ASTM A517 Steel in Liquid Ammonia - Environmental FactorsDocument11 pagesStress Corrosion Cracking of ASTM A517 Steel in Liquid Ammonia - Environmental FactorsEzzah HanifNo ratings yet

- Contents Centrifugal Oil CleanersDocument12 pagesContents Centrifugal Oil Cleanersg33sp0tNo ratings yet

- 7 SFW CFB BrochurerDocument11 pages7 SFW CFB BrochurerJuan SalcidoNo ratings yet

- Split Tensile Strength of ConcreteDocument9 pagesSplit Tensile Strength of Concreteabhineet srivastavaNo ratings yet

- Kobe Works eDocument13 pagesKobe Works eJagdish ShresthaNo ratings yet

- ACI Building Code Requirements for Thin Shells and Folded PlatesDocument84 pagesACI Building Code Requirements for Thin Shells and Folded PlateskrishnanunniNo ratings yet

- Week 2 Module - CHEMDocument13 pagesWeek 2 Module - CHEMMichael AustriaNo ratings yet

- Refrentador de Caras - Bb5000Document4 pagesRefrentador de Caras - Bb5000Marco BacianNo ratings yet

- Chemsheets GCSE 1069 Allotropes of CarbonDocument1 pageChemsheets GCSE 1069 Allotropes of CarbonNoah KellerNo ratings yet

- Chapter 12 - P-N JunctionDocument69 pagesChapter 12 - P-N JunctionShelly RismawatiNo ratings yet

- Cenizabusinessplan 2Document68 pagesCenizabusinessplan 2Dexterr DivinooNo ratings yet

- Transporte IntermodalDocument8 pagesTransporte IntermodalDavid LatorreNo ratings yet

- Study of Advanced Structural Concepts For FuselageDocument200 pagesStudy of Advanced Structural Concepts For FuselageaerostressNo ratings yet

- CV TemplateV2Document9 pagesCV TemplateV2Mark MarianoNo ratings yet

- Overall Heat Transfer CoefficientDocument3 pagesOverall Heat Transfer CoefficientcordobaluisfNo ratings yet

- Saudi Aramco furnace dryout inspection checklistDocument4 pagesSaudi Aramco furnace dryout inspection checklistAnonymous S9qBDVky0% (1)

- How Enzymes Dissolve EggsDocument3 pagesHow Enzymes Dissolve Eggsbhanuday100% (1)

- AURORA KN95 Face Mask Introduction 2020Document23 pagesAURORA KN95 Face Mask Introduction 2020victorcamposNo ratings yet

- Coutnry Wise All Commodities 2023 by IndiaDocument9 pagesCoutnry Wise All Commodities 2023 by IndiaindienkhanNo ratings yet

- Compact Ring-Torsion Load Cells RTNDocument4 pagesCompact Ring-Torsion Load Cells RTNAbdul Moeez AliNo ratings yet

- Johnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesDocument40 pagesJohnson Controls Automotive Experience Global Supplier Standards Manual Tooling and Equipment Chapter 2 Metals Stamping DiesMostafa Abd El AlemNo ratings yet

- Layout Arrangement For Centrifugal Pump PipingDocument20 pagesLayout Arrangement For Centrifugal Pump PipingKyaw Kyaw Aung50% (2)

- .Auwp Contentuploads2022030525 055 Install Guide Commercial Package Ver. 9 PDFDocument56 pages.Auwp Contentuploads2022030525 055 Install Guide Commercial Package Ver. 9 PDF7tddprzxbbNo ratings yet

- Calculating Expansion TanksDocument4 pagesCalculating Expansion TanksanescuveronicaNo ratings yet

- Specification Ball ValveDocument7 pagesSpecification Ball ValveJoshua HernandezNo ratings yet