Professional Documents

Culture Documents

IEC 61238-1 Compression and Mechanical Connectors For Power Cables

Uploaded by

quarktop123456Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IEC 61238-1 Compression and Mechanical Connectors For Power Cables

Uploaded by

quarktop123456Copyright:

Available Formats

1(A~E)-2

2015.4.9 11:46 AM

E2

MAC2 Lower-2540-color 2540DPI 175LPI

TECHINICAL INFORMATION

IEC 61238-1 Compression and Mechanical Connectors for Power Cables

for rated voltages up to 30 kV (Um = 36 kV).

DONG-A Terminal Lug "PPIO & PPIT" type, PPEO & PPET Type(see page E4~E15) are complied with

IEC61238-1 requirements and they have been carried out the tests according to "Class A" of IEC61238-1.

1. Scope and object of IEC61238-1

Compression and mechanical connectors for power cables for rated voltages up to 30kV(Um=36kV),

e.g. burried cables or cables installed in buildings, having

a) conductors complying with IEC60228 and IEC60228A with cross-sectional areas 10mm2 and

greater for copper and 16mm2 and greater for aluminum,

b) a maximum continuous conductor temperature not exceeding 90

Class A

These are connectors intended for electricity distribution or industrial networks in which they can be subjected

to short-circuits of relatively high intensity and duration. As a consequence, Class A connectors are suitable

for the majority of applications.

Class B

These are connectors for networks in which overloads or short-circuits are rapidly cleared by the installed

protective devices, e.g. fast-acting fuses.

Depending on the application, the connectors are subjected to the following tests :

Class A : heat cycle, short-circuit tests and mechanical tests.

Class B : heat cycle tests only.

2. IEC 61238-1 Class A Test Process.

Installation : All conductors of the same cross-sectional area in the test loop shall be taken from the same

continuous core and installed in a location where the air calm and the ambient temperature

between 15 and 30

Typical test circuit for through connectors and terminal lugs

Heat Cycle Test - Total 1000 cycles required.

- First heat cycle :

Current is circulated in the test loop, bringing the reference conductor to 120 at equilibrium.

Equilibrium is defined as the moment when the reference conductor and the connectors do not vary in

temperature by more than 2 K for 15 min.if the temperature of the median connector is equal to or greater

than 100 the reference conductor temperature for subsequent heat cycles shall be deemed to be 120

if not, then the current shall be increased until the median connector temperature reaches 100 at

equilibrium, subject to the reference conductor temperature not exceeding 140 If the temperature of the

median connector does not reach 100 even with a reference conductor temperature of 140 the test

shall be continued at that temperature.

E2

www.dongabestech.com

1(A~E)-2

2015.4.9 11:46 AM

E3

MAC2 Lower-2540-color 2540DPI 175LPI

TECHINICAL INFORMATION

- Second heat cycle :

The second heat cycle is to determine the heat cycle duration and temperature profile which will be used on the

test loop for all subsequent heat cycles. Current is circulated in the loop until the main reference conductor

temperature reaches the value

determined in first heat cycle, with a tolerance of +6/0 K and the median

connector temperature is stable within a band of 2K over a 10 min period.

An elevated current may be used to reduce the heating period.

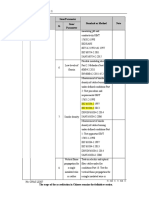

Nominal conductor

Al 16A50 50A150 150A630 A630

2

cross-sectional area, A mm Cu 10A35 35A95 95A400 A400

min

Time

5

10

15

20

- Subsequent heat cycles :

Measurements shall be made at the following cycles (Class A).

0 (before the first heat cycle)

200 cycles, before short-circuit

200 cycles, after short-circuit

250

Then every 75 cycles

(in total 14 measurements)

Short-circuit tests (for Class A connectors only).

Six short-circuits are applied after the 200th heat cycle.

The short-circuit current level shall be such that it raises the bare reference conductors from a temperature

of 35 to a temperature between 250 and 270

The maximum temperature, time and approximate current, or the actual current and time, used for the short-circuit

test, shall be recorded and stated in the test report. After each short-circuit, the test loop shall be cooled to a

temperature 35

Mechanical Tests.

The conductor lengths, between connector and tensile test machine jaws, shall be 500mm.

The rate of application of the load shall not exceed 10N per square millimetre of cross-sectional area and per

second up to the value in copper 60 x Aa(mm2) : maximum 20000N, which is then maintained for 1 min.

Quality Products.

Barrel Diameter : Type of conductors - compacted.

- non-compacted.

- flexible(class 5 and 6, according to IEC60228)

- number and arrangement of strands.

Color coding on the barrel for easy selection of crimping dies.

Eye-hole(inspection hole)

Quality Approved by DnV(Det Norske Veritas).

Certificate No : E-10595

Application : Cable shoes for installation inside switchboards/ enclosures onboard ships and mobile offshore units.

www.dongabestech.com

E3

1(A~E)-2

2015.4.9 11:46 AM

E4

MAC2 Lower-2540-color 2540DPI 175LPI

TERMINAL LUG - Comply with IEC61238-1

COPPER CABLES ONLY

Available wire range : IEC standard cables

Material : High Conductivity copper per 99.9% up with Electro-Tin Plated.

Voltage Rating : According to IEC61238-1 up to 30kV (Um 36kV)

ONE-HOLE

Fig 1

Wire Range(mm2)

Soild /

Stranded FLEX

0.75

1.5

2.5

10

16

25

0.75

1.5

2.5

10

16

25

35

35

50

50

70

70

PART NO.

PPEO0000.75 - xx03

PPEO0000.75 - xx04

PPEO0000.75 - xx05

PPIO0001.5-xx03

PPIO0001.5-xx04

PPIO0001.5-xx05

PPIO0001.5-xx06

PPIO0002.5-xx03

PPIO0002.5-xx04

PPIO0002.5-xx05

PPIO0002.5-xx06

PPIO0002.5-xx08

PPIO0004-xx03

PPIO0004-xx04

PPIO0004-xx05

PPIO0004-xx06

PPIO0004-xx08

PPIO0006-xx04

PPIO0006-xx05

PPIO0006-xx06

PPIO0006-xx08

PPIO0006-xx10

PPIO0010-xx05

PPIO0010-xx06

PPIO0010-xx08

PPIO0010-xx10

PPIO0010-xx12

PPIO0016-xx05

PPIO0016-xx06

PPIO0016-xx08

PPIO0016-xx10

PPIO0016-xx12

PPIO0025-xx05

PPIO0025-xx06

PPIO0025-xx08

PPIO0025-xx10

PPIO0025-xx12

PPIO0035-xx05

PPIO0035-xx06

PPIO0035-xx08

PPIO0035-xx10

PPIO0035-xx12

PPIO0035-xx05-F

PPIO0035-xx06-F

PPIO0035-xx08-F

PPIO0035-xx10-F

PPIO0035-xx12-F

PPIO0050-xx05

PPIO0050-xx06

PPIO0050-xx08

PPIO0050-xx10

PPIO0050-xx12

PPIO0050-xx05-F

PPIO0050-xx06-F

PPIO0050-xx08-F

PPIO0050-xx10-F

PPIO0050-xx12-F

PPIO0070-xx08

PPIO0070-xx10

PPIO0070-xx12

PPIO0070-xx14

PPIO0070-xx16

PPIO0070-xx08-F

PPIO0070-xx10-F

PPIO0070-xx12-F

PPIO0070-xx14-F

PPIO0070-xx16-F

Fig 2

Stud

Size

3

4

5

3

4

5

6

3

4

5

6

8

3

4

5

6

8

4

5

6

8

10

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

8

10

12

14

16

8

10

12

14

16

Fig 3

Certificate No : E-10595

Dimension (mm)

d2

3.3

4.3

5.4

3.3

4.3

5.4

6.4

3.3

4.3

5.4

6.4

8.5

3.3

4.4

5.4

6.4

8.5

4.4

5.4

6.4

8.5

10.5

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

8.4

10.5

13

15

17

8.4

10.5

13

15

17

W

(Min)

6.5

d1

2.8

C

1-S

2-L

17

1.8

2.3

19

21

9

6.5

DATH-40

TOOL

17

19

21

25.5

13

6.5

Fig1

Fig2

19.5

3

3.5

10

21.5

23.5

28

13

7.5

11

21.5

DATH-60

TOOL

26

15.5

30

30

40

13.5

36

46

41

51

33

43

39

49

41

51

43

48

48

53

45

50

48

53

4.5

15

25

19

11

13.5

5.5

15

25

19

13.5

7

20

25

19

15.6

8.2

20

25

19

17

Drawing

2-L

19

6.5

9.5

1-S

17

Dies

No.()

20

25

19

45

50

48

53

DCD30010C

DCD30016C

DCD30025C

DCD30035C

DCD30035F

19

9.5

23

35

53

65

DCD30050C

21

11

23

35

53

65

DCD30050F

11.5

25

35

64

74

DCD30070C

13

25

35

64

74

DCD30070F

Fig1

Fig2

Fig3

Fig4

Fig5

22

25

24

() Dies No : See detail page E44~E45

E4

www.dongabestech.com

1(A~E)-2

2015.4.9 11:46 AM

E5

MAC2 Lower-2540-color 2540DPI 175LPI

TERMINAL LUG - Comply with IEC61238-1

HOW TO ORDER

P P I O 0000 - X R 0 0 - X

Barrel I.D / See wire range

Stud Size (i.e. 10=M10, 12=M12 ... etc)

Barrel Length (i.e. 1-CI = standard barrel, 2-CI = Long Barrel)

Serial Number

Product Code (i.e. PPIO = One Hole type, PPIT = Two Hole type)

Wire Range

(mm2)

Soild /

Stranded FLEX

95

95

120

120

150

150

185

185

240

240

300

300

400

500

630

PART NO.

PPIO0095-xx08

PPIO0095-xx10

PPIO0095-xx12

PPIO0095-xx14

PPIO0095-xx16

PPIO0095-xx08-F

PPIO0095-xx10-F

PPIO0095-xx12-F

PPIO0095-xx14-F

PPIO0095-xx16-F

PPIO00120-xx08

PPIO00120-xx10

PPIO00120-xx12

PPIO00120-xx14

PPIO00120-xx16

PPIO00120-xx08-F

PPIO00120-xx10-F

PPIO00120-xx12-F

PPIO00120-xx14-F

PPIO00120-xx16-F

PPIO00150-xx08

PPIO00150-xx10

PPIO00150-xx12

PPIO00150-xx14

PPIO00150-xx16

PPIO00150-xx08-F

PPIO00150-xx10-F

PPIO00150-xx12-F

PPIO00150-xx14-F

PPIO00150-xx16-F

PPIO00185-xx10

PPIO00185-xx12

PPIO00185-xx14

PPIO00185-xx16

PPIO00185-xx20

PPIO00185-xx10-F

PPIO00185-xx12-F

PPIO00185-xx14-F

PPIO00185-xx16-F

PPIO00185-xx20-F

PPIO00240-xx10

PPIO00240-xx12

PPIO00240-xx14

PPIO00240-xx16

PPIO00240-xx20

PPIO00240-xx10-F

PPIO00240-xx12-F

PPIO00240-xx14-F

PPIO00240-xx16-F

PPIO00240-xx20-F

PPIO00300-xx10

PPIO00300-xx12

PPIO00300-xx14

PPIO00300-xx16

PPIO00300-xx20

PPIO00300-xx24

PPIO00300-xx10-F

PPIO00300-xx12-F

PPIO00300-xx14-F

PPIO00300-xx16-F

PPIO00300-xx20-F

PPIO00300-xx24-F

PPIO00400-xx12

PPIO00400-xx14

PPIO00400-xx16

PPIO00400-xx20

PPIO00400-xx24

PPIO00500-xx12

PPIO00500-xx14

PPIO00500-xx16

PPIO00500-xx20

PPIO00500-xx24

PPIO00630-xx12

PPIO00630-xx14

PPIO00630xx16

PPIO00630-xx20

PPIO00630-xx24

Stud

Size

8

10

12

14

16

8

10

12

14

16

8

10

12

14

16

8

10

12

14

16

8

10

12

14

16

8

10

12

14

16

10

12

14

16

20

10

12

14

16

20

10

12

14

16

20

10

12

14

16

20

10

12

14

16

20

24

10

12

14

16

20

24

12

14

16

20

24

12

14

16

20

24

12

14

16

20

24

Dimension (mm)

d2

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

10.5

13

15

17

21

10.5

13

15

17

21

10.5

13

15

17

21

10.5

13

15

17

21

10.5

13

15

17

21

25

10.5

13

15

17

21

25

13

15

17

21

25

13

15

17

21

25

13

15

17

21

25

W

(Min)

d1

25.5

Dies

No.()

1-S

2-L

1-S

2-L

13.5

31

45

70

84

DCD30095C

28

15

31

45

70

84

DCD30095F

29

15.5

35

45

85

95

DCD30120C

31.5

17

35

45

85

95

DCD30120F

32.5

17

35

45

87

97

DCD30150C

35.5

19

35

45

87

97

DCD30150F

35.5

19

40

50

93

103

DCD30185C

38.5

21

40

50

93

103

DCD30185F

41

21.5

45

55

100

110

DCD30240C

43.5

23

45

55

100

110

DCD30240F

46

24.5

58

68

122

132

DSD30300C

48

26

58

68

122

132

DSD30300F

55

27.5

70

137

DSD30400C

60

31

70

150

DSD30500C

66.5

35.5

80

162

DSD30630C

Drawing

Fig1

Fig2

Fig3

Fig4

Fig5

() Dies No : See detail page E44~E45

www.dongabestech.com

E5

1(A~E)-2

2015.4.9 11:46 AM

E6

MAC2 Lower-2540-color 2540DPI 175LPI

TERMINAL LUG - Comply with IEC61238-1

COPPER CABLES ONLY

Available wire range : IEC standard cables

Material : High Conductivity copper per 99.9% up with Electro-Tin Plated.

Voltage Rating : According to IEC61238-1 up to 30kV (Um 36kV)

TWO-HOLE

Certificate No : E-10595

Fig 3

Fig 2

Fig 1

Wire Range

(mm2)

Soild /

Stranded FLEX

10

16

25

10

16

25

35

35

50

50

70

70

95

95

PART NO.

PPIT0010-xx05

PPIT0010-xx06

PPIT0010-xx08

PPIT0010-xx10

PPIT0010-xx12

PPIT0016-xx05

PPIT0016-xx06

PPIT0016-xx08

PPIT0016-xx10

PPIT0016-xx12

PPIT0025-xx05

PPIT0025-xx06

PPIT0025-xx08

PPIT0025-xx10

PPIT0025-xx12

PPIT0035-xx05

PPIT0035-xx06

PPIT0035-xx08

PPIT0035-xx10

PPIT0035-xx12

PPIT0035-xx05-F

PPIT0035-xx06-F

PPIT0035-xx08-F

PPIT0035-xx10-F

PPIT0035-xx12-F

PPIT0050-xx05

PPIT0050-xx06

PPIT0050-xx08

PPIT0050-xx10

PPIT0050-xx12

PPIT0050-xx05-F

PPIT0050-xx06-F

PPIT0050-xx08-F

PPIT0050-xx10-F

PPIT0050-xx12-F

PPIT0070-xx08

PPIT0070-xx10

PPIT0070-xx12

PPIT0070-xx14

PPIT0070-xx16

PPIT0070-xx08-F

PPIT0070-xx10-F

PPIT0070-xx12-F

PPIT0070-xx14-F

PPIT0070-xx16-F

PPIT0095-xx08

PPIT0095-xx10

PPIT0095-xx12

PPIT0095-xx14

PPIT0095-xx16

PPIT0095-xx08-F

PPIT0095-xx10-F

PPIT0095-xx12-F

PPIT0095-xx14-F

PPIT0095-xx16-F

Stud

Size

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

8

10

12

14

16

8

10

12

14

16

8

10

12

14

16

8

10

12

14

16

Dimension (mm)

d2

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

W

(Min)

d1

C

1-S

2-L

9

13.5

16~

44.5

4.5

15

25

19

11

13.5

44.5

5.5

15

25

19

13.5

44.5

20

15.6

8.2

20

44.5

20

25

19

19

21

2-L

74.5

84.5

80.5

90.5

85.5

95.5

77.5

87.5

83.5

93.5

85.5

95.5

87.5

92.5

92.5

97.5

89.5

94.5

92.5

97.5

89.5

94.5

92.5

97.5

25

19

17

1-S

25

19

44.5

Dies

No.

Drawing

DCD30010C

DCD30016C

DCD30025C

DCD30035C

DCD30035F

44.5

9.5

23

35

97.5

109.5

DCD30050C

44.5

11

23

35

97.5

109.5

DCD30050F

44.5

11.5

25

35

108.5

118.5

DCD30070C

24

44.5

13

25

35

108.5

118.5

DCD30070F

25.5

44.5

13.5

31

45

114.5

128.5

DCD30095C

28

44.5

15

31

45

114.5

128.5

Fig1

Fig2

Fig3

Fig4

Fig5

22

25

DCD30095F

() Dies No : See detail page E44~E45

E6

www.dongabestech.com

1(A~E)-2

2015.4.9 11:46 AM

E7

MAC2 Lower-2540-color 2540DPI 175LPI

TERMINAL LUG - Comply with IEC61238-1

HOW TO ORDER

P P I T 0000 - X R 0 0 - X

Barrel I.D / See wire range

Stud Size (i.e. 10=M10, 12=M12 ... etc)

Barrel Length (i.e. 1-CI = standard barrel, 2-CI = Long Barrel)

Serial Number

Product Code (i.e. PPIO = One Hole type, PPIT = Two Hole type)

Wire Range

(mm2)

Soild /

Stranded FLEX

120

120

150

150

185

185

240

240

300

300

400

500

630

PART NO.

PPIT00120-xx08

PPIT00120-xx10

PPIT00120-xx12

PPIT00120-xx14

PPIT00120-xx16

PPIT00120-xx08-F

PPIT00120-xx10-F

PPIT00120-xx12-F

PPIT00120-xx14-F

PPIT00120-xx16-F

PPIT00150-xx08

PPIT00150-xx10

PPIT00150-xx12

PPIT00150-xx14

PPIT00150-xx16

PPIT00150-xx08-F

PPIT00150-xx10-F

PPIT00150-xx12-F

PPIT00150-xx14-F

PPIT00150-xx16-F

PPIT00185-xx10

PPIT00185-xx12

PPIT00185-xx14

PPIT00185-xx16

PPIT00185-xx20

PPIT00185-xx10-F

PPIT00185-xx12-F

PPIT00185-xx14-F

PPIT00185-xx16-F

PPIT00185-xx20-F

PPIT00240-xx10

PPIT00240-xx12

PPIT00240-xx14

PPIT00240-xx16

PPIT00240-xx20

PPIT00240-xx10-F

PPIT00240-xx12-F

PPIT00240-xx14-F

PPIT00240-xx16-F

PPIT00240-xx20-F

PPIT00300-xx10

PPIT00300-xx12

PPIT00300-xx14

PPIT00300-xx16

PPIT00300-xx20

PPIT00300-xx24

PPIT00300-xx10-F

PPIT00300-xx12-F

PPIT00300-xx14-F

PPIT00300-xx16-F

PPIT00300-xx20-F

PPIT00300-xx24-F

PPIT00400-xx12

PPIT00400-xx14

PPIT00400-xx16

PPIT00400-xx20

PPIT00400-xx24

PPIT00500-xx12

PPIT00500-xx14

PPIT00500-xx16

PPIT00500-xx20

PPIT00500-xx24

PPIT00630-xx12

PPIT00630-xx14

PPIT00630xx16

PPIT00630-xx20

PPIT00630-xx24

Stud

Size

8

10

12

14

16

8

10

12

14

16

8

10

12

14

16

8

10

12

14

16

10

12

14

16

20

10

12

14

16

20

10

12

14

16

20

10

12

14

16

20

10

12

14

16

20

24

10

12

14

16

20

24

12

14

16

20

24

12

14

16

20

24

12

14

16

20

24

Dimension (mm)

d2

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

10.5

13

15

17

21

10.5

13

15

17

21

10.5

13

15

17

21

10.5

13

15

17

21

10.5

13

15

17

21

25

10.5

13

15

17

21

25

13

15

17

21

25

13

15

17

21

25

13

15

17

21

25

Dies

No.

W

(Min)

d1

29

44.5

15.5

35

45

129.5

139.5

DCD30120C

31.5

44.5

17

35

45

129.5

139.5

DCD30120F

32.5

44.5

17

35

45

131.5

141.5

DCD30150C

35.5

44.5

19

35

45

131.5

141.5

DCD30150F

35.5

44.5

19

40

50

137.5

147.5

DCD30185C

38.5

44.5

21

40

50

137.5

147.5

DCD30185F

41

44.5

21.5

45

55

144.5

154.5

DCD30240C

43.5

44.5

23

45

55

144.5

154.5

DCD30240F

46

44.5

24.5

58

68

166.5

176.5

DSD30300C

48

44.5

26

58

68

166.5

176.5

DSD30300F

55

44.5

27.5

70

181.5

DSD30400C

60

44.5

31

70

194.5

DSD30500C

66.5

44.5

35.5

80

206.5

DSD30630C

1-S

2-L

1-S

Drawing

2-L

Fig1

Fig2

Fig3

Fig4

Fig5

() Dies No : See detail page E44~E45

www.dongabestech.com

E7

1(A~E)-2

2015.4.9 11:48 AM

E8

MAC2 Lower-2540-color 2540DPI 175LPI

TERMINAL LUG - Comply with IEC61238-1

COPPER CABLES ONLY

Available wire range : IEC standard cables of Metric Cables.

Color coded on the barrel to eliminate errors during

installation and select to easy crimping dies.

Material : High Conductivity copper per 99.9% up

with Electro-Tin Plated.

Voltage Rating : 35kV

ONE-HOLE(ROUND TYPE)

ONE-HOLE(SQUARE TYPE)

Certificate No : E-11820

Fig. 1

Wire Range

Metric

CODE

FLEX

0.75

0.75

1.5

2.5

10

16

25

1.5

2.5

10

16

25

35

35

50

50

70

70

Part No.

PPEO0000.75 - xx03 - xx04 - xx05 PPEO0001.5 - xx03 - xx04 - xx05 - xx06 PPEO0002.5 - xx03 - xx04 - xx05 - xx06 - xx08 PPEO0004 - xx03 - xx04 - xx05 - xx06 - xx08 PPEO0006 - xx04 - xx05 - xx06 - xx08 - xx10 PPEO0101 - xx05 - xx06 - xx08 - xx10 - xx12 PPEO0102 - xx05 - xx06 - xx08 - xx10 - xx12 PPEO0103 - xx05 - xx06 - xx08 - xx10 - xx12 PPEO0104 - xx05 - xx06 - xx08 - xx10 - xx12 - xx05-F

- xx06-F

- xx08-F

- xx10-F

- xx12-F

PPEO0105 - xx05 - xx06 - xx08 - xx10 - xx12 - xx14 - xx16 PPEO0106 - xx05 - xx06 - xx08 - xx10 - xx12 - xx14 - xx16 PPEO0107 - xx08 - xx10 - xx12 - xx14 - xx16 PPEO0108 - xx08 - xx10 - xx12 - xx14 - xx16 -

Fig. 2

Stud

Size

3

4

5

3

4

5

6

3

4

5

6

8

4

4

5

6

8

4

5

6

8

10

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

14

16

5

6

8

10

12

14

16

8

10

12

14

16

8

10

12

14

16

Dimension

W

d1

6.5

9

2.8

1.3

6.5

3.3

1.8

9

6.5

9

4.2

2.3

13

6.5

9.5

13

7.5

11

5.5

3.5

15.5

9.5

15.5

6.6

4.6

18

10.5

15.5

7.5

5.5

18

13.5

9.5

7.2

15.5

18

16

11

8.5

18

17

12

8.8

12

9.5

17.5

24.5

19

13.2

10.2

24

21

14.5

11.2

25

23

16

12.5

d2

3.3

4.3

5.4

3.3

4.3

5.4

6.4

3.3

4.3

5.4

6.4

8.4

4.3

4.3

5.4

6.4

8.4

4.4

5.4

6.4

8.4

10.5

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

15

17

5.4

6.4

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.2

10.5

8.5

10.5

12.5

5

6

8.5

10.5

12.5

17

5

6

8

8.5

10.5

12.5

17

10

5

6

8

4.5

13

17

14

6.2

C

1-S

Dies Part No.()

L

2-L

1-S

2-L

17

19

17

6

19

21

17

19

21

25.5

19.5

21.5

23.5

28

21.5

DATH-40

TOOL

Fig 1

Fig 2

DATH-60

TOOL

26

10

30

15

21

33

39

39

45

20

8.2

23

10.7

43

49

14

6.2

33

39

20

8.2

39

45

23

10.7

43

49

17

40

46

23

10.7

44

50

20

9.3

46

52

23

10.7

50

56

22

10

48

54

22

10.7

50

65

55

70

52

67

55

70

54

67

57

70

64

80

15

17

28

13

25

11

20

13

25

11

13

31

14.5

23

26

26

20

35

22

28

21

20

20

28

Drawing

24

35

35

40

DCI3

- 0010C

DCI3

- 0016C

DCI3

- 0025C

DCI3

- 0035C

DCI3

- 0035F

Fig 1

Fig 2

Fig 3

Fig 4

Fig 5

DCI3

- 0050C

DCI3

- 0050F

DCI3

- 0070C

DCI3

- 0070F

() Dies No : See detail page E44~E45

E8

www.dongabestech.com

1(A~E)-2

2015.4.9 11:48 AM

E9

MAC2 Lower-2540-color 2540DPI 175LPI

TERMINAL LUG - Comply with IEC61238-1

HOW TO ORDER

PPEO 0101 - X X 0 5 - F

Barrel I.D/see drawing

Stud Size

Wire Part

Tongue Form

R ; Round Type

S ; Square Type

Barrel Form

Product Part

PPEO ; One(1)-Hole Type

Fig. 3

S ; One(1) Clamping Type

CODE

FLEX

95

95

120

150

185

200

120

150

185

200

240

300

240

300

400

500

630

Part No.

PPEO0109 - xx08 - xx10 - xx12 - xx14 - xx16 - xx08-F

- xx10-F

- xx12-F

- xx14-F

- xx16-F

PPEO0110 - xx08 - xx10 - xx12 - xx14 - xx16 PPEO0111 - xx08 - xx10 - xx12 - xx14 - xx16 PPEO0111 - xx08-F

- xx10-F

- xx12-F

- xx14-F

- xx16-F

PPEO0112 - xx10 - xx12 - xx14 - xx16 - xx20 PPEO0113 - xx10 - xx12 - xx14 - xx16 - xx20 - xx10-F

- xx12-F

- xx14-F

- xx16-F

- xx20-F

PPEO0114 - xx10 - xx12 - xx14 - xx16 - xx18 - xx20 - xx24 PPEO0115 - xx10 - xx12 - xx14 - xx16 - xx20 - xx24 - xx10-F

- xx12-F

- xx14-F

- xx16-F

- xx20-F

- xx24-F

PPEO0116 - xx12 - xx14 - xx16 - xx20 - xx24 PPEO0117 - xx12 - xx14 - xx16 - xx20 - xx24 PPEO0118 - xx12 - xx14 - xx16 - xx20 - xx24 -

Stud

Size

8

10

12

14

16

8

10

12

14

16

8

12

12

14

16

8

10

12

14

16

8

10

12

14

16

10

12

14

16

20

10

12

14

16

20

10

12

14

16

20

10

12

14

16

18

20

24

10

12

14

16

20

24

10

12

14

16

20

24

12

14

16

20

24

12

14

16

20

24

12

14

16

20

24

Fig. 5

L ; Two(2) Clamping Type

PPET ; Double(2)-Hole Type

Wire Range

Metric

Fig. 4

For Flex, Conductor(Belled End)

Dimension

W

d1

24.5

17

13.3

26

18

14

27.5

19

15.2

31

21

16.8

31

22

17.5

34

23.5

18.5

37.5

25

20

37.5

26

20.5

40.5

28

22

43.5

30.5

24

46

32

25

49

34

26.5

56.5

64.5

40

45

30

35.5

d2

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

10.5

13

15

17

21

10.5

13

15

17

21

10.5

13

15

17

21

10.5

13

15

17

19

21

25

10.5

13

15

17

21

25

10.5

13

15

17

21

25

13

15

17

21

25

13

15

17

21

25

13

15

17

21

25

31

14.5

30

Dies Part No.()

L

2-L

1-S

2-L

29

40

69

80

DCI3

- 0095C

14

29

37

69

82

DCI3

- 0095F

31

14.5

29

50

70

90

DCI3

- 0120C

31

14.5

32

50

77

94

DCI3

- 0150C

-0120F

35

16

30

45

80

95

33

14.5

35

50

83

98

37

16.5

87

102

33

14.5

88

98

37

16.5

92

102

38

18

94

105

34

14.5

1-S

40

40

50

51

102

50

46

22

36

15

48

22

48

22

36

15

24

36

15

54

110

122

57

125

127

24

48

23

DCI3

- 0200C

-0185F

Fig 1

Fig 2

Fig 3

Fig 4

Fig 5

DCI3

- 0240C

DSI3

- 0240C

DCI3

- 0300C

-0240F

DSI3

- 0300C

DSI3

- 0300F

DSI3

- 0400C

131

122

60

48

DCI3

- 0185C

-0150F

114

57

48

Drawing

DSI3

- 500C

135

70

150

DSI3

- 0630C

() Dies No : See detail page E44~E45

www.dongabestech.com

E9

1(A~E)-2

2015.4.9 11:48 AM

E10

MAC2 Lower-2540-color 2540DPI 175LPI

TERMINAL LUG - Comply with IEC61238-1

COPPER CABLES ONLY

Available wire range : IEC standard cables of Metric Cables.

Color coded on the barrel to eliminate errors during(IEC61238:2003)

installation and select to easy crimping dies.

Material : High Conductivity copper per 99.9% up

with Electro-Tin Plated.

Voltage Rating : 35kV

TWO-HOLE(ROUND TYPE)

TWO-HOLE(SQUARE TYPE)

Certificate No : E-11820

Fig. 1

Wire Range

Metric

CODE

10

16

25

Part No.

FLEX

10

16

25

35

35

50

50

70

70

95

95

PPET0201 - xx05 - xx06 - xx08 - xx10 - xx12 PPET0202 - xx05 - xx06 - xx08 - xx10 - xx12 PPET0203 - xx05 - xx06 - xx08 - xx10 - xx12 PPET0204 - xx05 - xx06 - xx08 - xx10 - xx12 - xx05-F

- xx06-F

- xx08-F

- xx10-F

- xx12-F

PPET0205 - xx05 - xx06 - xx08 - xx10 - xx12 - xx14 - xx16 PPET0206 - xx05 - xx06 - xx08 - xx10 - xx12 - xx14 - xx16 PPET0207 - xx08 - xx10 - xx12 - xx14 - xx16 PPET0208 - xx08 - xx10 - xx12 - xx14 - xx16 PPET0209 - xx08 - xx10 - xx12 - xx14 - xx16 - xx08-F

- xx10-F

- xx12-F

- xx14-F

- xx16-F

Fig. 2

Stud

Size

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

5

6

8

10

12

14

16

5

6

8

10

12

14

16

8

10

12

14

16

8

10

12

14

16

8

10

12

14

16

8

10

12

14

16

Dimension

W

d1

9

15

6.6

4.6

19.5

7

15

7.5

5.5

19.5

13

9.5

7.2

15

19.5

16

11

8.5

19.5

17

12

8.8

17.5

12

9.5

24.5

19

13.2

10.2

24

21

14.5

11.2

25

23

25.5

26

16

17

18

12.5

13.3

14

d2

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

5.4

6.4

8.4

10.5

13

15

17

5.4

6.4

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

b1=b2

2

16

19

C

1-S

15

30

14

22

16

19

8

15

30

14

22

16

19

8

17

33

14

22

9

19

20

33

14

22

44.5

14

20

40

14

44.5

20

14

20

14

24

14

24

14

24

14

17

24

67

82

70

85

52

67

67

82

70

85

54

70

70

86

73

89

62

75

72

85

75

88

97

117

97

112

103

115

100

115

106

121

108

128

111

130

106

130

112

128

106

122

112

128

112

135

115

138

40

17

44.5

67

45

17

44.5

52

45

17

44.5

2-L

35

17

44.5

1-S

35

17

44.5

Dies Part No.()

L

2-L

47

Drawing

DCI3

- 0010C

DCI3

- 0016C

DCI3

- 0025C

DCI3

- 0035C

DCI3

- 0035F

DCI3

- 0050C

Fig 1

Fig 2

Fig 3

Fig 4

Fig 5

DCI3

- 0050F

DCI3

- 0070C

DCI3

- 0070F

DCI3

- 0095C

DCI3

- 0095F

() Dies No : See detail page E44~E45

E10

www.dongabestech.com

1(A~E)-2

2015.4.9 11:48 AM

E11

MAC2 Lower-2540-color 2540DPI 175LPI

TERMINAL LUG - Comply with IEC61238-1

HOW TO ORDER

PPET 0101 - X X 0 5 - F

Barrel I.D/see drawing

Stud Size

Tongue Form

R ; Round Type

S ; Square Type

Barrel Form

S ; One(1) Clamping Type

L ; Two(2) Clamping Type

Serial Number

Product Part

Fig. 3

PPEO ; One(1)-Hole Type

PPET ; Double(2)-Hole Type

Wire Range

Metric

CODE

FLEX

120

150

120

185

150

200

185

200

240

300

240

300

400

500

630

Part No.

PPET0210 - xx08 - xx10 - xx12 - xx14 - xx16 PPET0211 - xx08 - xx10 - xx12 - xx14 - xx16 - xx08-F

- xx10-F

- xx12-F

- xx14-F

- xx16-F

PPET0212 - xx10 - xx12 - xx14 - xx16 - xx20 PPET0113 - xx10 - xx12 - xx14 - xx16 - xx20 - xx10-F

- xx12-F

- xx14-F

- xx16-F

- xx20-F

PPET0214 - xx10 - xx12 - xx14 - xx16 - xx20 - xx24 PPET0215 - xx10 - xx12 - xx14 - xx16 - xx20 - xx24 - xx10-F

- xx12-F

- xx14-F

- xx16-F

- xx20-F

- xx24-F

PPET0216 - xx12 - xx14 - xx16 - xx20 - xx24 PPET0217 - xx12 - xx14 - xx16 - xx20 - xx24 PPET0218 - xx12 - xx14 - xx16 - xx20 - xx24 -

Stud

Size

8

12

12

14

16

8

10

12

14

16

8

10

12

14

16

10

12

14

16

20

10

12

14

16

20

10

12

14

16

20

10

12

14

15

20

24

10

12

14

16

20

24

10

12

14

16

20

24

12

14

16

20

24

12

14

16

20

24

12

14

16

20

24

Fig. 4

Fig. 5

For Flex, Conductor

(Belled End)

Dimension

27.5

19

d1

15.2

31

21

16.8

31

22

17.5

34

23.5

18.5

37.5

25

20

37.5

26

20.5

40.5

28

22

43.5

30.5

24

46

32

25

49

34

26.5

56.5

40

30

64.5

45

35.5

d2

8.4

10.5

13

15

17

8.4

10.5

13

15

17

8.4

10.5

13

15

17

10.5

13

15

17

21

10.5

13

15

17

21

10.5

13

15

17

21

10.5

13

15

17

21

25

10.5

13

15

17

21

25

10.5

13

15

17

21

25

13

15

17

21

25

13

15

17

21

25

13

15

17

21

25

b1=b2

2

C

1-S

14

44.5

24

Dies Part No.()

L

2-L

1-S

2-L

112

137

115

140

50

17

DCI3

- 0120C

DCI3

- 0150C

- 0120F

44.5

17

30

50

122

142

44.5

17

30

50

124

147

44.5

17

35

50

129

144

DCI3

- 0185C

- 0150F

44.5

17

35

50

129

144

DCI3

- 0200C

- 0185F

44.5

17

40

57

138

155

17

44.5

40

142

159

147

162

57

20

DCI3

- 00240C

DSI3

- 00240C

44.5

20

60

162

DCI3

- 0300C

- 0240F

DSI3

- 0300C

44.5

20

66

168

DSI3

- 0300F

44.5

21

66

168

DSI3

- 0400C

44.5

21

189

DSI3

- 0500C

44.5

23

195

DSI3

- 0630C

60

73

70

173

Drawing

Fig 1

Fig 2

Fig 3

Fig 4

Fig 5

() Dies No : See detail page E44~E45

www.dongabestech.com

E11

1(A~E)-2

2015.4.9 11:49 AM

E16

MAC2 Lower-2540-color 2540DPI 175LPI

TERMINAL LUG - Comply with IEC61238-1

ONE HOLE

L

C

d2

W

d1

Wire Range

Dimension

Part No.

mm2

Stud

Size

d1

d2

Dies Part No.()

2.5

PPEO0080 - xx03 -

7.9

3.8

2.3

3.2

10

4.5

20.5

PPEO0090 - xx04 -

7.9

4.5

4.3

10

4.5

10

23

DATH-40

TOOL

PPEO0100 - xx04 -

7.9

5.5

4.3

10

4.5

10

23

DATH-60

10

PPEO0101 - xS06 -

9.5

6.6

4.6

6.4

20

15

39

DCI3-0010C

16

PPEO0102 - xS06 -

11

7.5

5.5

6.4

17

18

39

DCI3-0016C

25

PPEO0103 - xS08 -

13.5

9.5

7.2

8.4

21

9.5

21

48

DCI3-0025C

35

PPEO0104 - xS10 -

10

17

12

8.8

10.5

24

10.5

24

55

DCI3-0035F

50

PPEO0105 - xS10 -

10

19

13.2

10.2

10.5

25

11

32

65

DCI3-0050F

70

PPEO0106 - xS12 F

12

21.5

15

11.4

13

29

13

35

70

DCI3-0070C

F70

PPEO0108 - xS12 -

12

23

16

12.5

13

35

15.5

35

80

DCI3-0070F

95

PPEO0109 - xS12 F

12

26

18

14

13

33

15.5

35

82

DCI3-0095F

120

PPEO0110 - xS12 -

12

27.5

19

15.2

13

31

14.5

50

90

DCI3-0120C

150

PPEO0111 - xS12 F

12

31.5

22

17.5

13

36

16

45

95

DCI3-0120F

185

PPEO0112 - xS12 F

12

37.5

26

20.5

13

39

18

50

105

DCI3-0185F

DCI3-0240C

240

PPEO0114 - xS12 -

12

40.5

28

22

13

46

18

50

110

300

PPEO0115 - xS12 F

12

46

32

25

13

48

22

57

125

DCI3-0300F

400

PPEO0116 - xS12 F

12

52

36

27

13

48

24

57

128

DCI3-0400C

500

PPEO0117 - xS12 -

12

57.5

40

30

13

48

24

60

135

DCI3-0500C

630

PPEO0118 - xS12 -

12

64.5

45

35

13

48

23

70

150

DCI3-0630C

b1

d2

W

d1

TWO HOLE

L

b2

Wire Range

Dimension

Part No.

Stud

Size

d1

d2

b1

b2

PPET0201 - xS06 -

9.5

6.6

4.6

6.4

25

6.5

30

75

DCI3-0010C

mm2

10

Dies Part No.()

16

PPET0202 - xS06 -

11

7.5

5.5

6.4

25

30

76

DCI3-0016C

25

PPET0203 - xS08 -

13.5

9.5

7.2

8.4

25

14

30

84

DCI3-0025C

35

PPET0204 - xS10 -

10

17

12

8.8

10.5

44.5

14

14.5

35

114

DCI3-0035F

50

PPET0205 - xS10 -

10

19

13.2

10.2

10.5

44.5

14

14.5

35

115

DCI3-0050F

70

PPET0205 - xS12 F

12

21.5

15

11.4

13

44.5

13

19.5

46

130

DCI3-0070C

F70

PPET0208 - xS12 -

12

23

16

12.5

13

44.5

13.5

15

47

130

DCI3-0070F

95

PPET0209 - xS12 F

12

26

18

14

13

44.5

14.5

15

50

136

DCI3-0095F

120

PPET0210 - xS12 -

12

27.5

19

15.2

13

44.5

15

17.5

50

137

DCI3-0120C

150

PPET0211 - xS12 F

12

31.5

22

17.5

13

44.5

16

18

55

146

DCI3-0120F

185

PPET0213 - xS12 F

12

37.5

26

20.5

13

44.5

17

19

58

155

DCI3-0185F

240

PPET0214 - xS12 -

12

40.5

28

22

13

44.5

17

23

60

160

DCI3-0240C

300

PPET0215 - xS12 F

12

46

32

25

13

44.5

17

20

66

168

DCI3-0300F

400

PPET0216 - xS12 F

12

52

36

27

13

44.5

18

20

66

168

DCI3-0400C

500

PPET0217 - xS12 -

12

57.5

40

30

13

44.5

21

21

73

189

DCI3-0500C

630

PPET0218 - xS12 -

12

64.5

45

35

13

44.5

23

23

70

195

DCI3-0630C

() Dies No : See detail page E44~E45

E16

www.dongabestech.com

1(A~E)-2

2015.4.9 11:49 AM

E17

MAC2 Lower-2540-color 2540DPI 175LPI

TERMINAL LUG - Comply with IEC61238-1

FOUR HOLE

Material : High Conductivity copper per 99.9% up with Electro-Tin Plated.

Voltage Rating : 35kV

Wire Range

(mm2)

240

300

400

500

630

300

400

500

630

800

1000

Part No.

Stud

Size

PPEF-0241

PPEF-0242

10

PPEF-0243

12

PPEF-0244

14

PPEF-0341

PPEF-0342

10

PPEF-0343

12

PPEF-0344

13

PPEF-0441

PPEF-0442

10

PPEF-0443

12

PPEF-0444

14

PPEF-0541

PPEF-0542

10

PPEF-0543

12

PPEF-0544

14

PPEF-0641

PPEF-0642

10

PPEF-0643

12

PPEF-0644

14

PPEF-0341H

PPEF-0342H

PPEF-0343H

PPEF-0344H

PPEF-0441H

PPEF-0442H

PPEF-0443H

PPEF-0444H

PPEF-0541H

PPEF-0542H

PPEF-0543H

PPEF-0544H

PPEF-0641H

PPEF-0642H

PPEF-0643H

PPEF-0644H

PPEF-0841H

PPEF-0842H

PPEF-0843H

PPEF-0844H

PPEF-1041H

PPEF-1042H

PPEF-1043H

PPEF-1044H

8

10

12

14

8

10

12

13

8

10

12

14

8

10

12

14

8

10

12

14

8

10

12

14

Dimension

W

d1

d2

a1

a2

61

27

21

13

25

20

15

35

50

128

61

30.5

24

13

25

20

15

35

55

135

61

34.5

27

13

25

20

15

35

59

150

61

40

30

13

25

20

15

35

59

146

61

43

33.5

13

25

20

15

35

59

150

75

32

25

13

40

20

15

40

55

150

75

34.5

27

13

40

20

15

40

59

165

75

40

30

13

40

20

15

40

70

172

75

43

35

13

40

20

15

40

70

187

75

50

39

13

40

20

15

40

70

190

80

56

43

13

40

20

20

40

88

215

www.dongabestech.com

E17

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 1Rating: 2.5 out of 5 stars2.5/5 (3)

- IEC 61238 1 Compression and Mechanical Connectors For Power Cables PDFDocument12 pagesIEC 61238 1 Compression and Mechanical Connectors For Power Cables PDFkarviz100% (1)

- Bs 6485 1999 PVC Insulated Conductors For Overhead Power LinesDocument12 pagesBs 6485 1999 PVC Insulated Conductors For Overhead Power LinesAnamulKabir100% (2)

- ( - Ekgo: TandcfrciDocument23 pages( - Ekgo: TandcfrciRajesh Arora100% (4)

- PGCIL Power & Control Cable Rev-5Document14 pagesPGCIL Power & Control Cable Rev-5uttam100% (1)

- Onshore Power & Control Cables Flame Retardant DatasheetDocument2 pagesOnshore Power & Control Cables Flame Retardant DatasheetBajjaliNo ratings yet

- BS en 50525Document20 pagesBS en 50525Dung Pham100% (1)

- B 231 - B 231M - 99 - Qjizms05oqDocument11 pagesB 231 - B 231M - 99 - Qjizms05oqAifam RawNo ratings yet

- Astm B 233Document4 pagesAstm B 233Ryan LasacaNo ratings yet

- Info IEC-60228 CablesDocument6 pagesInfo IEC-60228 CablesOscar Eusebio Jimenez33% (6)

- ICEA-S 96-659 5kVDocument2 pagesICEA-S 96-659 5kVAnamulKabirNo ratings yet

- 6387Document24 pages6387sohaib100% (3)

- Iec60245-4 (Ed2.2) en DDocument5 pagesIec60245-4 (Ed2.2) en DparameshvkrNo ratings yet

- PNO52 245 71687 v1 ENDocument8 pagesPNO52 245 71687 v1 ENjtcool74100% (1)

- Iec60227 6 PDFDocument7 pagesIec60227 6 PDFKLN Prasad0% (1)

- 1Document338 pages1eliassantos1989No ratings yet

- Why Cable Cleats Are Vitally Important in The Protection of A Cable Installation PDFDocument6 pagesWhy Cable Cleats Are Vitally Important in The Protection of A Cable Installation PDFRajuNo ratings yet

- Opgw - 2S 1 - 24B1 (59 - 30 - 57.9) PDFDocument8 pagesOpgw - 2S 1 - 24B1 (59 - 30 - 57.9) PDFTriyanto SoewawiNo ratings yet

- BS 07870-5-2011 (2012)Document22 pagesBS 07870-5-2011 (2012)bean bean50% (2)

- En 60050-195Document24 pagesEn 60050-195Chen Mark LCNo ratings yet

- Muros Cortafuego IEC 61936-1Document9 pagesMuros Cortafuego IEC 61936-1Nicole Albornoz GonzálezNo ratings yet

- En 60889Document3 pagesEn 60889Pankaj Goyal0% (1)

- En 50182Document1 pageEn 50182pankajnbi100% (2)

- Cable MT NFC 33 226 18 30 36 KV PDFDocument2 pagesCable MT NFC 33 226 18 30 36 KV PDFSourav BhattacharyaNo ratings yet

- Single-Core Cables with PVC or PE Sheaths for 10-30kV VoltagesDocument54 pagesSingle-Core Cables with PVC or PE Sheaths for 10-30kV VoltagesMuhammad Shahrul Izwan100% (1)

- Astm B 33Document6 pagesAstm B 33Kamer Bibuçukvolt SemerciogluNo ratings yet

- IEC 60502-2 (ed3.0.RLV) enDocument11 pagesIEC 60502-2 (ed3.0.RLV) envikivarma1470% (3)

- Material Datasheets for Fire Resistant CablesDocument74 pagesMaterial Datasheets for Fire Resistant Cablesabdowais0% (1)

- As NZS 5000.1 Standard For Earthing CableDocument20 pagesAs NZS 5000.1 Standard For Earthing CableKamlesh VaishnavNo ratings yet

- En 50525-1Document38 pagesEn 50525-1siddharth incertech100% (4)

- IEC 60446 - Cores de Cabos para CADocument3 pagesIEC 60446 - Cores de Cabos para CAwilson100% (1)

- BS EN 50395-2005a1-2011 PDFDocument17 pagesBS EN 50395-2005a1-2011 PDFwaqarNo ratings yet

- International StandardDocument5 pagesInternational StandardKln Prasad0% (1)

- IEC 61089 Round Wire Concentric Lay Overhead Electrical Stranded ConductorsDocument74 pagesIEC 61089 Round Wire Concentric Lay Overhead Electrical Stranded ConductorsManuel Novo50% (2)

- Aluminum vs. Copper Conductors A Serious AlternativeDocument7 pagesAluminum vs. Copper Conductors A Serious Alternativemhomar_2006339No ratings yet

- Cenelec: Harmonization Document Document D'Harmonisation HarmonisierungsdokumentDocument660 pagesCenelec: Harmonization Document Document D'Harmonisation HarmonisierungsdokumentMuhammad Shahrul IzwanNo ratings yet

- Measurement of Insulation Resistance (IR) - Part 2 PDFDocument17 pagesMeasurement of Insulation Resistance (IR) - Part 2 PDFvaratharajan g rNo ratings yet

- Ansi C29 4Document15 pagesAnsi C29 4AlbertoNo ratings yet

- BS 6724 1997Document42 pagesBS 6724 1997Simon Law100% (1)

- Iec Standard Cable LugsDocument4 pagesIec Standard Cable LugsYuliandiHidayat Gacodi Dalimunthe100% (2)

- 400.4-2015 Guide For Field Testing of Shielded Power Cable Systems Rated 5kV and Above With Damped Alternating Current (DAC) Voltage PDFDocument62 pages400.4-2015 Guide For Field Testing of Shielded Power Cable Systems Rated 5kV and Above With Damped Alternating Current (DAC) Voltage PDFkeishan narinesinghNo ratings yet

- (BS EN 50618) - Electric Cables For Photovoltaic SystemsDocument29 pages(BS EN 50618) - Electric Cables For Photovoltaic SystemsPiyush Goyal100% (5)

- BS 2627-1970 Specification For Wrought Aluminum For Electrical Purposes WireDocument12 pagesBS 2627-1970 Specification For Wrought Aluminum For Electrical Purposes WireThanh Dang67% (3)

- ASTM B 232 (ACSR Conductor)Document16 pagesASTM B 232 (ACSR Conductor)Nirmal WiresNo ratings yet

- Insulating and Sheathing Materials For CablesDocument8 pagesInsulating and Sheathing Materials For CablesHanh-Trang DangNo ratings yet

- BS EN 60811-1-1 1995 FileDocument28 pagesBS EN 60811-1-1 1995 Fileelmaadawy2002100% (3)

- BS 07655-1.1-2000Document9 pagesBS 07655-1.1-2000Reda ElawadyNo ratings yet

- ISO/IEC 17025认可证书标题Document1 pageISO/IEC 17025认可证书标题Renzo Romero ArenasNo ratings yet

- Icea Nema S-61-402 Parte 4Document23 pagesIcea Nema S-61-402 Parte 4DamiánNo ratings yet

- IEc 60898-1 - 2019Document46 pagesIEc 60898-1 - 2019Hop100% (1)

- Iec 62271-200-2021 (MVSWG)Document108 pagesIec 62271-200-2021 (MVSWG)Electrical DistributionNo ratings yet

- Info Iec60898-1 (Ed2.0) enDocument13 pagesInfo Iec60898-1 (Ed2.0) enshahirfanNo ratings yet

- mv calDocument11 pagesmv calrezaqesNo ratings yet

- Non-Linear Load Power Conditioning Isolation TransformerDocument5 pagesNon-Linear Load Power Conditioning Isolation Transformerjermaine divinaNo ratings yet

- Conductor Size, General: Table C-2 NEC References For Conductor SizingDocument4 pagesConductor Size, General: Table C-2 NEC References For Conductor SizingYashwanth NNo ratings yet

- MV Cables Sizing Verification Rev 00Document5 pagesMV Cables Sizing Verification Rev 00Ahmed SaberNo ratings yet

- Tests According To IEC-En Standards (WAGO)Document11 pagesTests According To IEC-En Standards (WAGO)va3ttnNo ratings yet

- FRS LED Indoor Lighting Specifications EOIDocument10 pagesFRS LED Indoor Lighting Specifications EOIManish GuptaNo ratings yet

- Volt Drop and Cable SelectionDocument36 pagesVolt Drop and Cable SelectionSteve Sayles100% (1)

- Cast Resin TransformersDocument7 pagesCast Resin TransformersNandkumar Chinai100% (1)

- Practical Electricity: Test Yourself 19.1 (Page 365)Document5 pagesPractical Electricity: Test Yourself 19.1 (Page 365)Jack Kowman67% (6)

- Before Installation: Meanings of Symbols Displayed On Indoor Unit And/Or Outdoor UnitDocument8 pagesBefore Installation: Meanings of Symbols Displayed On Indoor Unit And/Or Outdoor UnitcauvongkhongmauNo ratings yet

- DOMO Series: Part 1: General RequirementsDocument1 pageDOMO Series: Part 1: General RequirementsZulioTZNo ratings yet

- Electrical Design Calculation For Three-Storey Building: L×W L+W) HMDocument29 pagesElectrical Design Calculation For Three-Storey Building: L×W L+W) HMMoe Thant OoNo ratings yet

- Leviton IST 51110-SRG Surge+Protective DeviceDocument2 pagesLeviton IST 51110-SRG Surge+Protective DevicejairoNo ratings yet

- USER'S MANUAL FOR WINDOW AIR CONDITIONERSDocument32 pagesUSER'S MANUAL FOR WINDOW AIR CONDITIONERSJuan AbundisNo ratings yet

- Dvpec: Multi-Position, Variable-Speed, ECM-Based Air Handler With Internal EEV Communicating 2 To 5 TonsDocument12 pagesDvpec: Multi-Position, Variable-Speed, ECM-Based Air Handler With Internal EEV Communicating 2 To 5 TonsJohn AristaNo ratings yet

- Comparision Between HT-LT AVCDocument2 pagesComparision Between HT-LT AVCVyankatesh KulkarniNo ratings yet

- 2 Storey House PlanDocument4 pages2 Storey House PlanVinluan Erika AnnNo ratings yet

- General Electric NotesDocument3 pagesGeneral Electric Notesibrahim68No ratings yet

- Lec.01 - Building Design Concept - SE Sponsor 2021Document20 pagesLec.01 - Building Design Concept - SE Sponsor 2021moosuhaibNo ratings yet

- SEC Distribution Planning Standard Estimation GuideDocument42 pagesSEC Distribution Planning Standard Estimation Guideslama_abo67% (3)

- Schedule of LoadsDocument12 pagesSchedule of LoadsLee Ryan Reforma100% (1)

- Offline UPS Quick Start GuideDocument8 pagesOffline UPS Quick Start GuideJovan GligorevićNo ratings yet

- Roundup Warmer Drawers WD-20Document2 pagesRoundup Warmer Drawers WD-20wsfc-ebayNo ratings yet

- Installation & OperationDocument28 pagesInstallation & OperationRafael Adrian Báez RamírezNo ratings yet

- EPAS Q2 Job Sheet1Document7 pagesEPAS Q2 Job Sheet1madelyn CartasNo ratings yet

- QS SASO 2663-E - Final Draft PDFDocument22 pagesQS SASO 2663-E - Final Draft PDFNARENDER NIMMA100% (1)

- Vacuum Cleaner MODEL NO.: R-1560Document6 pagesVacuum Cleaner MODEL NO.: R-1560Makkay ZoltanNo ratings yet

- Trip Circuit and Trip Coil Supervision Relay: - Type VAXDocument5 pagesTrip Circuit and Trip Coil Supervision Relay: - Type VAXShara Maica Salvador100% (1)

- Guidance On Protective Conductors (2008 17th Edition) (P15480812)Document8 pagesGuidance On Protective Conductors (2008 17th Edition) (P15480812)Sumit VermaNo ratings yet

- Type MPB/MPG Test Plug and Universal Test BlockDocument4 pagesType MPB/MPG Test Plug and Universal Test Blockryreddy50% (2)

- Fuse Modular Terminal Block - PT 6-FSI/C-LED 24 - 3212172: Why Buy This ProductDocument4 pagesFuse Modular Terminal Block - PT 6-FSI/C-LED 24 - 3212172: Why Buy This ProductWin RobinNo ratings yet

- CM1060 IB 11973 00 RevisedDocument28 pagesCM1060 IB 11973 00 Revised1V4NDragoNo ratings yet

- XT2N 160 TMA 160-1600 3p F F circuit breaker detailsDocument3 pagesXT2N 160 TMA 160-1600 3p F F circuit breaker detailsmark anthony sulioNo ratings yet

- Rules To Know For Elec EnggDocument1 pageRules To Know For Elec EnggGokulNo ratings yet

- Black & Decker Advanced Home Wiring - Updated 3rd Edition - DC Circuits - Transfer Switches - Panel Upgrades PDFDocument349 pagesBlack & Decker Advanced Home Wiring - Updated 3rd Edition - DC Circuits - Transfer Switches - Panel Upgrades PDFHector100% (1)

- Sears Kenmore 580.54351500 Dehumidifier User ManualDocument11 pagesSears Kenmore 580.54351500 Dehumidifier User ManualRick McGuireNo ratings yet

- DispatcherDocument98 pagesDispatcherMaríaNo ratings yet

- Generator protection overview and functionsDocument24 pagesGenerator protection overview and functionsmuaz_aminu1422100% (1)