Professional Documents

Culture Documents

BV2311 en

Uploaded by

Jon LopezOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BV2311 en

Uploaded by

Jon LopezCopyright:

Available Formats

Installation Instructions

LAF 2346 4575

E BV2311 Version 1.1 / 06.02.2013

No part of this document may be reproduced in any form

(by printing, photocopying or other means) or processed,

duplicated or circulated electronically without prior written

approval of REINTJES GmbH.

2013 REINTJES GmbH

All Rights Reserved.

LAF 2346 4575

Table of contents

Table of contents

1

Safety .......................................................................................................................................................... 11

1.1 Meaning of Warnings and Notes ........................................................................................................... 11

1.2 Basic measures of caution ..................................................................................................................... 12

1.3 Requirements for installation personnel ............................................................................................... 13

1.4 Safety information for installation .......................................................................................................... 14

1.5 Protective measures against fire and danger of explosion ............................................................... 15

Introduction to this Documentation .............................................................................................. 17

2.1 Maintaining the documentation ............................................................................................................. 18

2.2 Preconditions of warranty ....................................................................................................................... 18

2.3 Brief product description ......................................................................................................................... 19

2.4 Area of application and manner of intended use ................................................................................ 20

2.5 Use of the gearbox within the European Union .................................................................................. 20

Technical Data ........................................................................................................................................ 21

Transport, Storage and Preservation ........................................................................................... 25

4.1 Transport ................................................................................................................................................... 25

4.2 Storage ...................................................................................................................................................... 26

4.3 Preservation ............................................................................................................................................. 28

Description ............................................................................................................................................... 35

5.1 Gearbox execution .................................................................................................................................. 35

5.2 Power Take Off PTO K41 ....................................................................................................................... 40

5.3 Power Take Off PTO K51 ....................................................................................................................... 41

5.4 Gearbox with shaft brake ....................................................................................................................... 43

Installation and Alignment ................................................................................................................ 45

6.1 Responsibility ........................................................................................................................................... 45

6.2 Steps in preparation ................................................................................................................................ 45

6.3 Place of installation requirements ......................................................................................................... 46

6.4 Demands on the installation personnel ................................................................................................ 46

6.5 Setting up the gearbox ............................................................................................................................ 46

6.6 Alignment .................................................................................................................................................. 48

6.7 Connection to Propeller Shaft ................................................................................................................ 48

6.8 Fixing the gearbox to the foundation .................................................................................................... 50

6.9 Seat Chocks ............................................................................................................................................. 57

6.10 Screwed Connections ............................................................................................................................. 58

6.11 Connection to Engine .............................................................................................................................. 61

6.12 Connection to the gearbox PTO ............................................................................................................ 64

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Table of contents

6.13 Alignment Check ......................................................................................................................................65

6.14 Connection of Gearbox Components ...................................................................................................65

Index ............................................................................................................................................................69

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Safety

Safety

1.1

Meaning of Warnings and Notes

Warnings and notes indicating various levels of danger or importance are used within

this documentation.

The signal word indicates the danger level in each case. Important notes to be observed for

problem-free, safe operation are indicated with an exclamation mark in front of them. These

are the individual danger levels:

1.1.1

Warnings

DANGER!

Imminent danger!

Death or serious injury will occur!

Human lives are acutely endangered

WARNING!

Possibly imminent danger

Death or serious injury may occur

Human lives are possibly endangered

CAUTION!

Possibly imminent danger

Light injury may occur

Danger of personal injury

1.1.2

Notes

NOTICE!

Important information for safe and problem-free operation.

Possibly imminent danger of damage to the gearbox

Note without signal word:

... Here you will find notes on working effectively and safely.

Additional information and recommendations

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Safety

1.2

Basic measures of caution

Frequently, accidents occur as a result of not observing general safety regulations or

cautionary measures.

The individual chapters of this installation instructions contain specific safety notes.

Accidents may often be avoided by recognizing potential hazard situations in advance.

Input side

Output side

Dangerous places on the gearbox

Symbol

Meaning

General Warning Sign

Symbol

Meaning

Smoking and open fires prohibited!

These warnings must be

observed!

Danger of being drawn or caught

in by rotating components

Wear tightly fitting protective

clothing e.g. coverall

Danger of electric shock!

Wear ear protectors

Do not disconnect or service this

device until power supply has been

disconnected!

1

Caution, hot components

Read instructions carefully!

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Safety

1.3

Requirements for installation personnel

Installation personnel must be trained in the use of transport aids and lifting equipment and

have a mastery of the tasks required in safely carrying out installation and alignment. This

includes skilled use of the tools required.

In order to maintain safety during operation, and to avoid any damage to the

gearbox, it is necessary for you to carefully read and to understand the chapters

Transport, Storage and Preservation from page 19 and Installation and Alignment from page 39.

In order to ensure your safety and the safety of others during installation, utilise only tools,

procedures, and methods of working in line with the most recent technology.

If the gearbox appears to require work not described in the documentation, please consult

the REINTJES service department or a REINTJES representative.

In addition to this documentation, please observe and follow applicable laws and

any other binding regulations governing accident prevention and environmental

protection!

General protective measures and personal protection in the engine room

The gearbox may be operated and maintained only by qualified staff knowledgeable in its

operation and maintenance.

DANGER!

Rotating Parts!

Danger of accidents due to getting caught or drawn in!

Prior to trial run mount covers to all rotating parts to prevent being

caught or drawn in.

Immediately repair any faults that pose a safety hazard!

Ensure that no foreign objects enter the inside of the gearbox during assembly.

Wear protective eyewear when cleaning with compressed air.

Danger of eye injuries due to dirt particles.

While the engine is running, wear ear protectors to prevent hearing

impairments.

Do not wear long hair loosely or any loose clothing or jewelry, including

rings, when near the gearbox while in operation.

Danger of injury due to getting caught or drawn in!

Do not touch the gearbox while it is warm from operation.

Danger of burns!

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Safety

1.4

Safety information for installation

The gearbox has been built in accordance with the most recent technology and with

recognized safety regulation standards. Yet, even when the gearbox is used appropriately,

due to its manner of functioning and depending on how it is installed, a danger of personal

injury or death to the user or other individuals may arise.

Observe the following procedures!

WARNING!

When working on the gearbox, prevent the engine from being switched on!

Danger of death due to rotating components!

Shut down the compressed air feed and bleed the air tubes.

Prior to any assembly work on the gearbox, place a sign reading "OUT OF

ORDER" or a similar warning sign on the start-up switch or starter button and on

the remote starter.

Make sure that the remote starter of the drive motor on the bridge is also disabled

and not functioning.

Safety prior to working on the gearbox

Before performing adjustments or repairs on the gearbox or on aggregates powered by the

gearbox, shut down the engine.

Secure the propeller and drive shafts against unchecked rotation.

Before loosening or dismantling any tubes or accessory parts in air, oil or water circulating

systems, first reduce the pressure.

WARNING!

Oil pipes on the gearbox are under pressure when in operation!

Any oil escaping as a result of cracks or other leakage can result in serious injury.

Avoid damaging piping during assembly.

Perform a daily sight check of the piping in order to recognize any leakage at any

early stage.

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Safety

1.5

Protective measures against fire and danger of explosion

General information

Immediately remove any oil residues completely.

Do not leave on the gearbox any rags or cloths used to wipe oil residues.

Pipes and tubes

Check all tubes and oil pipes daily for wear or damage.

Check to see that these have been laid, supported and fastened in accordance with

professional standards.

Tighten bolt joints only to the required torque.

Note that lubricants are flammable.

Never weld pipes or tubes carrying lubricants.

Do not straighten or bend any pipes or tubes under pressure during operation.

Immediately replace any bent or damaged pipes or tubes.

Do not replace steel pipes with copper ones.

Hoses

Do not damage hoses by subjecting them to mechanical force.

Check all hoses daily for any cracks forming or any mechanical damage.

Keep flames, acids and other corrosive or caustic liquids away from hoses.

Replace hoses no later than after 5 years.

Drained oil

Collect drained oil in a used oil collector.

Collect any rags soiled with oil in containers intended for this purpose.

Store all lubricants in appropriately labelled containers. Dispose of filter elements and

used oil either as recyclable substances or as hazardous wastes.

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Safety

Cables connected to the gearbox

Make sure that all cables are maintained in an undamaged condition.

Check to see that all cables are laid properly and cannot be damaged by abrasion.

Immediately after connecting any cables to the gearbox, remove any leftover pieces of cable

or refuse.

Use only wires and cables having the required diameter and type of insulation.

Protect cabling on the board side by means of fuses in front of them in circuits.

Foreign substances near to the gearbox

Ensure that no used parts, dirt or foreign substances are near the gearbox.

10

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Introduction to this Documentation

Introduction to this Documentation

This documentation comprises one set of installation and operating instructions for

gearboxes belonging to the LAF model series.

This installation instructions contains information about:

Safety

Technical data

Transport, storage and preservation

Description of gearbox models

Installation and alignment

The operating instruction contains information about:

Putting the unit into operation

Operation

Maintenance

Trouble-shooting

Spare and replacement parts

Drawings for installation and supervision

The procedures described in this documentation are of a general nature.

Actual characteristics may differ from this information depending on the particular

gearbox and equipment.

Please read the Installation instructions before installing the gearbox!

Please be especially careful to observe the preceding safety information!

In order for the unit to operate without fault as well as for any warranty claims to be honoured,

it is necessary to observe this documentation in its entirety.

Anyone responsible for transport, installation, operation or maintenance of this equipment

must adhere to the contents of this documentation.

Your safety as well as the safety of others depends on correctly operating this gearbox.

The best protection against possible accidents is for the party operating the equipment to

exercise caution.

REINTJES will accept no liability for damage or faults during operation if this documentation

is not observed.

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

11

LAF 2346 4575

Introduction to this Documentation

Constant improvement and continued development may result in changes to your gearbox

that is not yet mentioned in these instructions.

All illustrations show basic principles only and may vary from the actual product. You cannot

derive any claims from the illustrations shown in this documentation.

Please address any questions about your gearbox or about this documentation to REINTJES

customer service:

service@reintjes-gears.de or on

working days: Phone +49 5151 104 0

In emergencies and on weekends: Phone +49 5151 104 237

2.1

Maintaining the documentation

This documentation belongs to the gearbox.

Please maintain the documentation for the entire service life of the gearbox.

Please pass on the complete documentation to any later owner or user.

2.2

Preconditions of warranty

REINTJES will only accept warranty claims when:

You install, operate, monitor and maintain the gearbox in accordance with our instructions.

Only the types of oil listed in the lubricant table are used.

You comply with the performance ratings and labelling stamped on the type plate.

No modifications may be made to the gearbox unless they have been approved by REINTJES.

REINTJES, as supplier of one of the components of the complete propulsion system, will not

assume responsibility for any problems with vibration resulting from the system as a whole.

REINTJES will not therefore assume any liability for complaints or damage resulting from this

type of vibration.

REINTJES strongly recommends that you have a torsional vibration calculation

performed for the entire system.

In any case, a whirling calculation must be done for any shaftlines connected to the

input or output shafts.

We additionally recommend having an axial vibration calculation done for propeller

shaftlines.

Torsional, axial and whirling can mutually excite each another. In order to preclude

this possibility, the results of the whirling calculation, axial vibration calculation and

torsional vibration calculation should be compared with each other in order to rule out

that any of the vibration types have the same natural frequencies.

12

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Introduction to this Documentation

2.3

Brief product description

The gearboxes of the LAF series are axially offset marine reduction gearboxes with

a built-in hydraulic disc clutch.

Marine gearboxes can be supplied with identical and counter rotation of the input and

output shafts. The built-in thrust bearings absorb the propeller thrust.

The gearbox has been designed under the assumption that a highly flexible coupling

will be employed between the motor and the gearbox.

Control is effected by means of directional valves.

2.3.1

Illustration

LAF 2346 K41 (vertically offset)

Control valve

Pressure build-up system

Heat exchanger

Oil

filter

Input shaft

Oil

pump

Output shaft

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

13

LAF 2346 4575

Introduction to this Documentation

2.4

Area of application and manner of intended use

The gearboxes are intended for use in the propulsion systems of ships. They represent the

current state of the art.

Please refer to the type plate and/or the documentation for technical data and for information

on permissible conditions of operation (limits).

These details must be absolutely adhered to!

The coupling flange and flexible couplings must be suited to the gearbox. You must observe

the technical details of the gearbox. (see Technical Data on page 15.)

The gearbox may only be used in a flawless technical condition, in a manner consistent with

its intended use and in awareness of safety issues and potential hazards!

Use in accordance with the intended purpose also comprises compliance with mounting and

operating instructions and with inspection and maintenance conditions.

!

2.5

Any use of the gearbox in a manner not described here will be deemed usage that

is not in accordance with its intended purpose. REINTJES will not be liable for any

damage resulting from such use.

Use of the gearbox within the European Union

In cases when operation is subject to safety regulations of the European Union, the

manufacturer of the complete system must have it CE-approved and labelled accordingly.

Seagoing vessels are exempted from this requirement in accordance with the Machinery

Directive.

14

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Technical Data

Technical Data

You will find the technical data for your gearbox on the type plate. The type plate of the gearbox

is mounted at the top part of the gearbox housing.

Copy the data for your gearbox to the type plate printed here:

Requesting spare parts

When making enquiries and ordering parts, please provide the following information:

GEARBOX NO. -

e.g.: K xxxxx

TYPE -

e.g.: LAF ...

INPUT CAPACITY -

e.g.: 2000 kW

GEAR REDUCTION RATIO - e.g.: 4.05 : 1

Please provide this additional information, listed in the spare parts lists, when ordering

spare parts:

Item number of the part

Designation

Required no. of pieces

You will find the spare and replacement parts lists in the operating instructions beginning on

page 75.

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

15

LAF 2346 4575

Technical Data

The tables below present an overview of the performance data of the gearbox types described

in this documentation.

The data of your gearbox may differ from the information in these tables in individual

cases. The data on the type plate is authoritative in cases of doubt.

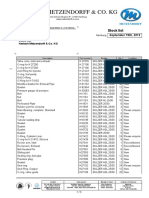

Table 1: Overview of characteristics for type LAF 2346 4575

Type

LAF 2346

LAF 2355

LAF 2365

LAF 2375

LAF 3445

LAF 3455

16

Gear ratio

Input torque Nm

Weight kg

Base gear

2,076

32470

5300

2,529

32470

3,033

32470

3,458

30950

4,041

28670

4,454

26700

3,923

32470

4,461

31160

4,916

29180

5,454

26750

5,762

25500

5,074

31270

5,560

28540

6,130

25890

6,455

24580

6,154

30350

6,440

29000

7,087

26350

7,455

25050

2,053

41540

2,515

41540

3,038

39620

3,462

37620

4,043

34560

4,524

32630

4,074

41540

4,480

37810

4,957

37810

5,524

35180

5,955

39920

6300

7200

9200

6400

7800

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Technical Data

Type

LAF 3465

LAF 3475

LAF 4545

LAF 4555

LAF 4566

LAF 4575

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

Gear ratio

Input torque Nm

Weight kg

Base gear

5,077

39740

9700

5,583

36140

5,870

34380

6,524

30930

6,955

28070

6,160

38090

6,458

36330

7,136

32880

7,524

31190

1,923

52530

2,455

52530

2,931

52530

3,423

47090

3,952

42050

4,429

38360

3,960

49850

4,583

44290

5,091

40600

5,429

38460

5,773

36510

4,958

47910

5,500

43920

6,091

40250

6,429

38420

6,818

36510

6,120

45300

6,739

41560

7,091

39500

7,476

37460

10800

8000

9500

11100

13100

17

LAF 2346 4575

Technical Data

18

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Transport, Storage and Preservation

Transport, Storage and Preservation

4.1

Transport

Upon receipt, immediately inspect the gearbox and accessories for any damage

incurred in transport.

Report any transport damage to the freight carrier immediately.

Inform the REINTJES service department.

Do not put the gearbox into operation if there is any transport damage

WARNING!

The gearbox can fall over if improperly supported!

This may result in serious injury or death!

Under no circumstances should you put slings around shaft ends, pipes or other

externally mounted parts.

When suspending the unit, use only the lifting eyes intended for this purpose.

The gearbox weight (without oil but including special accessories) is stamped on the type plate.

Slings must be suitable for this load. Secure slings to all of the eyebolts intended for this

purpose using shackles.

When lifting for transport, the gearbox must be secured against tilting. To ensure this, use all

of the eyebolts intended for this purpose.

With the gearbox suspended from a sling, the angle of the sling may not exceed 45

from the perpendicular!

Traversing bridge

Lifting eye

bolts

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

Sling

max.45

19

LAF 2346 4575

Transport, Storage and Preservation

WARNING!

Suspended load!

Danger of injury!

Use only transport aids and lifting equipment that are approved for the

anticipated load when used in the intended manner.

Transport aids and lifting equipment must be designed to be able to safely hoist

the load, hold it and set it down once again.

Observe the regulations and instructions for use provided by the manufacturer of

the transport aids and lifting equipment.

During transport, make sure:

Not to damage packaging, if further storage is intended afterward.

Transport is carried out only by individuals competent in the use of transport

4.2

and lifting equipment.

Appropriate and adequately dimensioned transport aids (e.g. traversing bridges)

are employed.

Slings do not press against piping or externally mounted parts.

Storage

Please note that appropriate storage conditions are necessary in order to avoid any

damage due to corrosion.

REINTJES will not be liable for any damage due to corrosion, nor any subsequent

damage arising from this, in cases when the guidelines and measures included in this

chapter are not observed.

Keep to a minimum the period of time between removal of the original packaging and putting

the gearbox into operation.

During this period, protect the gearbox from any harmful environmental effects and external

influences.

Until the gearbox is put into operation, leave all openings in the gearbox closed.

If, for inspection purposes, you cannot avoid opening the gearbox, you must close openings

immediately afterward. (see "Measures against corrosion during storage" on page 22.)

In cases of doubt, please contact the REINTJES service department.

20

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Transport, Storage and Preservation

To avoid damage, the gearbox must be stored in an enclosed area.

This reduces extreme variations in temperature and avoids any exposure to

moisture (e.g. through rain).

Outdoor storage is prohibited!

These factors have a positive effect on the permissible storage period:

High-quality packaging including an adequate amount of drying agent

Storage in climate-controlled rooms with low humidity

These factors have a negative effect on the permissible storage period:

Damage to the packaging

Storage under high humidity, with air containing salt or contaminated air

Additional steps are required if:

Premature opening of the gearbox cannot be avoided

The gearbox is stored for a longer period or under conditions other than those stipulated

(see "Measures against corrosion during storage" on page 22.)

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

21

LAF 2346 4575

Transport, Storage and Preservation

4.3

Preservation

4.3.1

General information

Initial preservation is done at REINTJES as specified in agreements by contract.

After a run on the test stand, the gearbox is preserved as specified in the order.

Spare parts or loose parts supplied with the shipment are treated using the preservation

procedures stipulated in the contract.

Preservation for dispatch is designed for a limited period of time and for certain storage

conditions.

The scope and effectiveness of these preservation procedures depend on:

4.3.2

Conditions of storage

Duration of storage

Packaging

Individual customer wishes

Initial preservation

During the factory bench test, the gearbox is run with a corrosion protection oil to preserve it.

In addition, following the bench test, the gearbox is filled with a VCI preservation oil (VCI = volatile

corrosion inhibitor).

Volatile corrosion inhibitors are agents that evaporate very slowly and deposit themselves on

the unpainted metal surfaces within the closed gearbox. Due to their polarity, they interrupt

electrochemical reactions resulting in corrosion.

In order to ensure that these volatile corrosion inhibitors retain their effectiveness for as long

as possible, all of the gearbox openings are closed. The shafts are sealed using v-rings

and/or an acid-free grease.

Externally exposed, unpainted metal parts are protected using a wax-like preservation

substance. When stipulated in the order, the gearbox is additionally protected against

corrosion by means of moisture-proof packaging or special marine packaging.

4.3.3

Measures against corrosion during storage

General information

The following assumes that the storage conditions described in chapter 4.2 are followed.

Here we can merely describe general measures against corrosion.

If you are not certain whether protection is adequate for your particular case of application,

please consult with REINTJES about the necessary measures.

22

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Transport, Storage and Preservation

As a result of damage to packaging, water and harmful environmental influences can have a

direct effect on the gearbox. Excessive moisture can penetrate the inner space of the gearbox

as a result of variations in temperature.

Immediately upon receipt of the gearbox, check the packaging for any transport damage.

Regularly check the outside packaging.

Table 2: Inspection intervals for corrosion protection of the gearbox

Inspection intervals:

European climate zone every 4 weeks

Tropical climate zone every 2 weeks

Inform REINTJES customer service immediately of any corrosion damage discovered

during inspection.

Immediately perform the following measures in the event of damage to packaging:

Dry off any pools of water collecting on the gearbox as a result of rain or condensation.

Check the drying agent provided with the shipment.

Replace the drying agent if its colour changes from white to blue.

Check preservation at shaft ends.

Repair the seal, if necessary, using acid-free grease.

Repair the damaged packaging.

-or better Replace the damaged film along with the drying agent.

Use only film of the same quality.

Remove the packaging when:

The gearbox is brought on board the vessel to be installed

The stipulated duration of storage is exceeded by more than 20%.

In this case, consult with REINTJES to decide on further protective measures.

Immediately after removing the original packaging, additional preservation measures

will be necessary for ensuring that the gearbox is adequately protected against

corrosion.

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

23

LAF 2346 4575

Transport, Storage and Preservation

Measures after removing the packaging:

Protect the gearbox as well as possible against water and harmful environmental effects.

For instance, when covering the gearbox with tarpaulins, leave some space between them

and the gearbox. They should not act as a vapour seal!

Regularly inspect the gearbox for external corrosion damage.

During inspection, check to ensure that shaft ends are preserved and sealed.

Repair the seal using acid-free grease. (Refer to table 2 on page 23 for inspection intervals)

Regularly refill the gearbox with Branorol preservation oil.

After removing the packaging, initial refilling should be done after half of storage duration,

as stipulated in the contract, has passed.

Initial refilling should, however, be done no later than 12 weeks (European climate zone)

or 8 weeks (tropical climate zone) afterwards.

Table 3: Intervals for refilling VCI preservation oil

Intervals for refilling VCI preservation oil:

Volume of preservation oil to be filled:

European climate zone every 12 weeks

1% of the operating oil volume, at least 1 litre

Tropical climate zone every 8 weeks

1% of the operating oil volume, at least 1 litre

You will find the operating oil volume on the type plate.

Please observe section "Opening the gearbox" on page 25 in this regard!

For unpacked gearboxes, apply the measures mentioned above even if the stipulated storage

duration has expired.

24

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Transport, Storage and Preservation

Opening the gearbox

The agents of the VCI preservation oil escape when the gearbox is opened.

Measures after opening the gearbox

Refill the gearbox with Branorol preservation oil. (Refer to table 3 on page 24 for volume)

IMPORTANT: Afterwards, close the gearbox air-tight.

A protective inhibitor atmosphere may not be able to form again after reclosing.

This depends on:

4.3.4

The concentration of VCI agents

The amount of moisture that has entered

How well the gearbox is resealed afterwards

Measures against corrosion after putting the gearbox into operation

Long interruptions in operation

If the operation of the vessel or gearbox is to be interrupted for several weeks, measures are

required to protect the gearbox against corrosion.

Corrosion damage to the gearbox cannot be ruled if these measures are not followed.

The type and scope of measure that need to be performed depend on the options available

at the particular location. Variants A, B and C, described in the following, are equally as

important.

Table 4:

Measures to protect against corrosion are required

after an interruption in operation of longer than

European climate zone: 4 weeks

Tropical climate zone: 2 weeks

Perform one of these protective measures once the period mentioned above has passed:

Variant A: Flush with operating oil

Flush the gearbox for 15 minutes using the mechanical gearbox oil pump by starting

the engine.

-or using the electrical stand-by pump, if available.

Replace the venting filter using the screw plug.

Repeat flushing weekly.

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

25

LAF 2346 4575

Transport, Storage and Preservation

Variant B: Flush with Valvoline 6 anticorrosive oil

Drain the operating oil.

Fill with Valvoline 6 anticorrosive oil. Volume: approx. 0.8 x operating oil volume.

Flush the gearbox for 15 minutes using the mechanical gearbox oil pump by starting

the engine.

-or using the electrical stand-by pump, if available.

Replace the venting filter using the screw plug.

Repeat flushing after no later than 12 weeks (Europe) or 8 weeks (tropics).

Seal the shafts using an acid-free grease.

Variant C: Fill the gearbox with Branorol VCI preservation oil

Drain the operating oil.

Fill with Branorol VCI preservation oil. Volume and further service intervals: see table 3 on

page 24.

Replace the venting filter using the screw plug.

Seal the shafts using an acid-free grease.

Note: Residual amounts of operating oil may remain in the gearbox after draining. This will not

reduce the effectiveness of the measures against corrosion. On the other hand, when putting

the gearbox back into operation, small residual quantities of anticorrosive oil may be mixed

with operating oil.

26

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Transport, Storage and Preservation

Corrosion protection of the heat exchanger

Follow the safety instructions provided in this Installation Instructions.

(refer to "Safety" beginning on page 5.)

In addition, observe any applicable safety precautions when mounting or

dismantling equipment.

Draining the water side of the heat exchanger during interruptions in operation

of longer than 2 weeks

Seawater circulating system:

Drain the seawater circulating system of the heat exchanger.

Flush the water side of the heat exchanger with freshwater.

Afterwards, fill the water side of the heat exchanger with freshwater mixed with an

anticorrosive additive.

The type of additive depends on the cooling system.

Observe the areas of application recommended by the additive manufacturer.

Freshwater circulating system:

Drain the freshwater circulating system of the heat exchanger.

Afterwards, fill the water side of the heat exchanger with freshwater mixed with an

anticorrosive additive.

The type of additive depends on the cooling system.

Observe the areas of application recommended by the additive manufacturer.

4.3.5

Product specifications for corrosion protection and preservation oils

VALVOLINE ROSTSCHUTZ 6, full-power anti-corrosion oil for gearboxes

BRANOROL 32/10, VCI preservation oil, mineral-oil-based

Attention!

Remove the v-rings marked with label before commissioning.

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

27

LAF 2346 4575

Transport, Storage and Preservation

28

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Description

Description

5.1

Gearbox execution

5.1.1

Gearbox type

The gearboxes of the LAF series are axially offset marine reduction gearboxes with a built-in

hydraulic disc clutch.

Marine gearboxes can be supplied with identical and counter rotation of the input and output

shafts. The built-in thrust bearings absorb the propeller thrust.

5.1.2

Path of drive

The engine power is transmitted to the input shaft by way of the flexible engine to gearbox

coupling.

Path of drive in counter rotation

Input shaft A - Clutch A (closed) - Pinion shaft A Output shaft C.

The output shaft rotates in the opposite direction from

the input shaft.

Path of drive with identical rotation

Input shaft A - Clutch housing A - Clutch housing B Clutch B (closed) - Intermediate shaft B Output shaft C.

The output shaft rotates in the same direction as the

input shaft.

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

29

LAF 2346 4575

Description

5.1.3

Aggregates and additionally mounted parts

Hydraulic system

The hydraulic system

consists of:

Control valve

Pressure delay

system

Oil pump

Oil filter

Oil

filter

Heat exchanger

Valve block with pressure

limiting valve

Control valve

Pressure oil system with

pressure delay pot

Lubrication oil system

The operating oil pressure is

controlled by the pressure

limiting valve.

Heat

exchanger

Output shaft

30

Oil

pump

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Description

Hydraulic diagram (LAF gearbox)

Main clutch

Heat exchanger

Oil filter

Gearbox

pump

Stand-by

pump

Dipstick

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

Lubrication oil

31

LAF 2346 4575

Description

Oil pump

The oil pump, mechanically driven by the transmission,

is a gear pump that serves to supply the gearbox with

pressure oil and lubrication oil.

Oil filter

The oil filter serves to filter out solid particles from the

operating oil. This is a duplex filter with two filter elements

(during operation it is possible to switch from the soiled filter

element to a clean one).

A mechanical or electrical contamination indicator indicates

when a filter element is contaminated. On changing filters,

please refer to the maintenance chapter of the operating

manual, page 50.

Heat exchanger

The heat exchanger is a tube-bundle heat exchanger.

Seawater or freshwater taken from a closed cooling

water circulating system is used as a coolant.

On maintenance of the oil cooler, please refer to the

maintenance chapter of the operating instructions,

beginning at page 54.

Valve block with pressure limiting function

Operating pressure is regulated by a spring-loaded

pressure limiting valve.

Standard operating pressure is approx. 25 bar (2500 kPa

or 362 psi).

32

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Description

Control valve, electrical

The gears are engaged by means of axial slide valves which

are brought into the desired position of engagement by axially

shifting the control piston.

LAF gearbox - 4/2 directional valve with lock (without return

spring)

Pressure build-up system

The pressure build-up system ensures smooth

engagement of the gearbox clutch.

Oil manometer and supervision

An oil pressure manometer is mounted on the gearbox for

monitoring oil pressure. This manometer indicates the operating

pressure.

Operating pressure is set differently depending on the gearbox

type.

Operating pressure is checked with the engine running at nominal

speed, the gearbox at operating temperature and the clutch

engaged.

With the engine running at nominal speed and the clutch

engaged, operating pressure must be within the range indicated

by the markers on the manometer.

The supervision system continuously measures current values

of operating characteristics such as temperature, pressure,

speed (optionnally) and oil level (optionnally). If any parameter

defined in the supervision plan is exceeded (e.g. temperature) or not

attained (e.g. pressure) an alarm is given in the form of an electrical signal.

Electrical stand-by pump

The oil pump with electrical motor is designed to be used as a

stand-by pump in the event that the mechanical gear pump fails.

Danger of electric shock!

Do not disconnect or service this device until

power supply has been disconnected!

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

33

LAF 2346 4575

Description

5.2

Power Take Off PTO K41

The power take off may be used for auxiliary units (e.g. generator or an additional pump).

Size and design are built to order. This power take off may therefore only be used for the

application it is designed for.

Power take off

Controllable

Speed

Rotating direction

K 41A

No

i x nengine

Counter to engine

K 41B

No

i x nengine

Counter to engine

K 41A: primary PTO - PTO shaft turns always even if the propeller standstill

K 41B: secondary PTO: PTO shaft turns only, if the propeller turns

K41A/B

K41 A

Position

Above input shaft, on the output side

Operating conditions

Running engine

primary PTO

K41 B

34

Path of drive

primary PTO:

Running engine - input shaft with clutch housing - PTO pinion

- PTO shaft

Operating conditions

secondary PTO

Running engine, oil pressure sufficient, engaged main clutch

Path of drive

secondary PTO:

Running engine - input shaft with clutch housing - engaged

main clutch - pinion shaft - PTO wheel - PTO pinion -PTO shaft

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Description

5.3

Power Take Off PTO K51

The power take off may be used for auxiliary units (e.g. generator or an additional pump).

Size and design are built to order. This power take off may therefore only be used for the

application it is designed for.

Power take off

Controllable

Speed

Rotating direction

K 51A

Yes

i x nengine

Counter to engine

K 51B

Yes

i x nengine

Counter to engine

K 51A: primary PTO - PTO shaft turns always even if the propeller standstill

K 51B: secondary PTO: PTO shaft turns only, if the propeller turns

K 51 A/B Position

above input shaft, output sided

K51 A

Running engine, oil pressure sufficient, PTO clutch engaged

Operating conditions

primary PTO

K51 B

Path of drive

primary PTO:

Running engine - input shaft with clutch housing - PTO pinion engaged PTO clutch - PTO shaft

Operating conditions

secondary PTO

Running engine, oil pressure sufficient, main clutch and PTO clutch

engaged

Path of drive

secondary PTO:

Running engine - input shaft with clutch housing main clutch engaged - pinion shaft - PTO wheel - PTO pinion PTO clutch engaged - PTO shaft

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

35

LAF 2346 4575

Description

5.3.1

Control of the PTO

The engaged speed range specified in the order acknowledgement has to be observed. Only

after this the main engine can be regulated to nominal speed. Any increase intended afterwards must be approved by REINTJES.

WARNING!

Manual engaging of the PTO control valve

Danger of personnel by unintentional turning of the PTO shaft!

Dont engage the PTO clutch manually!

STOP-position of the PTO-control valve

In the Stop position the oil is lead to the lube oil lines and the sump. The annular piston is pulled

into his starting position by the return springs.

36

The disengaged disc clutch is permanetly supplied with lube oil. This results in an

idling torque.

With disengaged clutch the PTO shaft may rotate provided the idling torque is higher

than the initial friction torque of the driven parts.

The idling torque depends on the present operating conditions.

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Description

5.4

Gearbox with shaft brake

5.4.1

Gearbox execution

The gearbox is the same as the standard execution (refer to 5.1) but with a mounted shaft

brake. This section therefore deals only with the components differing from the standard

model.

5.4.2

Aggregates and additionally mounted parts

The hydraulic system

Pressure build-up

system brake

The hydraulic system additionally

includes:

A control valve for the brake

The pressure build-up system

for the brake

The pneumatic control for the brake

control valve is additionally mounted

on the gearbox so as to be ready for

operation.

Shaft

brake

Brake control valve

An additional control valve, for controlling the brake,

is mounted on the gearbox.

The control piston is actuated pneumatically.

Control valve brake

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

37

LAF 2346 4575

Description

Brake pressure build-up system

The pressure build-up system ensures smooth application

of the brake.

Shaft brake

The shaft brake is applied automatically during disengaging

the clutch.

The brake is always engaged while the clutch is disengaged.

Hydraulic diagram (gearbox with brake)

Hydraulic block

Shaft brake

Main clutch

Heat exchanger

Oil filter

Control air

Gearbox pump

Dipstick

38

Stand-by

pump

Lubrication oil

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Installation and Alignment

Installation and Alignment

6.1

Responsibility

!

6.2

Installation and alignment are the responsibility of the yard.

Steps in preparation

WARNING!

The gearbox can fall over if improperly secured!

This may result in serious injury or death!

Under no circumstances should you put slings around shaft ends, pipes or

other externally mounted parts.

When suspending the unit, use only the lifting eyes intended for this purpose.

The lifting eye bolts are marked with the label "Sling here".

When installing the gearbox, ensure that:

Transport is carried out only by individuals competent in the use of transport

and lifting equipment.

Only suitable transport aids (e.g. traversing bridges) that are approved for the

weight of the gearbox are used.

Slings do not press against piping or externally mounted parts. A risk of

damage exists!

Steps before installing the gearbox

Remove all protective coverings (Films, Transport Packaging).

Remove any dust or dirt.

Suspend the gearbox from a crane hook using suitable slings.

Please additionally observe the generally safety information as well as the

information in chapter "Transport" on page 19 and the information provided above!

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

39

LAF 2346 4575

Installation and Alignment

6.3

Place of installation requirements

The necessary space for movement of the personnel in the working area must not be

restricted or may be hindered.

Free spaces to be considered especially are indicated in the drawing of installation.

The foundation must be designed to absorb the gearbox weight and working loads.

It has to be strictly considered that sufficient free space for dismantling of housing and shafts

is available for later maintenance.

6.4

Demands on the installation personnel

The installation must be carried out only by authorised staff of the supplier of the propulsion

system or the shipyard.

Required qualification of the installation personnel:

qualified mechanic for the mechanical installation

electrically skilled person for the electrical installation

The installation personnel must wear protective clothes according the regulations.

The protective clothes must be provided by the supplier of the propulsion system

or the shipyard.

6.5

Setting up the gearbox

Before setting up the gearbox, make sure that you have current versions

of these documents:

Installation Instructions (this manual)

Drawing of installation

Supervision Plan

Alignment calculation

Make sure that you have read and understood the descriptions and information

concerning alignment contained in this Installation Instructions.

The drawing of installation represents the basis for setting up the gearbox.

This drawing includes all dimensions and values relevant for setting up the gearbox.

The drawing number applying to your gearbox is indicated in the order acknowledgement.

The drawing of installation may also be obtained from REINTJES indicating the commission

number.

40

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Installation and Alignment

service@reintjes-gears.de

On weekdays: Phone +49 5151 104 0

In emergencies and on weekends: Phone +49 5151 104 237

Aleays carry out the lifting of heavy components with several persons or use

lifting equipment.

Set the gearbox on the foundation in the intended position.

Secure the gearbox against shifting on the foundation until it has been aligned and

permanently fastened.

Protect the gearbox against corrosion, contamination and damage (refer to Preservation

beginning at page 22).

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

41

LAF 2346 4575

Installation and Alignment

6.6

Alignment

Determine the permissible GAP and SAG values for all shaft connections taking into

account the technical information (alignment calculation, thermal expansion and

manufacturrers information) applying to the units to be connected.

In addition, take into account settlement effects for the cast-resin foundation. Request the

cast-resin manufacturer to send you detailed information on settlement.

Carry out the alignment work only after the vessel is afloat with absolutely no ground

contact with the sea bed.

The vessel should be equipped as far as possible. Missing heavy equipment, e.g. winches,

cranes, has to be duly considered.

Carry out the alignment work in the early morning. Direct sunlight can influence the

alignment result.

A prerequisite for the trouble-free operation of the gearbox is the careful alignment of

the input shaft of the gearbox with the engine shaft

the output shaft of the gearbox with the propeller shaft

the PTO shafts with the connected auxiliary units

Take into account the thermal expansion of the engine, gearbox, aggregates and

foundations at operating temperature.

Also if torsionally flexible couplings or cardan shafts are used, precise alignment with the

engine will be required. Any misalignment will have negative effects on the service life

of the gearbox and the connected components.

Observe the manufacturers' instructions when aligning:

6.7

the output shaft of the gearbox with the propeller shaft connection

the engine with the input shaft of the gearbox

the auxiliary units with the additional gearbox shafts (PTO)

Connection to Propeller Shaft

A prerequisite for the connection of the propeller shaftline with the gearbox is that the

propeller shaft and/or the intermediate shaft be in the static operating position.

To be in the static operating position means:

42

the propeller shaft and the intermediate shaft are in their bearings

the propeller is mounted

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Installation and Alignment

the intermediate shaft flanges are connected (if present)

the flange facing the gearbox is in the alignment position (if necessary)

Alignment

screws

Hole

for foundation bolts

Surface for

collision chocks

Surface for

lateral

collision chocks

Gearbox foot including fastening options

Steps in connecting to the propeller shaft

Screw the alignment screws into the gearbox foot.

Fix the adjusting screws on the foundation, with which you can align the gearbox

horizontally, in longitudinal and transverse directions.

With the adjusting screws, align the gearbox

vertically and horizontally in longitudinal and transverse directions with the propeller

flange, according to the specified data.

If an alignment calculation is available, you must observe the calculations and

procedures specified therein.

Take into consideration thermal expansion at operating temperature.

A thermal expansion diagram may be requested from REINTJES.

Additionally take into account settling effects when setting the gearbox up on a

cast-resin foundation.

Request detailed documentation on this from the manufacturer of the cast resin.

With approved methods

(gauges, laser), measure the

horizontal and vertical GAP and

SAG values between the gearbox flange and the counterflange on the propeller side.

Example: Measuring of the GAP and SAG values:

gearbox output

flange

propeller shaft

SAG

GAP

Permissible tolerances:

Radial misalignment 0.05 mm

(centreline run-out 0.025 mm) - SAG

Angular misalignment 0.05 mm related to 300 mm flange diameter - GAP

Document your GAP and SAG values

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

43

LAF 2346 4575

Installation and Alignment

Fix the gearbox to the foundation, as described in paragraph 6.8.

Check the gap and sag values.

Connect the propeller shaft to the gearbox output shaft after the gearbox is firmly

fixed to the foundation.

If you have a special, deviating installation situation, agree the necessary steps

with REINTJES prior to the installation.

service@reintjes-gears.de

On weekdays: Phone +49 5151 104 0

In emergencies and on weekends: Phone +49 5151 104 237

6.8

Fixing the gearbox to the foundation

Following the alignment with the propeller shaft, the gearbox can be fixed on the foundation,

as described in the following.

The design of the foundation bolts and their tightening torques lies exclusively with the

shipyard.

6.8.1

Gearboxes with Longitudinal Mounting Arrangement, Metal Seat Chocks,

Rigid Mounting

The following combinations are permissible for the gearbox fixation

1. Seat chocks with 4 fitting bolts, through bolts and collision chocks. for propeller

thrust AHEAD and ASTERN!

fitting bolt

through bolt

44

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Installation and Alignment

2.Seat chocks with fitting bolts and through bolts without collision chocks,

(Number of fitting bolts depending on propeller thrust)

3. Seat chocks with collision chocks, with the foundation bolts designed as

through bolts.

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

45

LAF 2346 4575

Installation and Alignment

6.8.2

Gearboxes with Longitudinal Mounting Arrangement, Cast Resin Seat Chocks,

Rigid Mounting

The following combinations are permissible for the gearbox fixation:

1. Cast-resin seat chocks with 4 fitting bolts, collision chocks for propeller thrust

"AHEAD" and "ASTERN", and through bolts

fitting bolt

through bolt

2. Cast-resin seat chocks with collision chocks, with the foundation bolts designed as

through bolts.

46

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Installation and Alignment

6.8.3

Gearboxes with Longitudinal Mounting Arrangement, Adjustable metal seat

chocks, Rigid Mounting

The following combinations are permissible for the gearbox fixation:

1. Vibracon SM elements or RotaChock elements with 4 fitting bolts, collision chocks

for propeller thrust "AHEAD" and "ASTERN", and through bolts

fitting bolt

through bolt

2. Vibracon SM elements or RotaChock elements with collision chocks, with the

foundation bolts designed as through bolts.

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

47

LAF 2346 4575

Installation and Alignment

6.8.4

Gearboxes with Transverse Mounting Arrangement, Rigid Mounting

The following combinations are permissible for the gearbox fixation:

1. Thrust bearing mounted on the engine side

Cast-resin seat chocks with through bolts and steel seat chocks with fitting bolts in the

area of the thrust bearing

with fitting bolts

2. Thrust bearing mounted on the engine side

Cast-resin seat chocks with through bolts, collision chocks for propeller thrust

"AHEAD", and fitting steel bushes with expansion bolts for propeller thrust "ASTERN"

48

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Installation and Alignment

3.Thrust bearing mounted on propeller side

Cast-resin seat chocks with through bolts and steel seat chocks with fitting bolts in the

area of the thrust bearing

with fitting bolts

4.Thrust bearing mounted on propeller side

Cast-resin seat chocks with through bolts and fitting sleeves with expansion bolts for

propeller thrust "AHEAD" and "ASTERN"

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

49

LAF 2346 4575

Installation and Alignment

Basic principle of a simple collision chock

The collision chocks are designed to transfer the propeller thrust to the foundation.

Ensure that the gearbox is installed distortion-free.

The design of the collision chocks lies within the responsibility of the shipyard.

The collision chocks are to be structurally designed so that they can withstand the maximum

occurring propeller thrust without taking into account the foundation bolt preloading. Stopper

chocks are to be made from metallic materials. There must be metal-to-metal contact on

both sides and they must be secured against displacement.

Stopper chocks are to be manufactured to a wedge or double wedge design. Positioning of

the wedge-shaped chocks without clearance must be executed with the plant at its operating

thermal condition. The subsequent fixing of the chocks is to be ensured by screws or welding up the wedges over the entire wedge length. The design and correct installation of the

stopper chocks lies within the responsibility of the shipyard.

Observe the demands on seat chocks specified in paragraph 6.9.

Fit the seat chocks between the gearbox feet and the top plate.

Back off the alignment screws before tightening the foundation bolts.

Following the alignment with the propeller shaft, screw the gearbox to the foundation, so that

it is protected against displacement. In doing so, observe the demands and notes on the

bolts stated in paragraph 6.10.

Any other foundation methods must be approved by REINTJES.

50

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Installation and Alignment

6.9

Seat Chocks

6.9.1

Metal Seat Chocks

The seat chocks have the task to keep the gearbox in the desired position and direct the reaction forces into the foundation as evenly as possible. The material to be preferred for metal seat

chocks shall be steel or cast steel. Cast iron may also be used.

The thickness of the seat chock shall amount to between 20 and 80 mm. When using cast

iron, the minimum thickness is 40 mm. The surface of recesses in the seat chock should be

less than 20% of the total surface of the seat chock.

Rectangular seat chocks must be used only.

The seat chock has to be manufactured from one part. Shims or lining plates are not

permissible.

Metal seat chocks have to be fit in through touching on both sides. The bearing share

achieved must be at least 75%.

Tack welding on seat chocks is not permissible.

Seat chocks must be sufficiently dimensioned and closely fitted. They have to be made in

accordance with the rules of the Classification Societies.

6.9.2

Cast-resin Seat Chocks

As a matter of principle, only approved material by authorised firms must be used in

compliance with the rules. Before casting resin under the gearbox, the calculations and the

tightening method for the foundation bolts have to be submitted to the Classification Society

for approval.

The foundation has to be designed such that the maximum stress values between the

gearbox and the cast-resin seat chock indicated by the manufacturer are not exceeded.

The height of the cast-resin seat chocks must be between 20 and 80 mm. In any case, the

height must always be less than the width and length of the part.

Observe the cast resin manufacturer's instructions.

The cast-resin seat chocks must be loaded only after thermosetting.

The alignment screws must be backed off before tightening the foundation bolts.

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

51

LAF 2346 4575

Installation and Alignment

6.9.3

Adjustable Metal Seat Chocks, type Vibracon SM or type RotaChock

As a matter of principle, only adjustable metal seat chocks, type Vibracon SM

(from Co. Machine Support, Netherlands) or type RotaChock, (Chock Design, Netherlands)

must be used in compliance with the instructions. Before installing the gearbox the

calculations and the tightening method for the foundation bolts have to be submitted to

the Classification Society for approval.

The foundation has to be designed such that the maximum stress values between the

gearbox and the Vibracon SM element or type RotaChock element indicated by the

manufacturer are not exceeded.

The alignment screws must be backed off out of contact with the foundation before

tightening the foundation bolts.

6.10

Screwed Connections

The gearbox foundation bolts comprise fitting bolts and/or through bolts.

The foundation bolts have to be calculated according to the state of the art. Under all operating

conditions, the preload of the bolts must be higher than the workload. The elongation of the

bolt has to be designed such, that the connection is not loosened in case of settlement

(recommendation: elongation of bolts must be greater than 0.17 mm).

Any lifting of the gearbox under dynamic stress must be excluded.

The working forces needed for calculating the bolts may be obtained from REINTJES. In

addition to the working forces, the forces added by mounted components must be included

in the calculation of the bolts.

As a matter of principle, the screwed connection must be secured against loosening.

The seats of bolt heads and nuts have to be plane-parallel. It must be ensured that the seat

under the bolt head and nut is sufficiently dimensioned in order not to exceed the permissible surface pressure.

52

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Installation and Alignment

6.10.1

Fitting Bolts

The fitting bolts are designed to firmly fix the gearbox on the foundation.

When using metal seat chocks and a sufficient number of fitting bolts, the propeller thrust can

be transmitted through the foundation bolts exclusively. In this case the fitting bolts have to be

checked for bolt bearing pressure and shear. The fitting bolts have to be positioned in the direct

vicinity of the thrust bearing.

When using cast resin seat chocks the propeller thrust must not be transmitted through the

fitting bolts.

The geometry of the fitting bolts must be designed such that at least 50% of the height of the

gearbox foot and 50% of the height of the top plate are covered by the fitting shank.

The fitting bolts used must at least be of tensile strength 8.8 in accordance with

ISO 898. The fitting bolt bores are predrilled.

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

53

LAF 2346 4575

Installation and Alignment

6.10.2

Fitting bolts in combination with adjustable Metal Seat Chocks

The task of the fitting bolts is the exact fixing of the gearbox on the foundation.

A transmitting of the propeller thrust by the fitting bolts isn't permissible.

The geometry of the fitting bolt has to be so formed that at least 50% of the gearbox foot

height and 50% of the heights of the top plate are covered by the pass shaft.

The used fitting bolts must correspond to at least the strength class 8.8 to ISO 898.

The drillings for the fitting bolts are pre-drilled.

6.10.3

Fitting steel bushes with Expansion Bolts

The fitting steel bushes are designed to firmly fix the gearbox on the foundation and

transfer the propeller thrust. The fitting steel bushes have to be checked for bolt bearing

pressure and shear. The fitting steel bush bores are predrilled. The expansion bolts

used must at least be of tensile strength 8.8 in accordance with ISO 898. The fitting

steel bushes must have comparable material properties, however, they must at least

have a tensile strength of Rm = 800 N/mm and a yield point of Re = 640 N/mm.

54

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Installation and Alignment

6.10.4

Through Bolts

The used through bolts must correspond to at least the strength class 8.8 according

to ISO 898.

The through bolts must comply with application-specific requirements and be tightened

to the specified torque.

6.11

Connection to Engine

Conditions for connection to engine:

The gearbox is aligned with the propeller shaft.

The gearbox is firmly fixed on the foundation.

The engine is aligned axially to the gearbox. The space between gearbox and engine

must correspond to the mounting length of the flexible coupling. The axial reaction

forces of the flexible coupling on engine and gearbox shall be as low as possible.

Observe the initial values of engine and flexible coupling manufacturer.

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

55

LAF 2346 4575

Installation and Alignment

Operational steps for connection to engine

Align the engine with the adjusting screws, horizontally in longitudinal and transverse

directions, and vertically in front of the input flange of the gearbox, according to the

specified data.

With approved methods (gauges, laser), measure the horizontal and vertical gap

and sag values.

Permissible tolerances:

Radial misalignment 0.05 mm (centreline run-out 0.025 mm) - sag

Angular misalignment 0.05 mm related to 300 mm flange diameter - gap

Document your gap and sag values.

Consider the thermal expansion of the engine, gearbox and foundation at operating

temperature.

Note that the resilient mounting elements of the engine will settle later.

Consider that displacement of the engine and gearbox can occur and that the working forces

can have an impact on the foundation.

Consider the maximum permissible reaction forces exerted by the flexible coupling on the

gearbox input shaft.

During all operations, observe the instructions of the engine and coupling manufacturers.

When the engine alignment and the alignment check are finished, the engine foundation can

be cast.

Connect gearbox and engine with the flexible coupling according to the manufacturer's

instructions.

56

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Installation and Alignment

Variables for determining the reaction forces of the flexible coupling

Determine the radial reaction force of the coupling FR due to radial misalignment.

FR = r x Cr dyn

r - radial shaft misalignment;

Cr dyn - radial stiffness of the flexible coupling

Determine the corresponding bending moment MB due to angular misalignment.

MB=0.5 x Cax x D x X1

Cax - axial stiffness of the flexible coupling;

D - diameter of the connection between the flange and the flexible coupling/flywheel

X1 - measured angular misalignment (GAP)

Inform REINTJES of the reaction force FR, the bending moment MB and the

distance L for approval.

L = S + X = distance from point of application FR to big cone diameter of gearbox input shaft

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

57

LAF 2346 4575

Installation and Alignment

6.12

Connection to the gearbox PTO

Pre-conditions for connection to the PTO:

The gearbox is aligned with the propeller shaft.

The gearbox is aligned with the engine.

The gearbox is firmly fixed on the foundation.

Operational steps for connection to PTO

Align the auxiliary unit driven by the PTO (e. g. generator) with the adjusting screws,

horizontally in longitudinal and transverse directions, and vertically in front of the PTO

shaft of the gearbox, according to the specified data.

With approved methods (gauges, laser), measure the horizontal and vertical gap

and sag values.

Permissible tolerances:

Radial misalignment 0.05 mm (centreline run-out 0.025 mm) - SAG

Angular misalignment 0.05 mm related to 300 mm flange diameter - GAP

Document your GAP and SAG values.

Consider the thermal expansion of the gearbox, auxiliary unit and foundation at

operating temperature.

Consider that displacement of the auxiliary unit and gearbox can occur and that the

working forces can have an impact on the foundation.

Consider the maximum permissible reaction forces exerted by the flexible coupling

on the gearbox PTO shaft.

During all operations, observe the instructions of the auxiliary unit and coupling

manufacturers. Fix the auxiliary unit on the foundation according to the supplier's

instructions.

Determine the reaction forces of the flexible coupling (as described in point 6.11).

Connect PTO and auxiliary unit with the flexible coupling, according to the manufacturer's

instructions.

58

The alignment will only be recognised as complete by REINTJES, if you completely

documented the alignment of propeller shaft - gearbox, gearbox - engine and gearbox

PTO - auxiliary unit!

Installation Instructions

E BV2311 Version 1.1 / 06.02.2013

LAF 2346 4575

Installation and Alignment

6.13

Alignment Check

6.13.1

Alignment Check on Engine Side

Check the gearbox foundation bolts for tightness.

Remove the flexible coupling on the engine.

Finally, check the gap and sag values and compare them with the data specified by the

coupling manufacturer. In case of deviations, please contact REINTJES.

6.13.2

Alignment Check on Propeller Side

Check the gearbox foundation bolts for tightness.

Remove the flange mounting screws on the propeller side.

Finally, check the gap and sag values and compare them with the specified data.

In case of deviations, please contact REINTJES.

6.13.3

Alignment Check PTO

Check the gearbox foundation bolts for tightness.

Remove the flexible coupling.

Finally, check the gap and sag values and compare them with the data specified by the

coupling manufacturer. In case of deviations, please contact REINTJES.

6.14

Connection of Gearbox Components

6.14.1

Connection of valve control and supervision system

Lay the cables for the control and supervision system to the gearbox junction box and

connect them in compliance with the supervision drawing.

On the gearbox itself, the cables for the control and supervision system are completely

connected.