Professional Documents

Culture Documents

Problem Set On N and Lime

Uploaded by

Carla Aquino0 ratings0% found this document useful (0 votes)

176 views1 pagea

Original Title

Problem Set on N and Lime

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenta

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

176 views1 pageProblem Set On N and Lime

Uploaded by

Carla Aquinoa

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

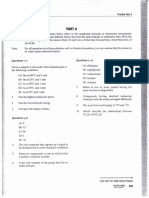

ChE 140 WCD/FRU & SDE/SWX

Problem Set on Nitrogen Compounds and Lime

Deadline: 28 March 2016 (Monday)

Show your complete solution to the following problems.

1. In a Haber plant the gas leaving the CuCl tower contains 75.16% H2, 24.57% N2, and 0.27%

inerts. The gas entering the first bank of converters contains 79.52% H2, while the gas

leaving the absorber, which follows the first bank, contains 80.01% H2. Absorption of NH3

is substantially complete, and the design of the absorber is such that the amount of

permanent gases removed from the system in the absorbing medium is negligible. What is

the efficiency of utilization of H2 in the first bank? What is the percent conversion of H2 per

pass, i.e., the mols of H2 reacting to form NH3 per 100 mols of H2 entering the converters?

2. A synthetic-ammonia unit with a single converter is converting a fresh feed gas containing

75.8% H2, 23.7% N2, and 0.5% inerts. The gas leaves the converter containing 18.6% NH3

and 70.0% H2. This converted gas is fed to a cooler under conditions of temperature and

pressure such that most of the ammonia leaving the converter is condensed to a liquid and

removed. On reduction of pressure all the dissolved gases are evolved from this liquid

ammonia. These are compressed and recycled to the inlet of the converter, except for a purge

provided in the recycle line. The uncondesed ammonia leaving the cooler in these gases is

found to be 8% of that leaving the converter. Calculate the amount and composition of the

purged gases per 100 mols of feed gas, and determine the net mols of residual gas recycled

to the converter inlet per 100 mols of feed gas.

3. A plant consisting of five identical vertical lime kilns was tested over a 12-hr period under

normal operating conditions to determine its performance. Each kiln was 63 ft high and had

an outside diameter of 10 ft. The kilns were housed in a building 40 ft high. Below the roof,

the average temperature was 120F. The average gas analysis of the charge was 97.5%

CaCO3. The total production of lime from all five kilns during the 12-hr period was 139,500

lb, and the average analysis 93% CaO, 3.8% core, and 3.2% inerts. The average temperature

of the lime at the fire boxed was 1920F and at the discharge table 569F. The fuel was

producer gas, which entered the kilns at an average temperature of 787F. The producer gas

contained 7.9% CO2, 1.0% O2, 18.4% CO, 3.7% CH4, 12.1% H2, and 56.9% N2; and its dew

point was 112F. The average composition of the top gas was 22.4% CO2, 5.6% O2, 0.3%

CO, and 71.7% N2; and its temperature averaged 626F. The air entered the bottom of the

kiln at an average temperature of 626F. The air entered the bottom of the kiln at an average

temperature of 60F, carrying 0.0046 lb H2O per pound dry air. Calculate the following

quantities:

a. Mols of dry producer gas per ton lime

b. Mols of dry air per ton lime

c. Mols of dry top gas per ton lime

d. Mols of H2O in the top gas per 100 mols dry gas

e. Percent excess air

f. Btu lost to the surroundings through the walls of the kiln per ton of stone

You might also like

- Trade - Gov 07192016global Monitor ReportDocument15 pagesTrade - Gov 07192016global Monitor ReportCarla AquinoNo ratings yet

- Sulfur Compounds 1 of 5Document11 pagesSulfur Compounds 1 of 5Carla AquinoNo ratings yet

- Circuit Ree ArticleDocument4 pagesCircuit Ree ArticleCarla AquinoNo ratings yet

- GuidelinesDocument133 pagesGuidelinesCarla AquinoNo ratings yet

- FirstSearch TutorialDocument16 pagesFirstSearch TutorialCarla AquinoNo ratings yet

- PHL Exports To The WORLD As of Nov 2015Document13 pagesPHL Exports To The WORLD As of Nov 2015Carla AquinoNo ratings yet

- Asia Pallet Brochure PDFDocument2 pagesAsia Pallet Brochure PDFCarla AquinoNo ratings yet

- Test Methods of Rubber Materials and Products PDFDocument118 pagesTest Methods of Rubber Materials and Products PDFCarla AquinoNo ratings yet

- Periodic Table AdvancedDocument1 pagePeriodic Table Advancedapi-287426421No ratings yet

- Acad Cal 2016-2017Document1 pageAcad Cal 2016-2017Carla AquinoNo ratings yet

- A Mathematical Model For Predicting The Flash Point of Binary SolutionsDocument10 pagesA Mathematical Model For Predicting The Flash Point of Binary SolutionsCarla AquinoNo ratings yet

- Some Critical Discussions On Flash and Fire Points of Liquid FuelsDocument10 pagesSome Critical Discussions On Flash and Fire Points of Liquid FuelsCarla AquinoNo ratings yet

- P48-003 (ChE 124 Reference)Document8 pagesP48-003 (ChE 124 Reference)Carla AquinoNo ratings yet

- PHL Imports From JapanDocument12 pagesPHL Imports From JapanCarla AquinoNo ratings yet

- PHL Imports From IndonesiaDocument11 pagesPHL Imports From IndonesiaCarla AquinoNo ratings yet

- BETP Stats - PHL Imports From Malaysia - 05sept2012Document11 pagesBETP Stats - PHL Imports From Malaysia - 05sept2012Carla AquinoNo ratings yet

- Problem Set On N and LimeDocument1 pageProblem Set On N and LimeCarla AquinoNo ratings yet

- 1999 UP ALCHEMES ConstitutionDocument10 pages1999 UP ALCHEMES ConstitutionCarla AquinoNo ratings yet

- 2010 UP ALCHEMES ConstitutionDocument11 pages2010 UP ALCHEMES ConstitutionCarla AquinoNo ratings yet

- Final Official List of Winners ESC Election 2010Document2 pagesFinal Official List of Winners ESC Election 2010Carla AquinoNo ratings yet

- Official List of Members (Updated, 10-11A)Document9 pagesOfficial List of Members (Updated, 10-11A)Carla AquinoNo ratings yet

- Illustrator CS6 shortcuts guideDocument2 pagesIllustrator CS6 shortcuts guideChristina Vaughn100% (1)

- CHEM ENG LAB PERMITDocument2 pagesCHEM ENG LAB PERMITCarla AquinoNo ratings yet

- EW 2016 Handbook v3Document294 pagesEW 2016 Handbook v3Carla AquinoNo ratings yet

- Up Residence HallsDocument4 pagesUp Residence HallsCarla AquinoNo ratings yet

- Waiver and Release From LiabilityDocument1 pageWaiver and Release From LiabilityCarla AquinoNo ratings yet

- EEGJulyrevisedFINAL1 2003 030 0548 2Document30 pagesEEGJulyrevisedFINAL1 2003 030 0548 2Carla AquinoNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- KSP & Reaction QuotientDocument2 pagesKSP & Reaction QuotientAndy TanNo ratings yet

- GUCET Syllabus and Books SuggestedDocument2 pagesGUCET Syllabus and Books SuggestedpremsempireNo ratings yet

- Atomic Models Seminar by Shanti SharmaDocument24 pagesAtomic Models Seminar by Shanti Sharmaahsanbgayo100% (1)

- Project Report On Continuous Contact EquipmentDocument16 pagesProject Report On Continuous Contact EquipmentSavan LadaniNo ratings yet

- Chapter 8 Crude Oil RefiningDocument52 pagesChapter 8 Crude Oil RefiningFatima Al-nNo ratings yet

- CM1401 NotesDocument33 pagesCM1401 NotesTeo Jia Ming NickolasNo ratings yet

- MOF-5 Composites Exhibiting Improved Thermal ConductivityDocument9 pagesMOF-5 Composites Exhibiting Improved Thermal Conductivitywudi zheNo ratings yet

- LTMDocument12 pagesLTMLuqyNo ratings yet

- Organic Chemistry 2021Document76 pagesOrganic Chemistry 2021Arah Mae BonillaNo ratings yet

- Chem TechDocument181 pagesChem TechDream CakeNo ratings yet

- Sat TestDocument14 pagesSat TestDuy Khang Bui100% (1)

- Redox Reactions in Daily LifeDocument5 pagesRedox Reactions in Daily LifeClaire DemayoNo ratings yet

- CM TB Solutions C05Document4 pagesCM TB Solutions C05Kyi Oo WaiNo ratings yet

- Test Bank For Organic Chemistry Structure and Function 6th Edition VollhardtDocument15 pagesTest Bank For Organic Chemistry Structure and Function 6th Edition Vollhardtverawinifredtel2No ratings yet

- Class 11 Notes on Periodic TableDocument18 pagesClass 11 Notes on Periodic Tablepallab mukherjeeNo ratings yet

- Revised Chemistry of Lanthanoides PDFDocument61 pagesRevised Chemistry of Lanthanoides PDFFarzana MustafaNo ratings yet

- The Process of DecaffeinationDocument3 pagesThe Process of Decaffeinationjrc5569No ratings yet

- Surface Texturing-Applications and MethodesDocument33 pagesSurface Texturing-Applications and MethodesmaheshNo ratings yet

- 2021 08 25 Atomic Notation Practice WorksheetDocument3 pages2021 08 25 Atomic Notation Practice WorksheetTimothy Urtz (Chicago)No ratings yet

- Periodic Trends WorksheetDocument5 pagesPeriodic Trends WorksheetChristy HuynhNo ratings yet

- Demostration of Boyle's Law ReportDocument5 pagesDemostration of Boyle's Law ReportميسرةNo ratings yet

- 9701 Y16 SP 4 PDFDocument22 pages9701 Y16 SP 4 PDFasipraw01No ratings yet

- UNIT 4 - T V NGDocument7 pagesUNIT 4 - T V NGKiều TrangNo ratings yet

- Ice Cream Process Production LabDocument5 pagesIce Cream Process Production Labsarah sharilNo ratings yet

- Phosphate Removal From Water Using Bottom Ash Adsorption Performance Coexisting Anions and Modelling StudiesDocument13 pagesPhosphate Removal From Water Using Bottom Ash Adsorption Performance Coexisting Anions and Modelling StudiesMiradatul Nabilah Binti Mohd RodhiNo ratings yet

- Heat Exchanger 1Document17 pagesHeat Exchanger 1tunjung bayu hernawanNo ratings yet

- NATURAL GAS BOILER CALCULATIONS INSTRUCTIONSDocument20 pagesNATURAL GAS BOILER CALCULATIONS INSTRUCTIONS@sss100% (1)

- R717 refrigerant thermodynamic propertiesDocument1 pageR717 refrigerant thermodynamic propertiesWillian SouzaNo ratings yet

- Measuring Temperature with ThermometersDocument57 pagesMeasuring Temperature with ThermometersCyril Lyn Natividad Credo91% (11)