Professional Documents

Culture Documents

Jsa Grinding Welding Gas Cutting

Uploaded by

Qomarudin ComenkOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Jsa Grinding Welding Gas Cutting

Uploaded by

Qomarudin ComenkCopyright:

Available Formats

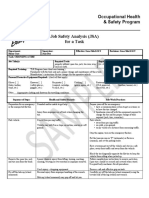

Project:

JOB SAFET ANALYSIS

Company Logo

Ref No.:

Rev No.:

Grinding, Welding & Gas cutting

Page:

Prepared by:

Reviewed by:

Approved by:

Date:

Step

No.

1

Description of

Task Step

Work start-up

& obtaining

PTW

Unauthorized work

Invalid permit

Lack of competency

Lack or poor

communication

Grinding

Rotating equipment

sparks.

Damaged grinding

disc

PTW applicant

Supervisor

PTW holder

Supervisor

Make sure guards are fitted to all moving parts

Ensure the proper use of guards

Inspect the grinding discs prior to starting work

(ring test)

Make sure that disc is compatible with the

grinding machine

Check the RPM of disc & machine

Proper PPE (Gloves + Mask).

Correct installation of Grinder Wheel.

Gas monitor correctly sited.

Spark containment to be used.

Electrocution.

High Pressure air

Responsible Person

Obtain a hot work permit before starting the job

Get the permit validated for the specific day

Supervisor must ensure that all work activities are

carried out by competent personnel

Conduct Toolbox meeting, review the Method

statement and Job safety analysis to all craftsmen

involved in the work activities.

Responsible person will conduct inspection,

monitor the work activities and have to ensure

safety standards and procedures are strictly

adhered to.

Haste or shortcut

Control Measures/

Preventive Measures

Hazard

1 of 3

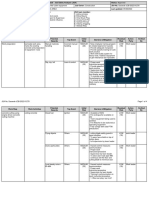

Project:

JOB SAFET ANALYSIS

Company Logo

Ref No.:

Rev No.:

Grinding, Welding & Gas cutting

Step

No.

Description of

Task Step

Gas Cutting

Welding

Control Measures/

Preventive Measures

Hazard

Flying object/eye

injuries

Page:

Only experienced personnel to use the equipment.

Wear a face shield while grinding

Make sure an eye wash station is available nearby

2 of 3

Responsible Person

Burns.

Fire Hazard.

Explosion.

Tripping.

Damaged or leaking

cylinders or hoses

Proper isolation of system.

All cylinders to be secured.

Flame arrestor between the cylinder & torch

Hoses in good condition.

Proper PPE.

Trained Fire Watch.

Gas Monitor correctly sited.

Correct Fire Extinguisher(s).

Deployment of Experienced personnel.

Cordoning of the area.

Fire Blanket.

Inspect the cylinders & hoses before starting the

job

Supervisor &

Workers

Fire Hazard

Burns.

Supervisor &

Workers

Electrocution/

Spatter burns

Before starting welding make sure the area is

clear of all types of combustible materials

Provide a fire blanket on site

Make sure fire extinguishers are available on site

Wear proper PPE for welding ie., leather jackets,

Gloves, welding goggles/welding mask,

Trained Fire Watch.

Gas Monitor correctly sited.

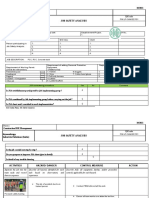

Project:

JOB SAFET ANALYSIS

Company Logo

Ref No.:

Rev No.:

Grinding, Welding & Gas cutting

Step

No.

Description of

Task Step

Control Measures/

Preventive Measures

Hazard

Damage cable

Hot tabs end pieces

of welding rods.

Sparking

Damage cable

Page:

UV rays

Certified Equipment and to be sited as near as

possible to work site.

Proper earthing of equipment.

Certified Welder.

Make sure spark containment is used such as a

welding hood/fire blanket.

Ensure that rod holder is in good condition.

Ensure that forward and return cables are in good

working condition.

Use proper cable connector for extension.

If cables are crossing the road then ensure proper

protection.

The welder & the welder helpers must wear

welding goggles

3 of 3

Responsible Person

You might also like

- Jsa For Arc WeldingDocument3 pagesJsa For Arc Weldingtnssbhaskar100% (4)

- Vehicular Movement Job Safety Analysis (JSA)Document2 pagesVehicular Movement Job Safety Analysis (JSA)sudam kumar raut100% (2)

- JSA Format NEW Equipment ErectionDocument5 pagesJSA Format NEW Equipment Erectionsakthi venkatNo ratings yet

- Jsa Grit BlastingDocument2 pagesJsa Grit BlastingHenryOdoh100% (3)

- JSA G17 Lift Container With CraneDocument4 pagesJSA G17 Lift Container With CraneYosep Sapto Rahyudi100% (3)

- Jsa For Drilling.Document3 pagesJsa For Drilling.Belsyah Nofriyan75% (4)

- Individualized Education PlanDocument7 pagesIndividualized Education PlanElaine Aninang Hupeda100% (2)

- Jsa Grinding Welding Gas CuttingDocument3 pagesJsa Grinding Welding Gas CuttingRana Waseem Khan82% (78)

- Gas Cutting JsaDocument4 pagesGas Cutting JsaMohammed Minhaj100% (1)

- JSA Mechanical Activity Risk AssessmentDocument1 pageJSA Mechanical Activity Risk Assessmentjithin shankarNo ratings yet

- VentilationDocument92 pagesVentilationRobert Nixon100% (1)

- JSA For Lifting of RebarsDocument5 pagesJSA For Lifting of RebarsNiraNo ratings yet

- Job Hazard Analysis For Desalination of First Effect RetubingDocument7 pagesJob Hazard Analysis For Desalination of First Effect Retubingmc chesterNo ratings yet

- SGD SAIPEM CAMP LOADING AND UNLOADINGDocument2 pagesSGD SAIPEM CAMP LOADING AND UNLOADINGsubhanmusadiq82% (55)

- JSA CarpentryDocument2 pagesJSA Carpentrysubhanmusadiq91% (11)

- Job Safety Analysis: 1 Confined Space Entry JSA ExampleDocument7 pagesJob Safety Analysis: 1 Confined Space Entry JSA Examplerashid zamanNo ratings yet

- Mie Hse Jha 002 - Welding, Cutting, Fabrication WorkDocument4 pagesMie Hse Jha 002 - Welding, Cutting, Fabrication WorkLuqman Osman100% (1)

- Jsa Nitrogen PurgingDocument2 pagesJsa Nitrogen PurgingKanthimathinathan Krishnan100% (5)

- Hard Hat, Safety Glasses, Safety Boots Compulsory: PowerDocument9 pagesHard Hat, Safety Glasses, Safety Boots Compulsory: PowerEbeneshwar Anthony71% (7)

- JSA FORMAT For Materials LoadingDocument2 pagesJSA FORMAT For Materials LoadingVikky KumarNo ratings yet

- JSA For Painting Works-Hazards ControlDocument4 pagesJSA For Painting Works-Hazards Controlkaleem0% (2)

- JSA Installation of Equipment For Electrical and InstrumentDocument3 pagesJSA Installation of Equipment For Electrical and InstrumentHong Hai Pham75% (4)

- JSA for Grinding WorkDocument5 pagesJSA for Grinding WorkM M PRADHANNo ratings yet

- JSA-020-Safety Watch-Hot WorkDocument2 pagesJSA-020-Safety Watch-Hot WorkNishad MuhammedNo ratings yet

- Job Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingDocument2 pagesJob Safety Analysis (Jsa) : Title of Activity / Work: Excavation & TrenchingJayendra Patel89% (9)

- JSA - CABLE TERMINATION TITLEDocument4 pagesJSA - CABLE TERMINATION TITLESyed Yousuf Ali100% (1)

- Electrical Isolation JSA SheetDocument1 pageElectrical Isolation JSA SheetLal Dhwoj100% (2)

- Jsa General HousekeepingDocument2 pagesJsa General HousekeepingHow Chin Engineering Sdn Bhd44% (9)

- Checklist For High Risk Work - Hot WorkDocument8 pagesChecklist For High Risk Work - Hot WorkSalsabilla Putri anggrainiNo ratings yet

- JSA Hot WorkDocument2 pagesJSA Hot Workchhotelal kumar100% (1)

- Nail Gun Pnuematic Work Method Statement SWMS V8Document5 pagesNail Gun Pnuematic Work Method Statement SWMS V8ferny.51No ratings yet

- JHA PlumberDocument3 pagesJHA PlumberEko Susanto100% (1)

- Safe Work Method Statement - Part 1: Company DetailsDocument14 pagesSafe Work Method Statement - Part 1: Company DetailsNithun DeenadayalanNo ratings yet

- Jsa - Electrical WorksDocument2 pagesJsa - Electrical WorksaneshseNo ratings yet

- Tie in Hot Work JHADocument4 pagesTie in Hot Work JHAmalik jahan100% (2)

- 0 JsaDocument54 pages0 JsaRavi AmarlapudiNo ratings yet

- Job Safety and Environmental Analysis WorksheetDocument2 pagesJob Safety and Environmental Analysis WorksheetCherry Betonio100% (1)

- Jsa Pipe Cutting at Fire PumpDocument5 pagesJsa Pipe Cutting at Fire PumpHow Chin Engineering Sdn BhdNo ratings yet

- JSA For Material ShiftingDocument3 pagesJSA For Material ShiftingMohammed Minhaj100% (1)

- Jsa For TELESCOPING BOOM AERIAL LIFTDocument2 pagesJsa For TELESCOPING BOOM AERIAL LIFTVipul Shankar100% (1)

- Chemicals Zetag DATA Powder Magnafloc 351 - 0410Document2 pagesChemicals Zetag DATA Powder Magnafloc 351 - 0410PromagEnviro.comNo ratings yet

- Jsa For Operating A BobcatDocument2 pagesJsa For Operating A Bobcatsoubhagya100% (2)

- Job Safety Analysis: Page 1 of 4Document4 pagesJob Safety Analysis: Page 1 of 4RakeshkasarlaNo ratings yet

- Project Report On Air FilterDocument5 pagesProject Report On Air FilterEIRI Board of Consultants and PublishersNo ratings yet

- JSA Unloading & SHIFTING by Manually 10-01-2017Document16 pagesJSA Unloading & SHIFTING by Manually 10-01-2017PAVANKUMAR100% (1)

- JSA WeldingDocument2 pagesJSA Weldingsubhanmusadiq100% (1)

- Blinding Deblinding Safety AnalysisDocument3 pagesBlinding Deblinding Safety Analysiskaremkoko33% (3)

- Hydro TestDocument3 pagesHydro TestAnonymous qos47GCByNo ratings yet

- JSA Sample 1 Changing A TireDocument3 pagesJSA Sample 1 Changing A Tiree smith100% (1)

- Sarawak JSA for Concrete CuttingDocument4 pagesSarawak JSA for Concrete CuttingMohammad Irfan Kiki IsmailNo ratings yet

- JSA for Above Ground Piping WorkDocument3 pagesJSA for Above Ground Piping WorkBhisamS SallehNo ratings yet

- JSA Earthpit Construction GeneralDocument4 pagesJSA Earthpit Construction Generalmukka88No ratings yet

- Job Safety Analysis (Rolling For MS Plates)Document1 pageJob Safety Analysis (Rolling For MS Plates)Muhammad Ali100% (2)

- Jsa - Cutting and WeldingDocument2 pagesJsa - Cutting and WeldingSantos Rex50% (2)

- JSA Electrical Maintenance LCSDocument8 pagesJSA Electrical Maintenance LCSmohamed yasinNo ratings yet

- Confine Space at Water TankDocument7 pagesConfine Space at Water TanknaraNo ratings yet

- JSA PaintingDocument1 pageJSA PaintingjonesNo ratings yet

- Terminal Tractors and Trailers 6.1Document7 pagesTerminal Tractors and Trailers 6.1lephuongdongNo ratings yet

- Ultratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSADocument5 pagesUltratech Cement Limited - Andhra Pradesh Cement Works: Format For HIRA / JSATFattah100% (1)

- Jsa forOperatingAForkliftDocument2 pagesJsa forOperatingAForkliftsupahing supahingNo ratings yet

- Jsa PaintDocument2 pagesJsa PaintKhalid NaseemNo ratings yet

- Thyssenkrupp Industrial Solutions (India) Job Safety AnalysisDocument5 pagesThyssenkrupp Industrial Solutions (India) Job Safety AnalysisNitesh KumarNo ratings yet

- Work at Height Safety AnalysisDocument2 pagesWork at Height Safety AnalysiszebmechNo ratings yet

- PTA-JSA-005-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-005-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- PTW JHA Electrical Wiring Installation Work at Air Dryer RoomDocument4 pagesPTW JHA Electrical Wiring Installation Work at Air Dryer RoomPHH9834No ratings yet

- Jamec Air FittingsDocument18 pagesJamec Air Fittingsgoeez1No ratings yet

- Overhead Set (OBC)Document19 pagesOverhead Set (OBC)MohamedNo ratings yet

- Regional Ecology Test ScoringDocument14 pagesRegional Ecology Test Scoringaisyah Wardah201No ratings yet

- SafewayDocument70 pagesSafewayhampshireiiiNo ratings yet

- Deadline Anchors BrochureDocument3 pagesDeadline Anchors Brochurejlmunozv100% (2)

- Mri 7 TeslaDocument12 pagesMri 7 TeslaJEAN FELLIPE BARROSNo ratings yet

- Pakistan List of Approved Panel PhysicianssDocument5 pagesPakistan List of Approved Panel PhysicianssGulzar Ahmad RawnNo ratings yet

- Catalogo Unidad Enfriadora Trane R-407C PDFDocument8 pagesCatalogo Unidad Enfriadora Trane R-407C PDFJUAN FRANCISCO AYALANo ratings yet

- TSB 20230831 - Reconnect FATL WM Error Code & Troubleshooting GuideDocument6 pagesTSB 20230831 - Reconnect FATL WM Error Code & Troubleshooting GuideNavjot KaurNo ratings yet

- Final TLE9 Nail Care9 Q1 Module 3Document20 pagesFinal TLE9 Nail Care9 Q1 Module 3Ma. Andrea LagmanNo ratings yet

- Heat Transfer Augmentation in Decaying Turbulent Swirl FlowDocument1 pageHeat Transfer Augmentation in Decaying Turbulent Swirl FlowOnkar ChavanNo ratings yet

- CWK-IDD-009-CC-2020: Reference Checking Consent and Authorization Form Candidate's Full NameDocument1 pageCWK-IDD-009-CC-2020: Reference Checking Consent and Authorization Form Candidate's Full NamePopa Alina-ManuelaNo ratings yet

- Grade 9 P.EDocument16 pagesGrade 9 P.EBrige SimeonNo ratings yet

- Stepan Formulation 943Document2 pagesStepan Formulation 943Mohamed AdelNo ratings yet

- (9F) Ankle - Bones, Joints, Tendons and LigamentsDocument4 pages(9F) Ankle - Bones, Joints, Tendons and LigamentsJeffrey RamosNo ratings yet

- Steps of Repertorization - 5e097dab9ad98Document18 pagesSteps of Repertorization - 5e097dab9ad98Sowjanya JyothsnaNo ratings yet

- Otology Fellowships 2019Document5 pagesOtology Fellowships 2019Sandra SandrinaNo ratings yet

- Marital Satisfaction in Dual Earner FamilyDocument4 pagesMarital Satisfaction in Dual Earner FamilyInternational Organization of Scientific Research (IOSR)No ratings yet

- Group 17-Solid State NMR - Questions-AnswersDocument5 pagesGroup 17-Solid State NMR - Questions-AnswersOmkar AkulwarNo ratings yet

- Environmental Product Declaration: PU EuropeDocument6 pagesEnvironmental Product Declaration: PU EuropeIngeniero Mac DonnellNo ratings yet

- Personal Chiller 6-Can Mini Refrigerator, Pink K4Document1 pagePersonal Chiller 6-Can Mini Refrigerator, Pink K4Keyla SierraNo ratings yet

- No.10 Procedure For The Selection, Training, Qualification and Authorisation of Marine Management Systems Auditors No.10Document9 pagesNo.10 Procedure For The Selection, Training, Qualification and Authorisation of Marine Management Systems Auditors No.10William DaslerNo ratings yet

- Eltra Cs 530Document122 pagesEltra Cs 530ahalonsoNo ratings yet

- Climate Change and Global Warming and Its Impact On BangladeshDocument7 pagesClimate Change and Global Warming and Its Impact On BangladeshAminulHoqueNo ratings yet

- Kidde Ads Fm200 Design Maintenance Manual Sept 2004Document142 pagesKidde Ads Fm200 Design Maintenance Manual Sept 2004José AravenaNo ratings yet