Professional Documents

Culture Documents

Chetan Arunrao Rekhate CV 15032012

Uploaded by

Sani TipareOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chetan Arunrao Rekhate CV 15032012

Uploaded by

Sani TipareCopyright:

Available Formats

CV of CHETAN ARUNRAO REKHATE

Contact: +91 8600939500 , +91 9423829199 , +91 8099473949

E-mail: CREKHATE@GMAIL.COM

Career Objectives:

Seeking a, suitable position which best suits my qualifications and

experience with your esteemed organization to serve the process,

in-service inspection services, exploration industries and enhance

my professional skills.

E-mail: crekhate@gmail.com

Mobile: +91-8600939500

CAREER OBJECTIVE:

To aspire, strive and excel in Quality Control field by utilizing my knowledge and

potential skills, thereby enhancing my corporate skills and ensuring utmost satisfaction of

my superiors and management.

EDUCATIONAL QUALIFICATIONS:

Mechanical engineering study is continue

DEPLOMA

INTERMEDIATE

SSC

INDIAN INSTITUDE

TECHNOLOGY& MANAGMENT

60%

MAHATMA PHULE RAJURA

YASVANT VIDHALAY AHMDPUR

D.B

67%

COMPUTER SKILLS:

Basic knowledge on Computer Fundamentals.

Knowledge on MS Word, Power point, Excel.

Professional Qualification & Certification:

ASNT NDT LEVEL III in UT [Certificate ID: 212581]

ASNT NDT LEVEL III in rt Certificate ID: 212581]

ASNT NDT LEVEL II IN PT

ASNT NDT LEVEL III in MT Certificate ID: 212581]

ASNT NDT LEVEL II in ET

CV of CHETAN ARUNRAO REKHATE

Contact: +91 8600939500 , +91 9423829199 , +91 8099473949

E-mail: CREKHATE@GMAIL.COM

ASNT NDT LEVEL II in VT

Experience:

7 year experience with shutdown experience

Experience:

Functions & Responsibilities:

Witnessing inspections as a third party,

Witnessing Hydro test

Material receiving inspection

Witnessing Alignment of Main Pumps

Witnessing the Installation of Firefighting Pipeline

Inspect the HDPE, GRVE,GRE Pipe Welding & Lamination

Inspect the Weld Fit-Up & Weld visual examination and offering for

visual repairs.

Monitoring the daily weld progress.

Conducting Welder qualification test

Training and qualification of NDE personnel

Review of NDT procedures and written practices.

Implementing the Quality Management System

Conducting weekly meetings and monitoring the welding and NDE

progress.

Witness Ultrasonic Testing & Penetrate Testing.

Reviewing the NDT test results

Conducting periodic Internal Audits and supporting the quality

assurance and quality control systems.

Review of NDT equipment specifications, manuals and calibration

records.

Responsible for Interpretation and evaluation of Radiographs as per

DEP and applicable specifications.

Maintenance of NDE status of the project.

Scheduling NDE training programs,

Instructing faculties and supervising the training programs,

Witnessing Conducting interviews on behalf of clients as a third

party.

COMMON INSPECTION: - FOR ALL ABOVE EQUIPMENTS

1. Hydro testing

2. Thickness gauging

CV of CHETAN ARUNRAO REKHATE

Contact: +91 8600939500 , +91 9423829199 , +91 8099473949

E-mail: CREKHATE@GMAIL.COM

3.

4.

5.

6.

7.

Sandblasting

Painting

NDT DPT, MPT, UT, RT,ET,RFET and AUT

INSPECTION:-PLANT EQUIPMENT

COLUMNS & PR. VESSELS: - External visual inspection includes

foundation bolts,skrits,platform & structural , nozzle and

reinforcement pad, telltale hole checking (pneumatic), external

corrosion & weld joints of nozzles, manholes, skirt joints. Internal

inspection includes demister pad, DSR, tray, TSR , feed pipes,

supports, chimney tray, different packing, nozzle points, Shell

includes Top zone, feed zone & bottom zone due to corrosion,

erosion, hydrogen blistering, cracking and mechanical damage

HEAT EXCHANGER & FIN FAN COOLER: - External visual

inspection includes foundation bolts, shell, shell cover, channel,

channel cover, floating head cover, split ring, tube bundle, STS, FTS,

baffle plate, impingement plates, tie rod and all weld joints etc.

External visual inspection of air cooler includes outer assembly body,

header, fins, tube sheets & plugs.

Company Name: M/S NDT CTC IN VIZAG

Designation

: NDT INSPECTOR

Period

: June 2008 June 2012

Summary of activities :

Upper Indravati Penstock Project (Shell Dia 3.5 mts and Tunnel Dia 4 mts) NDT involves

Radiography Testing and Ultrasonic Testing

HPCL Extension and Maintenance project (NDT involves Radiography testing of piping and

equipment, Ultrasonic Testing of Equipment, Ultrasonic Thickness gauging of equipment and piping,

Magnetic Particle Testing of equipment and Penetrant testing.

Responsible for performing gamma radiography and X-ray.

Responsible for corrosion and erosion monitoring by

Ultrasonic testing of various units

during shut down, Shear wave ultrasonic examination of welds for in-service pressure vessels,

identification of pipe lines.

Performing Magnetic Particle examinations of skirt fillet welds and Penetrant examinations of fire

water piping and other copper nickel piping.

Performing, evaluating and reporting Ultrasonic Shear wave examinations for penstock projects.

Performing gamma radiography in penstock project, interpretation and evaluation of Radiographs.

Following Safe work practices, acting as team leader and reporting to the project coordinator.

Maintaining the NDT status and sending to the Head office.

Performing Ultrasonic Shear wave examination of Tunnel to Shell Y joint and butt weld joints

where radiography is in accessible.

Various NDT inspections such as VT, UT, RT, MPT, DPT, LT etc.

CV of CHETAN ARUNRAO REKHATE

Contact: +91 8600939500 , +91 9423829199 , +91 8099473949

E-mail: CREKHATE@GMAIL.COM

Ultrasonic Flaw Detection (UFD) of welds,castings and lamination of

plates.

Thickness Gauging, Corrosion monitoring

of Vessels ,Storage Tank bottom &annular plates & Pipelines.

Radiography & X-ray Testing of Casting, Forging And Weld Joints.

Fluorescent and Non-fluorescent Magnetic Particle Testing. Dye

penetrate testing of various Ferrous and nonferrous items.

Coordination with client, preparation of monthly work abstract, followup of payment , work planning at site. Interpretation of radiograph

Hardness testing logistic at site. Holiday test of pipe coating material.

Report preparation maintenance of calibration status of NDT

instruments .QA documents at site such maintaining batch number of

consumables. Maintaining dark room accessories etc.

Considerable experience gained in NDT coordination work.

Client meeting, set

up of NDT sites, planning for

mobilization of man power as per work volume and work schedule at

site, consumables at site as per requirement. Preparation of

contingency plans, participation in technical discussion and process of

action plans as per requirement.

Employment History:

Company Name

Country

Designation

Period

: BABA INSPECTION TECHNICAL SERVICES

: INDIA

: NDT LEVEL 3

: june 2012 to 2013-Till Date

Summary of activities

External visual inspection includes foundation bolts,skrits,platform &

structural , nozzle and reinforcement pad, telltale hole checking

(pneumatic), external corrosion & weld joints of nozzles, manholes,

skirt joints. Internal inspection includes demister pad, DSR, tray,

TSR , feed pipes, supports, chimney tray, different packing, nozzle

points, Shell includes Top zone, feed zone & bottom zone due to

corrosion, erosion, hydrogen blistering, cracking and mechanical

damage.

Review and monitoring thickness for equipment and piping,

evaluate retirement life as per retirement thickness.

Internal and External inspections for Static Equipments (Exchangers,

columns, vessels and fired heater).

Maintenance all documentation with assistance of Document

controller.

Making inspection reports.

Review and close out for BOXUP.

Final document review and record findings for completed systems.

CV of CHETAN ARUNRAO REKHATE

Contact: +91 8600939500 , +91 9423829199 , +91 8099473949

E-mail: CREKHATE@GMAIL.COM

Equipments handles and familiar with:

Boroscopes, Magnifiers

Vernier calipers, Micro Meter, welding gauge, pitting gauge,

Profile gauge.

Dry Film Thickness Gauge, Holiday detectors, Wet Film Thickness

Gauge.

Densitometers, Ultrasonic flaw detectors, Ultrasonic Thickness

gauge, Ultrasonic ILI Tool, Magnetic Yoke, Magnetic Flux leakage

Equipment,

Radiographic

Crawlers,

X-ray

Equipments,

Radiographic Projectors, Survey meters

ROLI, TECHOPS and SPEC 2T Radiograph cameras.

Magnetic Particle yokes of Parker USA make.

SIMS electromagnetic (AC/DC) yoke.

Shut Down Experience:

Thickness monitoring and corrosion monitoring of Plant Piping.

Ultrasonic Testing of Welds

Performing magnetic particle and Penetrant testing

Monitoring PMI survey for specific piping circuits made up of materials like P5,

P9, P11, P22 etc

Performing Welders Qualification Tests according to WPS

Performing Fit-up inspection and witnessing welding process.

Performed Radiography Film Interpretation.

Visual inspection of Equipments and pipelines.

Thickness Gauging & Corrosion monitoring of vessels, Storage tanks and annular

plates.

Performing Weld Visual Examinations

Offering for Non Destructive Examinations as per the production requirements.

Performing DP test for nozzles, man way holes, chute plate. Header pipes, top

dished end c-seam, bottom dished end c-seam, skirt joint, and distributed nozzles

in vacuum column.

Performed visual inspection in columns and identified hot spots

Maintenance & inspection of static equipment such as columns

CV of CHETAN ARUNRAO REKHATE

Contact: +91 8600939500 , +91 9423829199 , +91 8099473949

E-mail: CREKHATE@GMAIL.COM

(Bubble cap, structural, mol. Sieve, valve cap, chimney tray),

Heat Exchanger (U Tube, floating head, Fixed, Air fin) vessels

(Actified charcoal, clay, paul ring, carbon ring, ceramic ring,

demisterpad, rotar) flare tip, filter, dryer, reboiler, kettle type

reboiler , scrubber, K. O. Drum, fin fan cooler (stud Type, Plug

type) still, stripper, etc. repair and ovehauling of furnace, hydro

testing of heat exchanger (shell test/ring test, tube test,

backshell test/overall test),Retubing,Refactory repair. Handling of

catalyst (Removal & reloading) .Involved in inspection of piping

vessels and exchangers by using Eddy Current testing ,RFET ,

TOFD and phased array.

Major Clients and Projects worked

Name of the Client

: M/s MEGHA ENGINEERING

&INFRASTRUCTURE PVT LTD

Project Name

: ARP-GROUP(A), ASSAM

Nature of the Project

: Cross country Pipe line

Position Held

: QA/QC Engineer

Name of the Client

: M/S Mynor enterprises Pvt Ltd,

Nature of the Project

: Cross country Pipe line

Position Held

: QA/QC Engineer

Name of the Client

: M/s J.K. Engineering

Nature of the Project

: Cross country Pipe line for ONGC

Pipe

line(Gadimukka,vudoor,kondamanda, Tatipaka)

Position Held

: QA/QC Engineer

Name of the Client

: M/s Thandava Lakshmi

Engineering

Nature of the Project

: Pressure vessel Construction

BHPV, Visakhapatnam

Position Held

: QA/QC Engineer

Name of the Client

: M/s Larsen&Toubro

Nature of the Project

: Pipe Line construction; at VTPS

Vijayawada

CV of CHETAN ARUNRAO REKHATE

Contact: +91 8600939500 , +91 9423829199 , +91 8099473949

E-mail: CREKHATE@GMAIL.COM

Nature of the Project

: New Boiler Construction; at NTPS,

Ramagundam

Nature of the Project

: RT of Structural works; at

Visakhapatnam

Position Held

: QA/QC Engineer

Name of the Client

: M/s Kasukurthi Sujatha

Construction Pvt Ltd.

Nature of the Project

: Kovvuru Pangidi Pipe Line Project

At Kovvuru(W.G Dist) Nature of the Project

: LANCO

Power project Shut down works

Nature of the Project

: IGL Delhi (city gas )

Nature of the Project

: Green Gas ltd Lucknow (city gas )

Position Held

: NDT Technician

Name of the Client

: M/s Pavani Engineering works

Nature of the Project

: Maintenance of HPCL

Position Held

: NDT Technician

Name of the Client

Nature of the Project

: Gopal Engineering Works

: Storage Tank Construction

Codes and Standards Familiar With:

ASNT SNT-TC-1A

ASNT CP-189

ASME SEC V

ASME SEC IX

ASME B 31.1 & 31.3

API 1104

AWS D1.1

Personal Details:

Name

Father Name

Date of Birth

CHETAN ARUN RAO REKHATE

ARUN REKHATE

12-FEB-1992

CV of CHETAN ARUNRAO REKHATE

Contact: +91 8600939500 , +91 9423829199 , +91 8099473949

E-mail: CREKHATE@GMAIL.COM

Sex

Marital Status

Nationality

Languages Known

Permanent Address

PIN COD

:

Passport.no

:

;

Male

Unmarried

Indian

Telugu, English. MARATHI.HINDI

PHC HER TQ UDGIR DISHTIC LATUR

413517

L2587539

Name: CHETAN ARUNRAO REKHATE

Date: 8/03/2014

You might also like

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Alc-10030c Alcotec Alloy Selection BrochureDocument2 pagesAlc-10030c Alcotec Alloy Selection BrochurefogdartNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Abhishek Resume AnceDocument5 pagesAbhishek Resume AnceSani TipareNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Abroad News Paper 11 MayDocument6 pagesAbroad News Paper 11 MaySani TipareNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Interior Designer - NOORA C.VDocument2 pagesInterior Designer - NOORA C.VSani TipareNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Abhishek Resume AnceDocument5 pagesAbhishek Resume AnceSani TipareNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 0000001Document2 pages0000001Sani TipareNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Curriculam Vitae: Post Applied For RT Technician Abhay Pratap SinghDocument5 pagesCurriculam Vitae: Post Applied For RT Technician Abhay Pratap SinghSani TipareNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Engg - Ref - Book (Steel Weight Cal.)Document246 pagesEngg - Ref - Book (Steel Weight Cal.)Anonymous Iev5ggSRNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- UT EquationsDocument2 pagesUT EquationsNavneet Singh100% (1)

- 10.kotti Update CVDocument3 pages10.kotti Update CVSani TipareNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Ultrasonic Inspection NDT Sample Test Report FormatDocument2 pagesUltrasonic Inspection NDT Sample Test Report Formatskynyrd7550% (4)

- Pages From Final Form-1Document1 pagePages From Final Form-1Sani TipareNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Pection NDT Sample Test Report FormatDocument1 pagePection NDT Sample Test Report FormatSani TipareNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Ultrasonic Report FormatDocument1 pageUltrasonic Report FormatAditya PratapNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- Dme 20Document5 pagesDme 20Sani TipareNo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Abhishek Resume AnceDocument5 pagesAbhishek Resume AnceSani TipareNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- App L3 Kuwait 2016 22 Final FinalDocument11 pagesApp L3 Kuwait 2016 22 Final FinalSani TipareNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Pages From Final Form-1Document1 pagePages From Final Form-1Sani TipareNo ratings yet

- Pages From Final Form-1Document1 pagePages From Final Form-1Sani TipareNo ratings yet

- App L3 Kuwait 2016 22 Final FinalDocument11 pagesApp L3 Kuwait 2016 22 Final FinalSani TipareNo ratings yet

- Abhishek Resume AnceDocument5 pagesAbhishek Resume AnceSani TipareNo ratings yet

- Pages From Final Form-1Document1 pagePages From Final Form-1Sani TipareNo ratings yet

- Karthick Subramaniyan - MD InspectorDocument4 pagesKarthick Subramaniyan - MD InspectorSani TipareNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 10.kotti Update CVDocument3 pages10.kotti Update CVSani TipareNo ratings yet

- Welding InspectorDocument4 pagesWelding InspectorSani TipareNo ratings yet

- MANIDocument6 pagesMANISani TipareNo ratings yet

- EPOCH600 EN 201409 WebDocument8 pagesEPOCH600 EN 201409 WebSani TipareNo ratings yet

- UT Level III exam Paper 2012 questions and answersDocument2 pagesUT Level III exam Paper 2012 questions and answersSani Tipare100% (1)

- Abs Mpi TestDocument7 pagesAbs Mpi TestSani TipareNo ratings yet

- Moving Systems & Escalators by Hyundai ElevatorDocument6 pagesMoving Systems & Escalators by Hyundai ElevatorNalin SenadeeraNo ratings yet

- Optimization of Prototype Projects of Aeronautical Engineering Students of Philippine State College of AeronauticsDocument119 pagesOptimization of Prototype Projects of Aeronautical Engineering Students of Philippine State College of AeronauticsDerik RoqueNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Control of Crack WidthsDocument55 pagesControl of Crack WidthsMahmood Mufti100% (1)

- Short Notes On: CamtechDocument2 pagesShort Notes On: CamtechSaptarshi PalNo ratings yet

- 3D Concrete Printing - From Material Design To Extrusion (ACE Workshop, 2017)Document15 pages3D Concrete Printing - From Material Design To Extrusion (ACE Workshop, 2017)Mirza BasitNo ratings yet

- Architecture Portfolio Ingrid AguilarDocument20 pagesArchitecture Portfolio Ingrid AguilaringridpaguilarNo ratings yet

- InstaPDF - in Anna University Affiliated Colleges List District Wise 567Document7 pagesInstaPDF - in Anna University Affiliated Colleges List District Wise 567Dr KumarNo ratings yet

- Crane RunwaysDocument22 pagesCrane RunwaysravikirangeNo ratings yet

- University of Engineering and Technology, Taxila Department of Mechanical EngineeringDocument2 pagesUniversity of Engineering and Technology, Taxila Department of Mechanical EngineeringYasir KhalidNo ratings yet

- Eight DimensionsDocument1 pageEight DimensionsAnonymous FfaqvAx45GNo ratings yet

- Carter Variator CatDocument40 pagesCarter Variator CatMatias MancillaNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Core OM - Term 1 - 2019Document5 pagesCore OM - Term 1 - 2019chandel08No ratings yet

- ECE104Document6 pagesECE104Angelo Gabriel E. AzucenaNo ratings yet

- Curriculum Vitae: Bio DataDocument3 pagesCurriculum Vitae: Bio DataMwesigye Batatwenda Peterson100% (1)

- NPTEL CseDocument3 pagesNPTEL CsePraveen BanasodeNo ratings yet

- AvRID PAC Jun 2019 PDFDocument2 pagesAvRID PAC Jun 2019 PDFnaqeejeeNo ratings yet

- YearinInfrastructure2018 DL PDFDocument332 pagesYearinInfrastructure2018 DL PDFLovepreet singhNo ratings yet

- ASi-Collapse Analysis of RC AssembliesDocument14 pagesASi-Collapse Analysis of RC AssembliesMuhannad AbdulRaoufNo ratings yet

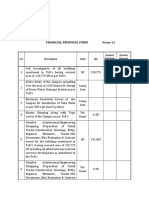

- Financial Proposal Form Form12Document3 pagesFinancial Proposal Form Form12wahabNo ratings yet

- Hyderabad Database BackupDocument48 pagesHyderabad Database BackupVikramNo ratings yet

- ASPE - 45 - Siphonic Drainage PDFDocument49 pagesASPE - 45 - Siphonic Drainage PDFsaftirikNo ratings yet

- US Canada Europe automotive electronics EMC standards regulationsDocument2 pagesUS Canada Europe automotive electronics EMC standards regulationschrosuNo ratings yet

- Design Guidelines For Sewage WorksDocument309 pagesDesign Guidelines For Sewage WorksRamadan RashadNo ratings yet

- Standard Welded Beams Dimensions and PropertiesDocument35 pagesStandard Welded Beams Dimensions and PropertiesKmt_Ae100% (2)

- Fema 303 Seismic DesignDocument366 pagesFema 303 Seismic DesignM Refaat Fath100% (1)

- Co CurriculumDocument380 pagesCo CurriculumRutujaNo ratings yet

- National Electric CodeDocument10 pagesNational Electric CodeRen MariNo ratings yet

- Name NIRF Rank 2021Document8 pagesName NIRF Rank 2021Sonu PrajapatiNo ratings yet

- StudentGradeHistory 19BCY10038Document4 pagesStudentGradeHistory 19BCY10038Help UsNo ratings yet

- 1 IntroductionDocument18 pages1 IntroductionMuhammad UmerNo ratings yet

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- The Cyanide Canary: A True Story of InjusticeFrom EverandThe Cyanide Canary: A True Story of InjusticeRating: 4 out of 5 stars4/5 (51)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)