Professional Documents

Culture Documents

KOORDINATOR-doc 135 Ewf 1090 Workshop 2013 Part 2

Uploaded by

Ivan DulicOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

KOORDINATOR-doc 135 Ewf 1090 Workshop 2013 Part 2

Uploaded by

Ivan DulicCopyright:

Available Formats

November 2013, Oeiras

Ing. Henk J. M. Bodt IWE

Bodt Welding Consultancy

Program!

The program for this afternoon:

1. Brief repetition of this mornings discussion.

2. How to qualify a Welding Coordinator?

3. Requirements for the Welding Coordinator in EA-6/02

4. How to practically comply with the requirements?

5. Checklist

6. Professional Interview

7. Questions for discussion

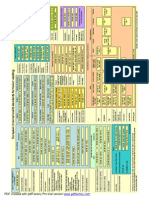

Involvement of the (R)WC, table A3 in EN 1090-2

EXC 1

EXC 2

EXC 3

EXC 4

7.1 General

EN-ISO 3834-4

EN-ISO 3834-3

7.4 Qualification of welding procedures and welding personnel

7.4.1 Qualification of welding

Nr

See Table 12 and

procedures

Table 13

7.4.2 Qualification of welders and EN 287-1 /

EN 287-1 /

operators

EN 1418

EN 1418

7.4.3 Welding coordination

Nr

Technical knowledge

according Tables 14

or 15

EN-ISO 3834-2

EN-ISO 3834-2

See Table 12 and

Table 13

EN 287-1 /

EN 1418

Technical knowledge

according Tables 14

or 15

See Table 12 and

Table 13

EN 287-1 /

EN 1418

Technical knowledge

according Tables 14

or 15

7.5.1 Joint preparation

Nr

Nr

Prefabrication

primers not allowed

Prefabrication

primers not allowed

7.5.6 Temporary attachments

Nr

Nr

Use to be specified

Use to be specified

Cutting and chipping Cutting and chipping

not permitted

not permitted

7.5.7 Tack welds

Nr

7.5.9 Butt welds

7.5.9.1 General

7.5.9.2 Single side welds

Nr

Qualified welding

procedure

Run on/run off

pieces if specified

Qualified welding

procedure

Run on/run off

pieces. Permanent

backing continuous

Qualified welding

procedure

Run on/run off

pieces. Permanent

backing continuous

Removal of spatter

Removal of spatter

EN-ISO 5817 Quality

level B

EN-ISO 5817 Quality

level B and

Additional B+

7.5.17 Execution of welding

7.6 Acceptance criteria

EN-ISO 5817 Quality

level D

EN-ISO 5817 Quality

level C generally

Tasks of the Welding Coordinator (EN-ISO 14731 Annex B)

B.1 Review of requirements (2 sub-items)

B.2 Technical review (6 sub-items)

B.3 Sub-contracting

B.4 Welding personnel

B.5 Equipment (5 sub-items)

B.6 Production planning (6 sub-items)

B.7 Qualification of the welding procedures

B.8 Welding procedure specifications

B.9 Work instructions

B.10 Welding consumables (4 sub-items)

B.11 Materials (3 sub-items)

B.12 Inspection and testing before welding (8 sub-items)

B.13 Inspection and testing during welding (8 sub-items)

B.14 Inspection and testing after welding (5 sub-items)

B.15 Post-weld heat treatment

B.16 Non-conformance and corrective actions

B.17 Calibration and validation of measuring, inspection and testing equipment

B.18 Identification and traceability (11 sub-items)

B.19 Quality records

Additional Tasks of the Welding Coordinator 1 (EN 1090-2)

Structural steel products (5.3)

Welding consumables (5.5)

(Suitability for welding)

List of handling and storage preventive measures (Table 8)

Thermal cutting (6.4.3) (hardness)

Flame straightening (6.5.3)

Cold forming (6.5.4) (heat treatment)

Specific requirements for the Welding Plan (7.2)

Welding processes (7.3)

Qualification of welding procedures and welding personnel (7.4)

Etc.

Additional Tasks of the Welding Coordinator 2 (EN 1090-2)

More from EN 1090-2:

Inspection and testing to be under supervision of the

(R)WC.

Weld repairs require approval of the Welding Coordinator.

The Welding Coordinator shall indicate what and how to

be calibrated!

Extra welding procedure tests are sometimes required;

the Welding Coordinator shall take care about that

Etc.

The Welding Coordinator, specifications from EN-ISO 14731

Tasks and responsibilities:

1. Specification of tasks and responsibilities for each

Welding Coordinator (4.2)

2. Knowledge:

a) General knowledge requirements for each Welding

Coordinator (6.1)

b) Specific knowledge requirements for the responsible

Welding Coordinator (RWC) (6.2)

Tasks of the Welding Coordinator (EN-ISO 14731)

4.2 Specification of tasks and responsibilities for each Welding Coordinator

The tasks of the Welding Coordinator shall be selected from the applicable part of ISO

3834, in accordance with the criteria defined in ISO 3834-1 (see Annex B).

Each single activity in Annex B may be associated with a number of tasks and

responsibilities, such as:

specification and preparation,

control,

inspection, check or witnessing.

Where welding coordination is carried out by more than one person, the tasks and

responsibilities shall be clearly allocated, such that responsibility is clearly defined and the

persons are qualified for each specific welding coordination task.

Welding coordination is the sole responsibility of the manufacturer.

The manufacturer shall appoint at least one responsible Welding Coordinator.

Welding coordination may be subcontracted. However, compliance to this International

Standard remains the responsibility of the manufacturer.

Tasks of the Welding Coordinator (EN-ISO 14731 Annex B)

Tasks (67 in total detail !)

B.1 Review of requirements

B.2 Technical review

B.3 Sub-contracting

B.4 Welding personnel

B.5 Equipment

B.6 Production planning

B.7 Qualification of the welding procedures

B.8 Welding procedure specifications

B.9 Work instructions

B.10 Welding consumables

B.11 Materials

B.12 Inspection and testing before welding

B.13 Inspection and testing during welding

B.14 Inspection and testing after welding

B.15 Post-weld heat treatment

B.16 Non-conformance and corrective actions

B.17 Calibration and validation of measuring, inspection and

testing equipment

B.18 Identification and traceability

B.19 Quality records

Specification &

preparation

Control

Inspection, check or

witnessing

Tasks of the Welding Coordinator (EN-ISO 14731)

5 Job description

5.1 General

A job description is required for the welding coordination personnel, which shall include their tasks

and responsibilities.

5.2 Tasks

For identification of the tasks assigned to the welding coordination personnel, see 4.2 and Annex B.

5.3 Responsibilities

The responsibilities assigned to the welding coordination personnel are identified as follows:

their position in the manufacturing organization and their responsibilities;

the extent of authorization accorded to them to accept by signature on behalf of the

manufacturing organization, as needed in order to fulfil the assigned tasks, e.g. for procedure

specification and supervision reports;

the extent of authorization accorded to them to carry out the assigned tasks.

The Welding Coordinator, specifications from EN-ISO 14731

Tasks and responsibilities:

1. Specification of tasks and responsibilities for each

Welding Coordinator (4.2)

2. Knowledge:

a) General knowledge requirements for each Welding

Coordinator (6.1)

b) Specific knowledge requirements for the responsible

Welding Coordinator (RWC) (6.2)

The Welding Coordinator (EN-ISO 14731)

2.a. General knowledge requirements of all welding coordination personnel (WC).

general technical knowledge;

specialized technical knowledge in welding and allied processes relevant to the assigned

tasks, which shall be attained by a combination of theoretical knowledge, training

and/or experience.

2.b. Specific requirements for the responsible Welding Coordinator (RWC).

Grouping of responsible Welding Coordinators:

a) personnel with comprehensive technical knowledge, where full technical knowledge is

required, in accordance with 6.1, for the planning, executing, supervising and testing of all

tasks and responsibilities in welding fabrication;

b) personnel with specific technical knowledge, where the level of technical knowledge

needs to be sufficient for the planning, executing, supervising and testing of the tasks and

responsibilities in welding fabrication within a selective or limited technical field;

c) personnel with basic technical knowledge, where the level of technical knowledge needs

to be sufficient for the planning, executing, supervising and testing of the tasks and

responsibilities within a limited technical field, involving only simple welded

constructions.

The Welding Coordinator (EN-ISO 14731)

Annex A

(informative)

Recommendations for technical knowledge in welding

The International Institute of Welding (IIW) has, on a voluntary basis, prepared recommendations

for minimum requirements for education, examination and qualification of welding coordination

personnel.

The recommendations are stated in the following documents:

International Welding Engineer (IWE),

Doc. IAB-252;

International Welding Technologist (IWT),

Doc. IAB-252;

International Welding Specialist (IWS),

Doc. IAB-252.

Welding coordination personnel fulfilling the requirements of these documents, or holding

acceptable national qualifications, may be considered to satisfy the relevant requirements of 6.2.

EWF addition to the system

European addition to the

education for Welding

Coordinator is here!

EWF introduced a

supplementary European

education scheme, meant

especially for the SME in

steel construction work.

B and S levels; EXC 2 and 3,

up to and including S355.

The Welding Coordinator (EN-ISO 14731)

So: the Welding Coordinator in three levels:

comprehensive technical knowledge

specific technical knowledge

basic technical knowledge

Sometimes there might be a requirement

for a certified Welding Coordinator.

Can/may be more than one person.

Always ONE responsible: the RWC!

EN 1090-2 par. 7.4.3 Welding Coordinators (table 14)

EXC

Thickness (mm)

Steels

(Steel group)

Reference standards

S235 to S355

(1.1, 1.2, 1.4)

EN 10025-2 EN 10025-3 EN 10025-4

EN 10025-5, EN 10149-2, EN 10149-3

EN10210-1, EN 10219-1

S420 to- S700

(1.3, 2, 3)

EN 10025-3 EN 10025-4 EN 10025-6

EN 10149-2, EN 10149-3

EN10210-1, EN 10219-1

S235 to S355

(1.1, 1.2, 1.4)

EN 10025-2 EN 10025-3 EN 10025-4

EN 10025-5, EN 10149-2, EN 10149-3

EN10210-1, EN 10219-1

S420 to S700

(1.3, 2, 3)

EN 10025-3 EN 10025-4 EN 10025-6

EN 10149-2, EN 10149-3

EN10210-1, EN 10219-1

All

All

t25

25 < t 50

t>50

EXC2

C

EXC3

EXC4

a

Column base plates and endplates 50mm

Column base plates and endplates 75mm

c

For steels up to and including S275 level S is sufficient

d

For steels N, NL, M and ML level S is sufficient

b

B:

S:

C:

Basic technical knowledge

Specific technical knowledge

Comprehensive technical knowledge

EN 1090-2 par. 7.4.3 Welding Coordinators (table 15)

EXC

Thickness (mm)

Steels

(Steel group)

Reference standards

t25

25 < t 50

t>50

Austenitic

(8)

EN

EN

EN

EN

10088-2:2005,

10088-3:2005,

10296-2:2005,

10297-2:2005,

Tabel

Tabel

Tabel

Tabel

3

4

1

2

Austenitic-ferritic

(10)

EN

EN

EN

EN

10088-2:2005,

10088-3:2005,

10296-2:2005,

10297-2:2005,

Tabel

Tabel

Tabel

Tabel

4

5

1

3

Austenitic

(8)

EN

EN

EN

EN

10088-2:2005,

10088-3:2005,

10296-2:2005,

10297-2:2005,

Tabel

Tabel

Tabel

Tabel

3

4

1

2

Austenitic-ferritic

(10)

EN

EN

EN

EN

10088-2:2005,

10088-3:2005,

10296-2:2005,

10297-2:2005,

Tabel

Tabel

Tabel

Tabel

4

5

1

3

EXC2

EXC3

EXC4

B:

S:

C:

All

All

Basic technical knowledge

Specific technical knowledge

Comprehensive technical knowledge

Qualification of a Welding Coordinator

Lots of questions:

Does the RWC have sufficient experience in the welding operations he supervise

as specified in EN-ISO 14731?

Does the RWC have a suitable role, with given responsibilities to coordinate the

welding operations, defined by the manufacturer? (See EN-ISO 14731, Annex B.)

Does the technical discussion with the RWC demonstrate that he has sufficient

knowledge about relevant standards, regulations and specifications as per

EN 1090-2, clause 7.4.3 and EN-ISO 14731, Annex B?

Does the RWC have the ability to detect and assess defects, to give instructions

on welding repairs and know how to avoid defects?

Does the RWC have relevant technical knowledge complying with one of the IIW

qualifications?

Etc.

But how to implement??

Qualification of a Welding Coordinator (EWF/IIW)

European Accreditation is quite clear in EA-6/02:2013

Special attention for the Audit Team in evaluating the competence of the

manufacturers Welding Coordinators in accordance with

EN ISO 14731 (reference 6).

The EN ISO 3834 Audit Team shall:

i.

contain persons with direct product/process/materials competence in the

products/processes/materials being audited, and

ii. contain at least one individual who is qualified and experienced in welding to

a level that is sufficient to demonstrate that he/she is competent to Audit the

companys Authorised Welding Coordinator(s) in accordance with

EN ISO 14731, Welding Coordination tasks and responsibilities

(reference 6).

Qualification of a Welding Coordinator (EWF/IIW)

Situation

Additional requirement

EWF/IIW qualification is None

available (E/IWE, E/IWT,

E/IWS)

Type 1

EWF/IIW Personnel

Certification is available

(CE/IWE, CE/IWT,

CE/IWS)

Type 1

If none of the above

EWF/IIW certifications or

qualifications are

available

Type 2

Schedule should

support the scope of

work allocated to the

Welding Coordinator

None

Activity required towards the (R)WC

Check on adequate experience and

competence in the products being

manufactured by means of a professional

interview and examination of the Welding

Coordinators curriculum vitae.

Check on adequate experience and

competence in the products being

manufactured by means of a professional

interview.

Verify compliance by means of a professional

interview covering knowledge, skills,

experience and competence with particular

emphasis on welding technology, materials

and their behaviour during welding, design

fundamentals of welded construction, as well

as fabrication and inspection aspects

(including knowledge of standards) in the

Qualification of a Welding Coordinator (EWF/IIW)

The professional interview process shall involve the

examination of specific contract(s) to Audit

compliance with the customers specification

E.g. in the following areas:

selection/development of welding procedures

welding sequences

NDT and heat treatment

approval of personnel

traceability

quality control and acceptance

sub-contracting

Qualification of a Welding Coordinator (EWF/IIW)

This means that technical discussions must take place

between each Welding Coordinator and the relevant

Auditor regarding the detailed technical scope of the

Welding Coordinator's responsibilities and the interview

should take the form of a peer review and challenge

process. This process will require the Auditor to examine

evidence of completed work done by each Welding

Coordinator and to investigate his/her knowledge and

understanding of it. The certification body shall maintain

full records of the process of evaluation of the

manufacturers Welding Coordinators.

Qualification of a Welding Coordinator (EWF/IIW)

Basically we can see two essentially different professional

interviews (see table in sheet 21):

1. Checking the actual knowledge related to the

manufactured products to be covered by the Welding

Coordinator.

2. As specified in 1, but additionally covering knowledge,

skills, experience and competence in the fields that are

supposed to be covered by EWF/IIW qualifications and

certifications.

Qualification of a Welding Coordinator (EWF/IIW)

That means:

General knowledge and skill check for the (R)WC:

Challenge the (R)WC by asking questions of the what-if type;

Try to cover his/hers whole scope of work.

Additional knowledge and skill check for the (R)WC:

Type 1:

Select a running (just delivered) contract and follow every single step as related

to the (Responsible) Welding Coordinator;

Type 2:

As under 1, but in addition select random questions out of the questions

database for EWF Guideline 652 or IAB 252 and use them as a guidance for the

Professional Interview Type 2. All relevant modules shall be covered!

Program!

The program for this afternoon:

Brief repetition of this mornings discussion.

How to qualify a Welding Coordinator?

Requirements for the Welding Coordinator in EA-6/02

How to practically comply with the requirements?

Checklist

Professional Interview

7. Questions for discussion

Questions for discussion for the professional interview (EWF/IIW)

Questions for discussion:

1. The system looks quite subjective; is there another way?

2. Should a minimum time be allocated to the professional Interview?

3. Should a technical shop-tour be an essential element in the

interview? (Note: thats not always possible!)

4. Should EWF/IIW make a detailed check list for the professional

interview as specified in the Rules EWF 639r2-12 and

IAB 340r2-12?

5. Shall the evaluation be carried out on the RWC only or should it also

involve the other WCs as mentioned in the companys WC matrix?

The group will be divided in 4 sub-groups; two groups will deal with

questions 1 and 2, the other two groups with questions 3, 4 and 5.

You might also like

- ISO Standards On WeldingDocument6 pagesISO Standards On WeldingwentropremNo ratings yet

- A Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersFrom EverandA Quick Guide to API 653 Certified Storage Tank Inspector Syllabus: Example Questions and Worked AnswersRating: 3.5 out of 5 stars3.5/5 (19)

- Design Stress and FatigueDocument30 pagesDesign Stress and FatigueAshok DargarNo ratings yet

- Tasks and Responsibilities of RWCDocument1 pageTasks and Responsibilities of RWCKDT100% (1)

- Quality Assurance and Control of Welding StructuresDocument150 pagesQuality Assurance and Control of Welding Structuresnedunchi100% (1)

- Guide To ISO14731Document8 pagesGuide To ISO14731scandalthegoodNo ratings yet

- The Crime of Galileo - de Santillana, Giorgio, 1902Document372 pagesThe Crime of Galileo - de Santillana, Giorgio, 1902Ivo da Costa100% (2)

- Welding CoordinationDocument3 pagesWelding CoordinationIon PlesaNo ratings yet

- CE Mark en 1090 Iso 3834 Manual DocumentsDocument10 pagesCE Mark en 1090 Iso 3834 Manual DocumentsDan DumbravescuNo ratings yet

- IIW/EWF Diploma in Welding QualificationDocument8 pagesIIW/EWF Diploma in Welding Qualificationreezman100% (1)

- Welding standards and references documentDocument2 pagesWelding standards and references documentMakhfud EdyNo ratings yet

- EN 15085 Part 5 - GaneshDocument36 pagesEN 15085 Part 5 - GaneshNiranjan Rajavel TigerNo ratings yet

- Welding Coordination Activities and ResponsibilitiesDocument7 pagesWelding Coordination Activities and ResponsibilitieseliiiiiiNo ratings yet

- Quality Requirements - Fusion Welding of Metalic MaterialDocument8 pagesQuality Requirements - Fusion Welding of Metalic MaterialStatus whatsapp status100% (2)

- Book - Vol.1&2 - BasicsAndQuality - 22junDocument82 pagesBook - Vol.1&2 - BasicsAndQuality - 22junlth770310No ratings yet

- (Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Document1 page(Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Ivan Briscoe100% (7)

- (Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Document1 page(Iso/tr 17671-5) (Iso/tr 17671-6) (Iso/tr 17671-7) (Iso/tr 17671-8)Ivan Briscoe100% (7)

- Properties of Skeletal MuscleDocument72 pagesProperties of Skeletal MuscleAakash GohilNo ratings yet

- False CeilingDocument70 pagesFalse CeilingBharti Sikri93% (15)

- Rolling Bearings in Electrical Motors & GeneratorsDocument122 pagesRolling Bearings in Electrical Motors & GeneratorsJurun_Bidanshi100% (1)

- Procedure for Flame Straightening Structural SteelDocument3 pagesProcedure for Flame Straightening Structural SteelAvishek Gupta100% (1)

- Poster - Weld Position - DIN ISO 6947 2011Document1 pagePoster - Weld Position - DIN ISO 6947 2011Anirban60% (5)

- Welding-Standards 23-03-2014Document1 pageWelding-Standards 23-03-2014givali100% (7)

- Welding-Standards 23-03-2014Document1 pageWelding-Standards 23-03-2014givali100% (7)

- Bashar Discusses Monatomics, White Powder Gold and Ormus MineralsDocument32 pagesBashar Discusses Monatomics, White Powder Gold and Ormus MineralsFlorin V. Iagaru100% (6)

- EN 1090 Checklist - Industries > Metal Fabrication > EN 1090 ComplianceDocument3 pagesEN 1090 Checklist - Industries > Metal Fabrication > EN 1090 Compliance26110100% (1)

- ISO 9692-3-2002 Joint PreparationDocument16 pagesISO 9692-3-2002 Joint PreparationtndeshmukhNo ratings yet

- Welding Catalogue PDFDocument292 pagesWelding Catalogue PDFvudinhnambrNo ratings yet

- Material and WeldingDocument226 pagesMaterial and WeldingIvan DulicNo ratings yet

- Welding ConsumablesDocument20 pagesWelding ConsumablesThillaivananNo ratings yet

- ISO 3834 Welding Certification GuideDocument11 pagesISO 3834 Welding Certification GuideWeld Bro Sandeep100% (1)

- En 1090 1 and CE Marking Guidence NoteDocument4 pagesEn 1090 1 and CE Marking Guidence Noteiergun80No ratings yet

- Welded Steel Pipe American Iron and Steel InstituteDocument80 pagesWelded Steel Pipe American Iron and Steel Institutemaminu1100% (1)

- GEC - US EU Welding Standards - Heavy Equipment and Machinery (Peter Gerster)Document47 pagesGEC - US EU Welding Standards - Heavy Equipment and Machinery (Peter Gerster)Stuart WickensNo ratings yet

- Individual tone frequencies have hidden qualitiesDocument7 pagesIndividual tone frequencies have hidden qualitiesArnauNo ratings yet

- Quest Audit 3834Document38 pagesQuest Audit 3834g33k59100% (2)

- Welding Requirements For The CE MarkDocument2 pagesWelding Requirements For The CE MarkAekJayNo ratings yet

- Welding Procedure Specification (WPS) According To DIN EN ISO 15614-1Document2 pagesWelding Procedure Specification (WPS) According To DIN EN ISO 15614-1Vijay OfficialNo ratings yet

- Need of ISO 3834 To Welding Fabrication IndustryDocument4 pagesNeed of ISO 3834 To Welding Fabrication IndustrySatish Keskar100% (1)

- EM 6815 EN - Solutions For Traction MotorsDocument20 pagesEM 6815 EN - Solutions For Traction MotorsIvan Dulic100% (1)

- WPS-6 Doc Rev00 On 17 Sept 2018 Final FormatDocument3 pagesWPS-6 Doc Rev00 On 17 Sept 2018 Final FormatSWARUP CHUGUGLENo ratings yet

- BS en 15085 - 2quality Requirements For ManufcturersDocument48 pagesBS en 15085 - 2quality Requirements For ManufcturersSubramanian R0% (1)

- Guideline Welding Coordination For ISO 1090-2Document33 pagesGuideline Welding Coordination For ISO 1090-2apostolidis83100% (1)

- VP16 PDFDocument13 pagesVP16 PDFKara WhiteNo ratings yet

- ISO 3834 Awareness Program OutlineDocument1 pageISO 3834 Awareness Program OutlineSatish KeskarNo ratings yet

- CE Marking GuideDocument26 pagesCE Marking GuideshaggerukNo ratings yet

- EWF Qualifications Guideline CatalogueDocument42 pagesEWF Qualifications Guideline Catalogueromanosky11No ratings yet

- HypnosisDocument2 pagesHypnosisEsteban MendozaNo ratings yet

- Minimum Requirements IweDocument52 pagesMinimum Requirements IweIonutz TelteuNo ratings yet

- ISO 3834 welding certification levelsDocument9 pagesISO 3834 welding certification levelsvilukNo ratings yet

- Implement ISO 3834 welding standardsDocument34 pagesImplement ISO 3834 welding standardschowhkNo ratings yet

- Iso 3834Document52 pagesIso 3834Akshay Kumar100% (1)

- CE Marking of StructuralDocument31 pagesCE Marking of StructuralRavi ValiyaNo ratings yet

- Awareness Programme for ASME and ISO Welding CodesDocument1 pageAwareness Programme for ASME and ISO Welding CodesSatish KeskarNo ratings yet

- 1143 Ewf Iiw Diploma August 2013Document4 pages1143 Ewf Iiw Diploma August 2013Marcus BarberNo ratings yet

- En 1090 - Norway Requirements and SpecificationsDocument76 pagesEn 1090 - Norway Requirements and SpecificationsVIJAYAKUMAR TNo ratings yet

- En 1090 Eng Forum GdanskDocument30 pagesEn 1090 Eng Forum GdanskKrzysiek MacekNo ratings yet

- Filler Materials TestingDocument34 pagesFiller Materials TestingSunilNo ratings yet

- Conformity Assessment For The Execution of Steel & Aluminium StructuresDocument14 pagesConformity Assessment For The Execution of Steel & Aluminium StructuresJevgenijsKolupajevsNo ratings yet

- KOORDINATOR-doc 135 Ewf 1090 Workshop 2013 Part 2Document28 pagesKOORDINATOR-doc 135 Ewf 1090 Workshop 2013 Part 2Ivan DulicNo ratings yet

- KOORDINATOR-doc 135 Ewf 1090 Workshop 2013 Part 2Document28 pagesKOORDINATOR-doc 135 Ewf 1090 Workshop 2013 Part 2Ivan DulicNo ratings yet

- KOORDINATOR-doc 135 Ewf 1090 Workshop 2013 Part 2Document28 pagesKOORDINATOR-doc 135 Ewf 1090 Workshop 2013 Part 2Ivan DulicNo ratings yet

- KOORDINATOR-doc 135 Ewf 1090 Workshop 2013 Part 2Document28 pagesKOORDINATOR-doc 135 Ewf 1090 Workshop 2013 Part 2Ivan DulicNo ratings yet

- BS en Iso 9606-5 - 2000Document26 pagesBS en Iso 9606-5 - 2000jesoneliteNo ratings yet

- BS en 1090-2:2008+a1:2011Document1 pageBS en 1090-2:2008+a1:2011234ahmed50% (2)

- Welding Procedure Specification (WPS) : Joint Design Welding SequencesDocument1 pageWelding Procedure Specification (WPS) : Joint Design Welding SequencesFerhat KahveciNo ratings yet

- Iso 15609-1-2019Document19 pagesIso 15609-1-2019HarikeshRana100% (2)

- EN 1090 Compliance for Structural SteelDocument42 pagesEN 1090 Compliance for Structural Steelbharani dharanNo ratings yet

- Overzicht en Iso 3834 Editie 2017 - Engels PDFDocument1 pageOverzicht en Iso 3834 Editie 2017 - Engels PDFrohit mathankerNo ratings yet

- Iso 3834 GuidelinesDocument3 pagesIso 3834 Guidelinesshabashakkim0% (1)

- VR 14-01 Supplier TC en 1090 Ce Marking Issue 1-15Document7 pagesVR 14-01 Supplier TC en 1090 Ce Marking Issue 1-15Bryan GonzalesNo ratings yet

- Clarification On CE Marking With en 1090 1Document5 pagesClarification On CE Marking With en 1090 1Simon KennyNo ratings yet

- DRAFT AS 3992:2019: Summary of Changes From As/Nzs 3992:2015Document18 pagesDRAFT AS 3992:2019: Summary of Changes From As/Nzs 3992:2015Osu AmpawanonNo ratings yet

- KGP-Flamme Cutting Proce For BEI PDFDocument4 pagesKGP-Flamme Cutting Proce For BEI PDFoomoomNo ratings yet

- 3.3.1-Basics of Weld Joint Design-9th Mar 21Document60 pages3.3.1-Basics of Weld Joint Design-9th Mar 21Vivek kmNo ratings yet

- Fb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischDocument13 pagesFb37 1rev0 Checkliste WPK Metallkonstruktionen EnglischDan DumbravescuNo ratings yet

- BS en 1090 - A Legal Requirement For The Structural Steel Industry (CE Marking)Document3 pagesBS en 1090 - A Legal Requirement For The Structural Steel Industry (CE Marking)alanlongfieldNo ratings yet

- Model WopqDocument2 pagesModel WopqAnilkumarGopinathanNairNo ratings yet

- Din 18800Document8 pagesDin 18800Batuhan TatarNo ratings yet

- BACKUP - Putanje Windows - ACAD - SWDocument1 pageBACKUP - Putanje Windows - ACAD - SWIvan DulicNo ratings yet

- Uporedno15614 288 3Document11 pagesUporedno15614 288 3Ivan DulicNo ratings yet

- Preciznost Sečenja Limova LaseromDocument1 pagePreciznost Sečenja Limova LaseromIvan DulicNo ratings yet

- Uporedno15614 288 3 PDFDocument11 pagesUporedno15614 288 3 PDFIvan DulicNo ratings yet

- BMS Snap door lockDocument2 pagesBMS Snap door lockIvan DulicNo ratings yet

- RENK Slide Bearings Couplings PDFDocument4 pagesRENK Slide Bearings Couplings PDFIvan DulicNo ratings yet

- DUZINA GIBLJIVOG CREVA - Stainless - Steel - Catalogue PDFDocument14 pagesDUZINA GIBLJIVOG CREVA - Stainless - Steel - Catalogue PDFIvan DulicNo ratings yet

- Bohler EAS 2-IG TDSDocument1 pageBohler EAS 2-IG TDSIvan DulicNo ratings yet

- ZM - Instructions For Installation, Operation, Maintenance and Inspection PDFDocument40 pagesZM - Instructions For Installation, Operation, Maintenance and Inspection PDFIvan DulicNo ratings yet

- NDT-ispitivanja SVA PDFDocument366 pagesNDT-ispitivanja SVA PDFIvan Dulic100% (1)

- DriveWorksXpressMobileGantryTutorial PDFDocument22 pagesDriveWorksXpressMobileGantryTutorial PDFIvan DulicNo ratings yet

- Hydroweld HGVDocument2 pagesHydroweld HGVIvan DulicNo ratings yet

- Manganese SteelDocument2 pagesManganese SteelIvan DulicNo ratings yet

- VRTP P Eg Eng Web PDFDocument4 pagesVRTP P Eg Eng Web PDFIvan DulicNo ratings yet

- Migtig 2514 NcsiDocument1 pageMigtig 2514 NcsiIvan DulicNo ratings yet

- ESAB OK Autrod 12.51Document2 pagesESAB OK Autrod 12.51hooky1No ratings yet

- Porter's Five Forces: Submitted by Subham Chakraborty PGDMDocument5 pagesPorter's Five Forces: Submitted by Subham Chakraborty PGDMSubham ChakrabortyNo ratings yet

- Materials Selection For Engineering DesignDocument31 pagesMaterials Selection For Engineering Designsyamsudin2006No ratings yet

- Intermediate Financial Management 13th Edition Brigham Test BankDocument25 pagesIntermediate Financial Management 13th Edition Brigham Test BankMonicaHoustonwjtgz100% (56)

- 5 & 6 Risk AssessmentDocument23 pages5 & 6 Risk AssessmentAzam HasanNo ratings yet

- BHCC Peri 5c Jyps - MK Classroom Toilet (Pending To Sign by Moe) - Removed - RemovedDocument8 pagesBHCC Peri 5c Jyps - MK Classroom Toilet (Pending To Sign by Moe) - Removed - RemovedrajavelNo ratings yet

- Research 3Document30 pagesResearch 3Lorenzo Maxwell GarciaNo ratings yet

- Legal Opinion WritingDocument53 pagesLegal Opinion WritingBenedict AnicetNo ratings yet

- Original Prusa I3 MK2S To MK3 Upgrade Parts ListDocument2 pagesOriginal Prusa I3 MK2S To MK3 Upgrade Parts ListLuan AlvesNo ratings yet

- DLookup Function - Access - Microsoft OfficeDocument2 pagesDLookup Function - Access - Microsoft OfficevinahackNo ratings yet

- Directory StructureDocument47 pagesDirectory StructureStevenNo ratings yet

- Cisco and Duo Presentation 8.2.18Document8 pagesCisco and Duo Presentation 8.2.18chris_ohaboNo ratings yet

- Installation Procedure for Castwel Supercast-II CastableDocument3 pagesInstallation Procedure for Castwel Supercast-II CastableRAJKUMARNo ratings yet

- Understand Shell and Rib Feature - Creo Elements ProDocument8 pagesUnderstand Shell and Rib Feature - Creo Elements ProWaqas AhmadNo ratings yet

- JURNAL PENCONG IJAS FixDocument12 pagesJURNAL PENCONG IJAS Fixmasri ridwanNo ratings yet

- List of British StandardsDocument6 pagesList of British StandardsPankajNo ratings yet

- Synopsis Sagar Project - A Study On The Need of CRM in OrganizatonDocument3 pagesSynopsis Sagar Project - A Study On The Need of CRM in OrganizatonViraja GuruNo ratings yet

- Ake Products 001 2016Document171 pagesAke Products 001 2016davidNo ratings yet

- Beamware 2: Users ManualDocument14 pagesBeamware 2: Users ManualAdi FaizinNo ratings yet

- ZF 4hp14 - 2Document9 pagesZF 4hp14 - 2Miguel BentoNo ratings yet

- 08 - Truck Driver's Dhobi SinkDocument3 pages08 - Truck Driver's Dhobi SinkfebousNo ratings yet

- Sae Technical Paper Series 2015-36-0353: Static and Dynamic Analysis of A Chassis of A Prototype CarDocument12 pagesSae Technical Paper Series 2015-36-0353: Static and Dynamic Analysis of A Chassis of A Prototype CarGanesh KCNo ratings yet

- Snel White Paper 2020Document18 pagesSnel White Paper 2020Zgodan NezgodanNo ratings yet

- Industrial Visit Report - 08 09 2018Document11 pagesIndustrial Visit Report - 08 09 2018HARIKRISHNA MNo ratings yet