Professional Documents

Culture Documents

SWP

Uploaded by

Samadarshi SarkarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SWP

Uploaded by

Samadarshi SarkarCopyright:

Available Formats

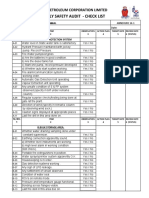

SAFE WORK PROCEDURE FOR TENTATIVE JOB

(Performance Criteria Perfection in job with no injury to persons or damage of property)

1) DEPARTMENT

2) SECTION/LOCATION

3) JOB TITLE

4) Job Duration

S/R

NO

Activities

Sequence of

work)

: PROJECTS

: 6hi 1

: ETL#1 Process Str. Changing

: 8 days

DOC NO ..

NAME OF WORK AGENCY: Raghav

Work order/requisition no : 301846

Start Date: 01/04/14

End Date: 09/04/14

Persons Responsible

HAZARDS

Safety Precautions

Name

G P NO

Condition of

tools/tackles

required-OK/Not

OK

Reference to

documents/criteria

and remarks

PPEs OK

Panel erection

1. Cable Laying

JB Febrication

.

Representative from TCIL

Representative from safety(TCIL)

Note: 1) This safe work procedure shall be prepared by owner department countersigned by working agency/contractor's representative and safety department

2) Sequence of work shall involve step-by-step jobs

3) All possible hazards shall be identified

4) With the change of work conditions, the procedures shall be amended and persons shall be trained accordingly.

5) Review on status of implementation shall be done through task observation and /or site severity audit.

Representative MEW

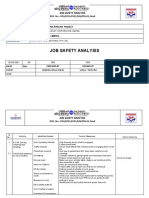

SAFE WORK PROCEDURE FOR TENTATIVE JOB

(Performance Criteria Perfection in job with no injury to persons or damage of property)

1) DEPARTMENT

2) SECTION/LOCATION

3) JOB TITLE

4) Job Duration

S/R

NO

Activities

Sequence of

work)

Job Starting

(General)

: PROJECTS

: Ecl-1

: Welder job at ECL-1

: 10 days

DOC NO ..

NAME OF WORK AGENCY: Raghav Enterprises

Work order/requisition no :

Start Date:14/01/16

Persons Responsible

HAZARDS

Safety Precautions

1. Unawareness about

the hazards at the

working area at TCIL

Site

2. Improper Supervision

3.Lack of Job

Knowledge/planning

4.Damage PPEs

* Before starting the job, take written clearance on permit to

work shall be obtain

* Safety talk must be given to all workmen before starting the

job, explaining the hazards involved and precaution to be taken

* Use PPEs Safety shoe, Safety helmet, Safety Goggle in good

condition.

* A competent supervisor must be present all the time at job site

during execution of work

.

Welding &

Gas cutting

*Skin Burning.

*electric shock to body

*Effect in eye due to

spark/welding spatter.

*Bursting of hose pipe

*Only certified welding M/C must be fitted with ELCB

Keep fire extinguisher/sand buckets near the job

*Rubber mat to be placed in front of M/C & switchboard

*Use cotton apron ,face shield & hand gloves to save the

radiation and fumes.

*Return path to be provided within 3 m of working area.

*Holder stand to be provided

Name

G P NO

Mukesh

Singh

(Cont.)

K.H.S.Mani

Shiv

Shankar

*Use flash back arrester on LPG & Oxygen cylinders.

*Joints should be joined by jubilee clamps

*Cylinder should be kept in vertical upright position

*Three pipe cutting torch with non-return valve is used.

*LPG & Oxygen should be kept at least 3 m apart

Representative from TCIL

Representative from safety(TCIL)

Note: 1) This safe work procedure shall be prepared by owner department countersigned by working agency/contractor's representative and safety department

2) Sequence of work shall involve step-by-step jobs

3) All possible hazards shall be identified

4) With the change of work conditions, the procedures shall be amended and persons shall be trained accordingly.

5) Review on status of implementation shall be done through task observation and /or site severity audit

End Date: 23/01/16

Condition of

tools/tackles

required-OK/Not

OK

Reference to

documents/criteria

and remarks

PPEs OK

*Welding M/C ok

*Electrical Cable ok

*Return path ok

*ELCB ok

*Hosepipe ok.

*Spanner ok.

*Gas cutting torch

ok.

*Regulator ok

Holder ok

Representative Raghav Enterp.

SAFE WORK PROCEDURE FOR TENTATIVE JOB

(Performance Criteria Perfection in job with no injury to persons or damage of property)

1) DEPARTMENT

: PROJECTS

2) SECTION/LOCATION : Pickling-1

3) JOB TITLE

: Crane girder shifting

4) Job Duration

DOC NO ..

NAME OF WORK AGENCY: M/s Vacon

Work order/requisition no : 4210000154

: 1

Activities

S/R

NO Sequence of

work)

Unloading/shiftin

g of Material/

Equipments

HAZARDS

Safety Precautions

Start Date :30/07/14

Persons

Responsible

Name

*Tippling of

Crain

*Fall of material

*Failure of lifting

equipment

*Over loading

*Hit injury by the

swinging

material

*Unskilled

operator &

negligence in

operation.

Representative from TCIL

*Crane will be placed on hard and farm place.

*Sling, D cackles will be in good condition & certify by competent

persons and will check visually before used.

*Load shall never be used beyond the capacity of Crain and

cling.

*D cackles, guide rope will be used to control the movement of

swinging material.

*Flagman will be deputed to control the movement of vehicle and

workers.

*Competent persons/rigger will be engaged for the job.

*Competent supervisor will be engaged of the job.

*Dunnege will be provided below the unloading material.

*Barricade the material after unloading.

No load will be carried beyond the capacity of crane/hydra

*In any case no load shall be carried 50 kg /man & 20

kg/woman.

* No one will be allowed to stand below the suspended load.

* Every driver/operator of material handling machinery shall

posses adequate skill, physical fitness, documented training in

the operation of crane and hydra.

* Driver must fasten the seat belt. Operator shall leave no

machinery unattended while power is on or load is suspended.

Representative from safety(TCIL)

G P NO

End Date : 30/07/14

Condition of

tools/tackles

required-OK/Not

OK

Reference to

documents/criteria

and remarks

* Slings and wire

rope ok

* Hooks ok

* Pull Lift ok

* D-shackles ok

*Guide rope ok

Representative from MEW

Note: 1) This safe work procedure shall be prepared by owner department countersigned by working agency/contractor's representative and safety department

2) Sequence of work shall involve step-by-step jobs

3) All possible hazards shall be identified

4) With the change of work conditions, the procedures shall be amended and persons shall be trained accordingly.

5) Review on status of implementation shall be done through task observation and site severity audit

SAFE WORK PROCEDURE FOR TENTATIVE JOB

(Performance Criteria Perfection in job with no injury to persons or damage of property)

1) DEPARTMENT

2) SECTION/LOCATION

3) JOB TITLE

4) Job Duration

S/R Activities

NO

Sequence of

work)

Lifting and lowering

of the material by

nylon rope

Working at

height

&

Material handling

: PROJECTS

:

:

: days

HAZARDS

DOC NO ..

NAME OF WORK AGENCY:

Work order/requisition no :

Safety Precautions

Start Date :

Persons

Responsible

Name

* Fail of object from

height

*Over loading

*Failure of lifting

equipment.

*Load should never raised over people or occupied area.

*No person will be allowed below the suspended load.

* Job to be done under strict supervision.

*Guide rope will be used to control the swinging material.

* No load will be given beyond the SWL.

Falling of person from

height.

Use proper safety belt having double lanyard.

Proper scaffolding with handrails.

All tools and tackles should be kept in a bag and raise it height by

rope.

Dont allow any unfit person for working at height.

Dropping of material

from height.

Representative from TCIL

G P NO

Representative from safety(TCIL)

Note: 1) This safe work procedure shall be prepared by owner department countersigned by working agency/contractor's representative and safety department

2) Sequence of work shall involve step-by-step jobs

3) All possible hazards shall be identified

4) With the change of work conditions, the procedures shall be amended and persons shall be trained accordingly.

5) Review on status of implementation shall be done through task observation and site severity audit

End Date :

Condition of

tools/tackles

required-OK/Not

OK

Reference to

documents/criteria

and remarks

* Slings and wire

rope ok

* Chain Block ok

* D-shackles ok

*Guide rope ok

*Safety Belt - OK

Representative Sujata Fiber

SAFE WORK PROCEDURE FOR TENTATIVE JOB

(Performance Criteria Perfection in job with no injury to persons or damage of property)

1) DEPARTMENT

2) SECTION/LOCATION

3) JOB TITLE

4) Job Duration

DOC NO ..

NAME OF WORK AGENCY: MEW

Work order/requisition no :301846

Start Date : 01/04/14

Persons Responsible

S/R Activities

NO Sequence of

work)

Gas cutting

: PROJECTS

: ETL#1

: ETL#1 Process Str. Changing

: 8 days

HAZARDS

Safety Precautions

*Skin burn by cutting.

*Explosion in cylinder

due to leakage

*Bursting of hose

pipe.

*Suffocation due to

toxic gases.

*Catch fire.

*Check all six direction of work place well before starting

the job.

*Use flash back arrester on LPG & Oxygen cylinders.

*Good quality hosepipe should be used.

*Joints should be joined by jubilee clamps.

*Three pipe cutting torch with non-return valve is used.

*LPG & Oxygen should be kept at least 3 m apart.

*The cylinder should be kept in open space away from

electrical cables and inflammable materials.

*Cylinder should be kept in vertical upright position.

*Gas cutter should be wearied only cotton cloth With full

sleeve shirt.

*Keep fire extinguishers at site.

Representative from TCIL

Representative from safety(TCIL)

Name

G P NO

End Date : 09/04/14

Condition of

tools/tackles

required-OK/Not

OK

*Hosepipe ok.

*Spanner ok.

*Gas cutting torch

ok.

*Regulator ok

Reference to

documents/criteria

and remarks

Representative from MEW

Note: 1) This safe work procedure shall be prepared by owner department countersigned by working agency/contractor's representative and safety department

2) Sequence of work shall involve step-by-step jobs

3) All possible hazards shall be identified

4) With the change of work conditions, the procedures shall be amended and persons shall be trained accordingly.

5) Review on status of implementation shall be done through task observation and site severity audit

6) Before start of job, induction shall be given to persons engaged at site by departmental representative and subsequent daily induction shall be given by Working

Agency/Contractors Representative

SAFE WORK PROCEDURE FOR TENTATIVE JOB

(Performance Criteria Perfection in job with no injury to persons or damage of property)

1) DEPARTMENT

: PROJECTS

DOC NO ..

2) SECTION/LOCATION : ETL#1

NAME OF WORK AGENCY: MEW

3) JOB TITLE

: ETL#1 Process Str. Changing

Work order/requisition no : 301846

4) Job Duration

: 8 days

:

Start Date : 01/04/14

Date : 09/04/14

Condition of

Reference to

S/R Activities

Persons Responsible

tools/tackles

documents/criteria

NO Sequence of

HAZARDS

Safety Precautions

and remarks

Name

G P NO required-OK/Not

work)

OK

*Welding

*Only certified welding M/C must be fitted with ELCB by

*Welding M/C ok

6 Welding

electrocution

*Effect in eye due to

spark/welding spatter.

*Radiating effects on

body.

*Skin Burning.

*electric shock to

body

*Catch fire

Representative from TCIL

certified technician/electrician.

*Welding M/C and switchboard should have separate

grounding connection.

*Return path to be provided within 3 m of working area.

*Holder stand to be provided.

*Double body earthing to M/C to be provided.

*Rubber mat to be placed in front of M/C & switchboard.

*Use proper welding cable .Double lead to be used.

*Use cotton apron ,face shield & hand gloves to save the

radiation and fumes.

*All the safety equipments like fuse protection. over

current protection & earth protection should be used.

*Earth leakage protection device (30A) Should be used

for ground fault protection.

*Used GI sheet/cotton asbestos cloth to catch the

spatter.

Keep fire extinguisher/sand buckets near the job.

*If the job to be carried out at height, confined

place/gaseous hazard places ,prevent falling of spatter

with the used of ceramic/GI sheets.

*Cable and hosepipe to be lying at proper height with

good support arrangement/telescopic stand.

*Used good quality of welding cable, holder ,electrical

cable & ELCB.

Representative from safety(TCIL)

*Electrical Cable

ok

*Return path ok

*ELCB ok

*Holder ok

Representative from MEW

Note: 1) This safe work procedure shall be prepared by owner department countersigned by working agency/contractor's representative and safety department

2) Sequence of work shall involve step-by-step jobs

3) All possible hazards shall be identified

SAFE WORK PROCEDURE FOR TENTATIVE JOB

(Performance Criteria Perfection in job with no injury to persons or damage of property)

1) DEPARTMENT

2) SECTION/LOCATION

3) JOB TITLE

4) Job Duration

: PROJECTS

: ETL#1

: ETL#1 Process Str. Changing

: 8 days

DOC NO ..

NAME OF WORK AGENCY: MEW

Work order/requisition no : 301846

Start Date:01/04/14

S/R Activities

NO Sequence of

work)

Rigging

Persons Responsible

HAZARDS

Safety Precautions

*Failure of slings &

wire rope,tripping

hazards

*failure of lifting

equipments(tools/tack

les)

*Incompetent

worker/rigger

*People should not stand in swing area, flagman with

whistle to be available

*It is of adequate strength,suitable quantity & free from

patent defects.

*It will be tested 7 examined by competent person &

obtent a certificate.

*Regging equipment for material handling should be

visually inspected prior by us.

*Rigging equipment should not be in excess of its

recommended safe working load.

* Rigging & lifting equipment should be clear marked with

its safe work load and identify number.

*Workmen area should be baricated .

*Precautions should be taken through the use of pcking

or prevent the edges of the load from coming into contact

with the sling.

*The place of anchor should be strong and rigid.

*Competent worker/rigger to be engaged.

Representative from TCIL

Representative from safety (TCIL)

Name

G P NO

End Date: 09/04/14

Condition of

tools/tackles

required-OK/Not

OK

* Slings and wire

rope ok

* Chain Block ok

* Hooks ok

* Pull Lift ok

* D-shackles ok

Reference to

documents/criteria

and remarks

Representative from MEW

Note: 1) This safe work procedure shall be prepared by owner department countersigned by working agency/contractor's representative and safety department

2) Sequence of work shall involve step-by-step jobs

3) All possible hazards shall be identified

4) With the change of work conditions, the procedures shall be amended and persons shall be trained accordingly.

5) Review on status of implementation shall be done through task observation and site severity audit

6) Before start of job ,induction shall be given to persons engaged at site by departmental representative and subsequent daily induction shall be given by Working

Agency/Contractors Representative.

You might also like

- Risk Assessment Rib Erection & FabricationDocument2 pagesRisk Assessment Rib Erection & FabricationAkash SharmaNo ratings yet

- JSA Format Erection of Column 903-C-02,03Document5 pagesJSA Format Erection of Column 903-C-02,03sakthi venkat100% (1)

- 28.1.1 Mobile Equipment Inspection ChecklistDocument1 page28.1.1 Mobile Equipment Inspection Checklistmohamed abdelmoniemNo ratings yet

- Safe Work Method Statement - PlumbingDocument4 pagesSafe Work Method Statement - PlumbingJohn KurongNo ratings yet

- 04.unloading of MaterialsDocument6 pages04.unloading of MaterialsKiran ChenchalaNo ratings yet

- JHA for Hill Cutting Activities at Port of SalalahDocument8 pagesJHA for Hill Cutting Activities at Port of SalalahSreekumarNo ratings yet

- NASDA WIND POWER SUB-STATION EXCAVATION SAFETYDocument2 pagesNASDA WIND POWER SUB-STATION EXCAVATION SAFETYRaza Muhammad SoomroNo ratings yet

- Dr. Nirali Patel Pediatric Emergency MedicineDocument31 pagesDr. Nirali Patel Pediatric Emergency Medicinemarsan12No ratings yet

- 021 Crane Operator ChecklistDocument1 page021 Crane Operator ChecklistJunard Lu HapNo ratings yet

- 07 - TDS - Masterflow 520Document3 pages07 - TDS - Masterflow 520Alexi ALfred H. TagoNo ratings yet

- 3 SPS Sop RCC FullDocument14 pages3 SPS Sop RCC FullDwitikrushna RoutNo ratings yet

- GroutingDocument1 pageGroutingraphael damanikNo ratings yet

- Hazard Task Risk Control MeasuresDocument5 pagesHazard Task Risk Control MeasuresIshan DankharaNo ratings yet

- Safe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201Document18 pagesSafe Work Method Statement For Survey Work: CMS Surveyors Pty LTD ABN: 79 096 240 201mkash028100% (1)

- Asian Paints - Prem Gloss EnamelDocument1 pageAsian Paints - Prem Gloss EnamelwilliumstNo ratings yet

- Daily Safety ChecklistDocument4 pagesDaily Safety ChecklistKalyan ReddyNo ratings yet

- Concrete Mixer Safety ChecklistDocument1 pageConcrete Mixer Safety ChecklistSafety Man Shop100% (1)

- Workplace Hazards in ConstructionDocument2 pagesWorkplace Hazards in ConstructionDWi Uwee DejHeNo ratings yet

- Tools & Tackles Monthly InspectionDocument4 pagesTools & Tackles Monthly InspectionDeepu ChandranNo ratings yet

- Trestles and StagingDocument2 pagesTrestles and Stagingdak comeiNo ratings yet

- ISC-JSA Grouting Works For Shared FenceDocument4 pagesISC-JSA Grouting Works For Shared FenceSameer AlmahboubNo ratings yet

- TRA 13 Loading or Unloading Chems With ForkliftDocument2 pagesTRA 13 Loading or Unloading Chems With ForkliftPirlo Polo100% (1)

- RMDJV Pj74 Hiradc Subc 05a (Piling Work)Document1 pageRMDJV Pj74 Hiradc Subc 05a (Piling Work)myn maliQue100% (1)

- Risk Assessment - Tower DecommissioningDocument5 pagesRisk Assessment - Tower DecommissioningJeffery Mulei100% (1)

- JHA Stacks EDG Substation r0 14 August 2017 EdittedDocument5 pagesJHA Stacks EDG Substation r0 14 August 2017 EdittedJeniffer Ong100% (1)

- Risk Assessment Record for BPGIC TerminalDocument4 pagesRisk Assessment Record for BPGIC TerminalAbdul HadiNo ratings yet

- Jsa For Piping and Erection RevisedDocument1 pageJsa For Piping and Erection RevisedDr AnwarNo ratings yet

- Monthly Ladder Inspection ChecklistDocument1 pageMonthly Ladder Inspection ChecklistshahidNo ratings yet

- Job Hazard Analysis (Earth Mounted Tank)Document8 pagesJob Hazard Analysis (Earth Mounted Tank)jay RNo ratings yet

- JSA Hand ToolsDocument1 pageJSA Hand ToolsInoy dy hesusNo ratings yet

- Working at Height Op (Eration Scaffolding Work Risk AssessmentDocument22 pagesWorking at Height Op (Eration Scaffolding Work Risk AssessmentAhmed Farman AlqaysiNo ratings yet

- HSE-F-314 Passenger-Material Hoist Monthly ChecklistDocument1 pageHSE-F-314 Passenger-Material Hoist Monthly ChecklistAhmad RazaNo ratings yet

- Jsa For The Installation of I EamDocument5 pagesJsa For The Installation of I EamMohammed MinhajNo ratings yet

- Air Compressor Operation SafetyDocument10 pagesAir Compressor Operation SafetyKelvin TanNo ratings yet

- JHA Worksheet Safety TipsDocument6 pagesJHA Worksheet Safety TipsAbdul Khairul RiduanNo ratings yet

- Humed Method Statement For Mono-Poles InstallationDocument3 pagesHumed Method Statement For Mono-Poles InstallationUtibe EkongNo ratings yet

- C&C-EHS-F-002 HIRARC Working at Height (Roof Top)Document4 pagesC&C-EHS-F-002 HIRARC Working at Height (Roof Top)Najman HamdiNo ratings yet

- Jha Crane OperationsDocument2 pagesJha Crane OperationsJaycee Bareng Pagador100% (1)

- Tower Crane Dismantling JSA HSE ProfessionalsDocument2 pagesTower Crane Dismantling JSA HSE ProfessionalsnabeelNo ratings yet

- JSA For Erection & Dismantling of ScaffoldingDocument4 pagesJSA For Erection & Dismantling of ScaffoldingNoe AranelNo ratings yet

- Safe Work Method StatementDocument7 pagesSafe Work Method StatementAjith NairNo ratings yet

- JHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDocument4 pagesJHA No. 06, Manual Excavation and Instalasi Formwork For Barier Pole Dan Concrete Slab HydrantDarmawan OnradNo ratings yet

- SOP - ForkliftDocument4 pagesSOP - ForkliftGyanendra Narayan Nayak100% (1)

- Risk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityDocument2 pagesRisk Assessment Form: Project: Gem Residences Location: E. Rodriguez Ave. C5, Pasig CityJhundel FactorNo ratings yet

- Pha ExcavationDocument13 pagesPha ExcavationirshadNo ratings yet

- Hino Tipper Risk AssesmentDocument9 pagesHino Tipper Risk AssesmentGnamaSayaNo ratings yet

- Akk Jha Installation of Diesel TankDocument3 pagesAkk Jha Installation of Diesel TankDouglas Delly0% (1)

- JSA NO 2 Piling WorkDocument6 pagesJSA NO 2 Piling WorkfadliNo ratings yet

- Excavation Safety ProceduresDocument7 pagesExcavation Safety ProceduresHasanuddin HAMIDNo ratings yet

- Camp Cleaning ScheduleDocument4 pagesCamp Cleaning Schedulerashid zamanNo ratings yet

- Contractor Personnel and Safety Statistics Monthly Summary - Form S2052Document1 pageContractor Personnel and Safety Statistics Monthly Summary - Form S2052Safety professionalNo ratings yet

- PTA-JSA-003-Material Handling by Farhana F-15 CraneDocument6 pagesPTA-JSA-003-Material Handling by Farhana F-15 CraneSaiyad RiyazaliNo ratings yet

- Tower Crane Installation SOP SummaryDocument3 pagesTower Crane Installation SOP SummaryRashidi RahmanNo ratings yet

- Job Safety Analysis (JSA) - Night Work DateDocument2 pagesJob Safety Analysis (JSA) - Night Work Datenabeel100% (2)

- Emergency Rescue Plan For Electric Shock (29!10!19)Document4 pagesEmergency Rescue Plan For Electric Shock (29!10!19)Ashok sNo ratings yet

- Using Hand Drill (WS)Document2 pagesUsing Hand Drill (WS)John KalvinNo ratings yet

- HIRA No. 02-Use of Access Scaffolding SBDDocument2 pagesHIRA No. 02-Use of Access Scaffolding SBDVenkadesh Periathambi25% (4)

- Job Safety AnalysisDocument19 pagesJob Safety AnalysisVineet Agrawal100% (1)

- JHA Arc WeldingDocument2 pagesJHA Arc WeldingechaNo ratings yet

- JSA for Above Ground Piping WorkDocument3 pagesJSA for Above Ground Piping WorkBhisamS SallehNo ratings yet

- Tata Sky ALC Channel ListDocument13 pagesTata Sky ALC Channel ListIndianMascot33% (3)

- India Pack 2018Document2 pagesIndia Pack 2018Samadarshi SarkarNo ratings yet

- Rahul Bhattia and Vijay Mallya - Comparison of Leadership StylesDocument23 pagesRahul Bhattia and Vijay Mallya - Comparison of Leadership Stylesabcxyz2811100% (2)

- Presentation 1 - 2013 PDFDocument40 pagesPresentation 1 - 2013 PDFSamadarshi SarkarNo ratings yet

- Airtel Market 2015Document29 pagesAirtel Market 2015Samadarshi SarkarNo ratings yet

- Economic Instruments For Env MGMTDocument26 pagesEconomic Instruments For Env MGMTSamadarshi SarkarNo ratings yet

- Job satisfaction and employee engagement case study at Bella's day spaDocument22 pagesJob satisfaction and employee engagement case study at Bella's day spaSamadarshi Sarkar100% (1)

- MP Sheet Blank FormatDocument1 pageMP Sheet Blank FormatSamadarshi SarkarNo ratings yet

- Newell IzationDocument8 pagesNewell IzationSamadarshi SarkarNo ratings yet

- BayesDocument11 pagesBayesSamadarshi SarkarNo ratings yet

- Eco Efficiency Based GSCM Current Status and OpportunitiesDocument6 pagesEco Efficiency Based GSCM Current Status and OpportunitiesSamadarshi SarkarNo ratings yet

- Finance and SDDocument41 pagesFinance and SDSamadarshi SarkarNo ratings yet

- Isdcs Lca PDFDocument25 pagesIsdcs Lca PDFSamadarshi SarkarNo ratings yet

- Economic Instruments For Env MGMTDocument26 pagesEconomic Instruments For Env MGMTSamadarshi SarkarNo ratings yet

- The PGP Company (Dashman)Document2 pagesThe PGP Company (Dashman)Samadarshi SarkarNo ratings yet

- WACC Spreadsheet Template2010Document2 pagesWACC Spreadsheet Template2010Samadarshi SarkarNo ratings yet

- WACC TutorialDocument15 pagesWACC TutorialAbhishek P BenjaminNo ratings yet

- Performance Management and AppraisalDocument51 pagesPerformance Management and AppraisalSuprabhat TiwariNo ratings yet

- Kota SolutionDocument59 pagesKota SolutionAlvaro M. JimenezNo ratings yet

- Tata HitachiDocument16 pagesTata HitachiSamadarshi SarkarNo ratings yet

- Green Economy by Group12Document29 pagesGreen Economy by Group12Samadarshi SarkarNo ratings yet

- Case Study On SuccessionDocument8 pagesCase Study On SuccessionSamadarshi SarkarNo ratings yet

- Install Windows 7 From USBDocument133 pagesInstall Windows 7 From USBSamadarshi SarkarNo ratings yet

- Corporate Social Responsibility and Strategic CSRDocument10 pagesCorporate Social Responsibility and Strategic CSRSamadarshi SarkarNo ratings yet

- Concrete CanvasDocument20 pagesConcrete CanvasJet Espejon JavierNo ratings yet

- ERM99B ERP99B 3/16/07 Champion Gardner DenverDocument62 pagesERM99B ERP99B 3/16/07 Champion Gardner DenverManualstoHelpNo ratings yet

- Gas LasersDocument53 pagesGas LasersDheeraj100% (1)

- Warna Daun Padi LCCDocument12 pagesWarna Daun Padi LCCM Hisyam NasrullohNo ratings yet

- Stainless Steel 304 FlangesDocument6 pagesStainless Steel 304 FlangesiSteelindiaNo ratings yet

- Instruction and Technical Manual for CentrifugesDocument56 pagesInstruction and Technical Manual for CentrifugesDiana RaieNo ratings yet

- (VESBO) Catalog en 100317Document55 pages(VESBO) Catalog en 100317AnhNguyen100% (1)

- Rition Feeaing: Ruminant AnatomyDocument30 pagesRition Feeaing: Ruminant AnatomySMP SeriesNo ratings yet

- Toxic Substances and Disease Registry MRLs for March 2016Document16 pagesToxic Substances and Disease Registry MRLs for March 2016KodeChandrshaekharNo ratings yet

- Mass Transfer 2Document35 pagesMass Transfer 2Zel SalvadorNo ratings yet

- Calculation Dilute Phase Pressure Drop Rhodes MethodDocument3 pagesCalculation Dilute Phase Pressure Drop Rhodes MethodBTENo ratings yet

- Groundwater ContaminationDocument25 pagesGroundwater ContaminationjoshjethNo ratings yet

- Rigaku Nex QCDocument12 pagesRigaku Nex QCLuis ReyesNo ratings yet

- Studies On The Production of Defatted Sunflower Meal With Low Polyphenol and Phytate Contents and Its Nutritional ProfileDocument4 pagesStudies On The Production of Defatted Sunflower Meal With Low Polyphenol and Phytate Contents and Its Nutritional Profileamco2kNo ratings yet

- Appchem 1 1Document18 pagesAppchem 1 1Fate SoteroNo ratings yet

- Final - Report Hydroelectric Power PlantDocument39 pagesFinal - Report Hydroelectric Power PlantnisarNo ratings yet

- Chemical Properties of Food-1Document47 pagesChemical Properties of Food-1Mbabazi Jackson CalmaxNo ratings yet

- Makrolon® ET3137: Grades / ExtrusionDocument4 pagesMakrolon® ET3137: Grades / ExtrusionDiegoTierradentroNo ratings yet

- Recall Machine Design Past Board Cebu Mar 2011 11 PDFDocument12 pagesRecall Machine Design Past Board Cebu Mar 2011 11 PDFCMD100% (1)

- Vestamid L Polyamide 12 - EvonikDocument12 pagesVestamid L Polyamide 12 - EvonikHaryo Armono100% (1)

- 12 Biology Notes Ch06 Molecular Basis of InheritanceDocument14 pages12 Biology Notes Ch06 Molecular Basis of Inheritancehimanshu kumarNo ratings yet

- Mineral-rich Bilimbi fruit analysisDocument3 pagesMineral-rich Bilimbi fruit analysisveronica francisNo ratings yet

- Unit 1 - Construction Materials - WWW - Rgpvnotes.inDocument21 pagesUnit 1 - Construction Materials - WWW - Rgpvnotes.inmadhavi likharNo ratings yet

- Big Batch Soap MakingDocument24 pagesBig Batch Soap MakingAnonymous Vu1R35s4WZ100% (2)

- DTS Thoracic R4Document2 pagesDTS Thoracic R4Arief FaqihNo ratings yet

- Sikament NNDocument2 pagesSikament NNMasrul WijayaNo ratings yet

- Sansico Top Access Floor Trap - S3Document20 pagesSansico Top Access Floor Trap - S3Biggie ColdAngelNo ratings yet

- Chemical Reactions and Energy ChangesDocument6 pagesChemical Reactions and Energy ChangesMiku HatsuneNo ratings yet

- Ethanol Absolut (Ethyl Alcohol)Document6 pagesEthanol Absolut (Ethyl Alcohol)Fitra Isni RositaNo ratings yet

- Comparison of Triode and Diode Ion PumpDocument7 pagesComparison of Triode and Diode Ion PumpAarkayChandruNo ratings yet