Professional Documents

Culture Documents

Manjung Power Station - Malaysia

Uploaded by

Makoya_malumeCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Manjung Power Station - Malaysia

Uploaded by

Makoya_malumeCopyright:

Available Formats

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

MANJUNG POWER STATION

MALAYSIA

Offshore Cooling Water Intake Culvert

Leighton LAMA Joint Venture

END OF CONTRACT REPORT

July 2000 to October 2001

Leighton-LAMA Joint Venture

Section 1: Page 1 of 4

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

Table of Contents

VOLUME 1 MAIN REPORT

SECTION 1.

SECTION 2.

SECTION 3.

SECTION 4.

SECTION 5.

SECTION 6.

SECTION 7.

SECTION 8.

SECTION 9.

SECTION 10.

SECTION 11.

SECTION 12.

SECTION 13.

SECTION 14.

SECTION 15.

SECTION 16.

SECTION 17.

SECTION 18.

SECTION 19.

SECTION 20.

Leighton-LAMA Joint Venture

INTRODUCTION

JOINT VENTURE RELATIONSHIP

PRE CONTRACT AWARD

BRIEF PROJECT DESCRIPTION

DESIGN OF THE COOLING WATER INTAKE

GEOTECHNICAL CONDITIONS ENCOUNTERED ON

THE CULVERT ROUTE

PRODUCTION RATES, PLANT UTILISATION AND

CREW SIZES

COST VS BUDGET

RISKS/LESSONS LEARNED

STAFFING LEVELS

SUBCONTRACTORS & SUPPLIERS

TEMPORARY WORKS

PRECASTING OPERATIONS

IN-SITU CULVERT & COFFERDAM

MARINE WORKS

DOSING LINE

NAVIGATION STRUCTURE

FINANCIAL

SITE PHOTOGRAPHS

APPENDICES CD OF DRAWINGS

Section 1: Page 2 of 4

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

SECTION 1. INTRODUCTION

1.1. SCOPE

The contract is for the construction of a Cooling Water Intake System as part of the Manjung

Power Station. The plant is coal fired, utilizing available sea water for cooling purposes. The

project is constructed on a joint venture design and construct basis between Leighton

Contractors (main civil subcontractor for the Manjung Power Station Project) and LAMA

International Contractors (Design and specialist Marine Works Contractors.)

The purpose of the structure is to draw and deliver seawater, from 1500 metres offshore, to

the power station cooling system on land, at a rate of 88.2m3/sec when in full operation. This

requirement is being achieved by the construction of a sub-sea triple celled culvert, 1500

meters long. This culvert was constructed over a period of 13 months, involving land and

marine construction operations, including a substantial amount of underwater work using

divers. The locations of the seawater intake points have been carefully selected based on the

tight specifications for minimum depth of water, water temperature, and the turbidity of h

te

seawater.

The project has been carefully designed and constructed to ensure that the clients

requirements are met in full, with due consideration for the environment, local authorities

requirements, constructability, programme and budget.

1.2. PROJECT DESCRIPTION

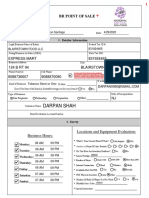

Name of Client:

Joint Venture Partner:

Location:

Type of contract:

Initial Budget:

Leighton Contractors (Malaysia) SDN BHD

Leighton Contractors (Malaysia) SDN BHD

Lekir, Perak Darul Ridzuan, Peninsular Malaysia

Design and Construct Lump Sum

Design MYR

1 677 000.00

Construction - MYR

60 000 000.00

Final Cost:

Design MYR

1 883 998.47

Construction - MYR

63 250 000.00

Planned Programme: Completion - July 2001

Actual programme:

Completion - October 2001

Leighton-LAMA Joint Venture

Section 1: Page 3 of 4

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

Manjung Power Station

1.3. PROJECT SUMMARY

The design and construction of the cooling water intake culvert consists of the following:

Dredging of 380 000 cubic metres of in-situ material to form the sub-sea trench for the

culvert.

Underwater piling using 312 no 1000mm diameter spun concrete pipe piles to tight

positional and level tolerances using GPS equipment.

Placing of reinforced pre -cast pile caps underwater and the underwater grouting of these

pile caps into the piles.

Manufacture and handling of 142 no, 10 m long, 3 celled, pre -cast concrete culvert units,

each weighing 400 tonnes.

Transporting of these 400 ton pre -cast culverts on land, using heavy lift trailers, and at

sea using a specially designed floating gantry to place them in line in the pre-dredged

sub-sea foundation trench, to form the triple celled culvert at depths varying between

8m and 16m ACD.

Underwater grouting operations to seal the joints between the culvert units, to prevent

ingress of silt or sand.

Construction, handling and placing of 6 no pre -cast intake units weighing 150 tonnes

each, offshore at the end of the cooling water intake culvert.

Construction of a load out jetty to facilitate loading out of the precast concrete units.

Construction of 70 metres of in-situ concrete culvert within a 12m deep cofferdam to

provide the connection from the offshore precast concrete culverts to the land based

water pool, which is the reservoir for the power stations intake cooling water pumps.

Installation of three 225mm diameter 1450m sub-sea pipelines for the delivery of

hypochlorite to the intake structures at the end of the culvert, to prevent marine growth

inside the cooling water intake system.

Design simulations, including physical and computer modelling, as well as on site testing,

formed a major part of the successful design and construction of the project.

Leighton-LAMA Joint Venture

Section 1: Page 4 of 4

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

SECTION 2. PRE CONTRACT AWARD

This section deals with the contractual process prior to award of contract. The first contact took

place in October 1999 with Leighton (Malaysia) requesting LAMA to assist them with the

preparation of a price which was to be submitted to Peremba for the construction of an intake and

outlet conduit for a new power station to be constructed at Manjung in Malaysia.

Various alternative designs were considered, including steel, HDPE and concrete pipes, all in a

buried trench, concrete pipes above sea level supported on a piled structure and concrete culverts

in a trench on the seabed.

A budget price was submitted by LLJV to Peremba on 18 October 1999 based on steel pipes with

an HDPE alternative. The price was developed further to exclude the outlets and an option of steel

pipes on trestles above water was also priced and a budget price was submitted on the 1st

November 1999.

In January 2000 negotiations moved from Peremba to Alstom (who had been presumably awarded

the Main Contract at that stage). No pre-bid agreement between ourselves and Leighton was put in

place at this stage due to the nature of the discussions being around budget pricing etc. rather than

the submission of a formal tender. Leighton were now also in negotiations with Alstom regarding

the Main Civil Works Contract.

At this stage Alstom produced their first Design and Construct Specification, which was to be used

for the design of the intake conduits, whichever option was selected. At this stage, however,

Alstom had still not decided whether the contract would go out as a D&C or whether they would

design it themselves to their own design, or thirdly whether they would carry out the design based

on the contractors chosen type of conduit.

During the mo nth of January 2000, various options based on a steel pipe in a trench on the seabed

were priced in order to reduce the contract sum. A presentation was made by the Leighton-LAMA

team to Alstom on the proposed scheme at that time. Leighton had also requested prices from

Van Oord and See Yong & Sons.

A further alternative, that of precast concrete culverts was developed, which started looking like

being the most cost effective solution. The development of the preliminary design of the culvert

then commenced in more detail, in order to further refine the costs of this system. The basic sizing

was taken from Alstom layout drawings showing an internal cell size of 3.42m square. A budget

price based on precast concrete culverts was submitted on 29th January 2000. This price was

developed and reduced further during the month of February 2000. The price which Leighton

submitted for the overall Civils Works included the offshore work based on a price and submission

from See Yong (assumed immersed tube construction) as LAMA were not prepared to agree to a

fixed price at that stage due to the short time given to price the works. Leighton was awarded the

Civil Works Contract including the offshore works as an option to be taken up before end May

2000.

At this stage pricing of the culvert system based on Alstom doing the design as well as the project

being carried out as a design and construct contract, were carried out in parallel, as there was still

no confirmation from Alstom as to which way they were intending to go.

In February an internal Tender review report states that Alstom have indicated that they would

consider a EPC type of contract in order to advance this part of the works but might still insist on

completing the design themselves. This report also discusses two possible bid strategies being:

1. Alstom doing the design and

2. EPC type of contract.

Leighton-LAMA Joint Venture

Section 2: Page 1 of 2

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

Both options were priced assuming different design fees as well as variable contingencies to cater

for the design risk.

By mid-March 2000, there was still no confirmation that LAMA would be responsible for the

permanent works design.

During the week ending the 19th May, we were informed by Leighton that Alstom required the JV to

do a presentation on the proposed culvert design with a view to awarding the offshore contract on

a design and construct basis by the beginning of June. This was the first time that Alstom had

confirmed their intention to go the D&C route. A LAMA team travelled to Kuala Lumpur on the 20 th

May to make the presentation to Alstom and then spent the next 10 days finalising the design and

price. A revised Performance Specification was issued by Alstom as the basis on which the D&C

contract was to be awarded.

The main issue at that time was the interface between the offshore works and the waterpool, and a

solution was arrived at by the Leighton-LAMA team based on a pipe -jacking operation. LAMAs

design fee was adjusted during the final pricing and was based on the scope of work as defined at

that time. Discussions were also held with Nelson Borch of TerraGeotechnics (through Peter

Furness) for them to assist in both the design approval process as well as providing specialist

geotechnical advice. After submission of the price, various negotiations took place between

Leighton and Alstom and a final price of RM 63.25M for the Offshore Works was agreed to,

although at this stage it was still not clear what our involvement would be.

Leighton notified LAMA during the first week of June that they (Leighton) had been awarded the

offshore contract. A LAMA team then travelled to KL to finalise LAMAs involvement, the JV

agreement, and to discuss staffing and the programme for the contract. It was at this stage that a

revised JV agreement and consultancy agreement appeared for the first time and LAMA was

asked to sign it as a basis of LAMAs design responsibility to Leighton. During this visit in June

discussions were held with the site team (including the Project Director) and a decision was made

to change from pipe-jacking to a cofferdam for the inshore tie-In to the waterpool.

A potential standoff position developed on this visit between Leighton and LAMA around issues of

representation in the JV, the JV Agreement, Indirect Cost split, sponsors fees and profit.

Leightons view was that the marine work had been secured by Leighton as LAMA had not

appeared willing to commit themselves at the time of the original price submission. Leighton

threatened to drop LAMA if no agreement could be reached on the outstanding issues which were

only finally resolved at the first JV EXCO meeting.

Leightons initial requirement was that the responsibility for the design of the works be directly

between Leighton as the Main Civil Works Contractor and LAMA. After discussions at the first JV

Exco meeting on 5 September 2000, it was agreed that if there was going to be a formal

agreement, then the agreement should be between the LAMA and the LLJV and not directly

through Leighton.

Leighton-LAMA Joint Venture

Section 2: Page 2 of 2

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

SECTION 3. JOINT VENTURE RELATIONSHIP

3.1. BACKGROUND

Referring to Section 2 it will be noted that Leighton played the major role in securing this

project. This was largely due to the fact that Leighton had already secured the main civils

contract and the CW Inlet was to be a sub-contract to the civils package. Because of this

existing relationship with the client, all pre -award negotiations were through Leighton, with

technical and pricing backup being provided by LAMA.

At the first JV meeting held in Malaysia in June, just after the contract award, a new format of

joint venture agreement and joint venture exco was proposed by Leighton. This differed to

those previously used and clearly the intention of Leighton was to reduce the role of LAMA in

joint venture decision-making. This was considered to be unacceptable to LAMA and

eventually it was agreed by the parties to revert to the standard Leighton LAMA JV

agreement previously used on the JV projects.

3.2. DURING THE CONTRACT EXECUTION

The relationship between the Leighton and LAMA Staff on site during execution of the project

was generally good, but between the Parties was complicated by two factors:

The JV was executing the work as a subcontractor to Leighton, and the project director of

the Civils contract (a Leightons contract employee) also acted as the Joint Venture

Project Manager.

LAMA was carrying out the design works on a lump sum basis for the joint venture. On

previous projects generally the design was carried out by LAMA within the Joint Ventrure

and at the JVs risk.

3.2.1.

Subcontract to Leighton

Contractual issues

LAMA commenced work on the project only having seen a generic Leightons Sub contract agreement. The proposed agreement was only prepared after the details

of the CW Inlet subcontract were concluded between Leighton and the Client, which

was some months after the start of the project. The proposed conditions were

unacceptable to LAMA, but Leighton refused to accept any changes to their

standard subcontract agreement The result is that this subcontract agreement

remains unsigned.

Management issues

Leighton had, at the start of the works stated that the main civil works took

precedence over the CW Inlet and they would not permit a disagreement between

the parties to jeopardise progress on the main contract.

All negotiations with the Client which were of a commercial nature were dealt with

by Leighton as they were the Main Contractor, and LAMA was generally excluded

from these discussions. Very little in the way of correspondence between the main

contractor and client which was of a commercial nature was made available to

LAMA or the JV management on site. Agreements on issues such as incentives,

bonuss, penalties and commercial issues surrounding the geotechnical problems

were only received second -hand from Leightons.

Leighton-LAMA Joint Venture

Section 3: Page 1 of 3

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

It was agreed at the start of the contract that the Leightons Project Director on the

Civil Works would also act as the JVs Project Manager for the CW Inlet, despite

LAMA having placed a very experienced Project manager on site. The commercial

support to the JV was provided by the Leightons Commercial Manager on site.

Some of the Leighton staff found it difficult to be even-handed in their dealings with

the two JV Partners and in particular their approach taken in regard to LAMAs claim

for additional design costs and the resolution of the Geotechnical problems were

questionable. LAMA were treated as sub -contractors by the Leightons Management

although they were also JV Partners.

3.2.2.

Design Works

The decision by the Client to award the CW Inlet on a Design & Construct basis

was only made at a very late stage in the contract negotiation stage. With the very

tight program, and the impact that the CW Works had on the Main Civil works, the

design team were put under pressure from the start of the project.

In particular, the design of the cofferdam at the waterpool, and later the revised

founding to the culvert units consumed a much greater design effort than was

previously assessed.

Leighton at an early stage raised a number of issues with regard to their perception

that the design which LAMA was carrying out was overly conservative and more

expensive to construct than tendered. These perceptions were largely unfounded.

The greatest influence on the JV relationship was brought about by the geotechnical

problems encountered with the culvert foundations (elsewhere detailed). These

problems led to a change in design in the foundations, with the resultant increase in

cost. Although the decision to change the foundation system was made relatively

quickly it resulted in a polarisation between the parties which was never completely

repaired.

There was a large amount of additional design work carried out for the project as a

result of, amongst other things:

Cofferdam design, as a result of the variable ground conditions, and to suit piling

methods and materials.

Redesign of various plant items to suit the requirements of the site team.

Redesign of the Temporary Jetty in order that it satisfy the requirements of a

permanent structure.

Change of the culvert foundation to a piled solution

Design of the navigation structure.

Dosing line change

Although the design work was done as a Lump Sum, additional compensation was

requested for some of the additional work, especially where the additional work was

done to suit the site requirements.

An agreement was reached on payment for certain of the minor additional work, but

despite lengthy submissions and discussions with Leighton on the balance, they

argued that much of this redesign was merely design development; no additional

structures were built than were tendered, and therefore there were no grounds for

additional payment to the designers.

Leighton-LAMA Joint Venture

Section 3: Page 2 of 3

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

In fact, in the final negotiations with Leighton on the settlement of the piling

foundation claim, all design variation costs (including those agreed to be paid) were

forfeited by LAMA.

3.3. LESSONS LEARNT

Conflict of interest issues must be identified and dealt with in appropriately worded

agreements.

The potentially disastrous arrangement of sub -contracting to your Joint Venture Partner

can severely stress the Joint Venture, particularly when technical or financial problems

are encountered on the project. Similar joint venturing arrangements were in place on

Sha Chau (with Leighton) and on the Natal Pipelines (with Pentow Marine). The Sha

Chau project had no technical problems and was financially very successful so the

relationship was never tested and remained good. The Natal Pipelines project had

technical and financial problems and led to a breakdown in the Joint Venture relationship.

Ideally, the design risk and the cost of producing the design should be shared by the

partners in the JV and not transferred to one of the partners. In this way the cost vs.

benefit of design development can best be managed.

Leighton-LAMA Joint Venture

Section 3: Page 3 of 3

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

SECTION 4. BRIEF PROJECT DESCRIPTION

The cooling water intake culvert is approximately 1490m in length, extending from the intake

structures at the seaward end to the diaphragm wall of the pump station water pool onshore. The

triple cell culverts have interior barrel dimensions of 3.750m vertically and 3.450m horizontally,

with 0.300m chamfers. The culvert consists of an in-situ section, 142 pre-cast sections with 6

intake towers towards the end, 3 x 225mm HDPE dosing lines on top of the culvert and a

navigation structure 50m offshore of the end of the culvert. These items are described in more

detail below.

4.1. IN-SITU CONCRETE CULVERTS

Water pool Opening into In -Situ Culvert

Cofferdam for In-situ Culvert

The in-situ concrete culvert is 70m long, which was constructed in three sections i.e. one

10m and two 30m long sections, from the open trench through the island revetment to the

connection to the water pool diaphragm wall. Each section was constructed within a sheetpiled cofferdam. All the sheet piles were removed after construction with the exception of

the sheet piles up against the diaphragm wall of the water pool. The diaphragm wall of the

water pool in the region of the tie-in to the in-situ culvert, was cast prior to the construction

of the in-situ concrete culvert. A reinforced concrete chimney, which provides access to all

three barrels, is positioned towards the end of Section 1. This concrete chimney allows the

three interior structural steel bulkheads to be installed into the barrels of the in-situ culvert.

The bulkheads were required to retain the water in the culvert during the construction of the

opening in the diaphragm wall of the water pool. The existing VIB wall surrounding the bulk

of the power station civil works cuts across Section 1 of the culvert.

There are movement joints between each section of the in-situ culvert and at the connection

to the external face of the cooling water pool. Heavy-duty water bars were installed at the

movement joints between the in-situ culvert sections as well as the connection to the water

pool wall. The reinforcement in the concrete culvert is not continuous across these joints.

The poor soil conditions in the area where the cofferdam was constructed, as well as the

large future settlements predicted for this area, dictated that the in-situ culvert needed to be

supported on pre -cast concrete bearing piles. Pre-cast reinforced concrete piles provide

support to the culverts, positioned in four rows longitudinally under the culvert walls. The

longitudinal pile spacing varies along the length of the in-situ culvert. The in-situ concrete

Leighton-LAMA Joint Venture

Section 4: Page 1 of 9

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

culvert is underlain by a 75mm concrete blinding layer. The piles penetrate the 75mm

blinding layer to tie into the reinforced concrete culvert base slab.

The culverts are founded at approximately 7,680m ACD (underside concrete floor), with

the top of the concrete roof at 3,070m ACD. Over Section 1, fill is placed to a level of

+4,650m ACD. The fill slopes down through the revetment over the length of Section 2 to

meet the general seabed level of 1,600m ACD. This level is maintained over the full length

of Section 3.

4.2. PRE-CAST CONCRETE CULVERT UNITS

Typical Pre -Cast Unit

Pre-Cast Unit being placed by Gantry

The cooling water intake consists of 142 Pre -cast Concrete units extending from the in-situ

culvert to the end of the intake culvert, which are divided into 11 different types as follows:

Pre -cast Culvert Units Type A and B.

Unburied Unit 54 Type A

Buried Unit 71 Type B

Units type A and B are installed in a dredged trench and are supported on 4 concrete pile

caps which are supported on 4 No. 1m diameter, class C, grade 80N/mm2 concrete spun

piles. The cooling water intakes consist of 54 No intake culvert type A & 71 No intake

culvert type B units, which are each 10m long, 11.810m wide by 4.610m high overall. Unit

type A and Bs are triple cell pre -cast culvert units, which have interior barrel dimensions of

3.750m vertically and 3.450m horizontally, with 0.300m chamfers. Unit type Bs are

identical to unit type As except that they have more reinforcement in them to cater for a

greater cover of seabed material due to their location in the length of the intake culvert.

Pre -cast Culvert Units Type F.

Access Unit 6 Type F

Units type Fs are installed in a dredged trench and are supported on 4 concrete pile caps,

which are supported on 4 No. 1m diameter, class C, grade 80N/mm2 concrete spun piles.

The cooling water intakes consist of 6 No intake culvert type F units, which are each 10m

long, 11.810m wide by 4.610m high overall. Unit type Fs are triple cell pre-cast culvert

units, which have interior barrel dimensions of 3.750m vertically and 3.450m horizontally,

Leighton-LAMA Joint Venture

Section 4: Page 2 of 9

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

with 0.300m chamfers. Unit type Fs are the units that have the 3 manhole covers in them in

order to access the inside of each of the 3.750m x 3.450m barrels.

Pre -cast Culvert Units Type H

Transition Unit 1 Type H

The transition unit type H is the first pre -cast unit that will be placed in front of Section 3 of

the in -situ concrete culvert. The north end is cast at an angle to match the south end of

Section 3 of the in-situ culvert. The transition unit Type H is 8.180 m long along the centre

line and is 11.810 m wide x 4.610 m high overall. Reinforced concrete piles provide support

to the transition pre-cast unit Type H as follows:

2 No. 1000 mm diameter concrete spun piles, positioned longitudinally under the

external culvert walls, on the offshore end of unit Type H as per the typical pre-cast unit

and;

2 No. 700mm diameter concrete spun piles, positioned under the internal walls of the

culvert, at the joint between Section 3 of the in -situ culvert and the transition pre-cast

unit Type H. A continuous crosshead beam and 2 no. rectangular pile caps are cast

over the 2 No. 700mm diameter concrete spun piles to support the pre-cast transition

unit Type H.

Pre -cast Culvert Units Type J&K

Intake Unit 3 Type J

Intake Unit 3 Type K

Units type J&K are installed in a dredged trench and are supported on 8 concrete pile caps

which are supported on 8 No. 1m diameter, class C, grade 80N/mm2 concrete spun piles.

The cooling water intakes consist of 3 No intake culvert type J & K units, which are each

10m long, 11.810m wide by 4.610m high. The triple cell pre-cast culvert units have interior

barrel dimensions of 3.750m vertically and 3.450m horizontally, with 0.300m chamfers.

They are similar to a typical unit except that they have a 3.450m square opening in the top

slab, which incorporates an up stand beam cast around the opening which caters for the in situ connection of the pre -cast Intake towers to the pre-cast units. The unit types J&K also

have internal walls for diverting and channelling the water flow into the culverts. Units J & K

support the 6 No. Intake Tower Structures at the end of the intake culvert.

Pre -cast Culvert Units Type L&M

Unit Right 1 Type L

Unit Left Type M

Units type L&M are installed in a dredged trench and are supported on 4 concrete pile caps

which are supported on 4 No. 1m diameter, class C, grade 80N/mm 2 concrete spun piles.

The cooling water intakes consist of 1 No intake culvert type L and 1 No intake culvert type M

units, which are each 9.5m long, 11.810m wide by 4.610m high. The triple cell pre-cast

culvert units have interior barrel dimensions of 3.750m vertically and 3.450m horizontally,

with 0.300m chamfers. Units L & M are the Side Units Left and Right. Units L & M are

similar to the typical 10m pre-cast units. Unit L & M consists of one additional interior wall

(over part of the 9.5m length), with two interior walls angled to direct flow.

Leighton-LAMA Joint Venture

Section 4: Page 3 of 9

Manjung Power Station CW Intake Culvert

Pre -cast Culvert Unit Type N

End of Contract Report Volume 1

End Unit 1 Type N

Units type N is the last pre -cast unit at the end of the intake culvert and it is installed in a

dredged trench and is supported on 4 concrete pile caps which are supported on 4 No. 1m

diameter, class C, grade 80N/mm2 concrete spun piles. There is only 1 No intake culvert

type N, which is 9.5m long, 11.810m wide by 4.610m high. It is also a triple cell pre-cast

culvert unit with interior barrel dimensions of 3.750m vertically and 3.450m horizontally, with

0.300m chamfers. Unit type N is similar to unit type F in tha t it has three access manhole

openings in it, except that it has an end wall, which closes the unit off.

Pre -cast Culvert Units Type P

Unit Adjacent to Transition Unit 1 Type P

Unit type P is the same as a typical unit type B and it is the unit that is situated adjacent to

the transition unit type H. There is only 1 No intake culvert type P, which is 10m long,

11.810m wide by 4.610m high with the same interior barrel dimensions as all the other

culverts.

The pre-cast culverts units all have grout socks between each unit and they will form the joint

seal between two consecutive units.

Each pre-cast unit has a concrete housing structure on top of it, which contains the three

dosing line pipes.

4.3. INTAKE TOWERS

The intake tower structure is supported on the pre-cast unit types J (or K) by a monolithic in situ connection between the pre -cast elements i.e. unit J & K and the intake tower. There

are 6 No intake towers, which consist of a concrete roof slab supported on 8 concrete

columns. There is an opening all the way around which is closed off by a stainless steel

grating. There is a diver access gate provided in the grating on one of the splayed corners of

the intake tower. The intake towers are funnel-shaped structures which end in a 3.45m

square

opening

in

Intake Tower Structure

the top of unit

type J (or K).

The

hypochlorite

dosing ring is

attached to

the

intake

tower

structures.

The

intake

towers

are

indicated in

the

photograph.

Access Grating

Leighton-LAMA Joint Venture

Dosing Line Ring

Section 4: Page 4 of 9

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

4.4. DOSING LINES

The dosing line pipes, which supply a hypochlorite solution to the cooling water intake

culverts via the 6 intake towers, consists of three separate 225mm diameter, class 10, HDPE

pipes which are continuously butt welded together in 12m lengths as indicated in the

photograph below.

225mm diameter

class 10 HDPE

dosing line pipes

Butt

Welding

Station

The dosing line pipes are

approximately

1500m

long with a dosing ring

and nozzles distributed

around the intake towers.

The chlorine dosing line

pipes are housed in a

small closed concrete

cavity structure located

on the top of the intake

culverts. All three dosing

line pipes are located

within this housing, which

comprises two sloping

pre-cast concrete kerbs

fixed to the top of the

culvert, each with a

recess at the top, into which a pre-cast concrete cover slab is positioned. The dosing line

pipes will thus not be subject to significant wave forces, and will be protected from direct

snagging dangers.

The pipes were pulled out through HDPE sleeves that are cast into pre-cast concrete

diaphragm walls, which are located at 5.0m c/c on the top of the pre-cast units. The housing

and diaphragm walls are indicated in the photograph below.

Concrete Dosing Line Housing on top of pre-cast units.

Diaphragm Wall

The dosing lines come ashore through the revetment. The 225mm diameter pipes are

contained in a 355mm diameter class 10 HDPE sleeve above the in-situ culverts in the

Leighton-LAMA Joint Venture

Section 4: Page 5 of 9

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

revetment to protect the dosing lines from the backfill material and they end in a junction

box where they will be connected to the pipe work from the chlorine dosing building. The

onshore pipes and connection box is indicated in the photographs below.

Dosing Line Land Section

255mm

dosing

line pipe

Junction

Box

355mm

sleeve

Dosing Line Junction Box

4.5. NAVIGATION STRUCTURE

A south cardinal navigation structure marks the cooling water intake culvert. The navigation

structure is situated approximately 50m south of the end pre-cast culvert type N at Latitude

4 00830.93318 and Longitude 100 03827.03496 with reference to the WGS 84 system. It

consists of a structural steel tower structure, which supports the Tideland ML -300 Maxlumina

Lantern. The tower is supported on a 1m thick concrete slab, which in turn is supported by 3

No. 900mm diameter raking pre-cast concrete spun piles. The concrete slab and equipment

platform are fitted with steel handrails, access ladders and a small craft berthing fender

structure. The structure is fitted with warning signs in English and Bahasa. The navigation

structure is indicated in the photograph below.

Navigation Structure

South Cardinal Marker

ML-300 Maxlumina Lantern

Lightning Conductor

Warning sign

Access Ladder and Fender

Leighton-LAMA Joint Venture

Section 4: Page 6 of 9

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

4.6. PROJECT ORGANISATION AND RESOURCES

4.6.1.

Overall Organigram

Client

TNBJ

Main Contractor

ALSTOM-PEREMBA J.V.

Contractor

ALSTOM

Sub Contractor Civil Works

Leighton Contractors (Malaysia) SDN BHD

Sub Contractor Cooling Water Intake System

Leighton - LAMA Joint Venture

Sub Contractor - Design and Engineering Consultant

Murray & Roberts Engineering Solutions Ltd

Leighton-LAMA Joint Venture

Section 4: Page 7 of 9

Manjung Power Station CW Intake Culvert

4.6.2.

End of Contract Report Volume 1

Murray & Roberts Engineering Solutions Organigram.

Project Leader

Greig Wolfe

Engineering Manager

Derek Paul (MRES)

Project Engineer

Karl Heath (MRES)

Quality Assurance

Mike Quarmby (MRES)

On - Site Design Co -Ordinator

Alec Dixon (LLJV (MRES))

Project Design Team

Dra wing Office

Rolf Aebischer

(MRES)

CAD Operators

Nadeema Amlay

Guillame Du Toit

Adrian Julie

Theo Nel

In-house Design Engineers

Chris Michau

Hamied Mohammed

Stephan Hock

Pierre Botha

Simon Meyer

Richard Wegener

External Consultants

Ninham Shand

ZLH

Soil & Rock

(Malaysia)

Terra Geotechnics

(Malaysia)

Knight Hall Hendry

Document Controller

Cindy Feldman

Monica Mbusi

Leighton-LAMA Joint Venture

Section 4: Page 8 of 9

Manjung Power Station CW Intake Culvert

4.6.3.

End of Contract Report Volume 1

Cooling Water Intake Leighton LAMA Joint Venture Site Management Team

Leighton -LAMA

Joint Venture Exco

Project Manager

Rick Moore (LLJV)

CWIC Construction Manager

Rudi Voerman (LLJV (MRES))

General Superintendent

George Salmon

(LLJV)

Design Coordinator

Section Engineer

Dosing Lines

Section Engineer

Marine

Section Engineer

Pre -Cast Yard

Alec Dixon

(LLJV (MRES))

Francois Labuschagne

(LLJV (MRES))

Barry Hofmeyr

and later

Dean Pearson

(LLJV (MRES))

Dean Pearson

(LLJV (MRES))

Leighton-LAMA Joint Venture

Section 4: Page 9 of 9

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

SECTION 5. DESIGN OF THE COOLING WATER INTAKE

5.1. BACKGROUND TO THE DESIGN OF THE COOLING WATER INTAKE CULVERT

The permanent and temporary works design were carried out by Murray & Roberts

Engineering Solutions in Cape Town with some of the detailed design and analysis being

carried out by external consultants.

The purpose of the Cooling Water Intake System is to draw and deliver seawater from

1500m offshore to the power station cooling system on land at a flow of 88.2m per second.

The proposed design concept was to use pre-cast reinforced concrete triple cell culverts,

each having a dry mass of 400 tonnes. The culverts were to be pre-cast on land,

transported offshore and placed on a stone foundation bed in a pre-dredged trench, then

sealed underwater against the previous culvert unit using a filter fabric grout sock as

indicated in figure 1 below.

Dredged Trench

Rock Armour

Stone Bed

Figure 1.

Sand Backfill

Proposed Design Concept

The cooling water intake culvert extends from a 56m-diameter cooling water pond onshore

through the island revetment to the 6 intake tower structures 1500m offshore. The reinforced

concrete culvert consists of a 68.5m long in-situ culvert, connecting into the 56m-diameter

cooling water pond, 142 no. pre-cast culvert sections, 6 pre -cast intake tower structures, 3 x

225mm HDPE dosing lines on top of the culvert and a south cardinal piled navigation

structure 50m south of the end of the last pre -cast culvert as indicated in figure 2 below.

Leighton-LAMA Joint Venture

Section 5: Page 1 of 2 0

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

To optimise the culvert dimensions and minimise the head losses through the intake

structures, a model of the proposed intake structure was constructed at the University of

Stellenbosch in Cape Town, South Africa.

Navigation

Structure

6 No. Pre-Cast

Intake Structures

142 No. Pre -Cast Culverts

3 HDPE Dosing Lines

In-Situ

Culvert

Connection to the

Cooling Water Pond

Figure 2.

Cooling Water Intake

To optimise the structural design, and minimize the mass, 3-D finite element structural

analyses of the pre-cast culvert units were carried out, taking into account all the various

load cases. The load cases modelled included the transportation of the units on heavy lift

trailers to the load-out jetty, the lifting of the units off the load-out jetty using a specially

designed 400 tonne floating gantry, the transportation of the units in the sea to its final

position taking into account surge loads and wave loads.

The intake tower structures were also modelled using 3-D finite element structural analyses.

1:50 and 1:20 models of the intake structures were constructed in the 1m wide wave flume

at the University of Stellenbosch in order to measure the wave forces on the intake towers,

to check overall stability and to optimise the design of the connection between the intake

tower and the culvert.

Two distinct soil layers were evident from the borehole logs. A 25m thick upper layer

comprising highly plastic grey, silty clays and a 15m to 18m thick grey fine to coarse -grained

sand layer below the grey, silty clay upper layer.

The culvert was set below the seabed in a 1500m long dredged trench. During the dredging

operation, however, it was found that a firm founding material on which to place the stone

foundation bed could not be established.

Probes by divers found firm material

approximately 1m below the surface of the very soft clay. However, when the dredger

removed this soft layer, it disturbed the firmer material below, preventing a firm founding

layer from being established. Four additional boreholes with laboratory testing of core

samples were carried out during January 2001 and it was found that the moisture content of

the very soft clay was often greater than the liquid limit, causing the soil to liquefy during

dredging.

In order to reduce the risk of excessive differential settlements between the culverts, it was

decided to change the foundation design. After a careful time, risk and cost evaluation, a

Leighton-LAMA Joint Venture

Section 5: Page 2 of 2 0

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

decision was taken to construct a piled foundation for the culvert units. The design change,

due to the unforeseen founding conditions, occurred seven months after the start of the

project. While a piling barge was sourced, the piled foundation design was carried out and

all the approvals and testing requirements were put in place. As the pre -cast culvert

construction was already well advanced the original structural design of the units had to be

checked for the piled support condition. The first working pile was driven eight weeks after

the decision to change the foundation design was taken.

28m long, 1m diameter, 80Mpa, hollow pre-stressed concrete piles were driven down to the

bottom of the dredged trench with a follower to a specified level, to a tolerance of 50mm.

Three to four piles were installed on site per day. Two piles were placed at each joint

between the pre-cast culvert units. Pre-cast pile caps were constructed, then placed and

grouted into the top of the hollow concrete piles as indicated in figure 3 below.

Pre -cast Culvert Unit

Intake Tower Structure

1000mm dia hollow prestressed concrete piles

Pile Cap

Figure 3.

Piled Foundation

The 142 no culvert units, each with a mass of 400 tonne, were pre -cast on land under

controlled conditions and transported by heavy lift trailers to a specially designed load-outjetty for placement offshore. The units were placed on the piled foundation by a specially

designed 400 tonne capacity, floating gantry. Grout bags were then placed between the

underside of the units and the top of the pile cap and pumped full of grout to take up any

relative movement.

This operation progressed extremely well and any time lost due to the change in design of

the foundation was made up and e ven improved upon. The works were handed over within

15 months in October 2001 at a final cost of US$16 million.

Leighton-LAMA Joint Venture

Section 5: Page 3 of 2 0

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

The successful completion of this project required innovative engineering and the

involvement of experienced marine personnel throughout all phases of the project. Design

simulations, including physical and computer modelling, as well as on site testing formed a

major part of the success of this design and construct project.

Both the permanent and temporary works were designed by Murray & Roberts Engineering

Solutions. The various elements required permanent works design and temporary works

design were as follows:

5.2. PERMANENT WORKS

5.2.1.

Hydraulic Assessment of the Cooling Water Intake Culverts

Professor Basson of the University of Stellenbosch wa s appointed to calculate the

expected friction losses in the main culverts.

Manning friction factors of 0,0116 and 0,0162 for "new and clean" and "old and

fouled" roughness conditions respectively were used to calculate the total expected

head losses. The head losses for "new and clean" conditions and "old and fouled"

conditions were calculated to be about 1,6m and 2,6m respectively, both less than

the specified corresponding maximum losses of 2,3m and 2,8m.

Energy losses through the intakes into the culverts were difficult to quantify

theoretically, due to the many changes in flow direction, and contraction and

expansion of flow. It was therefore decided that a model study should be carried out

in order to verify the design assumptions. In view of the complex geometry of the

intake structure, it was decided to construct a 1 in 15 scale hydraulic model of one of

the two sets of intakes discharging into the outer barrel culverts. The model was

built and tested at the Hydraulics Laboratory of the Department of Civil Engineering

of the University of Stellenbosch, South Africa, under the supervision of Professor

GR Basson during November-December 2000.

The total energy losses across two intakes and the bend was less than was

predicted theoretically. The sq uare layout of the intakes with their relatively large

throat areas therefore assisted in reducing losses.

The maximum local velocities through the screen openings at Intake 1 under still

water conditions was 0.49 m/s, which was less than the specified maximum velocity

of 0,5 m/s. Velocities through a significant proportion of the screens at Intake 1

were lower and maximum velocities at all other intakes were also slightly lower.

The model tests and results are fully described in Appendix D of the Report on the

Hydraulic Assessment of the cooling water Intake Culverts Report No.

MNJ/99/W/UPA/---/CA/06 rev 04. The model is indicated in the photograph below.

Leighton-LAMA Joint Venture

Section 5: Page 4 of 2 0

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

Hydraulic Model of Intakes

Leighton-LAMA Joint Venture

Section 5: Page 5 of 2 0

Manjung Power Station CW Intake Culvert

5.2.2.

End of Contract Report Volume 1

Assessment of the Wave Loading on Intake Towers

The wave clima te for the design of the intake structures was determined, as

recommended in Report No ZLH-554-02 Rev 01, November 2000, Manjung Power

Station Project, Cooling water Intake Culverts and Jetty, Design Wave Conditions

and Report No ZLH-554 -03 Rev 01, November 2000, Manjung Power Station

Project, Wave Conditions for Calculation of Fatigue Loads for the Manjung Cold

Water Intake Structures.

Wave loads were computed using diffraction theory combined with Morrison drag

forces where appropriate. Allowance was made for up to 50mm marine growth on

the intake towers, when calculating the drag components of the forces. However,

no information was available on the expected thickness of the marine growth.

The wave and current loads on the structure were computed using WIFS (Wave

Interaction with Fixed Structures), C J Garrison, 2000 and API RP2A,

Recommended Practice for Planning, Designing and Constructing Fixed Offshore

Platforms, Nineteenth Edition, 1991. Wave and current loads were computed for

extreme conditions, as well as for fatigue design purposes.

The theoretical hydrodynamic loads calculated for the design of the structures was

compared with model tests that were carried out at scales of 1:20 and 1:50 for both

broken and unbroken waves. The main purpose of the model study was to serve as

a control on the numerical models that were used to calculate the forces and

moments on the structure. The models were built and tested at the Hydraulics

Laboratory of the Department of Civil Engineering of the University of Stellenbosch,

to establish the wave induced moments on the intake structures.

A comparison of the numerical wave force analysis results with those from the

model tests resulted in the numerical results being used for design purposes, for the

6.3m design wave height.

The model tests are described in the Appendix of design report no.

MNJ/99/W/UPA/---/CA/021 rev 01. The model is indicated in the photograph below.

1:20 Wave Model

Leighton-LAMA Joint Venture

1:50 Wave Model

Section 5: Page 6 of 2 0

Manjung Power Station CW Intake Culvert

5.2.3.

End of Contract Report Volume 1

Structural Analysis and Design

The reinforced concrete in the culverts had the following properties:

45Mpa, 28 day characteristic strength

Total cementitious content 485kg

PFA content 30% of the total cementitious content

Water/cement ratio 0.33

Reinforcement cover 60mm

5.2.3.1. In-situ Culverts

The in-situ culvert consists of three sections of lengths 30m, 30m and 8.7m

respectively. Movement joints are provided at the diaphragm wall and

between the sections of the culvert, allowing full relative rotation across the

joint. The joint design is described in document no. MNJ/99/W/UPA/---/CA

19.1.

A reinforced concrete chimney, which provides access to all three barrels,

is positioned towards the end of Section 1. This concrete chimney allowed

temporary interior bulkheads to be installed into the in -situ culvert. The

bulkheads were required to provide a dry interior when the water pool

diaphragm wall was broken out to connect to the in-situ culverts.

Reinforced concrete piles provide support to the culverts, positioned in four

rows longitudinally under the culvert walls. The longitudinal pile spacing

varies along the length of the in-situ culvert.

No further detailed analysis or calculations were carried out for Section 2.

Section 2 was detailed using the design carried out for Section 1 as the

loads for Section 2 are the same as or less than Section 1.

Reinforced concrete piles provide support to Section 3 of the Cooling Water

Intake in -situ culvert. One row of 4 No. 400mm square pre-cast concrete

piles, positioned longitudinally under the culvert walls, 1.5m from the

movement joint between Section 2 and Section 3 and, 2 No. 700mm

diameter concrete spun piles, under the internal walls of Section 3 of the

in-situ culvert, at the joint between Section 3 of the in-situ culvert and the

transition pre-cast unit. A continuous crosshead beam and 2 no.

rectangular pile caps are cast over the 2 No. 700mm diameter concrete

spun piles to support the pre-cast transition unit on.

Finite elements analyses were carried out using LUSAS Ver 13, with pre

and post processing using LUSAS Modeller Ver 13. The floor, walls and

roof of the culvert were modeled to the mid-surface using 8 noded thick

shell elements (QTS8 element type). The piles were modeled using

engineering thick beam elements (type BMS3), with a single vertical spring

element at the base of each pile to simulate the foundation stiffness. The

interface between the piles and the culvert floor was modeled locally using

20 noded solid confinuum elements (type HX20), to simulate the load

transfer from the beam elements (piles) to the shell elements (culvert floor).

Ultimate Limit State (U.L.S.) structural design of the culvert section has

been carried out using ultimate bending moments and shear forces

extracted from contour plots for the worst load combinations.

Leighton-LAMA Joint Venture

Section 5: Page 7 of 2 0

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

The Serviceability Limit State (S.L.S.) cracking checks have been carried

out using the worst service bending moments, and a maximum permissible

design crack width of 0,2mm. The design of Section 1 and 3 of the in-situ

culvert is described in document nos. MNJ/99/W/UPA/---/CA 04, Ca04.1

and CA 04.2.

Figure 4.

In-situ Culvert

Connection to Water Pool

Pre -Cast

Concrete Units

Concrete Chimney

Steel Bulkheads

1000mm dia Piles

Section 3

700mm dia Piles

Section 2

Section 1

400mm square Pre-Cast Concrete Piles

5.2.3.2. Pre -cast Culverts

The pre-cast culvert section of the cooling water intake consists of approx.

142 No., 10m long, 11.810m wide by 4.610m high units supported on a

concrete pile cap which is supported on 1m diameter, class C, grade

80N/mm 2 concrete spun piles. The triple cell pre-cast culverts have interior

barrel dimensions of 3.750m vertically and 3.450m horizontally, with

0.300m chamfers.

Figure 5. Pre-cast Culvert Lusas Computer Model

Leighton-LAMA Joint Venture

Section 5: Page 8 of 2 0

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

The 10m long pre -cast culvert with three interior cells has been modeled

using the LUSAS finite element software. The bottom slab, walls and top

slab of the culvert unit was modeled to the mid-surface using 8-noded thick

shell elements (QTS8 element type). The piles were modeled using beam

elements (type BMS3) and the pile caps as 3-D solids (type HX20). The

contact between the pile caps and the bottom slab thick shell elements

was modeled using 3-D joint elements (type JNT4), in order to simulate the

contact over the correct area on the pile caps. Axial joint elements (type

JSH4) were used at the bottom of the piles to simulate the long term loadsettlement behavior of the piles. The computer model is indicated in

Figure 5.

The position of the piles and pile caps relative to the culvert unit was

varied. In each case the pile cap joint elements were revised such that the

contact area was correctly approximated.

Full fixity boundary conditions were applied to the bottom of the piles. All

nodes on the piles were given horizontal spring stiffnesses in the two

global horizontal directions, based on the horizontal coefficient of subgrade

reaction determined by Soil & Rock Engineering for the 1,0m diameter

spun concrete piles. The magnitude of the spring stiffnesses used for the

lateral soil restraint was increased until the horizontal deflection of the piles

was approximately the same as that obtained by Soil & Rock Engineering

in the full geotechnical analysis. The detailed geotechnical and structural

design calculations for the piled foundation are contained in:

Design report No. MNJ/99/W/UPA/---/CA/24

Design report No. MNJ/99/W/UPA/---/CA/24.1

Design report No. MNJ/99/W/UPA/---/CA/24.2

Design report No. MNJ/99/W/UPA/---/CA/25.

5.2.3.3. Intake Structures

The cooling water intakes consist of 6 intake culvert units, which have

internal walls for diverting and channeling the water flow and intake tower

structures which are fixed in-situ to the top of the culvert units which are

supported on 8 concrete pile caps on 8 No. 1m diameter, class C, grade

80N/mm concrete spun piles. The layout of the intakes is indicated in

figure 6.

The pre -cast culvert units supporting the intake towers were constructed

onshore on a number of prepared casting beds. The units were cast on

plinths in an elevated position to allow the heavy-lift trailers to move in

underneath the units in order to lift and load the units. Each units dry

weight was approximately 400t. The culverts were then transported by

heavy-lift trailers onto a specially constructed temporary load-out jetty. This

allowed a floating gantry to straddle the jetty and unit, to lift it off to

transport it out to a temporary stone foundation bed offshore

The intake tower structures were constructed onshore on a number of

prepared casting beds. The intake tower structures were cast separately

from the intake culvert units supporting them. Each intake towers dry

weight was approximately 156t. The heavy-lift trailers then transported the

intake tower structures onto the specially constructed temporary load-out

jetty. The floating gantry then straddled the jetty and intake tower, and

Leighton-LAMA Joint Venture

Section 5: Page 9 of 2 0

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

lifted it off for transport out to the culvert unit, which had already been

placed on the temporary stone foundation bed offshore. The intake tower

structures were then fixed to the submerged culvert units by means of an

in-situ concrete connection at low tide.

The floating gantry then moved the completed intake culvert units including

the intake towers to their final positions on the piled foundations.

The intake units on which the towers are supported were analysed as per

the typical pre-cast units using the LUSAS finite element software. The

intake tower structure was also modeled using the LUSAS finite element

software. All components of the structure were modeled to the midsurface using 8 noded thick shell elements (QTS8 element type). The

tower model was provided with a continuous support at the bottom, with

fixity in all global axis directions to model the connectivity to the pre-cast

unit. The wave pressures on each component of the structure were

calculated using the maximum resultant horizontal and vertical loads on

the structure as determined from the model tests and numerical analyses

carried out using MORA. This previous study determined that the worst

extreme wave conditions anticipated will be unbroken waves (Waves on

point of breaking) with Hmax = 6.0m and a period of 8 seconds. A typical

contour plot from the Lusas software is indicated in figure 7.

The detailed geotechnical and structural design calculations for the intake

structures are contained in Design report No.

MNJ/99/W/UPA/--/CA/25.1..

Figure 6.

Leighton-LAMA Joint Venture

Layout of Pre-Cast Intake Towers

Section 5: Page 1 0 of 20

Manjung Power Station CW Intake Culvert

Figure 7.

End of Contract Report Volume 1

Lusas FE Model Contour Plot of Pre -Cast Intake

5.2.3.4. Navigation Structure

The Navigation Light Structure has been modeled as a space frame on

Staad Pro 2001, using shell elements to model the pile caps and the piles

were modeled as 900 mm diameter x 130 mm thick concrete beam

elements. The horizontal loads on the piles are applied as trapezoidal

beam loads and the horizontal loads on the slab are applied through a

special dummy beam element at the slab perimeter. Horizontal spring

supports were calculated to simulate fixity of the structure. Lateral soil

springs were provided at different depths along the length of the piles,

which were based on a lateral modulus of subgrade reaction as determined

by Soil & Rock Engineering.

Vessel berthing loads were calculated based on the recommendations of

BS 6349 : Part 4 : 1994 Section 4.7. A berthing velocity of 0.5 m/sec was

used in the calculations. An EXCEL spreadsheet was developed for

determining the wave particle velocities and wave forces based on Linear

Airy wave theory using Morisons equation.

The detailed geotechnical and structural design calculations for the

navigation structure are contained in Design repo rt No. MNJ/99/W/UPA/--/CA/03. The navigation structure is indicated in the photograph below.

Leighton-LAMA Joint Venture

Section 5: Page 1 1 of 20

Manjung Power Station CW Intake Culvert

5.2.4.

End of Contract Report Volume 1

Geotechnical Analysis of the Piled Foundations

The PIES computer program was used to estimate the geotechnical safe working

loads for the concrete piles which support the in -situ, pre -cast and intake structure

culverts. The PIES software was developed by Professor Poulos at the University

of Sydney. The software uses a simplified boundary element formulation and

models the interface between the pile and soil in a hyperbolic manner. The

programme calculates the down drag load of a pile embedded in settling marine

clays and the pile head settlement for different applied pile head loads. In this way,

a complete load vs settlement curve was derived.

The safe working load of the piles was also calculated using theoretical models

provided by Professors Fleming and Randolph.

The safe working loads

(geotechnical) of the concrete piles were calculated for different pile penetrations.

These static analyses were carried out using the computer program PILER.

Soil and Rock Engineering, Geotechnical Consultants in Kuala Lumpur, carried out

the PIES and PILER analyses referred to above.

Soil & Rock Engineering evaluated horizontal spring stiffnesses in the two global

horizontal directions at all the nodes on the piles. These horizontal spring

stiffnesses where based on the horizontal coefficient of subgrade reaction of the

soil profile. These spring stiffnesses were used in the structural analyses.

Leighton-LAMA Joint Venture

Section 5: Page 1 2 of 20

Manjung Power Station CW Intake Culvert

5.2.5.

End of Contract Report Volume 1

Hydraulic, Installation and Design of the Dosing Lines

5.2.5.1. Hydraulic Design.

The hydraulic assessment for the dosing lines for the cooling water intake

culverts from the skid to the intake was modelled with the nozzles, without

any backpressure or non-return valve. The design parameters were as

follows: Maximum flow in pipes 186 m3/hr per pipe, Nominal flow 62 m3/hr,

Minimum flow (one pump) 10 m3/hr, Head from pump curve for 51,66 l/s =

28.4m, Head loss on shore to battery limit (Max flow) = 6.7m, Elevation of

pumps (above sea level) = 4.15m.

We did not have information of the actual pump curves, and we assumed

that the losses of -6.7m in the pipe work and control valves were correct

for the high flow condition. We used the PIPEN software to analyse the

dosing line system.

Wave action will create a dynamic affect in the system, this may influence

the short term dosing at the individual intakes, but the general level of

chlorination in the line should not be affected.

The output from the PIPEN analysis software for the various runs are

contained in design report No. MNJ/99/W/UPA/---/CA/05. The analysis

was based on a 140 dosing ring pipe, but this was subsequently

changed to a 160 dosing ring pipe as this size was more readily

available than the 140 pipe. Please note that there is not a significant

difference in the analysis between the 140 and 160 pipe for the

dosing ring line as most of the losses occur in the main 225 mm line.

Wave action will create a dynamic effect in the system, this may influence

the short term dosing at the individual intakes, but the general level of

chlorination in the line should not be affected.

5.2.5.2. Installation Design

The pipes were pulled out through HDPE sleeves that were cast into

concrete diaphragm walls located at 5.0m c/c on the top of the pre-cast

units. The pipes are located in a closed cavity (covered with concrete

cover slabs), and were thus not subject to significant wave forces, and will

also be protected from direct snagging dangers.

The pipes were assembled on land in lengths of 24m and then joined

before being pulled out by a suitable barge or vessel, through the sleeves.

There were three different pulling lengths i.e. 1315m, 1375m and 1435m.

The pipe was designed to overcome the following forces during installation

(pulling): inertia, friction at sleeves from buoyancy, affects of mis-alignment

of the sleeves from placing tolerances in the pre -cast units or settlements

and launching friction on the land rollers. A pulling nose was designed and

attached to the front of each pipe. An opening was provided in the pulling

nose to allow water to enter the pipe to flood it as it was being launched.

Leighton-LAMA Joint Venture

Section 5: Page 1 3 of 20

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

The calculation of the installation forces and the pipe stresses in the HDPE

PE80 225 Class PN 10 dosing line pipe are contained in design report

no. MNJ/99/W/UPA/---/CA/05.1

5.2.5.3. Pre -cast concrete housing design

The chlorine dosing lines are housed in a small concrete structure located

on the top of the intake culverts. All three dosing lines are located within

this housing, which comprises two sloping kerbs fixed to the top of the

culvert, each with a recess at the top, into which a pre-cast cover slab is

positioned. These pre-cast concrete housings are subject to various

forces, the most significant of these forces is uplift on the slabs and drag

forces on the kerbs, due to the action of waves and current.

A model test is the most reliable method to obtain the forces and uplift on

the units, but time and cost constraints prevented this. The analytical

methods used to calculate the design uplift on the top of the culverts was

therefore an approximation The analytical calculations were based on the

best estimates for the combined effects of a depth limited wave for 10m of

seawater over the culvert and an allowance for up to 2m scour next to the

culvert, together with the design current of 1.0 m/sec.

Linear wave theory was used to estimate the wave induced water velocities

in the region of the housing units. Drag and lift pressures were calculated

using Morisons equation. The resulting pressures with 2% included for

added mass were calculated as 35 KPa Lift and 17.7 kPa Drag. The lift

force was applied to the top of the pre -cast element, and the drag forces

have been applied as 79% to the front kerb as a pressure, and the

remaining 21% to the back kerb as a suction force.

Bolts were recommended to hold down the pre-cast concrete covers but

the JV chose not to use holding down bolts. The calculations for the pre cast concrete housing are contained in design report no. MNJ/99/W/UPA/--/CA/05.2

Leighton-LAMA Joint Venture

Section 5: Page 1 4 of 20

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

5.3. TEMPORARY WORKS

The temporary works elements requiring detailed design were as follows:

5.3.1.

Load Out Jetty

A reinforced concrete jetty, supported on concrete spun piles, was designed to

provide a structure over the water where the pre -cast units could be positioned and

lifted off the jetty using a floating gantry, before being towed to the dredged trench

and lowered onto the foundation bed in their final position.

The full jetty was mode led using an assemblage of beam elements and analysed

using the PROKON software package. The pre -cast deck slabs were modeled

using beam elements, with each beam having a width equal to half the width of a

pre-cast slab panel.

Horizontal supports for the piles were provided at -4.40m ACD, which corresponds

to a point about 2,5 pile diameters below the scoured seabed level. A scour of

1,0m was taken into account. At the pile toe (taken at 14,40m ACD) horizontal

supports were provided, as well as a vertical spring with a stiffness of 70 000kN/m,

which corresponds to the lower bound pile spring stiffness as calculated by Soil &

Rock Engineering. Towards the rear of the jetty the horizontal restraints were

positioned higher up the pile to take account of the sloping landfill embankment and

revetment.

The detailed structural design was carried out in accordance with BS6349, BS5400

and BS8110. Bending moment and shear force envelopes at Ultimate Limit State

were extracted from the PROKON analysis, for the primary elements of the

structure, namely the pre -cast deck slabs, the longitudinal deck beams near the

end of the jetty, the crosshead beams and the piles. Reinforced concrete design

calculations based on the formulae in BS8110 were carried out for the peak forces

on each primary element, using spreadsheet calculations.

These were

supplemented with additional hand calculations where necessary. Spreadsheet

calculations were used to check the Serviceability Limit State crack widths, based

on the crack width formulae in BS5400.

Leighton-LAMA Joint Venture

Section 5: Page 1 5 of 20

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

The calculations for the load out jetty are contained in design report no.

MNJ/99/W/UPA/---/CA/02.

Lateral load analyses for the concrete spun piles were carried out using the

geotechnical software, DEFPIG 6XB (1999), which was developed by Professor

Poulos at the University of Sydney. The programme analyses the behaviour of

single piles and pile groups when subjected to axial and horizontal forces and

moments. The piles were divided into 50 elements and limiting pile- soil stresses

(ultimate skin friction values) and elastic moduli were assigned to each element.

The pile head reactions determined from PROKON software were applied to the

700mm spun piles and lateral deflections and bending moments were calculated for

single piles driven through the revetment and offshore. The lateral deflection at the

pile head level ranged from < 2mm to about 10mm. The maximum bending

moments ranged from about 30kNm to 150kNm. The effects of a 2 No x 760kN

berthing force on the 39 piles supporting the load out jetty was modelled using

DEFPIG. The maximum lateral deflection at pile head level was estimated to be

14mm and the maximum bending moment was estimated to be 1860kNm. The

calculations for the loadout jetty are contained in design report No.

MNJ/99/W/UPA/---CA/02.1.

5.3.2.

Cofferdam

A 53.2m long by 14.4m wide cofferdam was required in order to construct in-situ

section of the concrete culvert for the connection of the cooling water intakes to the

cooling water pond. The cofferdam was a multi-propped type with three layers of

props at +1.50m, -2.70m. and 5.50m ACD respectively. The excavation depth

inside the cofferdam was approximately 8.00m ACD. The ground surface of the

existing island was about +4,65m ACD. The ground level for a distance of

approximately 8m around the cofferdam was reduced to a level of +3m ACD to

reduce the soil loads on the sheet piles. A second row of Lx 16 sheet piles was

driven around the cofferdam and the water table inside this area was reduced to

approximately 0.0m ACD, in order to reduce the water pressure on the cofferdam.

Boreholes were drilled, SPTs, hand shear vane tests, and later CPTs were carried

out to determine the properties of the soil in the area to enable an analysis of the

cofferdam to take place.

The ground conditions varied significantly over the Cofferdam area. The cofferdam

was therefore divided into 3 distinct sections for design, referred to as Sections 1, 2

and 3 respectively. Section 1 Onshore - from 20m to 33m from the Diaphragm

Wall, Section 2 - Revetment - from 33m to 52.2m from the Diaphragm Wall (Section

2a - from 33m to 42m, Section 2b from 42m to 52.2m), Section 3 Offshore from 52.2m to 73.2m from the Diaphragm Wall. The ground conditions for Section

1 (Onshore) were better than for Section 2 (Revetment) and Section 3 (Offshore)

as they were surcharged by the reclamation.

The 3 Sections of the cofferdam consisted of 4 different types of sheet pile

sections. Section 1 (Onshore) - 13m of 18m long PU25 sheet piles driven to 15m

ACD, Section 2 (Revetment) - Section 2a - 9m of 24m long PU25 sheet piles

driven to 21.0m ACD plus Section 2b - 10.2m of 24m long reinforced PU25 sheet

piles driven to 21.0m ACD, Section 3 (Offshore) - 21m of 24m long reinforced Lx

32 (or equivalent 24m long reinforced PU 25) sheet piles driven to 21.0m ACD.

Leighton-LAMA Joint Venture

Section 5: Page 1 6 of 20

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

The WALLAP and PLAXIS finite element computer programs were used to perform

the stage-by-stage analyses of the structure, in order to determine the stability of

the cofferdam, the waler loads and the bending moments and shear forces in the

sheet-piles, during the construction process. The programs can be used to model

a braced excavation in layered soil deposits.

PLAXIS is a finite element program that is capable of analysing excavation

problems in 2-dimensional continuum under plain strain conditions. A 6-node

isoparametric element was used to model the soil medium. Underneath the firm

clay layer was the sand stratum and a fixed base was assumed. The phreatic line

was assumed to be at +1.0m ACD. Beam elements were used to model the wall

and struts. The problem was symmetrical and therefore only half of the cross

section was analysed.

The sequence of construction involving the excavation of a soil layer, the

installation of sheet piles and struts, and ground dewatering can readily be modeled

by the programs. The construction sequence generally consisted of: i) Installing

concrete piles for the culvert foundation, ii) Installing sheet piling to toe elevations

of -15m and 21m ACD, iii) Excavation for the cofferdam, iv) Installing the three

layers of struts and walers and de-watering as the excavation proceeded, v)

Casting the in-situ culvert base slab hard up against the sheet piles and vi)

Removing layer 3 of the struts and walers, vii) Completing the in-situ culvert

construction and, viii) Removing layers 2 and 1 of the struts and walers as the

backfilling proceeded.

WALLAP carries out two (2) separate types of analysis: i) Limit equilibrium analysis

where factors of safety are calculated in accordance with recognised and codified

procedures; and ii) Bending moment and displacement analysis. This is carried out

Leighton-LAMA Joint Venture

Section 5: Page 1 7 of 20

Manjung Power Station CW Intake Culvert

End of Contract Report Volume 1

by modeling the stage -by-stage development of forces and wall movements as

excavation proceeds. The results of the WALLAP analyses were not included in

the report as they were only used as a design check. The client would also not

accept designs carried out using WALLAP.

5.3.3.

The calculations for the cofferdam are contained in design report no.

MNJ/99/W/UPA/---/CA/13.2.

Tied back cantilever sheet pile walls were designed at the end of the cofferdam

to enable the placing of the first pre-cast unit next to the in-situ culvert.

The calculations for the wing walls are contained in design re port no.

MNJ/99/W/UPA/---/CA/13.3

400 tonne Floating Gantry

The floating gantry was a space frame structure consisting primarily of Grade 43A

steel (or equivalent) tubular members. The structure spanned between two 120 x

40 x 8 barges in order to stra ddle the load out jetty on which the culvert unit was

placed. The function of the gantry was to lift the unit at two lift points on the gantry

structure and transport the unit while hanging from the gantry to the offshore

location where the unit was lowered into its final position in a pre-dredged trench.

The gantry was towed out from the load out jetty to the final placement location.

The geometric configuration was determined by the following factors : Clearance

over the culvert unit placed on the loadout jetty, Barge dimensions and locations of