Professional Documents

Culture Documents

1 - Physical Properties of Food

Uploaded by

amal_postCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1 - Physical Properties of Food

Uploaded by

amal_postCopyright:

Available Formats

SCT 363-2

Physical Characteristics of Food Materials

Important properties of Food Materials

Physical properties of foods are manifestations of a foods chemical composition and

structural organization over several orders of length scales from the molecular to the

macroscopic. A change in either composition or structure usually results in a

simultaneous change in several properties.

Thermal properties

Optical properties

Electrical properties,

Mechanical properties

Thermal Properties

Most processed and fresh foods receive some type of heating or cooling during handling or

manufacturing. Design and operation of processes that involve heat transfer require special

attention due to the heat-sensitivity of foods. Thermal properties play an important role in

the design and prediction of heat transfer operations during the handling, processing,

canning, storing, and distribution of foods. Modes of Heat Transfer as follows.

Radiation

Transfer of heat by electromagnetic waves (as in a microwave oven).

Conduction

The transfer of thermal energy due to molecular oscillations (for example, heating of food by

direct fire through metal containers).

Convection

Transfer of heat by bulk movement of molecules in heated fluids such as liquids or gases (for

example, air in heated oven or in tank during juice evaporation).

Heat transport properties

Specific heat Cp,

The amount of heat needed to raise the temperature of unit mass by unit degree at a given

temperature. The SI units for Cp are therefore (kJ kg1 K1).It is common to use the constant

pressure specific heat, Cp, which thermodynamically represents the change in enthalpy H (kJ

Kg1) for a given change in temperature T when it occurs at constant pressure P.

= ( )

Only with gasses is it necessary to distinguish between Cp and Cv, the specific heat at a constant

volume. Assuming there is no phase change, the amount of heat Q that must be added to a

unit mass M (kg of mass or specific weight kg/m3) to raise the temperature from T2 to T1

can be calculated using the following equation

= ( )

Thermal conductivity

Represents the quantity of heat Q that flows per unit time through a food of unit thickness

and unit area having unit temperature difference between faces; SI units for Q are [W m 1K1].

In other words, represents the ability of the food to transmit heat.

Department of Science Technology UWU

SCT 363-2

A

x

T1

T2

Physical Characteristics of Food Materials

(_ _)

=

- Surface area of the food,

- Thickness,

- Temperature at the outer surface where heat is absorbed

- Temperature at the inner surface.

Thermal diffusivity

SI units [m2/s], defines the rate at which heat diffuses by conduction through a food

composite. Expressed in terms of Cp, density and k Thermal diffusivity determines the

speed of heat of three-dimensional propagation or diffusion through the material. It is

represented by the rate at which temperature changes in a certain volume of food

material,

Optical Properties

Visual assessment has a central role in the food industry. In the case of foods, the main optical

property considered by consumers in evaluating quality is color, followed by gloss and

translucency or turbidity among other properties.

Color

A beam of light composed of irregularly distributed energy emitted at different wavelengths.

Foods, along with other materials, have color properties, which depend exclusively on their

composition and structure.

Department of Science Technology UWU

SCT 363-2

Physical Characteristics of Food Materials

Gloss

Light specularly reflected from a plain smooth surface.

Translucency

Large number of products are translucent, that are neither opaque nor completely transparent.

In this kind of product light is reflected, absorbed, transmitted, and scattered, and the objective

measurement of optical properties present serious difficulties.

Electrical Properties

There are two main electrical properties in food engineering: electrical conductivity and electrical

permittivity. Electrical properties are important when processing foods involving electric

fields, electric current conduction, or heating through electromagnetic waves. These properties

are also useful in the detection of processing conditions or the quality of foods.

Electrical conductivity

Measure of how well electric current flows through a food (unit cross-sectional area a, unit

length L, and resistance R.) is expressed in SI units S/m in the following relation:

L

=

AR

Electrical permittivity

Dielectric property used to explain interactions of foods with electric fields. It determines the

interaction of electromagnetic waves with matter and defines the charge density under an

electric field. In solids, liquid, and gases the permittivity depends on two values:

Dielectric constant , related to the capacitance of a substance and its ability to store

electrical energy; and the dielectric loss factor , related to energy losses when the food is

subjected to an alternating electrical field (i.e., dielectric relaxation and ionic

conduction).

Mechanical Properties

Density, shrinkage, porosity and some of the strength related properties are discussed here.

The importance of these properties can be identified with following application.

Process design, operation, and optimization

Product characterization Quality determination

Estimation of other properties ( Thermal conductivity of food material using the

porosity of the individual components of diffusion coefficient of shrinkage systems

using porosity and volume change)

Handling of food material

Grading of fruits and vegetables

Separation if impurities in food materials b density differences

Estimation of Floor space during the storage and transportation

Density

Mass per unit volume (the SI unit of density is kg/m3). Based on the method of volume

measurement density can be categorized as follows true, material, particle, apparent, and

bulk that can be used, depending on its application in process calculations or product

Department of Science Technology UWU

SCT 363-2

Physical Characteristics of Food Materials

characterization. In the literature most of the density data is correlated empirically as a

function of temperature, water, solids, and fat content. Different types of nonlinear

correlation, such as exponential, quadratic, and cubic, are used to relate density and moisture

content.

True Density (t)

A pure substance or a composite material calculated from its

components densities considering conservation of mass and

volume.

Material Density(m)

A material has been thoroughly in to pieces small enough to

guarantee no closed pores remain

Particle Density(p)

A particle that has not been structurally modified and includes

the volume of all closed pores but externally connected.

Apparent Density(a)

a substance including all pores remaining in the material

Bulk Density(b)

A material when packed or stacked in bulk and is defined as

the mass of the material per the total volume it occupies

Porosity

Porosity indicates the volume fraction of void space or air space inside a material. Volume

determination is relative to the amount of internal (or closed) or external (or open) pores

present in the food structure. Types of porosities include open pore, closed pore, apparent,

bulk, and total porosities.

Shrinkage

This is the reduction in volume or geometric dimensions during processing. When

post-processing volume is larger than initial volume, it is termed as expansion.

Shrinkage occurs as a result of moisture loss (during drying), ice formation (during

freezing), and formation of pores (by drying, puffing, extrusion, and frying). Two

types of shrinkage.

Isotropic expansion

Isotropic shrinkage is described as the uniform shrinkage of the materials under all

geometric dimensions, Type of shrinkage is common in fruits and vegetables.

Anisotropic expansion

Non-uniform shrinkage develops in different geometric dimensions. Type of shrinkage

animal tissue, such as in fish.

Department of Science Technology UWU

SCT 363-2

Physical Characteristics of Food Materials

Rheology

Another important parameter that come under mechanical properties of food. Food rheology

is the study of those properties of materials that control their deformation and flow behaviors

when subjected to external forces. Rheological properties include viscosity, Power law

parameters, elasticity, stress relaxation function & creep compliance function, In the study

of the Rheology its two of the most important parameters are stress () and strain () . Strain

measure of the extent an element of material has been deformed (Change in the shape), While

strain the force per unit area

= F/A ; A =W*H

= L/Lo

.

= d/dt

Importance of Rheology

Design and select equipment such as pumps, pipes lines, extruders, mixers, heat

exchangers etc.

Rheological behavior relates to food texture and sensory data.

To determine ingredients functionality in product development

Shelf life testing

To obtain some information about atomic and molecular scale phenomena

Department of Science Technology UWU

You might also like

- Physical Properties of Food Problems and SolutionDocument5 pagesPhysical Properties of Food Problems and SolutionMohamed100% (4)

- Physical Properties of Foods Problems: Sphericity, Density, Porosity CalculationsDocument1 pagePhysical Properties of Foods Problems: Sphericity, Density, Porosity CalculationsMohamed100% (1)

- DocumentDocument5 pagesDocumentveronicafind0% (1)

- Introduction To Food Freezing - 3Document50 pagesIntroduction To Food Freezing - 3tadsrikanth_chainlu100% (1)

- How To Estimate The Heat Penetration Factor FH of Packaged Foods PDFDocument71 pagesHow To Estimate The Heat Penetration Factor FH of Packaged Foods PDFAlex Samuel SilvaNo ratings yet

- Viscosity Specific Heat of Oils With TempDocument9 pagesViscosity Specific Heat of Oils With Templokeshsharma4433No ratings yet

- HumidificationDocument68 pagesHumidificationA AshokNo ratings yet

- Typical Cam Inc. Fiber Dryer P&Id DrawingDocument1 pageTypical Cam Inc. Fiber Dryer P&Id DrawingAnonymous SAlMdQNo ratings yet

- Renewable Energy: An Introduction to Key Sources and ConceptsDocument26 pagesRenewable Energy: An Introduction to Key Sources and ConceptsjaazsinghNo ratings yet

- Biodiseal Cooked OilDocument4 pagesBiodiseal Cooked OildineshlathiaNo ratings yet

- Plant DesignDocument30 pagesPlant Designsadiqchem179No ratings yet

- Combustion of Vegetable Oils Under Optimized Conditions of Atomization and Granulometry in A Modified Fuel Oil BurnerDocument6 pagesCombustion of Vegetable Oils Under Optimized Conditions of Atomization and Granulometry in A Modified Fuel Oil BurnerThiago ValenteNo ratings yet

- Heat Exchanger (FT)Document9 pagesHeat Exchanger (FT)Aron BalinesNo ratings yet

- Spray Dryer & Freeze DryerDocument20 pagesSpray Dryer & Freeze DryerHaroon RahimNo ratings yet

- Chapter 9 EvaporationDocument134 pagesChapter 9 EvaporationTÚ Cao Ngọc ThiệnNo ratings yet

- Blanching CoconutDocument1 pageBlanching CoconutAndriyana Miyano SantiNo ratings yet

- Tutorial 5Document3 pagesTutorial 5pleco4meNo ratings yet

- Food freezing processDocument27 pagesFood freezing processElsamila AritestyNo ratings yet

- Drying Notes FinalDocument34 pagesDrying Notes FinalKeith OmwoyoNo ratings yet

- Ch7 Dimensional Analysis and SimilarityDocument29 pagesCh7 Dimensional Analysis and Similaritya u khanNo ratings yet

- Heat Chap07 035Document16 pagesHeat Chap07 035Kerem GönceNo ratings yet

- Spray Drying Design and Operation Guide Under 40 CharactersDocument24 pagesSpray Drying Design and Operation Guide Under 40 CharactersHOMAYOUN KHADIVINo ratings yet

- CrystallizerDocument31 pagesCrystallizersivsyadavNo ratings yet

- COOLINGThe circular solution to counterflow cooling. Impacting Industries WorldwideDocument6 pagesCOOLINGThe circular solution to counterflow cooling. Impacting Industries WorldwideMusheer BashaNo ratings yet

- Thermal Properties of FoodsDocument12 pagesThermal Properties of FoodspedroloxxxNo ratings yet

- Physical Properties of Food ProblemsDocument4 pagesPhysical Properties of Food ProblemsMohamedNo ratings yet

- Engineering Thermodynamics ProblemsDocument3 pagesEngineering Thermodynamics Problemsdhruv0010% (1)

- TGADocument31 pagesTGABhuvnesh SharmaNo ratings yet

- Mechanical Unit OperationsDocument8 pagesMechanical Unit OperationsFA AyNo ratings yet

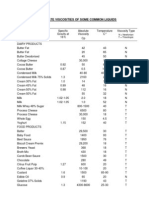

- Viscosities of common liquidsDocument4 pagesViscosities of common liquidsaaro_oraalNo ratings yet

- Review: Gelatin, Source, Extraction and Industrial ApplicationsDocument14 pagesReview: Gelatin, Source, Extraction and Industrial ApplicationsJade NguyenNo ratings yet

- Thermal Properties of FoodsDocument31 pagesThermal Properties of Foodsmaster7c5qoioNo ratings yet

- 1 Artigo Heat and Mass Transfer in Industrial Biscuit Baking Oven and Effect ofDocument12 pages1 Artigo Heat and Mass Transfer in Industrial Biscuit Baking Oven and Effect ofMarianne Soares100% (1)

- Batch Processing & Scheduling EDITED 19-3-2019Document47 pagesBatch Processing & Scheduling EDITED 19-3-2019Engr Muhammad IrfanNo ratings yet

- CH 5 Heat Exchanger Design MethodsDocument30 pagesCH 5 Heat Exchanger Design Methodsapi-3765936100% (1)

- Spray Drying TheoryDocument36 pagesSpray Drying TheorySunday PaulNo ratings yet

- Energia PDFDocument1 pageEnergia PDFKarthy GanesanNo ratings yet

- Fisicoquímica Problemario 1/3Document1 pageFisicoquímica Problemario 1/3Kari BustamanteNo ratings yet

- Heat Transfer and Pressure Drop Properties of High Viscoussolutions in Plate Heat Exchangers (2008)Document16 pagesHeat Transfer and Pressure Drop Properties of High Viscoussolutions in Plate Heat Exchangers (2008)Aman KumarNo ratings yet

- Limiting FactorsDocument7 pagesLimiting FactorsERICNo ratings yet

- Lec6 TorsionDocument26 pagesLec6 TorsionJordan DavidsonNo ratings yet

- Food Plant and Machinery Design - 2020 - K17Document109 pagesFood Plant and Machinery Design - 2020 - K17Nguyễn ThuNo ratings yet

- Heat Exchanger (NTU)Document8 pagesHeat Exchanger (NTU)Aron BalinesNo ratings yet

- Application of DryingDocument31 pagesApplication of Dryinguzzal ahmedNo ratings yet

- Heat and Mass TransferDocument90 pagesHeat and Mass TransferAnonymous 0zrCNQNo ratings yet

- 10-Drying of Milk Dairy and Food EngineeringDocument7 pages10-Drying of Milk Dairy and Food Engineeringariyani yantoNo ratings yet

- Drum Dryer Moisture ControlDocument12 pagesDrum Dryer Moisture ControlJason RichardsonNo ratings yet

- 1R16 - Project StudyDocument27 pages1R16 - Project StudyRenzo Cadag MacasilNo ratings yet

- Batch Distillation and Plate and Packed Column Sizing (Compatibility Mode)Document70 pagesBatch Distillation and Plate and Packed Column Sizing (Compatibility Mode)gggggg82No ratings yet

- Fluidization and Fluidized BedsDocument12 pagesFluidization and Fluidized BedsIfeanyi EzenanduNo ratings yet

- CLB 10904 / CLB12004: Chemical Process PrinciplesDocument39 pagesCLB 10904 / CLB12004: Chemical Process PrinciplesAhmad Safwan HakimNo ratings yet

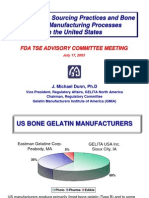

- US Bone Gelatin Sourcing and ManufacturingDocument26 pagesUS Bone Gelatin Sourcing and ManufacturingTapan SharmaNo ratings yet

- Plant ManagerDocument3 pagesPlant Managerapi-78774140No ratings yet

- Food EngineeringDocument4 pagesFood EngineeringJezzabie G. GamisNo ratings yet

- Heat and Mass Transfer in Food EngineeringDocument5 pagesHeat and Mass Transfer in Food EngineeringJuan Victor ChampeNo ratings yet

- Week 5Document62 pagesWeek 5bettieboomNo ratings yet

- 脉冲电场预处理改善冻干植物材料的微观结构和松脆性:以草莓为例Document8 pages脉冲电场预处理改善冻干植物材料的微观结构和松脆性:以草莓为例blk wtNo ratings yet

- Marcotte 2008Document8 pagesMarcotte 2008Alexandru-Adrian BrateiNo ratings yet

- Thermal Properties of Biological Agricultural Materials: Milena Jiřičková, Zbyšek Pavlík, Robert ČernýDocument4 pagesThermal Properties of Biological Agricultural Materials: Milena Jiřičková, Zbyšek Pavlík, Robert ČernýPedro Casanova TretoNo ratings yet

- Unit 4Document52 pagesUnit 4International Food ConferenceNo ratings yet

- Meps Streetlight - 0Document34 pagesMeps Streetlight - 0amal_postNo ratings yet

- As Lighting StandardsDocument4 pagesAs Lighting Standardsamal_postNo ratings yet

- Untitled MapDocument1 pageUntitled Mapamal_postNo ratings yet

- 6 - Extended Summary of Service and Installation Rules of New South WalesDocument43 pages6 - Extended Summary of Service and Installation Rules of New South Walesamal_postNo ratings yet

- 1 - Power Generation, Transmission and DistributionDocument41 pages1 - Power Generation, Transmission and Distributionamal_postNo ratings yet

- Service and Installation RulesDocument2 pagesService and Installation Rulesamal_postNo ratings yet

- Core Valus - Answered by MeDocument1 pageCore Valus - Answered by Meamal_postNo ratings yet

- SOP MacbookAirDocument1 pageSOP MacbookAiramal_postNo ratings yet

- Microbiology - Voulenteer WorkDocument1 pageMicrobiology - Voulenteer Workamal_postNo ratings yet

- What Is CANVASDocument1 pageWhat Is CANVASamal_postNo ratings yet

- Beckman Coulter Trouble ShootingDocument1 pageBeckman Coulter Trouble Shootingamal_postNo ratings yet

- Proposed Modifications of The Lab: But We Need Few Plugs HereDocument2 pagesProposed Modifications of The Lab: But We Need Few Plugs Hereamal_postNo ratings yet

- Practical ReportsDocument1 pagePractical Reportsamal_postNo ratings yet

- LecturesDocument1 pageLecturesamal_postNo ratings yet

- Lecture Times and LocationsDocument1 pageLecture Times and Locationsamal_postNo ratings yet

- DATA Collection - Biostat1Document10 pagesDATA Collection - Biostat1amal_postNo ratings yet

- 1 - PTE Amaple Essay 1Document1 page1 - PTE Amaple Essay 1amal_postNo ratings yet

- MIM TimesheetDocument1 pageMIM Timesheetamal_postNo ratings yet

- 03 - Shedder Machine - Vol 3 - Tender Document 2018.12.20Document3 pages03 - Shedder Machine - Vol 3 - Tender Document 2018.12.20amal_postNo ratings yet

- Bio Statistics - Experiment DesgnDocument2 pagesBio Statistics - Experiment Desgnamal_postNo ratings yet

- Application 14 - NISHADIDocument3 pagesApplication 14 - NISHADIamal_post100% (1)

- 2 - System DrawingsDocument3 pages2 - System Drawingsamal_postNo ratings yet

- Refurbishment of BOC Head Office Building (C1426)Document1 pageRefurbishment of BOC Head Office Building (C1426)amal_postNo ratings yet

- BIOL1181 and ONPS2340 Milk AssayDocument6 pagesBIOL1181 and ONPS2340 Milk Assayamal_postNo ratings yet

- ISO 18781-1 Elevator Ride Quality StandardDocument26 pagesISO 18781-1 Elevator Ride Quality Standardamal_postNo ratings yet

- Hola AussiDocument2 pagesHola Aussiamal_postNo ratings yet

- Chem Dosing V.O. 11 22.01.2019 ScanedDocument2 pagesChem Dosing V.O. 11 22.01.2019 Scanedamal_postNo ratings yet

- Chaiman - 17.09.2018Document1 pageChaiman - 17.09.2018amal_postNo ratings yet

- Lab VentilationDocument1 pageLab Ventilationamal_postNo ratings yet

- 2 - Section IDocument2 pages2 - Section Iamal_postNo ratings yet

- Germs! They're Hiding...Document1 pageGerms! They're Hiding...The London Free PressNo ratings yet

- Pre-Assessment in G8 - English First QuarterDocument2 pagesPre-Assessment in G8 - English First QuarterLOVILLADNo ratings yet

- Use of English - Part 3Document4 pagesUse of English - Part 3Virginia Ruiz Jimenez0% (2)

- SP 1582795277Document7 pagesSP 1582795277muznah kidwaiNo ratings yet

- 7-7-150-330 PublishDocument4 pages7-7-150-330 PublishBethala kumeeraNo ratings yet

- An Introduction To Iso 22000 Food Safety Management An Introduction ToDocument39 pagesAn Introduction To Iso 22000 Food Safety Management An Introduction Tommarikar27No ratings yet

- Test 1: The Passive / Test 1 (43 Adet Soru)Document5 pagesTest 1: The Passive / Test 1 (43 Adet Soru)Raşit Kurşun100% (1)

- Cloud 9 Soical ThemeDocument10 pagesCloud 9 Soical Themeapi-440375252No ratings yet

- Jose Rizal Memorial State University: The Premier University in Zamboanga Del NorteDocument30 pagesJose Rizal Memorial State University: The Premier University in Zamboanga Del NorteJay Calalang ManatadNo ratings yet

- TensesDocument49 pagesTenseskrishunblackNo ratings yet

- The Monkey and The CrocodileDocument4 pagesThe Monkey and The Crocodile32Novita Marfid Pratiwi XI MIA 1No ratings yet

- Grammar Unit Test - 1 RevisionDocument10 pagesGrammar Unit Test - 1 RevisionSobithaa SivakumarNo ratings yet

- Classification of FoodDocument19 pagesClassification of FoodMuhammad HannanNo ratings yet

- Final Term PaperDocument48 pagesFinal Term PaperKerwin Andrei PamplonaNo ratings yet

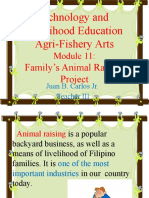

- TLE6-Agri-FisheryQ2 - (Week 6) - Modules 10 & 11Document35 pagesTLE6-Agri-FisheryQ2 - (Week 6) - Modules 10 & 11Honeylet CauilanNo ratings yet

- Universidad Alas Peruanas: Examen Parcial DDocument4 pagesUniversidad Alas Peruanas: Examen Parcial Destadistico17No ratings yet

- Personal Care Folder - GB - EN 2016Document16 pagesPersonal Care Folder - GB - EN 2016Dragan ZNo ratings yet

- LN - The Angel Next Door Spoils Me Rotten - Volume 01 - YPDocument294 pagesLN - The Angel Next Door Spoils Me Rotten - Volume 01 - YPsekiroNo ratings yet

- Fragrances, Flavors and Food Additives NotesDocument3 pagesFragrances, Flavors and Food Additives NotesArianne BatallonesNo ratings yet

- Practice Test Unit 1-2-3Document4 pagesPractice Test Unit 1-2-3Bao TranNo ratings yet

- ANNEX A Template For The HAPAG Project LaunchingDocument3 pagesANNEX A Template For The HAPAG Project LaunchingBRGY MABUHAYNo ratings yet

- Mit 3 CDS: Tears of The GiraffeDocument88 pagesMit 3 CDS: Tears of The Giraffecorso100% (1)

- International MarketingDocument19 pagesInternational MarketingDenza Primananda AlfurqanNo ratings yet

- Best Ad Content Entire Pub (WCJ) Nov 9Document22 pagesBest Ad Content Entire Pub (WCJ) Nov 9Ron SchottNo ratings yet

- Juniar SiraitDocument8 pagesJuniar SiraitRaenyta Adhe WulandariNo ratings yet

- Describe A Photo You Took That You Are Proud ofDocument3 pagesDescribe A Photo You Took That You Are Proud ofDespair TheNo ratings yet

- (English) How To Stop Screwing Yourself Over - Mel Robbins - TEDxSF (DownSub - Com)Document18 pages(English) How To Stop Screwing Yourself Over - Mel Robbins - TEDxSF (DownSub - Com)Maulana Yazid Al AnnuriNo ratings yet

- Health Care EnvironmentDocument17 pagesHealth Care EnvironmentrockheartyNo ratings yet

- Written ReportDocument19 pagesWritten ReportAaron PaladaNo ratings yet

- 9 High Protein Vegan Recipes VeganLiftzDocument13 pages9 High Protein Vegan Recipes VeganLiftzsutreja Clan100% (1)