Professional Documents

Culture Documents

Filtration Equipment-Water Filtration Systems-Web

Uploaded by

heri monawir zebuaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Filtration Equipment-Water Filtration Systems-Web

Uploaded by

heri monawir zebuaCopyright:

Available Formats

Water Filtration

Systems

Lubrons range of pressure filter systems is readily configured for removing both particulates and various

dissolved species in effluent, ground, process and surface waters.

The filters are based on an extensive range of high quality steel vessels, built to the latest European standards,

with excellent internal access. The manifolds, available in PVC or, to special order, stainless steel, incorporate

pneumatic or motorised backwash control valves, which are governed by a dedicated programmable

microprocessor unit.

The most common applications include

for iron and manganese removal from borehole water

for the removal of particulates in effluent, process and surface waters

for elimination of organics, such as pesticides and chlorine.

Iron removal from groundwater and borehole supplies calls for a knowledge of both the chemical reactions

involved and how to engineer systems to ensure these can work effectively. Un-aerated groundwater usually

contains dissolved iron salts. Introducing oxygen or air to the water causes

the water marque

Iron removal from groundwater and

borehole supplies calls for a knowledge

of both the chemical reactions involved

and how to engineer systems to ensure

these can work effectively. Un-aerated

groundwater usually contains dissolved

iron salts. Introducing oxygen or air to

the water causes the iron to oxidise and

precipitate. Under correct conditions it

can be filtered and removed from the

water.

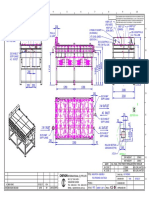

1

2

3

4

5

The efficiency of the process is

dependent on many factors such as pH,

level of oxygenation, operating

pressure, media selection. filtration

rate, etc. Also, because the process is

catalysed by the presence of precipitated and filtered iron, new filters require

a running in period during which the

optimum conditions are established.

6

7

8

9

Uniquely, the precipitation and filtration

process occurs within the filter bed - not

just on the surface -increasing the

capacity over other manufacturers designs.

1.

2.

3.

4.

5.

6.

7.

8.

9.

Filter tank

Microprocessor

Membrane connectors

Pressure gauge

Aeration tank

Air line

Vent cock

Test cock

Manhole

Manganese removal is effected in a similar manner, but the chemical and physical conditions for efficient

precipitation and filtration are different to that of iron.

Lubrons own technical team of qualified chemists and engineers understand these requirements, as

proven by their numerous successful installations, and are always pleased to provide recommendations

and advice for specific treatment projects.

Great care has been taken to design all filter systems to use only the absolute minimum of backwash

water by employing the following techniques

fully programmable backwash cycles with user-friendly interface

air scour - standard on all systems

multiplexed installation can use just filtered water from one vessel to backwash another

raw water may be used for backwashing by incorporating a service direction to drain final stage

backwashing can be programmed to initiate on head loss or time basis.

Filter Options Summary

internal/external coatings to meet project requirements

manifold and valve materials and control systems

single, duplex, triplex or quadruplex installations as standard

dedicated or customer specified plc steering

fully automatic or manual backwash initiation

filter media selected for specific filtrates

all necessary backwash tanks and transfer pump systems can be included in proposals

ancillary chemical dosing and air systems provided if required

TECHNICAL DATA - IRON AND MANGANESE FILTERS

Dimensions shown are for reference only. Contact Lubron for certified drawings.

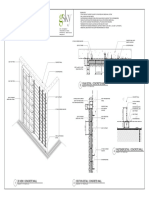

TECHNICAL DATA - SAND FILTERS

SAND FILTERS

Typical applications of Lubrons filters

when configured with sand media are:

removal of particulates from

effluent water (primary or polishing)

for filtering coagulated suspended

solids (such as for algae or other debris)

as a pre-treatment for any effluent or

surface derived source.

It is always important to establish the

appropriate effective chemical and flow

conditions, either by trial or experimentation, and the programmable

backwash is highly configurable to

ensure thorough cleaning for any

Dimensions shown are for reference only. Contact Lubron for certified drawings.

filtrate.

ACTIVATED CARBON FILTERS

TECHNICAL DATA - ACTIVATED CARBON FILTERS

When charged with the appropriate grades of activated

carbon, Lubrons filter vessels are ideal for the removal of

organic species, such as pesticides, or the elimination of

chlorine residuals or chlorine dioxide or ozone.

The programmable backwash system allows for

configuration of the appropriate media rinsing

program in order to achieve the best performance

with the minimum backwash water consumption.

The steel vessels are equipped with excellent media access,

via both top and bottom manways, which ensures fast

media extraction (by suction) and replacement, so that

downtime and labour costs can be kept to an absolute

minimum.

For potable or food industry applications all filters

Dimensions shown are for reference only. Contact Lubron for certified drawings.

are available with approved internal and external

finishes.

FILTER VESSEL MANUFACTURING STANDARDS

Extreme care and quality control is observed throughout the filter and vessel manufacturing process. Along with ISO 9001

Quality Assurance procedures the following also apply:

Maximum Working Pressure

Standard working pressure of 5 bar, higher working pressures to customer requirements. Pressure test carried out to 1.43x

working pressure.

Materials

Steel plate thickness and construction code EN286/1.

Plate manufacture to EN10025 - S235JRG2. Head and dished ends cold pressed to DN28011. Flanges to DIN

2573/2576/2631/2632/2633. Welding sockets to DIN 2986 (heavy type).

Construction and Welding

Manufacturing operatives qualified to EN287. Welding procedures to EN288.

Test and Inspection

All vessels visually inspected prior to galvanising and individually pressure tested.

Fabricator qualified to European Directives 87/404/CE and 97/23/CE.

Finishing

All vessels are hot dipped galvanised to a thickness corresponding to local galvanising and drinking water standards.

Alternative approved coatings are available -details on request.

Lubron UK

Lubron UK Limited

Lubron House

8 Challenge Way, Hythe Hill

Colchester, Essex CO1 2LY

Tel: +44 (0)1206 866444

Fax: +44 (0)1206 866800

www.lubron.co.uk

LUBRON UK LIMITED reserve the right to

change equipment specification without

prior notice, as part of our continuous

product development programme.

Lubron Nederland

Lubron Belgi

Lubron Deutschland

Lubron Waterbehandeling B.V.

Mechelaarstraat 38

4903 RE Oosterhout (NB)

Postbus 540

Nederland

Tel: +31 (0)162-426931

Fax: +31 (0)162-459192

www.lubron.eu

Lubron Belgium B.V.B.A.

Antwerpsesteenweg 124

B-2630 Aartselaar

Belgi

Tel: +32 (0)3877 1519

Fax: +32 (0)3877 2884

Lubron Wasseraufbereitung GmbH

Bahnhofstrasse 39

D-71691 Freiberg am Neckar

Deutschland

Tel: +49 (0)7141 2986130

Fax: +49 (0)7141 2986159

www.lubron.de

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- ASPE Pool PDFDocument29 pagesASPE Pool PDFHany RifaatNo ratings yet

- Resd Load CalcDocument5 pagesResd Load CalcOre Ulil DesuNo ratings yet

- Swimming Pool DesignDocument49 pagesSwimming Pool Designcashlover100% (1)

- A-60 To 75 CMD MBBR - Technical OfferDocument15 pagesA-60 To 75 CMD MBBR - Technical OfferYegetafikerNo ratings yet

- Meteorology Guide Explains Tropopause Heights and TemperaturesDocument185 pagesMeteorology Guide Explains Tropopause Heights and TemperaturesYuvaraj UdayagiriNo ratings yet

- DUCT SIZING GUIDEDocument4 pagesDUCT SIZING GUIDEheri monawir zebuaNo ratings yet

- Biosafety Level 3 (BSL-3) Laboratory Design Standards: January 2020Document71 pagesBiosafety Level 3 (BSL-3) Laboratory Design Standards: January 2020giiirii gasdsadNo ratings yet

- Mechanical VentilationDocument75 pagesMechanical Ventilationgege_ufesNo ratings yet

- Peak Water Demand Study ExecutiveDocument23 pagesPeak Water Demand Study Executiveheri monawir zebuaNo ratings yet

- Head PompaDocument8 pagesHead Pompaheri monawir zebuaNo ratings yet

- Design Considerations For Hot Water Plumbing PDFDocument105 pagesDesign Considerations For Hot Water Plumbing PDFdanateoNo ratings yet

- MJS 2 EXT PerhitunganDocument1 pageMJS 2 EXT Perhitunganheri monawir zebuaNo ratings yet

- Tide Load 4 Z05Document30 pagesTide Load 4 Z05NghiaNo ratings yet

- CFPA E Smoke and Heat Exhaust Venting SystemsDocument14 pagesCFPA E Smoke and Heat Exhaust Venting SystemsAhmed HussainNo ratings yet

- 017-PZ0001 (Remote Radiator - 2000 TRG) - 1Document1 page017-PZ0001 (Remote Radiator - 2000 TRG) - 1heri monawir zebuaNo ratings yet

- Inverse Solution Estimates Corrosion LocationDocument1 pageInverse Solution Estimates Corrosion Locationheri monawir zebuaNo ratings yet

- Peak Water Demand Study ExecutiveDocument23 pagesPeak Water Demand Study Executiveheri monawir zebuaNo ratings yet

- Hydrostorm Plus pump performance and specificationsDocument16 pagesHydrostorm Plus pump performance and specificationsheri monawir zebuaNo ratings yet

- Centrifugal PumpDocument23 pagesCentrifugal Pumpheri monawir zebuaNo ratings yet

- RF Cloud CeilingsDocument60 pagesRF Cloud Ceilingsheri monawir zebuaNo ratings yet

- Installation Operation Maintenance Manual IOM 720 XDocument14 pagesInstallation Operation Maintenance Manual IOM 720 Xheri monawir zebuaNo ratings yet

- Eaching High-Rise Plumbing DesignDocument19 pagesEaching High-Rise Plumbing Designm_salah20202000No ratings yet

- Halgan Automatic Grease Seperator A4 - 2003201424559 - 1Document4 pagesHalgan Automatic Grease Seperator A4 - 2003201424559 - 1heri monawir zebuaNo ratings yet

- Halgan Reflux Valves and Flap Valves - 2003201430235 - 1Document8 pagesHalgan Reflux Valves and Flap Valves - 2003201430235 - 1heri monawir zebuaNo ratings yet

- Fire SprinklerDocument5 pagesFire Sprinklerheri monawir zebuaNo ratings yet

- Hot Water SystemsDocument28 pagesHot Water SystemsalejovelNo ratings yet

- TreeDocument6 pagesTreeheri monawir zebuaNo ratings yet

- Design Examples Urban Drainage and Flood Control DistrictDocument39 pagesDesign Examples Urban Drainage and Flood Control DistrictAli Mohsen100% (1)

- Us 7308906Document18 pagesUs 7308906heri monawir zebuaNo ratings yet

- Hvac Formulas PDFDocument25 pagesHvac Formulas PDFSaraswatapalit0% (1)

- An Excel/Visual Basic For Applications (VBA) Programming PrimerDocument19 pagesAn Excel/Visual Basic For Applications (VBA) Programming Primerrahpooye313No ratings yet

- Caltrans A1Document91 pagesCaltrans A1RubyNo ratings yet

- Vent Pipe From 2018 International Plumbing CodeDocument2 pagesVent Pipe From 2018 International Plumbing CodeSuthi Sae DanNo ratings yet

- Mofad ProfileDocument30 pagesMofad ProfileSAMUEL KIMANINo ratings yet

- Acid Digestion ProcedureDocument2 pagesAcid Digestion ProcedureSolehah OmarNo ratings yet

- Slimsplit - 1.0 Manual PDFDocument206 pagesSlimsplit - 1.0 Manual PDFkalpesh deora83% (6)

- Biology M4 PhotosynthesisDocument31 pagesBiology M4 PhotosynthesisDiana Dealino-SabandalNo ratings yet

- Air-Conditioning Fundamentals ExplainedDocument6 pagesAir-Conditioning Fundamentals ExplainedMikaela Grace OrenseNo ratings yet

- Boiled Feed WaterDocument31 pagesBoiled Feed WaterNowshad ArefinNo ratings yet

- TP PaperDocument70 pagesTP PapersannndyNo ratings yet

- S & CSR End Term Part 1Document25 pagesS & CSR End Term Part 1Zankhana JadhavNo ratings yet

- Vasthu Sasthra and ArchitectureDocument32 pagesVasthu Sasthra and ArchitectureTarkesh MishraNo ratings yet

- Engineering Hydrology GradeupDocument74 pagesEngineering Hydrology GradeupCaalaa MirgaaNo ratings yet

- Tekmar 284 Multi Boiler Control p9450 02Document2 pagesTekmar 284 Multi Boiler Control p9450 02api-221502147No ratings yet

- Jet Fuel Safety Data SheetDocument13 pagesJet Fuel Safety Data SheetSon NguyenNo ratings yet

- Manual Cloro MerkDocument1 pageManual Cloro MerkzegoNo ratings yet

- Warranty Book FullDocument27 pagesWarranty Book FullGeemoNo ratings yet

- GSKY Green Wall Panel Installation on Concrete WallDocument1 pageGSKY Green Wall Panel Installation on Concrete WallAbbasi HussainNo ratings yet

- Eco-Friendly Home Cleaning Recipes and TipsDocument24 pagesEco-Friendly Home Cleaning Recipes and TipsAndrés PacompíaNo ratings yet

- Photosynthesis under stress overviewDocument28 pagesPhotosynthesis under stress overviewnaufal samiNo ratings yet

- Percussion Drilling: A 3000-Year-Old Technique for Drilling WellsDocument21 pagesPercussion Drilling: A 3000-Year-Old Technique for Drilling WellsMudassar KhanNo ratings yet

- Curtis D. Bungard, P.E. Engineering & BuildingDocument14 pagesCurtis D. Bungard, P.E. Engineering & Buildingj_brug571No ratings yet

- 7745858w D2-55, D2-75 OPERATOR'S MANUALDocument64 pages7745858w D2-55, D2-75 OPERATOR'S MANUALm.kelleci72480% (1)

- Grundfosliterature NB NBE NK NKE 60HzDocument20 pagesGrundfosliterature NB NBE NK NKE 60HzCarla RamosNo ratings yet

- Introduction To Acid RainDocument8 pagesIntroduction To Acid RainDevendarsingh rawatNo ratings yet

- Adaptations To Climatic VariabilityDocument30 pagesAdaptations To Climatic VariabilityMuni Vijay ChaudharyNo ratings yet

- Environmental LawDocument4 pagesEnvironmental LawManohar RNo ratings yet

- Philippine Priority Chemicals List PCLDocument7 pagesPhilippine Priority Chemicals List PCLDustin GonzalezNo ratings yet

- General EcologyDocument152 pagesGeneral Ecologykidest100% (2)