Professional Documents

Culture Documents

4920-w1 Guidelines For Carbon and Stainless Steel Tubing

Uploaded by

LorenaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4920-w1 Guidelines For Carbon and Stainless Steel Tubing

Uploaded by

LorenaCopyright:

Available Formats

Standard

Engineering Standards

4920

Page

1 of 2

GUIDELINES FOR CARBON AND STAINLESS STEEL

TUBING SIZE RANGES 1 O.D. AND SMALLER

Issue Date

06/86

1

06/91

Rev. No.

Date

1.

SCOPE

This standard provides guidelines to be used in the design and procurement of carbon and stainless steel tubing for

use in all Company facilities. Such tubing is generally used for instrument, control and sampling lines and related

components in sizes 1" O.D. and smaller.

2.

CODES AND STANDARDS

Steel tubing should be specified and manufactured in accordance with an applicable ASTM specification. ASTM

specifications referenced herein are applicable to tubing for general use in the Company's facilities. Steel tubing

manufactured under other ASTM specifications may be acceptable if it is determined that the materials, physical

and chemical properties and pressure testing are compatible with the design and service requirements.

3.

GUIDELINES

3.1

For design pressures (maximum operating pressure) of 0 to 1000 psig, a safety factor (S.F.) of 8:1 is

recommended. For design pressures of 1000 to 2500 psig a S.F. of 6.1 is recommended.

3.2

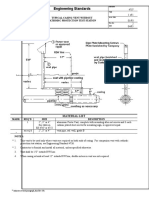

Reference Table I for carbon and stainless steel tubing wall thickness in various sizes and pressure ranges.

This is a guide since some manufacturers do not make all wall thicknesses or sizes. The Project Engineer

should review the application and vendor availability to determine if the desired size, wall thickness and

material are available.

TABLE I: Wall Thickness (WT) versus Working Pressure (WP)

WT vs WP for Carbon Steel

S.F.: 8:1

S.F.: 6:1

500

1000

1500

2000

psi

psi

psi

psi

.032

.032

.032

.032

.032

.032

.032

.032

.035

.035

.035

.035

.035

.035

.035

.035

WT vs WP for Stainless Steel

S.F.: 8:1

S.F.: 6:1

500

1000

1500

2000

psi

psi

psi

psi

.032

.032

.032

.032

.032

.032

.032

.032

.035

.035

.035

.035

.035

.035

.035

.035

3/8

1/2

5/8

3/4

.035

.035

.049

.049

.035

.035

.049

.049

.035

.035

.049

.065

.035

.049

.065

.095

.035

.035

.049

.049

.035

.035

.049

.049

.035

.035

.049

.049

.035

.035

.049

.049

7/8

1

.049

.049

.065

.065

.065

0.65

.095

.110

.049

.049

.049

.049

.065

.065

.065

.065

Tube O.D.

inches

1/8

3/16

1/4

5/16

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4920

Page

2 of 2

GUIDELINES FOR CARBON AND STAINLESS STEEL

TUBING SIZE RANGES 1 O.D. AND SMALLER

Issue Date

Rev. No.

Date

3.3

06/86

1

06/91

Example Purchase Specifications

3.3.1

Carbon Steel

feet, steel tubing

in. O.D. x

in. wall thickness,

seamless or electric weld mandrel drawn, manufactured in accordance with ASTM A-214

(welded) or A-179 (seamless), latest edition. Maximum Operating Pressure

psig.

3.3.2

Type 304 Stainless Steel

feet, stainless steel tubing

in. O.D. x

in. wall

thickness, seamless or welded, manufactured in accordance with ASTM A-269 or ASTM A632, latest edition. Maximum Operating Pressure

psig. Material to be type 304.

Note:

ASTM A-632 applies for sizes less than 1/2" O.D. and ASTM A-269 applies for sizes 1/2"

O.D. and greater.

3.4

Tube fittings are ordered by manufacturer's part number indicating the type, material, size and pressure

rating. Catalogues for the various suppliers of acceptable fittings should be utilized in order to provide an

accurate fitting description on the purchase order. The material in the fitting should be comparable to the

tubing, e.g., only steel fittings should be used with steel tubing. Stainless steel tubing and fittings should

be specified for corrosive service or where the tubing will not otherwise be protected from atmospheric

corrosion.

* Indicates revised paragraph, this Rev. No.

You might also like

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 4910-w1 Engineering Guideline For Flexible Metal HoseDocument1 page4910-w1 Engineering Guideline For Flexible Metal HoseLorenaNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- 4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineDocument1 page4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineLorenaNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Series 1500 Cooling Tower SpecificationDocument9 pagesSeries 1500 Cooling Tower SpecificationLorenaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- 4802-w2 Concrete Anchor Block - Installation DetailsDocument2 pages4802-w2 Concrete Anchor Block - Installation DetailsLorenaNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- 4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSDocument2 pages4764 Typical Pipeline Bolt On Type Concrete Weight NEW GRAPHICSLorenaNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- 4762-w0 Typical Canal Undercrossing, Lined or UnlinedDocument1 page4762-w0 Typical Canal Undercrossing, Lined or UnlinedLorenaNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- 4758-w0 Restoration of TerracesDocument1 page4758-w0 Restoration of TerracesLorenaNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 4760-w0 Typical Stream or Ditch Pipeline UndercrossingDocument1 page4760-w0 Typical Stream or Ditch Pipeline UndercrossingLorena100% (1)

- 4776 Subsea Pipeline CrossingDocument4 pages4776 Subsea Pipeline CrossingLorenaNo ratings yet

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 4737-w2 Typical Casing Vent Without Junction Box AssemblyDocument1 page4737-w2 Typical Casing Vent Without Junction Box AssemblyLorenaNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- 4861 Gathering System - Type 10 Drip For 4,6 & 8 Gathering Lines-Dwg Available From Eng. RecordsDocument2 pages4861 Gathering System - Type 10 Drip For 4,6 & 8 Gathering Lines-Dwg Available From Eng. RecordsLorenaNo ratings yet

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- 4910-w1 Engineering Guideline For Flexible Metal HoseDocument1 page4910-w1 Engineering Guideline For Flexible Metal HoseLorenaNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 4780-w8 Selection and Design of Branch Connections and ReinforcementDocument8 pages4780-w8 Selection and Design of Branch Connections and ReinforcementLorenaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- 4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)Document3 pages4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)LorenaNo ratings yet

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (345)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)