Professional Documents

Culture Documents

3555diesel1pdf 00000005693

Uploaded by

MohamedSalahOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

3555diesel1pdf 00000005693

Uploaded by

MohamedSalahCopyright:

Available Formats

28-32 Diesel

3/3/08

2:45 PM

Page 28

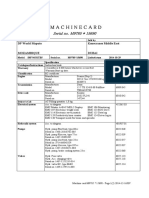

Main Bearing Housing Bore For

Caterpillar 10.0 & 12.0L C10 &

C12 Diesel Engines

Originally published specifications

regarding the main bearing housing bore for Caterpillar 10.0 and

12.0L C10 and C12 diesel engines

were apparently inaccurate, so

review this information carefully.

Standard Main Housing Bore

4.5844-4.5856

(115.925mm-115.975mm)

Oversize Main Housing Bore

4.5640-4.5659

(116.445mm-116.471mm)

Although some machine shops

have reported a discrepancy while

measuring main housing bores for

these engines, no apparent bearing

damage existed even though the

measured sizes were consistently

.002-.003 smaller than the published specification.

Caterpillar also offers .020 (.508

mm) oversize OD main bearings for

these engines to repair severely

damaged bores. Refer to the chart

above to determine the proper

machining dimensions for the above

engines.

At this time, we are unaware of

an aftermarket source for main bearings for these engines.

Main Bearing Housing Bore

Caution For 1997-2007 Caterpillar

C15 Diesel Engines

Oversize main bearing bores have

been reported during engine rebuilding operations on 1997-2007

Caterpillar diesel engines.

To allow additional salvage operations and block reclamation the

Caterpillar Corporation does offer an

Part #

4W5700

4W5701

Description

Main Bearing

Main Bearing

oversize .025 (.635 mm) outside

diameter bearing set. Caterpillar also

offers main bearing sets for oversize

bore bearings in both standard and

.025 (.635 mm) inside diameters (see

chart below).

To determine if a block youre

checking has the oversize bores, use

the following procedures:

1) Install main bearing caps in

original positions.

2) Lubricate cap bolt threads and

bolt head contact surfaces with a small

quantity of thread lubricant 2P2506.

3) Install and tighten main cap

bolts on the left side to 180-200 ft.lbs.

(246-274 Nm).

4) Install and tighten main cap

bolts on the right side to 180-200

ft.lbs. (246-274 Nm).

5) Tighten the main cap bolts on

the right side by rotating them an

additional 120.

6) Tighten the main cap bolts on

the left side by rotating them an additional 120.

7) Measure bores with a dial bore

gauge which has a dial indicator calibration in .0001 increments.

8) Record your measurements and

compare to the standard main bore

diameter specification of 5.11335.1143 (129.878-129.903 mm).

If the block you are checking is

larger than the above standard specification, compare it to the oversize

dimension

of

5.1383-5.1393

(130.513-130.538 mm). If there is a

need to resize, it is recommended to

go to the oversize, rather than repairing by align boring back to standard

dimensions.

Coolant Loss On 1985-2000

Cummins 5.9L Diesel Engines

The following information regarding coolant loss on Cummins 5.9L

Oversize OD

.025 (.635 mm)

.025 (.635 mm)

Inside Diameter

Standard inside ID

.63 mm undersize

inside ID

Caterpillar main bearing sets.

28 AERA TECH SOLUTIONS GUIDE | February 2008

diesel engines is known to apply to

12 valve engines, but this condition

is certainly a possibility for 24 valve

engines as well.

Cylinder porosity has been reported in the front cylinder toward the

intake manifold side of the engine.

This porosity concern was not a result

of an unconditioned cooling system.

In this instance the condition was not

revealed until oversize cylinder boring was performed. The amount of

oversize was the first oversize available, .020 (.5 mm).

One way of determining if this

condition is present on an oversize

bore engine is to pressure test the

cylinder block after all honing operations have been completed.

Revised Cylinder Head Bolt For

1985-1996 Cummins 10.0L, L-10

Diesel Engines

A revised cylinder head bolt has

been introduced for for Cummins

10.0L, L10 diesel engines.

This change has been implemented as a product improvement

to address cap screw corrosion failures. The cap screw (head bolt) was

first used with engine serial number

35124397. The old and new cap

screws can be intermixed within the

engine.

The new cap screws have a grey

coating on them and do not have

the <90 marking on the head of

the cap screw.

The cap screws should also be

checked for stretch using a set of

calipers. The maximum allowable

free length is measured from the

bottom of the flange head to the

end of the cap screw.

The new long cylinder hex head

flange cap screw (p/n 4923187) that

supersedes p/n 3045850.

Cylinder Head Cap Screw Free Length

3045849 Short Intake Port Cap Screws

3045850 Long Hex Head Cap Screws

4923187 Long Hex Head Cap Screws

mm

inch

74.5 2.933

139.5 5.492

139.5 5.492

Cummins 10.0L cylinder head cap screw chart.

28-32 Diesel

3/3/08

2:45 PM

Page 30

Valve & Valve Guide Caution For

Cummins 11.0L ISM, M11 & QSM

Diesel Engines

Engine builders are cautioned that

11.0L M11, IAM and QSM

Cummins diesel engines have valves

and valve guides that may be incompatible. As a condition of a product

improvement, Cummins implemented chrome intake valve stems

and a reverse scroll valve guide for all

locations beginning with engine

serial number (ESN) 35135680 built

in July 2005.

These reverse scroll guides were

implemented to prevent excess

exhaust valve guide wear in the

lower portion of the valve guide

inside diameter. The reverse scroll

guide has 50 percent more surface

New P/N

4926069, 4955239

4923471

4923473

Description

Intake Valve

Standard Valve Guide

Valve Kit

Oversize Valve Guide

area in the lower portion of the

valve guide inside diameter.

The valve guides are the same for

the intake and exhaust valves.

Engines prior to ESN 35135680

were built with chrome plated

exhaust valve stems and nonreversed scroll valve guides. To

accommodate the change in the

valve guides, it was required that the

intake valve stems also be chrome

plated to prevent excess wear on the

intake valve stem. The chrome plated intake valve stems were released a

month before the release of the

Old P/N

3417778

3328786

3800636

3417559

reverse scroll valve guides in order to

prevent usage of non-chrome plated

valve stems with the reverse scroll

guides. Do not use intake valves

from prior serial number engines in

cylinder heads with reverse scroll

vale guides.

Intake valves with chrome plated

valve stems, p/n 4926069 or

4955239, must be used on cylinder

heads which have the reverse scrolled

valve guides, p/n 4923471, or reverse

scrolled oversized valve guides, p/n

4923473.

Either chrome plated intake valve,

p/n 4926069, or non-chrome

plated intake valve, p/n

3417778, can be used on

cylinder heads which have the

non-reverse scrolled valve

guides, p/n 3328786.

Reverse scroll valve guides

can be identified by the inner

threading (spiral) of the guide

at the top end, as opposed to

no threads (spiral) on the nonreverse scroll guides.

Cylinder Head Installs For

1986-2004 Cummins 14.0L

N, NT & N14 Diesel Engines

Because different cylinder

head bolts have been used in

Cummins, 14.0L N, NT and

N14 diesel engines, the

installation procedures may

be different depending on

the age of the head.

This service parts topic provides the correct procedure to

tighten the cylinder head gasket

cap screws (Figure 1, page 31).

Information about the different

cylinder head bolts have been

used as described previously in

AERA Technical Bulletin TB

Circle 230 for more information

30 AERA TECH SOLUTIONS GUIDE | February 2008

28-32 Diesel

3/3/08

2:45 PM

Page 31

683.There is a difference between procedures of cylinder heads manufactured before and after January 1991.

Pre-1991 Cylinder Heads

When tightening the head bolts on N

Series engines built before January

1991 and using head bolt, p/n

209700 or 3013623, the following

procedure should be used.

Torque Value (Step):

1) 50 ft.lbs. [68 Nm]

2) 175 ft.lbs. [237 Nm]

3) 184 ft.lbs. [251 Nm]

4) Rotate all headbolts in sequence 90

degrees clockwise, at least one flat,

but not more than two flats.

Head bolts part numbers 209700

and 3013623 can be identified by an

NT or NTC stamped

on the head of the bolt.

1991 and Later

Cylinder Heads

When tightening the head

bolts on N Series engines

built in January 1991 and

later, and using head bolt,

Part No. 3071161, 3068897,

or 3068898, the following

procedure should be used.

Figure 1 Cylinder head torque sequence

for Cummins, 14.0L diesel engines.

engines. has been introduced and

engine builders should be aware of

the differences.

The cylinder head gasket (p/n

4926316) contains two individual

pieces, one for the high pressure oil

supply and one for the low pressure

oil return.

The old cylinder head gasket

(p/n 4059350) included a onepiece steel carrier for the high pressure supply and low pressure oil

return (Figure 2, page 32).The old

gasket has been made obsolete and

superseded by the new one (Figure

3, page 32).

The first engine serial number

(ESN) for the new cylinder head

gasket is 79156618, built on January

20, 2006.

Connecting Rod Caution For 19982002 Detroit Diesel 40 Series 7.6L

Diesel Engines

The connecting rods for 1998-2002

Detroit Diesel 40 Series 7.6L diesel

engines may have pin bushings

machined offset, so engine builders

Torque Value (Step):

1) 100 ft.lbs. [136 Nm]

2) 220 ft.lbs. [298 Nm]

3) Rotate all headbolts in sequence

90 degrees clockwise, at least one

flat, but not more than two flats.

Head bolt part numpers

3071161, 3068897 and

3068898, can be identified by

a <90 stamped on the bolt.

Head Gasket Change On

Cummins ISX Signature

600 Series Engines

A revised cylinder head gasket for the Cummins ISX

Signature

600

Series

Circle 231 for more information

www.enginebuildermag.com | ENGINE BUILDER

31

28-32 Diesel

3/3/08

2:45 PM

Page 32

rod. If this method of piston pin fit

is used, excessive piston protrusion

may result, allowing piston to

cylinder head contact if the engine

is started.

Figure 2 Cummins ISX 600 Series Old head gasket.

Figure 3 Cummins ISX 600 Series New head gasket.

are cautioned to check rod lengths

carefully.

It is believed this occurred to

re-establish the intended centerto-center length (8.638-8.642

(219.405-219.507 mm) of the connecting rod.The reported offset has

been to the rod big end, thus short-

ening the rod as measured without

the bushing installed.

While it is common practice for

some machine shops to hone fit

connecting rod bushings after

installation. That process does not

allow for adjustment of the centerto-center length of a connecting

Circle 232 for more information

32 AERA TECH SOLUTIONS GUIDE | February 2008

Rocker Shaft Disassembly Caution

For 2000-2007 Mack 11.0L MP7 &

MP8 Diesel Engines

When disassembling the rocker

shaft for 2000-2007 Mack 11.0L

MP7 and MP8 engines you must

pay attention to engines equipped

with the PowerLeash engine

brake. In this system the exhaust

rocker arm incorporates an integral

engine brake valve and piston.

When removal of the rocker

shaft is necessary, the pistons must

be retained to keep them fully

retracted in the bores.

Suitable tie wraps or

mechanics wire can be used

to secure the pistons in place.

Failure to secure the

engine brake piston before

removing the rocker shaft

assembly will allow the piston to drop from the bore as

the shaft is removed. Should

this occur, it may not be

noticed, or it may be difficult

to push the piston fully back

into the bore.

Additionally, plungers are

a match-fit to the rocker

arm, and inadvertent mix-up

of components must be

avoided. Assembling the

rocker shaft to the engine or

operating an engine with the

engine brake pistons not

fully retracted will result in

breakage of valve train components and significant

engine damage.

Note: The tie wraps or

mechanics wire must be

removed only after the rocker shaft has been reinstalled

on the engine. TSG

You might also like

- Machinecard: Serial No. M9785 15690Document2 pagesMachinecard: Serial No. M9785 15690MohamedSalahNo ratings yet

- Calibrate Boom Sensors on Reach StackersDocument8 pagesCalibrate Boom Sensors on Reach StackersMohamedSalahNo ratings yet

- 060378en - General Reachstacker Forklift - SCANIA ENGINE DC13 (74A AND 76A)Document11 pages060378en - General Reachstacker Forklift - SCANIA ENGINE DC13 (74A AND 76A)MohamedSalahNo ratings yet

- 84463001accumulator Charging Valves - 2Document28 pages84463001accumulator Charging Valves - 2MohamedSalahNo ratings yet

- Failure Analysis of Hydraulic Gear Pumps Manual - Danfoss WatermarkedDocument8 pagesFailure Analysis of Hydraulic Gear Pumps Manual - Danfoss WatermarkedMohamedSalahNo ratings yet

- Super Charged Piston Pumps: PAVC Medium PressureDocument40 pagesSuper Charged Piston Pumps: PAVC Medium PressureDarioNo ratings yet

- Vögele MT 1182 en CompleteDocument225 pagesVögele MT 1182 en CompleteMohamedSalah72% (18)

- Hydraulic gear pumps and motors PL 03 T ADocument92 pagesHydraulic gear pumps and motors PL 03 T AMohamedSalahNo ratings yet

- HANGCHA SERVICE MANUAL CPD10 CPD40 1 5t J Series Counterbalanced Battery Forklift Truck Spec - 5340518cc952a9ed5Document64 pagesHANGCHA SERVICE MANUAL CPD10 CPD40 1 5t J Series Counterbalanced Battery Forklift Truck Spec - 5340518cc952a9ed5colive175% (8)

- PAVC100ServicePM3240 22Document15 pagesPAVC100ServicePM3240 22MohamedSalah100% (1)

- Vögele MT 1182 en CompleteDocument225 pagesVögele MT 1182 en CompleteMohamedSalah72% (18)

- Failure Analysis of Hydraulic Gear Pumps Manual - Danfoss WatermarkedDocument8 pagesFailure Analysis of Hydraulic Gear Pumps Manual - Danfoss WatermarkedMohamedSalahNo ratings yet

- 1 PDFDocument144 pages1 PDFMohamedSalah100% (3)

- Mini MbaDocument6 pagesMini MbaMohamedSalahNo ratings yet

- Pavc100 Service Pm3240-04Document12 pagesPavc100 Service Pm3240-04MohamedSalahNo ratings yet

- DRF 400-450 Workshop ManDocument1,040 pagesDRF 400-450 Workshop ManMohamedSalah100% (5)

- TRC and VSCDocument14 pagesTRC and VSCMohamedSalah0% (1)

- Mini MBA ENG MoscowDocument4 pagesMini MBA ENG MoscowMohamedSalahNo ratings yet

- Terberg RT Brochure enDocument8 pagesTerberg RT Brochure enMohamedSalahNo ratings yet

- Mini MBA ENG MoscowDocument4 pagesMini MBA ENG MoscowMohamedSalahNo ratings yet

- Atlas Copco Hydraulic BreakersDocument16 pagesAtlas Copco Hydraulic BreakersAkshay Yewle100% (1)

- Mini MbaDocument6 pagesMini MbaMohamedSalahNo ratings yet

- Onderhoud DRD GBDocument298 pagesOnderhoud DRD GBMohamedSalah100% (5)

- Drf450-60s5m Volvotwd1240ve EngDocument3 pagesDrf450-60s5m Volvotwd1240ve EngMohamedSalahNo ratings yet

- DRD Boom PartsDocument12 pagesDRD Boom PartsMohamedSalah100% (1)

- Instruction Manual DRD ContChamp GBDocument62 pagesInstruction Manual DRD ContChamp GBMohamedSalah80% (5)

- OttawaMaintManual EN2Document205 pagesOttawaMaintManual EN2MohamedSalahNo ratings yet

- Terberg RT Brochure enDocument8 pagesTerberg RT Brochure enMohamedSalahNo ratings yet

- FMP ManualDocument315 pagesFMP ManualMohamedSalahNo ratings yet

- Engine Repair GuidesDocument41 pagesEngine Repair Guidesrajitchatterjea100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Philips 32pfl2508 f8Document118 pagesPhilips 32pfl2508 f8Victor Hugo PiedrahitaNo ratings yet

- Curricula SubjectsDocument2 pagesCurricula SubjectsSumanNo ratings yet

- Vernacular HungarianDocument51 pagesVernacular HungariandeltagNo ratings yet

- CE8395 QB - by WWW - Easyengineering.net 1Document18 pagesCE8395 QB - by WWW - Easyengineering.net 1sureshkumarNo ratings yet

- LR24A-MF 1 2 enDocument8 pagesLR24A-MF 1 2 enSasa RisticNo ratings yet

- MTF - CSSDocument14 pagesMTF - CSSEdmar SamortinNo ratings yet

- 7 FeedforwardDocument12 pages7 FeedforwardHamdi MakniNo ratings yet

- EDI MessageDocument3 pagesEDI Messagerameshkola1434No ratings yet

- Dokumen - Pub The City Amp Guilds Textbookbook 2 Electrical Installations For The Level 3 Apprenticeship 5357 Level 3 Advanced Technical Diploma 8202 Amp Level 3 Diploma 2365 1510432256 9781510432253Document610 pagesDokumen - Pub The City Amp Guilds Textbookbook 2 Electrical Installations For The Level 3 Apprenticeship 5357 Level 3 Advanced Technical Diploma 8202 Amp Level 3 Diploma 2365 1510432256 9781510432253Abdulrahim Abdulhasiz100% (1)

- Overview of NGV Cylinder Safety StandardsDocument11 pagesOverview of NGV Cylinder Safety StandardsImam BuchairiNo ratings yet

- Instrumentation Engineer ResumeDocument3 pagesInstrumentation Engineer ResumeVIMALNo ratings yet

- Shrinkage Cracking in Restrained Reinforced Concrete MembersDocument93 pagesShrinkage Cracking in Restrained Reinforced Concrete MembersPeter MsomaNo ratings yet

- ResumeDocument2 pagesResumekoduruabhinavNo ratings yet

- GHBG7Document124 pagesGHBG7ナンドフェルナンドNo ratings yet

- Karcher Operation ManualDocument60 pagesKarcher Operation ManualDadi SucahyonoNo ratings yet

- Shear Forces and Bending Moments: Understanding Structural AnalysisDocument2 pagesShear Forces and Bending Moments: Understanding Structural AnalysisKang Lee76% (25)

- Concrete DurabilityDocument19 pagesConcrete Durabilityapi-3766593100% (2)

- 76 5500 1 I1Document152 pages76 5500 1 I1shawn allen100% (4)

- Whirling of ShaftsDocument4 pagesWhirling of ShaftsAshline DsouzaNo ratings yet

- ARM Cortex M3 RegistersDocument22 pagesARM Cortex M3 RegistersRaveendra Moodithaya100% (2)

- GHS - Liquid (KOH Liquid)Document12 pagesGHS - Liquid (KOH Liquid)Yeniffer Geraldine guerra quispeNo ratings yet

- Catálogo Anderson Greenwood 400sDocument32 pagesCatálogo Anderson Greenwood 400sDaniela BeltranNo ratings yet

- WS A25 Connecting Rod Types Guidelines For Assessment at Bottom End TB00-3301-16Document4 pagesWS A25 Connecting Rod Types Guidelines For Assessment at Bottom End TB00-3301-16DPNo ratings yet

- DSP Course Overview by Prof. Deepa KundurDocument2 pagesDSP Course Overview by Prof. Deepa KundurBEN AMAR100% (1)

- PDF Table ExtractorDocument17 pagesPDF Table ExtractorJaneNo ratings yet

- Aluminide and Silicide Diffusion Coatings by Pack Cementation For Nb-Ti-AlalloyDocument12 pagesAluminide and Silicide Diffusion Coatings by Pack Cementation For Nb-Ti-Alalloybrunoab89No ratings yet

- Guidelines On Preconstruction Survey PDFDocument30 pagesGuidelines On Preconstruction Survey PDFNathan VincentNo ratings yet

- Shubham Sonar CVDocument2 pagesShubham Sonar CVKuldip PardeshiNo ratings yet

- 2GM (Mmbta56)Document3 pages2GM (Mmbta56)josealcantarafranco100% (1)