Professional Documents

Culture Documents

Diferencial Lock Valve

Uploaded by

miguel_catCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Diferencial Lock Valve

Uploaded by

miguel_catCopyright:

Available Formats

140K Motor Grader SZL00001-UP (MACHINE) POWERED BY C7 Engine(SEBP500...

Pgina 1 de 4

Cerrar SIS

Pantalla anterior

Producto: MOTOR GRADER

Modelo: 140K MOTOR GRADER SZL

Configuracin: 140K Motor Grader SZL00001-UP (MACHINE) POWERED BY C7 Engine

Pruebas y Ajustes

12K, 140K, 140K Series 2 and 160K Motor Graders Power Train

Nmero de medio -KENR8427-03

Fecha de publicacin -01/02/2011

Fecha de actualizacin -25/02/2011

i03911074

Differential Lock Pressure - Check

SMCS - 3272-535-PX

Introduction

When testing and adjusting the transmission and power train, move the

machine to an area clear of obstructions, with safe exhaust ventilation

for the exhausts. Sudden movement of the machine or release of oil

under pressure can cause injury to persons on or near the machine. To

prevent possible injury, do the procedure that follows before testing and

adjusting the transmission and power train.

NOTICE

Care must be taken to ensure that fluids are contained during

performance of inspection, maintenance, testing, adjusting, and repair

of the machine. Be prepared to collect the fluid with suitable containers

before opening any compartment or disassembling any component

containing fluids.

Dispose of all fluids according to local regulations and mandates.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb... 19/07/2016

140K Motor Grader SZL00001-UP (MACHINE) POWERED BY C7 Engine(SEBP500... Pgina 2 de 4

Required Tools

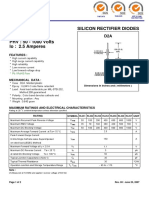

Illustration 1

g01089423

Illustration 2

g01623868

Table 1

Tool

Item

Part Number

Description

Qty

A1

8T-0856

Pressure Gauge

(0 to 6,000 kPa (0 to 870 psi))

A2

6V-3989

Fitting

A3

6V-4143

Quick Connect Coupler

A4

177-7860

Hose As

(3.0 m (10 ft))

198-4240

Digital Pressure Indicator Gp

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb... 19/07/2016

140K Motor Grader SZL00001-UP (MACHINE) POWERED BY C7 Engine(SEBP500... Pgina 3 de 4

B1

198-4234

Digital Indicator

B2

198-4238

Pressure Sensor Gp

(0 to 3,440 kPa (0 to 5000 psi))

B3

198-4236

Adapter Cable As

Machine Preparation

ReferenceRefer to Testing and Adjusting, "Machine Preparation for Troubleshooting" before

beginning the test.

1. Operate the machine until the transmission oil is at operating temperature of 80 10C (176

18F).

2. Stop the machine on a hard level surface. Engage the parking brake. Shut off the engine.

Illustration 3

g01127219

Test port (1)

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb... 19/07/2016

140K Motor Grader SZL00001-UP (MACHINE) POWERED BY C7 Engine(SEBP500... Pgina 4 de 4

3. Remove the dust cap. Attach Tooling (A) or (B) to test port (1) .

Test Procedure

1. Start the engine and run the engine at high idle.

2. Move the differential lock switch to the ON position.

3. The gauge should read 2750 50 kPa (400 10 psi). If the pressure reading is too high or if the

pressure reading is too low, the transmission relief valve must be tested.

ReferenceRefer to Testing and Adjusting, "Transmission Charging Pump Pressure - Test" for

more information about testing the transmission relief valve.

4. If the setting for the transmission relief valve is correct and the pressure reading is still

incorrect, inspect the differential lock valve. If the differential lock valve appears to be working

properly, the differential lock clutch must be tested.

5. Shut off the engine. Remove the test equipment.

Copyright 1993 - 2016 Caterpillar Inc.

Tue Jul 19 22:57:58 EST 2016

Todos los derechos reservados.

Red privada para licenciados del SIS.

https://127.0.0.1/sisweb/sisweb/techdoc/techdoc_print_page.jsp?returnurl=/sisweb/sisweb... 19/07/2016

You might also like

- Plano Hidráulico Retroexcavadora 420fDocument13 pagesPlano Hidráulico Retroexcavadora 420fgerardo92% (13)

- Plano Hidráulico Retroexcavadora 420fDocument13 pagesPlano Hidráulico Retroexcavadora 420fgerardo92% (13)

- 3024C Crankshaft - InstallDocument2 pages3024C Crankshaft - Installmiguel_catNo ratings yet

- Hydraulic System: Operación de SistemasDocument5 pagesHydraulic System: Operación de Sistemasmiguel_catNo ratings yet

- Ccs C Manual 410Document410 pagesCcs C Manual 410Omar SolanoNo ratings yet

- Important Information: Testing and AdjustingDocument78 pagesImportant Information: Testing and Adjustingmiguel_catNo ratings yet

- Hydraulic System Operation for D11N Track-Type TractorDocument43 pagesHydraulic System Operation for D11N Track-Type Tractormiguel_catNo ratings yet

- Tabela de TransistoresDocument116 pagesTabela de Transistoresmiguel_catNo ratings yet

- Convert Id orDocument6 pagesConvert Id ormiguel_catNo ratings yet

- Servo 769dDocument71 pagesServo 769dmiguel_catNo ratings yet

- TRANSMISIONDocument11 pagesTRANSMISIONmiguel_catNo ratings yet

- S Hidraulico 2Document29 pagesS Hidraulico 2miguel_catNo ratings yet

- Rl251 - Rl257 (2.5a Rectifier)Document2 pagesRl251 - Rl257 (2.5a Rectifier)miguel_catNo ratings yet

- 1N5400Document3 pages1N5400Robert CristobalNo ratings yet

- TP4056 English DocumentationDocument3 pagesTP4056 English DocumentationsuocNo ratings yet

- Prender Led Con BotonDocument3 pagesPrender Led Con Botonmiguel_catNo ratings yet

- 1 OhmDocument1 page1 Ohmmiguel_catNo ratings yet

- 1 OhmDocument1 page1 Ohmmiguel_catNo ratings yet

- Rl251 - Rl257 (2.5a Rectifier)Document2 pagesRl251 - Rl257 (2.5a Rectifier)miguel_catNo ratings yet

- P CD Reference ManualDocument489 pagesP CD Reference Manualmiguel_catNo ratings yet

- Installation AutodataDocument2 pagesInstallation Autodataadrins22100% (2)

- ds28002 83776Document4 pagesds28002 83776alareeqiNo ratings yet

- 3Document1 page3miguel_catNo ratings yet

- Ccs C Manual 410Document410 pagesCcs C Manual 410Omar SolanoNo ratings yet

- PDF BT136 600D PDFDocument13 pagesPDF BT136 600D PDFmiguel_catNo ratings yet

- D6TDocument6 pagesD6Tllesli1750% (2)

- What's New in Autodata 3.45 PDFDocument12 pagesWhat's New in Autodata 3.45 PDFadrins2257% (7)

- Material Schematic Hydraulic System Track Type Tractors d8r Dozer Caterpillar PDFDocument4 pagesMaterial Schematic Hydraulic System Track Type Tractors d8r Dozer Caterpillar PDFvasanth kumar100% (1)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 2 Lifting PlanDocument10 pages2 Lifting Plan-Rizki SuLindo-No ratings yet

- Automatic Gain Control Pre-Amplifier Circuit Diagram - Electronic Circuits PDFDocument7 pagesAutomatic Gain Control Pre-Amplifier Circuit Diagram - Electronic Circuits PDFHaggai Ben BaruchNo ratings yet

- Electric VehiclesDocument1 pageElectric VehiclesVINCENCIUS S Y PNo ratings yet

- Power Contactors: Basics Constructions Operation Parameters SelectionDocument22 pagesPower Contactors: Basics Constructions Operation Parameters SelectionVikram PorjeNo ratings yet

- Rfid Access Control SystemDocument16 pagesRfid Access Control SystemManjeet SinghNo ratings yet

- XQ Trailer Spec SheetDocument6 pagesXQ Trailer Spec Sheetmohammad hazbehzadNo ratings yet

- STD Uei Wheel Loader Weekly Maintenance ChecklistDocument1 pageSTD Uei Wheel Loader Weekly Maintenance Checklistmuhammad lukmanNo ratings yet

- Manual de Partes Sk210lc 8 Acera Mark 8Document645 pagesManual de Partes Sk210lc 8 Acera Mark 8Aris SuryantoNo ratings yet

- HwlogDocument167 pagesHwlogsidsatx102No ratings yet

- Single Synchronous Buck Controller: RT8209A/B/CDocument18 pagesSingle Synchronous Buck Controller: RT8209A/B/CscobaNo ratings yet

- Lecture Notes 08Document25 pagesLecture Notes 08Abdul Hakeem Semar KamaluddinNo ratings yet

- Bearings For Agricultural MachineryDocument9 pagesBearings For Agricultural MachineryMai Thế ToanNo ratings yet

- Esquema Elétrico - PM565 - KENR25230001Document2 pagesEsquema Elétrico - PM565 - KENR25230001Ismael GaldinoNo ratings yet

- FR-SX Adjustment ProcedureDocument6 pagesFR-SX Adjustment ProcedureAlexNo ratings yet

- Honeywell Sensing Bipolar Digital Hall Effect Sensor Ic Installation Instructions Ss41 Pk87881 6 enDocument3 pagesHoneywell Sensing Bipolar Digital Hall Effect Sensor Ic Installation Instructions Ss41 Pk87881 6 enMeghamala MandalNo ratings yet

- Electrical Installation Condition ReportDocument9 pagesElectrical Installation Condition ReportAlrx BennettNo ratings yet

- ARUV216BTE5: Multi V™ 5 - 220V - 18RT Outdoor Unit For Cooling OnlyDocument2 pagesARUV216BTE5: Multi V™ 5 - 220V - 18RT Outdoor Unit For Cooling OnlyCristian monsalve mendozaNo ratings yet

- FND-XXXX-GD-DB-03-XX-00 CCTV Design BasisDocument2 pagesFND-XXXX-GD-DB-03-XX-00 CCTV Design BasiskhuzaimNo ratings yet

- Ricoh AF 2035 2045 Service ManualDocument852 pagesRicoh AF 2035 2045 Service Manualacecopyinc100% (5)

- Evo X SST ManualDocument18 pagesEvo X SST ManualSheldon Gilkes100% (1)

- Cabinet Liner and Door Parts: For Models: KUIS155HRS2 (Stainless Steel)Document8 pagesCabinet Liner and Door Parts: For Models: KUIS155HRS2 (Stainless Steel)chevicitNo ratings yet

- Pre-Piped Vertical Bladder TanksDocument6 pagesPre-Piped Vertical Bladder TanksGabrielaNo ratings yet

- Valve Components and Design Explained in DetailDocument19 pagesValve Components and Design Explained in DetailIzziyyahNo ratings yet

- TITAN ECU Manual IntroductionDocument96 pagesTITAN ECU Manual IntroductionZanko FitnessNo ratings yet

- Data Line Chokes and xDSL Transformers Technical SpecificationsDocument4 pagesData Line Chokes and xDSL Transformers Technical SpecificationsHAHAH JAJAJANo ratings yet

- PIC16 (L) F1938/9 Data SheetDocument452 pagesPIC16 (L) F1938/9 Data SheetCynthia AlvarezNo ratings yet

- Hyundai Escalators & Moving Walks 2021Document15 pagesHyundai Escalators & Moving Walks 2021Lekule, Ibrahim HamisNo ratings yet

- Freidora DeanDocument54 pagesFreidora Deanjose marcanoNo ratings yet

- ZW 220 PDFDocument24 pagesZW 220 PDFTaufik BinasrNo ratings yet

- UCM224FDocument8 pagesUCM224F3efooNo ratings yet