Professional Documents

Culture Documents

4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)

Uploaded by

LorenaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)

Uploaded by

LorenaCopyright:

Available Formats

Engineering Standards

Standard

4907

Page

1 of 3

STANDARD FOR PURCHASE OF LINE PIPE

FOR LOW TEMPERATURE SERVICE

SUPPLEMENT TO ASTM A333

Issue Date

11/91

Rev. No.

Date

1.

SCOPE

This standard covers the requirements for the manufacture of pipe for low temperature service in natural gas

transmission facilities. This standard applies only to pipe which is less than 16 NPS, seamless or welded, and

manufactured to ASTM A333, Grades 3, 6, 7 and 9.

2.

REQUIREMENTS

2.1

Pipe shall be manufactured, tested and inspected in accordance with ASTM Specification A333, latest

edition referenced by 49 CFR Part 192, and as modified by this standard.

2.2

The steel used for the pipe shall be fine grain and fully killed.

2.3

Two (2) product (check) analyses per heat of steel are required.

2.4

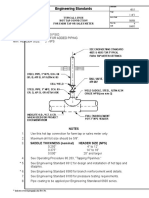

If specified on the specification sheet, all pipe ends shall be beveled to an angle of 30 (+5, -0) and with

a root face of 1/16" (+1/32, -0"). An inside bevel or crimped or belled end is not acceptable. All magnetic

particle or dye penetrant technique. Laminations or other visible defects 1/4" or greater in the longest

dimension on the bevel surface are not permitted. Non-metallic inclusions or separations less than 1/4" in

length are acceptable if separated by 4" of sound metal.

2.5

The Company's purchase order number and nominal pipe size (or outside diameter) shall be marked on

the pipe in addition to the following markings per ASTM A333 (and ASTM A530 by reference):

Manufacturer's name or mark

ASTM Specification Number (A333), grade

process of manufacture,

schedule number (or nominal wall thickness),

impact test temperature.

2.6

Pipe shall be furnished bare with no loose mill scale, foreign matter or oil. A light coat of clear lacquer

shall be sprayed over the stenciled areas on each end.

2.7

The materials, source of materials, manufacturing and all testing, test specimens and test results shall be

available for inspection and approval by the Company. The Company's representatives shall be provided

free access to the operation at all times while work is in progress on this order and shall be provided

reasonable facilities for accomplishing the inspection. The waiver of approval or inspection shall not

relieve the Manufacturer of the responsibility of meeting this standard.

2.8

The Manufacturer shall furnish three (3) certified copies of the mill test report for each heat of steel. They

shall contain the chemical analyses (both heat and product) and the mechanical and fracture toughness

test results. Each test report shall reference the applicable Company purchase order, quantity produced,

tag and items numbers and all of the identifying information marked on the pipe.

2.9

Handling, storage and shipping and shipping of pipe shall be in accordance with Engineering Standard

4915.

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4907

Page

2 of 3

STANDARD FOR PURCHASE OF LINE PIPE

FOR LOW TEMPERATURE SERVICE

SUPPLEMENT TO ASTM A333

Issue Date

11/91

Rev. No.

Date

2.10

The Manufacturer shall be liable and reimburse Company for total direct replacement costs of any pipe

furnished under this specification what fails the field hydrostatic test due solely to material or

manufacturing defects in this pipe. Manufacturer shall supply a copy of his warranty with his bid for

approval by Company.

* Indicates revised paragraph, this Rev. No.

Engineering Standards

Standard

4907

Page

3 of 3

STANDARD FOR PURCHASE OF LINE PIPE

FOR LOW TEMPERATURE SERVICE

SUPPLEMENT TO ASTM A333

Issue Date

11/91

Rev. No.

Date

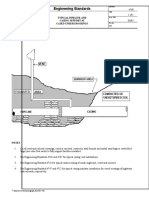

SPECIFICATION SHEET

Location:

Project:

Prepared By:

Date:

Purchase Order No.

Requisition No.

Project No.

Approved By:

Revision:

Revised Date:

P.O. Date:

SERVICE REQUIREMENTS

Item Number

Tag Number

Quantity (miles or feet)

Service Fluid

Service Temperature Range (F)

Pipe

Size (inches O.D.)

Wall Thickness (inches)

Grade (3, 6, 7 or 9)

Seamless or Welded

Plain or beveled Ends

NOTES OR ADDITIONAL REQUIREMENTS

* Indicates revised paragraph, this Rev. No.

You might also like

- A 972 - A 972M - 00 Qtk3mi9botcytqDocument4 pagesA 972 - A 972M - 00 Qtk3mi9botcytqfekihassanNo ratings yet

- Specification For Subsea Flange FittingDocument16 pagesSpecification For Subsea Flange FittingMuzammil Makandar100% (1)

- Double pipe heat exchangers design guideDocument18 pagesDouble pipe heat exchangers design guideJhonny Rafael Blanco CauraNo ratings yet

- Technical Data NRL 02301Document8 pagesTechnical Data NRL 02301Attiq Ahmad ChoudhryNo ratings yet

- Electric-Resistance-Welded Steel Pipe: Standard Specification ForDocument9 pagesElectric-Resistance-Welded Steel Pipe: Standard Specification Foramit02mechNo ratings yet

- Austenitic Chromium-Nickel-Silicon Alloy Steel Seamless and Welded PipeDocument4 pagesAustenitic Chromium-Nickel-Silicon Alloy Steel Seamless and Welded PipeJosé Ramón GutierrezNo ratings yet

- 8a. Insulating Joint - PDF 2 PDFDocument9 pages8a. Insulating Joint - PDF 2 PDFBalasubramanian AnanthNo ratings yet

- C. Specifications For Cone Roof TKDocument21 pagesC. Specifications For Cone Roof TKFajar Sidiq AliwiyonoNo ratings yet

- Tender9 Vol II o II Pig Launcher and Receiver by MeconDocument31 pagesTender9 Vol II o II Pig Launcher and Receiver by MeconVeena S VNo ratings yet

- SampleDocument5 pagesSamplehaldunNo ratings yet

- Astm A179 1990Document4 pagesAstm A179 1990DhruvNambiarNo ratings yet

- Pipe, Steel, Electric-Fusion (Arc) - Welded (Sizes NPS 16 and Over)Document4 pagesPipe, Steel, Electric-Fusion (Arc) - Welded (Sizes NPS 16 and Over)Sriniramu SriniramuNo ratings yet

- Astm A 106 - 08Document9 pagesAstm A 106 - 08Alvin Irfani AzharNo ratings yet

- Technical Specs Externally Finned TubesDocument4 pagesTechnical Specs Externally Finned Tubesyulianus_srNo ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Ajesh Kumar MuraleedharanNo ratings yet

- Astm A192 (Tubos de Calderas) PDFDocument2 pagesAstm A192 (Tubos de Calderas) PDFHenry CruzNo ratings yet

- A 498 - 98 Qtq5oc1sruqDocument4 pagesA 498 - 98 Qtq5oc1sruqsingaravelan narayanasamyNo ratings yet

- Essar Steel PlantDocument62 pagesEssar Steel PlantKrishnadev C.SNo ratings yet

- A 954 - 96 QTK1NC05NGDocument4 pagesA 954 - 96 QTK1NC05NGsachinguptachdNo ratings yet

- Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser TubesDocument2 pagesSeamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser TubesVishal SharmaNo ratings yet

- A 524 - 96 R01 QtuynaDocument8 pagesA 524 - 96 R01 QtuynaJuan GonzalesNo ratings yet

- المواسيرDocument15 pagesالمواسيرshamashergyNo ratings yet

- Piping BasisDocument32 pagesPiping Basislowermine100% (2)

- Astm B517-09Document3 pagesAstm B517-09Srinivasan KrishnamoorthyNo ratings yet

- A179A179M-90a (2012) Standard Specification For Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes PDFDocument2 pagesA179A179M-90a (2012) Standard Specification For Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser Tubes PDFJosé Israel HGNo ratings yet

- High-Carbon Anti-Friction Bearing Steel: Standard Specification ForDocument4 pagesHigh-Carbon Anti-Friction Bearing Steel: Standard Specification Fornelwan_topanNo ratings yet

- Threaded Couplings, Steel, Black or Zinc-Coated (Galvanized) Welded or Seamless, For Use in Steel Pipe JointsDocument5 pagesThreaded Couplings, Steel, Black or Zinc-Coated (Galvanized) Welded or Seamless, For Use in Steel Pipe JointssachinguptachdNo ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Thân KhaNo ratings yet

- Asme Section II A Sa-31Document4 pagesAsme Section II A Sa-31Anonymous GhPzn1xNo ratings yet

- A 861 - 04 QTG2MQ - PDFDocument28 pagesA 861 - 04 QTG2MQ - PDFMung Duong Xuan100% (1)

- Equipment SpecificationDocument8 pagesEquipment SpecificationPraveen ChandrakarNo ratings yet

- Technical notes on valvesDocument29 pagesTechnical notes on valvesNilesh Mistry100% (2)

- A660Document4 pagesA660Amreusit SaschimbnumeleNo ratings yet

- Asme Section II A Sa-376 Sa-376mDocument10 pagesAsme Section II A Sa-376 Sa-376mAnonymous GhPzn1xNo ratings yet

- Split Tee Specifications and Drawings - 20130906 - 191217Document17 pagesSplit Tee Specifications and Drawings - 20130906 - 191217Anonymous cuOIjrLINo ratings yet

- Steel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)Document3 pagesSteel Joint Bars, Low, Medium, and High Carbon (Non-Heat-Treated)mulong83No ratings yet

- A 949 - A 949m - 00 Qtk0os9botq5ts1sruqDocument6 pagesA 949 - A 949m - 00 Qtk0os9botq5ts1sruqsachinguptachdNo ratings yet

- A 822 - 90 r00 Qtgymi9bodiytqDocument3 pagesA 822 - 90 r00 Qtgymi9bodiytqsachinguptachdNo ratings yet

- A 861 - 02 QTG2MS0WMG - PDFDocument28 pagesA 861 - 02 QTG2MS0WMG - PDFMung Duong XuanNo ratings yet

- Fabrication ProcedureDocument16 pagesFabrication ProcedureAryo WicaksonoNo ratings yet

- A134-96 (2012) Standard Specification For Pipe, Steel, Electric-Fusion (Arc) - Welded (Sizes NPS 16 and Over) PDFDocument4 pagesA134-96 (2012) Standard Specification For Pipe, Steel, Electric-Fusion (Arc) - Welded (Sizes NPS 16 and Over) PDFJosé Israel HGNo ratings yet

- Api-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Document4 pagesApi-582-2016-Welding-Guidelines-For-The-Chemical-Oil-And-Gas-Industries-Apiasme-Practice-Test Clause 11.3Ahmed ElsharkawNo ratings yet

- SPC-0804.02-50.09 Rev D2 Welding of Pipe For Station ConstructionDocument14 pagesSPC-0804.02-50.09 Rev D2 Welding of Pipe For Station ConstructionAbdul Hakam Mohamed YusofNo ratings yet

- A688A688 ASS Feed WaterDocument6 pagesA688A688 ASS Feed Waterkhot2000No ratings yet

- Hot Tapping Split Tee SpecificationDocument19 pagesHot Tapping Split Tee SpecificationAli ClubistNo ratings yet

- Polyurethane Lining and Coating Specification Penstock Welded Joints 20120327Document12 pagesPolyurethane Lining and Coating Specification Penstock Welded Joints 20120327anbilselvamNo ratings yet

- Guidelines and Checklist For Specification and Construction For Recovery BoilersDocument26 pagesGuidelines and Checklist For Specification and Construction For Recovery Boilersgovimano100% (1)

- Debswana DP 0gs104Document28 pagesDebswana DP 0gs104Riyadi HendraNo ratings yet

- Auto LPG Dispensing Station SpecificationDocument5 pagesAuto LPG Dispensing Station SpecificationShyBokxNo ratings yet

- Nickel-Iron-Chromium-Silicon Alloy Welded Pipe: Standard Specification ForDocument2 pagesNickel-Iron-Chromium-Silicon Alloy Welded Pipe: Standard Specification ForhamidharvardNo ratings yet

- ENTS 400 NewDocument62 pagesENTS 400 Newmohammadimranshah0% (1)

- Technical Notes and Specifications Part CDocument29 pagesTechnical Notes and Specifications Part Cهيمنت بيلوديا100% (1)

- Inspection Check List 3Document22 pagesInspection Check List 3r.devendranNo ratings yet

- A 872 - 91 R02 Qtg3mi05mviwmgDocument3 pagesA 872 - 91 R02 Qtg3mi05mviwmgsachinguptachdNo ratings yet

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Trusting JesusDocument1 pageTrusting JesusLorenaNo ratings yet

- Tower of BabelDocument5 pagesTower of BabelLorenaNo ratings yet

- What's New - CADWorx 2016Document5 pagesWhat's New - CADWorx 2016LorenaNo ratings yet

- Series 1500 Cooling Tower SpecificationDocument9 pagesSeries 1500 Cooling Tower SpecificationLorenaNo ratings yet

- Demonstration of Hydrogen Air-Assisted FlaDocument18 pagesDemonstration of Hydrogen Air-Assisted Flahk168No ratings yet

- 2813 HXGN Live 2813 MccombDocument19 pages2813 HXGN Live 2813 MccombLorenaNo ratings yet

- 4940-w3 Standard For Purchase of Valves For Critical Gas ServiceDocument8 pages4940-w3 Standard For Purchase of Valves For Critical Gas ServiceLorena DávilaNo ratings yet

- Good Cooling Tower PractiseDocument59 pagesGood Cooling Tower Practiseamahmoud3No ratings yet

- Fluidos Termicos y Circuitos de CalentamientoDocument38 pagesFluidos Termicos y Circuitos de CalentamientoClaudio Antonio Figueroa PulgarNo ratings yet

- Report DesignerDocument255 pagesReport Designerdgrant775No ratings yet

- Fire protection system philosophy for Collie Urea PlantDocument60 pagesFire protection system philosophy for Collie Urea PlantLorena Dávila100% (1)

- Good Cooling Tower PractiseDocument59 pagesGood Cooling Tower Practiseamahmoud3No ratings yet

- 4815 Typical 1 Hot Tap Connection For Farm Tap or Sales MeterDocument1 page4815 Typical 1 Hot Tap Connection For Farm Tap or Sales MeterLorenaNo ratings yet

- 4910-w1 Engineering Guideline For Flexible Metal HoseDocument1 page4910-w1 Engineering Guideline For Flexible Metal HoseLorenaNo ratings yet

- Onshore and Offshore: Echnical PresentationDocument66 pagesOnshore and Offshore: Echnical PresentationAnonymous 4MwmDaNbNo ratings yet

- 4760-w0 Typical Stream or Ditch Pipeline UndercrossingDocument1 page4760-w0 Typical Stream or Ditch Pipeline UndercrossingLorena100% (1)

- Flare System PDFDocument41 pagesFlare System PDFAzar Deen100% (1)

- 4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)Document3 pages4907-w0 Standard For Purchase of Line Pipe For Low Temperature Service (Supplement To ASTM A333)LorenaNo ratings yet

- 4763-w2 Yard Applied Concrete Pipe CoatingDocument7 pages4763-w2 Yard Applied Concrete Pipe CoatingLorena DávilaNo ratings yet

- 4890 Guide Bar Installation For Weld TeesDocument2 pages4890 Guide Bar Installation For Weld TeesLorena DávilaNo ratings yet

- 4802-w2 Concrete Anchor Block - Installation DetailsDocument2 pages4802-w2 Concrete Anchor Block - Installation DetailsLorenaNo ratings yet

- 4895-w2 Standard For Purchase of Forged Flanges and FittingsDocument3 pages4895-w2 Standard For Purchase of Forged Flanges and FittingsLorenaNo ratings yet

- Selecting and Designing Branch ConnectionsDocument8 pagesSelecting and Designing Branch ConnectionsLorenaNo ratings yet

- 4762-w0 Typical Canal Undercrossing, Lined or UnlinedDocument1 page4762-w0 Typical Canal Undercrossing, Lined or UnlinedLorenaNo ratings yet

- 4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineDocument1 page4764-n1 Typical Pipeline Bolt On Type Concrete Weight For 42 O.D. PipelineLorenaNo ratings yet

- 4752-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Railroad UndercrossingDocument1 page4752-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Railroad UndercrossingLorenaNo ratings yet

- Enron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsDocument2 pagesEnron Gas Pipeline Engineering Standards for Concrete Pipeline WeightsLorenaNo ratings yet

- 4748-w0 Typical Pipeline and Casing Support at Cased UndercrossingsDocument1 page4748-w0 Typical Pipeline and Casing Support at Cased UndercrossingsLorenaNo ratings yet

- 4758-w0 Restoration of TerracesDocument1 page4758-w0 Restoration of TerracesLorenaNo ratings yet

- 4747-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Cased Highway UndercrossingDocument1 page4747-w2 Typical Natural Gas Pipeline and Pipeline Insulator Installation For Cased Highway UndercrossingLorenaNo ratings yet

- (6600) - 4 CYL AG TRACTOR (9/75-12/81) (06E01) - OIL PUMP & PAN (SUMP) New Holland AgricultureDocument4 pages(6600) - 4 CYL AG TRACTOR (9/75-12/81) (06E01) - OIL PUMP & PAN (SUMP) New Holland AgriculturerodrigoNo ratings yet

- EN 25 - 2016 - TT-BCT - 339051 THÔNG TƯ 252016TT-BCT NGÀY 30112016 QUY ĐỊNH HỆ THỐNG ĐIỆN TRUYỀN TẢI DO BỘ TRƯỞNG BỘ CÔNG THƯƠNG BAN HÀNHDocument48 pagesEN 25 - 2016 - TT-BCT - 339051 THÔNG TƯ 252016TT-BCT NGÀY 30112016 QUY ĐỊNH HỆ THỐNG ĐIỆN TRUYỀN TẢI DO BỘ TRƯỞNG BỘ CÔNG THƯƠNG BAN HÀNHngomanhlinh2009No ratings yet

- Flammable & Combustable LiquidsDocument3 pagesFlammable & Combustable LiquidssizweNo ratings yet

- Dynamic Balancing of Hydronic SystemsDocument65 pagesDynamic Balancing of Hydronic Systems黃偉哲100% (4)

- Chvcm4 Instructions NaDocument1 pageChvcm4 Instructions NaCarlos CabralesNo ratings yet

- Tom MDocument98 pagesTom MChetanya93No ratings yet

- Liquid Crystal ColloidsDocument313 pagesLiquid Crystal ColloidsyyyyyyyNo ratings yet

- Introduction To Green EconomyDocument11 pagesIntroduction To Green Economyvineet soodNo ratings yet

- 1 4-Mr CA-LeeDocument24 pages1 4-Mr CA-Leerm414725No ratings yet

- Everest Group RFP Questionnaire For ESG AttributesDocument7 pagesEverest Group RFP Questionnaire For ESG AttributesAbhijeet ShindeNo ratings yet

- Mitsubishi Electric PLFY-P VBM-E Service Manual EngDocument44 pagesMitsubishi Electric PLFY-P VBM-E Service Manual Engengenharia proclimaNo ratings yet

- Citel Certif Ue Ds440Document2 pagesCitel Certif Ue Ds440ShivamNo ratings yet

- UNIT5-Ground Wave Propagation PDFDocument44 pagesUNIT5-Ground Wave Propagation PDFRameshbabu SadineniNo ratings yet

- MK6 Golf GTI Wiring Diagrams & Component Locations PDFDocument1,165 pagesMK6 Golf GTI Wiring Diagrams & Component Locations PDFMorarescu Andrei100% (5)

- Motors Efficiency Standards & Regulations LAFERTDocument6 pagesMotors Efficiency Standards & Regulations LAFERTRoberto Becerra RiveraNo ratings yet

- GMAW Lesson PlanDocument77 pagesGMAW Lesson PlanKentDemeterioNo ratings yet

- TL 071Document85 pagesTL 071Angel baez gonzalezNo ratings yet

- Optimization of Piping Layout With Respect To Pressure and Temperature Using Caeser-IiDocument6 pagesOptimization of Piping Layout With Respect To Pressure and Temperature Using Caeser-IichabibNo ratings yet

- QC Engr CV PDFDocument5 pagesQC Engr CV PDFMuthazhagan SaravananNo ratings yet

- LPE Insulated and Armored Cable GuideDocument5 pagesLPE Insulated and Armored Cable GuideRaja ManiNo ratings yet

- Hydraulic Calculations MudpumpDocument1 pageHydraulic Calculations MudpumpSudish BhatNo ratings yet

- Digitrax SDN144PS Decoder ManualDocument12 pagesDigitrax SDN144PS Decoder ManualJustin GilmoreNo ratings yet

- E Beam ManualDocument7 pagesE Beam ManualMarco SalvatoriNo ratings yet

- 16 - Lubricate and Bleed ProcedureDocument1 page16 - Lubricate and Bleed ProcedureJunaid MateenNo ratings yet

- ClassNK - MEPC80 SummaryDocument5 pagesClassNK - MEPC80 SummaryPereira JenNo ratings yet

- WENZEL WayBeyondPetroleum 2015Document10 pagesWENZEL WayBeyondPetroleum 2015aesasportNo ratings yet

- Dismantling of BoilerDocument2 pagesDismantling of BoilerElie ShNo ratings yet

- Practical Power System Protection - Book ReviewDocument2 pagesPractical Power System Protection - Book Reviewحمزة الفيتوريNo ratings yet

- 1 PDFDocument2 pages1 PDFRandy MorcoNo ratings yet

- Vivek Pal-2Document36 pagesVivek Pal-2Vivek palNo ratings yet