Professional Documents

Culture Documents

Light Transmitting Cable Reg

Uploaded by

karunamoorthi_pCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Light Transmitting Cable Reg

Uploaded by

karunamoorthi_pCopyright:

Available Formats

International Journal On Engineering Technology and Sciences IJETS

ISSN (P): 2349-3968, ISSN (O): 2349-3976

Volume 2 Issue 4, April -2015

STUDY OF BEHAVIOUR OF LIGHT TRANSMITTING

CONCRETE USING OPTICAL FIBRE

Sathish Kumar V

Assistant Professor

Valliammai Engineering College

Mail id:sathishkumarcivil@yahoo.co.in

Suresh T

Final Year Student (Civil)

Valliammai Engineering College

Abstract Energy saving and safety evaluation are two key issues for infrastructure. In this paper, the concrete specimen is produced by

reinforcing Optical fibres with the different percentages and comparing it with the conventional concrete. Different tests were carried out on

the specimen like Compressive strength test, Split tensile strength, Intensity of light passing through it, etc. The experimental results show

than an optical fibre can be easily combined with concrete and it can provide a steady light transmitting ability. The compressive strength

results obtained for the specimen with the optical fibre was found to be higher strength as compared to the conventional concrete, which

clearly indicates that light transmitting concrete transmits light without affecting the strength of the concrete.

Index Terms Compressive strength, Light transmitting concrete, LDR, Optical fibre.

I. INTRODUCTION

II.

ungarian architect AronLosonczi was first introduced the

light transmitting concrete in 2001 at the Technical University

of Budapest and then successfully produced the first

transparent concrete block in 2003. LiTrancon (light

transmitting concrete) is also called as Translucent concrete.

It presents the concept of light transmitting concrete in the

form of applicable new building material. It can be used for

interior walls or exterior walls, decorative pavements or even

in design objects. By reinforcing the optical fibres in the

concrete, light can be transmitted from the one end to another

end of the fibre.

In this paper, the main purpose is to use sunlight as a

light source in order to reduce the power consumption,

because the brightness of indoor environment is entirely

created by artificial lighting which has consuming a large

amount of power supply. The mechanical performance like

compressive strength, Split tensile strength of light

transmitting concrete is compared with the conventional

concrete is also determined.

As references from literature review, the light transmitting

concrete with optical fibre has high strength than with the

glass rod in the concrete, hence we are preferred optical fibre

with different proportion based on the volume of the cube by

0.15%, 0.25%, 0.35%. The cube and cylinder mould used in

this project is standard size of 150mm*150mm and

150mmdia*300mm respectively.

The orientation of fibre in the cube plays a vital role in the

strength. In general, the orientation of fibre parallel to the load

has high strength than the fibre perpendicular to the load. The

testing is carried out in both orientations by fibre parallel to

the load and fibre perpendicular to the load.

We also used LDR (light dependent resistor) to measure the

intensity of light passing through the light transmitting

concrete. A Light-Dependent resistor is a light controlled

variable resistor. The resistance of a incident light intensity, in

other word, it exhibits photoconductivity. LDR is used to

measure the Light transmitting property of concrete.

MATERIALS AND ITS PROPERTIES

A. Cement

The type of cement used in this work is 53-grade OPC. The

specific gravity of the cement uses is 3.15 and its fineness

modulus of 2% which is less than the maximum value of 7%.

B. Fine Aggregate

Fine aggregate used in this project is having the specific

gravity of 2.65.The density of the fine aggregate is found to be

511.4 kg/m3. The zone of fine aggregate is determined by

sieve analysis. As per the Indian standards the zone obtained

is zone-II.

Table 1: Fineness modulus of fine aggregate

I.S. Sieve

% of passing as

% of passing

designation

per IS (zone II)

(obtained)

10mm

100

100

4.75mm

90-100

95.88

2.36mm

75-100

88.4

1.18mm

55-90

68.6

600 micron

35-59

35.7

300 micron

8-30

12.6

150 micron

0-10

4.0

C. Coarse Aggregate

Coarse aggregate having a size of 12mm were used. Its

specific gravity is 2.65 and its impact strength is 13.3%,

which is found to be satisfied as per Indian standards.

D. Optical Fibre

It is an optical fibre which is made out of plastic.

PMMA(acrylic) is the core material and fluorinated polymers

are the cladding materials. In large diameter fibre, 96% of its

cross section is the core that allows the transmission of light.

It is similar to the traditional glass fibre, POF transmit light

through the inner core of the fibre. The core size of POF is in

cases 100 times larger than glass fibre. The core has the higher

refractive index of 1.5 and its cladding having lower

refractive index of 1.4.

International Journal On Engineering Technology and Sciences IJETS

ISSN (P): 2349-3968, ISSN (O): 2349-3976

Volume 2 Issue 4, April -2015

Figure 3: Cube mould

V. TESTING OF CONCRETE

Figure 1: Optical fibre

The core and cladding layer are based upon Extremely pure

fused silica, which is a fibre glass which almost no impurities

which helps to very low loss for the long distance

transmission. Snells law guides how light travels at interface

of the core and the cladding (reflection and refraction).

III. MIX PROPORTION

Control mixture for M25 grade concrete was designed as

per IS:10262-2009. In this paper, we have four types of

concrete mixes namely CC, OFRC1, OFRC2 & OFRC3 with

different proportions of optical fibre say 0%,0.15%,0.25%

and 0.35% respectively were casted and cured with normal

water for 28 days. For each mix, we have prepared 6 numbers

of cubes and 3 numbers of cylinders were casted and tested.

Table 2: concrete mix proportion

Optical

Cement

F.A

C.A

Water

fibre

Specimen

(kg/m3)

CC

457.78

606.5

1032.7

206

Nil

OFRC1 457.75

606.5

1032.7

206

3.25

OFRC2 457.75

606.5

1032.7

206

5.33

OFRC3 457.75

606.5

1032.7

206

7.40

A. Compressive Strength

Compressive strength of concrete is carried out by

Compressive testing machine. It is known that concrete is

good in compression and weak in tension. The cubes were

tested by placing the cube with fibres parallel to load and

fibres perpendicular to load.

Table 3: 28th day compressive strength of concrete

Compressive

Compressive

Avg. Load

Avg. Load

Specimen

strength

strength

(KN)

(KN)

(N/mm2)

(N/mm2)

CC

594

26.4

Load Applied

Load Applied

Parallel to optical

Perpendicular to

fibre

optical fibre

OFRC1

639

28.4

616.9

27.42

OFRC2

730.5

32.47

637.6

28.34

OFRC3

718.8

31.93

653.1

29.03

IV. MOULD PREPARATION

To place the optical fibre like a reinforcement in the cube,

mould to be prepared by which the placing of optical fibre

work can be easily done while casting. In this work plastic

straws have been used to insert the optical fibres and then

removed as soon as the concrete is poured.

Figure 2: cylinder mould

Figure 4: 28th day compressive strength of OFRC

B. Split Tensile Strength

With the increase in technology in construction field many

innovative concrete have been developed such that the

concrete having the capacity to with stand more tensile

strength than its actual strength. By reinforcing optical fibre in

concrete the tensile nature of the concrete is also studied. The

formula for the calculating of tensile strength of concrete is

given below,

Tensile strength=

Table 4: 28th day Split tensile strength of concrete

Load

Tensile strength

Specimen

(kN)

(N/mm2)

CC

207.71

2.93

OFRC1

270.59

3.83

OFRC2

377.27

5.39

OFRC3

360.32

5.1

International Journal On Engineering Technology and Sciences IJETS

ISSN (P): 2349-3968, ISSN (O): 2349-3976

Volume 2 Issue 4, April -2015

VI. RESULTS AND DISCUSSIONS

1. The results obtained from the compressive test shows

that the increases in the compressive strength of the

concrete with reinforcement of optical fibre.

2. There is a gradual increase in the Mechanical

properties of the concrete by increasing the optical

fibre up to 0.25% and on further addition of the

optical fibre decreases the strength parameters.

3. Compressive strength of the concrete is higher in the

optical fibre parallel to the load applied than the

optical fibre perpendicular to the load applied.

4. Compressive strength of the concrete is increased by

22.99% of the normal concrete mix for 0.25% of

optical fibre (OFRC2).

5. The tensile strength of the concrete is increased by the

83.95% for the 0.25% of optical fibre (OFRC2).

6. Thus, the reinforcing of optical fibre will transmit

light and also eventually increases the strength of the

concrete.

Figure 5: Split tensile strength of concrete

C. Light Transmittance Test

The light transmittance ability of the specimens is tested by

an electrical circuit setup with an LDR. The light

transmittance through the sample can be measured by

measuring the current corresponding to the light which can be

measured by the LDR. From the circuit setup, we are taking

two reading from ammeter, one without sample (A1), and one

with sample (A2). The source of light used is taken as 40w

incandescent bulb, a resistance of 100 is applied in the

circuit setup and uniform DC voltage of 10V is kept between

the circuits.

REFERENCES

[1]

[2]

[3]

[4]

Figure 6: Electrical setup

[5]

Figure 7: Experimental work

( 40w incandescent bulb placed over specimen)

Table 5: Test results for light transmittance

Specimen

Optical fibre specimen

OFRC1 OFRC2 OFRC3

Ammeter

Without

24.4

24.4

24.4

Reading

Sample

(Ma)

(A1)

With

3.8

4.2

4.5

sample

(A2)

Light Transmittance

15.57

17.21

18.45

=100-((A1-A2)/A1)*100%

Basma F. Bashbash (2013) paper on Basics of light Transmitting

Concrete, (2013)

AkshayaB.KAmdi, paper on Transparent concrete as a Green Material

For Building, ISSN2319-6009.Volu 2, No.3, August 2013.

BhavinK.Kashiyani, et.al A Study on Transparent Concrete: A Novel

Architectural Material to Explore Construction Sector IJEIT.

M.N.V. Padma Bhushan et.al Optical fibre in the modelling of

translucent concrete blocks, ISSN: 2248-9622.Vol.3, Issue 3,

May-June 2013.

Soumyajit Paul and AVikDutta Translucent Concrete IJSRP, vol. 3,

Issue 10, October 2013.

You might also like

- Light Transmitting ConcreteDocument29 pagesLight Transmitting ConcreteAnvesh Jakke67% (3)

- Light Transmitting ConcreteDocument14 pagesLight Transmitting ConcreteAchmad Zultan MansurNo ratings yet

- Experimental Study on Light Transmitting Concrete Using Optical FibersDocument9 pagesExperimental Study on Light Transmitting Concrete Using Optical FiberssaikirankasivojjulaNo ratings yet

- 5919 English PDFDocument5 pages5919 English PDFBEYENA GEDEFANo ratings yet

- Seminar Report on Light Transmitting ConcreteDocument45 pagesSeminar Report on Light Transmitting ConcreteJyothsnaNo ratings yet

- Beginner GuideDocument39 pagesBeginner GuideKaustav SahaNo ratings yet

- Transparent Concr TeDocument10 pagesTransparent Concr TeAbhijeeth NagarajNo ratings yet

- Transparent (Light Transmitting) ConcreteDocument3 pagesTransparent (Light Transmitting) Concretevenkateswara rao PothinaNo ratings yet

- UV Mapping GamesDocument5 pagesUV Mapping GamesPrem MoraesNo ratings yet

- Connecting DevicesDocument30 pagesConnecting Devicesdavid seaNo ratings yet

- Glass Reinfored Concrete El Cezeri January 2018Document28 pagesGlass Reinfored Concrete El Cezeri January 2018Wail Zineddine DAHMANENo ratings yet

- Noise Control of Buildings 1Document23 pagesNoise Control of Buildings 1Naveed BNo ratings yet

- Refactoring Application Architecture A Complete Guide - 2019 EditionFrom EverandRefactoring Application Architecture A Complete Guide - 2019 EditionNo ratings yet

- Morgan Kaufmann - Advanced Renderman - Creating Cgi For Motion PicturesDocument441 pagesMorgan Kaufmann - Advanced Renderman - Creating Cgi For Motion Picturesdsads100% (1)

- Sheet Lamination Additive ManufacturingDocument2 pagesSheet Lamination Additive ManufacturingYeabsraNo ratings yet

- LUCEM PlannimailDocument44 pagesLUCEM PlannimailAyashkanta RoutNo ratings yet

- Light Transmitting ConcreteDocument19 pagesLight Transmitting ConcreteSurabhi AnandNo ratings yet

- Basalt Fiber Reinforced Polymer CompositesDocument143 pagesBasalt Fiber Reinforced Polymer Compositesmseymour91100% (1)

- Study of Transparent ConcreteDocument17 pagesStudy of Transparent ConcreteIrfan KhanNo ratings yet

- Study of Transparent Concrete: Presented ByDocument17 pagesStudy of Transparent Concrete: Presented ByGaurav JainNo ratings yet

- Reallusion IClone Pro 6.51.3127Document7 pagesReallusion IClone Pro 6.51.3127AgustinZavaletaNo ratings yet

- Mastering D3.js Sample ChapterDocument20 pagesMastering D3.js Sample ChapterPackt PublishingNo ratings yet

- 4A High Strength Concrete HandoutDocument2 pages4A High Strength Concrete HandoutNathanniel Pogado GonzalesNo ratings yet

- Optical FiberDocument43 pagesOptical FiberPrema Kumar GaddayiNo ratings yet

- Mit PDFDocument80 pagesMit PDFHIRA SHABBIRNo ratings yet

- 3d Printing-With-Biomaterials Web PDFDocument89 pages3d Printing-With-Biomaterials Web PDFAlexi WiedemannNo ratings yet

- Graphene Material Properties & ApplicationsDocument16 pagesGraphene Material Properties & ApplicationsRajveer SinghNo ratings yet

- Crush Tester (RCT Ect FCT Pat)Document1 pageCrush Tester (RCT Ect FCT Pat)Rohit ChawlaNo ratings yet

- Solr ArchitectureDocument2 pagesSolr ArchitectureKothapally AnithaNo ratings yet

- Study On Properties of Concrete Using Rice Husk Ash and Fly Ash With Sisal Fiber As Partial Replacement of Fine Aggregate and Cement A ReviewDocument13 pagesStudy On Properties of Concrete Using Rice Husk Ash and Fly Ash With Sisal Fiber As Partial Replacement of Fine Aggregate and Cement A ReviewEditor IJTSRDNo ratings yet

- Translucent ConcreteDocument22 pagesTranslucent ConcreteRicha ShahNo ratings yet

- Boe Linien en 090616onlinedoppelseite PDFDocument19 pagesBoe Linien en 090616onlinedoppelseite PDFxavicojmNo ratings yet

- Ncurses Programming HowtoDocument100 pagesNcurses Programming HowtoLinuxman RjNo ratings yet

- Direct3D OverviewsDocument84 pagesDirect3D OverviewsferretchromosomeNo ratings yet

- Nanocellulose Film ProductionDocument1 pageNanocellulose Film ProductiongoldennanukNo ratings yet

- Fly Ash-Based Geopolymer ConcreteDocument10 pagesFly Ash-Based Geopolymer ConcreteUpadesh ShresthaNo ratings yet

- Versatile Industrial Mineral WollastoniteDocument2 pagesVersatile Industrial Mineral Wollastonitemujib uddin siddiqui100% (1)

- Rsumners PDFDocument12 pagesRsumners PDFSaloni guptaNo ratings yet

- Innovation in Civil Engineering 369Document20 pagesInnovation in Civil Engineering 369talatzahoorNo ratings yet

- Final PPT LITRACONDocument15 pagesFinal PPT LITRACONRAmyaNo ratings yet

- GameSalad ManualDocument43 pagesGameSalad ManualAkmal Sandi B ZakeriaNo ratings yet

- BISCO Material Selection Guide PDFDocument9 pagesBISCO Material Selection Guide PDFAmir Hooshang Ghadymi MahaniNo ratings yet

- Autogenous Shrinkage of ConcreteDocument197 pagesAutogenous Shrinkage of ConcreteraviupparNo ratings yet

- CLC CostingDocument34 pagesCLC CostingpipestressNo ratings yet

- Jaycar 2020 Catalogue AU PDFDocument548 pagesJaycar 2020 Catalogue AU PDFSteveMate100% (1)

- Acc BlocksDocument14 pagesAcc BlocksAbdul RehamanNo ratings yet

- (Re - Work) One Simple Thing Worksheet PDFDocument1 page(Re - Work) One Simple Thing Worksheet PDFChris SantosNo ratings yet

- Metamerism and IlluminantsDocument6 pagesMetamerism and IlluminantsAshraf AliNo ratings yet

- All Product Brochure 360 BrochureDocument20 pagesAll Product Brochure 360 BrochureBryon ChenNo ratings yet

- Matlab ImagenesDocument766 pagesMatlab ImagenesRicardo Rodriguez OrtegaNo ratings yet

- Smart Materials and Its ApplicationsDocument44 pagesSmart Materials and Its ApplicationsAjay AjaiNo ratings yet

- Mini Project Final ReviewDocument19 pagesMini Project Final Reviewjagandas chouhanNo ratings yet

- 4D Printing: Self-Assembly & Programmable MatterDocument18 pages4D Printing: Self-Assembly & Programmable MatterAnonymous iI88LtNo ratings yet

- CONCRETE REPAIR MATERIALS AND TECHNIQUESDocument72 pagesCONCRETE REPAIR MATERIALS AND TECHNIQUESNiranjan Shuttler CrazeNo ratings yet

- An Investigation Into The Effect of Rice Husk ASh On Mortar When Added in Varying Proportions - Andrew WoodDocument73 pagesAn Investigation Into The Effect of Rice Husk ASh On Mortar When Added in Varying Proportions - Andrew WoodNarayan Singhania100% (1)

- Beginning PBR Texturing: Learn Physically Based Rendering with Allegorithmic’s Substance PainterFrom EverandBeginning PBR Texturing: Learn Physically Based Rendering with Allegorithmic’s Substance PainterNo ratings yet

- Non-Autoclaved Aerated Concrete (NAAC) Blocks: An Alternative Building Construction MaterialDocument5 pagesNon-Autoclaved Aerated Concrete (NAAC) Blocks: An Alternative Building Construction MaterialIJRASETPublicationsNo ratings yet

- 5-Axis 3D Printer - The Latest Advancements - All3DPDocument12 pages5-Axis 3D Printer - The Latest Advancements - All3DPHeart SoulNo ratings yet

- Powerful mantras for money, health, love and moreDocument10 pagesPowerful mantras for money, health, love and morekarunamoorthi_p100% (2)

- BOGARDocument1 pageBOGARkarunamoorthi_pNo ratings yet

- Dwadasi ThithiDocument170 pagesDwadasi Thithikarunamoorthi_pNo ratings yet

- O - I - I/ Price List Ot, L/RV) LGN Ctnu JTL N: RS (Is 8887:1995Document2 pagesO - I - I/ Price List Ot, L/RV) LGN Ctnu JTL N: RS (Is 8887:1995karunamoorthi_pNo ratings yet

- Irc - Gov.in - sp.021.2009 Guidelines On Landscaping & Tree PlantationDocument90 pagesIrc - Gov.in - sp.021.2009 Guidelines On Landscaping & Tree Plantationkarunamoorthi_p63% (8)

- Faridabad-Demolition-Order Supreme Court Order For Shrines, Temples Shops Etc.Document11 pagesFaridabad-Demolition-Order Supreme Court Order For Shrines, Temples Shops Etc.karunamoorthi_pNo ratings yet

- All Products Vat Revised From 4% To 5% W.E.F 12.07.2011: Ref:Cs/RateDocument1 pageAll Products Vat Revised From 4% To 5% W.E.F 12.07.2011: Ref:Cs/Ratekarunamoorthi_pNo ratings yet

- Price List: RS (IS 8887:1995) Bulk R/C Drums Hdpe Drums New DrumsDocument1 pagePrice List: RS (IS 8887:1995) Bulk R/C Drums Hdpe Drums New Drumskarunamoorthi_pNo ratings yet

- Bitumen & Emulsion RateDocument4 pagesBitumen & Emulsion Ratekarunamoorthi_pNo ratings yet

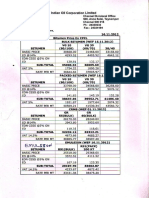

- IOCL Chennai Divisional Office announces bitumen pricesDocument3 pagesIOCL Chennai Divisional Office announces bitumen priceskarunamoorthi_pNo ratings yet

- Om Namo Bhimasyaa Amuk Grahe Uchchatan Kuru Kuru Swaha LLDocument2 pagesOm Namo Bhimasyaa Amuk Grahe Uchchatan Kuru Kuru Swaha LLkarunamoorthi_pNo ratings yet

- Hindustan Colas Price List for Contractors RS, MS, SS Bitumen GradesDocument1 pageHindustan Colas Price List for Contractors RS, MS, SS Bitumen Gradeskarunamoorthi_pNo ratings yet

- Collated Tables of MoRT&H (5th Revision) Sections 100-3100Document72 pagesCollated Tables of MoRT&H (5th Revision) Sections 100-3100karunamoorthi_pNo ratings yet

- G.O of Power of TS G.O.ms - No. 80highways (HN 1) Department DT 28.03.2007Document3 pagesG.O of Power of TS G.O.ms - No. 80highways (HN 1) Department DT 28.03.2007karunamoorthi_pNo ratings yet

- PBH Health Benefit ReviewDocument32 pagesPBH Health Benefit Reviewkarunamoorthi_pNo ratings yet

- TN Highways Manual - Volume - 4-2 With IndexDocument233 pagesTN Highways Manual - Volume - 4-2 With Indexkarunamoorthi_p50% (2)

- Ration Card Application Form For The State of Tamil Nadu, IndiaDocument2 pagesRation Card Application Form For The State of Tamil Nadu, IndiaN Rakesh90% (10)

- Irc 67 - 2012Document121 pagesIrc 67 - 2012Rajneesh Chaturvedi63% (8)

- Girish Deshpande V CIC - Income Details RTIDocument13 pagesGirish Deshpande V CIC - Income Details RTISCOIBlogNo ratings yet

- Manmatha Varusha Panchangam2015-2016Document18 pagesManmatha Varusha Panchangam2015-2016shganesh81No ratings yet

- 2015 Calender EnglishDocument4 pages2015 Calender EnglishBawani BalachandranNo ratings yet

- (Milestones in Drug Therapy) - Indacaterol - The First Once-Daily Long-Acting Beta2 Agonist For COPD, 2014 Edition (PDF) (DR - Carson) VRGDocument150 pages(Milestones in Drug Therapy) - Indacaterol - The First Once-Daily Long-Acting Beta2 Agonist For COPD, 2014 Edition (PDF) (DR - Carson) VRGkarunamoorthi_pNo ratings yet

- Practical English 1000 Most Effective Words PDFDocument353 pagesPractical English 1000 Most Effective Words PDFJojo Leaon100% (1)

- Nutrition in Old AgeDocument16 pagesNutrition in Old Agekarunamoorthi_p100% (1)

- Guidelines For Music Therapy Practice in Adult Medical CareDocument400 pagesGuidelines For Music Therapy Practice in Adult Medical Carekarunamoorthi_p100% (13)

- Union of India Vs State of Gujarat & Ors On 29 September, 2009Document3 pagesUnion of India Vs State of Gujarat & Ors On 29 September, 2009karunamoorthi_pNo ratings yet

- Bitumen Rates-01 (1) .07.2010Document1 pageBitumen Rates-01 (1) .07.2010karunamoorthi_pNo ratings yet

- Ready ReckonerDocument36 pagesReady Reckonerkarunamoorthi_pNo ratings yet

- Chem 137.1 - Exer 1 PostlabDocument15 pagesChem 137.1 - Exer 1 PostlabGerry Mark Gubantes100% (1)

- 2005.00305v3 - Defocus Deblurring Using Dual-Pixel DataDocument27 pages2005.00305v3 - Defocus Deblurring Using Dual-Pixel DatageilsonNo ratings yet

- Apostila PDFDocument143 pagesApostila PDFDandaraNo ratings yet

- Tutorial Test 3 QPDocument3 pagesTutorial Test 3 QPMohan Kumar100% (1)

- Dispersion Problems (8.1) : Fiber-Optic Communication Systems, Govind P AgrawalDocument6 pagesDispersion Problems (8.1) : Fiber-Optic Communication Systems, Govind P AgrawalPallaviNo ratings yet

- CC12 enDocument76 pagesCC12 enemadhsobhyNo ratings yet

- Index of Refraction: OutlineDocument22 pagesIndex of Refraction: OutlineaqsaehsanNo ratings yet

- Skema Fizik Kertas 3 Trial PerlisDocument9 pagesSkema Fizik Kertas 3 Trial PerlissadyehclenNo ratings yet

- Applied PhysicsDocument2 pagesApplied Physicsanil.gNo ratings yet

- Physics Investigatory ProjectDocument13 pagesPhysics Investigatory ProjectAnonymous 125GjEaNo ratings yet

- 1st Year Physics Notes Chap05Document15 pages1st Year Physics Notes Chap05phoool83% (6)

- D. TrueDocument11 pagesD. TruepetriNo ratings yet

- CVD Diamond BookletDocument28 pagesCVD Diamond BookletАндрей ВольхинNo ratings yet

- Interference Tutorial Sheet SolutionsDocument7 pagesInterference Tutorial Sheet SolutionsPranav RawatNo ratings yet

- 35 Modern-Wave Particle DualityDocument4 pages35 Modern-Wave Particle DualityeltytanNo ratings yet

- Mechanical Technology A Two Year Course PDFDocument573 pagesMechanical Technology A Two Year Course PDFNurul LatifahNo ratings yet

- Cells and Microscopes. Ms CooperDocument33 pagesCells and Microscopes. Ms CooperzeeNo ratings yet

- Physics For Engineers Laboratory ExperimentDocument11 pagesPhysics For Engineers Laboratory ExperimentChristian Nathaniel Ramon PalmaNo ratings yet

- Double Beam UV Vis Spectrophotometer LUS B12Document3 pagesDouble Beam UV Vis Spectrophotometer LUS B12cheeputNo ratings yet

- Carl Zeiss, Jena: THE Firm OFDocument1 pageCarl Zeiss, Jena: THE Firm OFAlexNo ratings yet

- Principles of NanometrologyDocument33 pagesPrinciples of NanometrologysahilmirNo ratings yet

- 937 Anatomy of The EyeDocument34 pages937 Anatomy of The EyeThariqNo ratings yet

- Electric Potential PDFDocument31 pagesElectric Potential PDFEka NurbaizuraNo ratings yet

- Wavelength SVDocument4 pagesWavelength SVAlexis MUHIRWANo ratings yet

- PH8151 - Engineering PhysicsDocument3 pagesPH8151 - Engineering PhysicsK.GAYATHRINo ratings yet

- LDLS Selection Guide Lasing 2Document1 pageLDLS Selection Guide Lasing 2valerioloNo ratings yet

- To Russia With LoveDocument280 pagesTo Russia With LoveAnonymous yu09qxYCM100% (1)

- Digital Image ProcessingDocument33 pagesDigital Image Processingapi-19658682No ratings yet

- Magnetic and Electromagnetic: Dr. Mohd Irfan Hatim Mohamed DzahirDocument72 pagesMagnetic and Electromagnetic: Dr. Mohd Irfan Hatim Mohamed DzahirAbdirahman Elmi GurreNo ratings yet

- The Physics of Light ProductionDocument5 pagesThe Physics of Light ProductionJoshua OneillNo ratings yet