Professional Documents

Culture Documents

ACI 222.1-96 Test Method For Water Soluble Chloride PDF

Uploaded by

Ahmad ZaidOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

ACI 222.1-96 Test Method For Water Soluble Chloride PDF

Uploaded by

Ahmad ZaidCopyright:

Available Formats

TEST METHOD FOR WATER-SOLUBLE CHLORIDE

222.1-1

ACI 222.1-96

Provisional Standard Test Method for

Water-Soluble Chloride Available for

Corrosion of Embedded Steel in Mortar

and Concrete Using the Soxhlet Extractor

Reported by ACI Committee 222

Some water-soluble chlorides, primarily in certain aggregates, do not induce corrosion of

embedded reinforcing steel since these chlorides are bound within the aggregate. Currently,

available test methods cannot distinguish between the water-soluble chlorides that support

corrosion and those that do not. This test method detects only water-soluble chlorides that

contribute to the corrosion of the reinforcing steel.

Keywords: Water-soluble chlorides; corrosion; steel; mortar; concrete; Soxhlet Extractor.

ACI COMMITTEE 222

Corrosion of Metals in Concrete

Brian B. Hope

Keith A. Pashina

Chairman

Secretary

John P. Broomfield

Kenneth C. Clear

James R. Clifton

Israel Cornet

Marwan Daye

Bernard Erlin

John K. Grant

Kenneth C. Hover

Bret James

Thomas D. Joseph

David G. Manning

Walter J. McCoy

Theodore L. Neff

Charles K. Nmai

William F. Perenchio

Randall W. Poston

Robert E. Price

D. V. Reddy

William T. Scannell

David C. Stark

Wayne J. Swiat

Thomas G. Weil

Richard E. Weyers

David A. Whiting

Stephen L. Amey

Steven F. Dailey

Stephen D. Disch

Hamad Farzam

Per Fidjestol

Rodney R. Gerard

Michael P. Gillen

Associate Members

Odd E. Gjorv

Clayford T. Grimm

Alan K. C. Ip

Andrew Kaminker

Mohammad S. Khan

Philip J. Leclaire

Joseph A. Lehmann

Mohamad A. Nagi

Morris Schupack

Ephraim Senbetta

Robert E. Shewmaker

Bruce A. Suprenant

William F. Van Sisseren

Michael C. Wallrap

Provisional Standards provide temporary standards

to expedite development and updating of Codes,

Code Cases, or Specifications. Provisional Standards are required due to emergency conditions,

regulatory changes, special circumstances, or technology development.

Copyright (c) 1997, American Concrete Institute. All rights reserved including

rights of reproduction and use in any form or by any means, including the making of

copies by any photo process, or by any electronic or mechanical device, printed or

written or oral, or recording for sound or visual reproduction or for use in any knowledge of retrieval system or device, unless permission in writing is obtained from the

--``,`,,,`,```,,,,,``,,,```,```-`-`,,`,,`,`,,`--copyright proprietors.

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=AL UMAIR, OMAR

222.1-1

Not for Resale, 06/13/2007 06:10:16 MDT

222R-2

ACI PROVISIONAL STANDARD

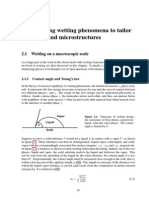

Fig. A1Soxhlet extraction apparatus

1Scope

1.1This test method provides procedures for the sampling and analysis of hydraulic-cement mortar, concrete, or

aggregate for chloride that is water-soluble and available for

the corrosion reaction under the conditions of the test.

1.2This test method does not purport to address all of

the safety problems, if any, associated with its use. It is the

responsibility of the user of this test method to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

2Significance and Use

2.1Water-soluble chloride, when present in sufficient

amounts, may initiate or accelerate the corrosion of metals

such as steel embedded in or contacting a cement system

such as mortar, grout, or concrete. Other test methods exist

for the determination of water-soluble chloride in a cement

system.* However, some aggregates contain a considerable

amount of chloride that is bound in the aggregate and is not

available for the corrosion reaction. The test method described in ASTM C 1218 measures a portion of the chloride

contained in these aggregates. However, the amount of chloride

*ASTM Standard Test Method C 1218-92, Standard Test Method for Water-Soluble

Chloride in Mortar and Concrete.

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

3Apparatus

3.1Sampling equipment: The apparatus required for obtaining samples by coring or sawing is described in ASTM C

42. Sampling by drilling is not applicable for this test and

shall not be used.

3.2Sample processing apparatus:

3.2.1 Samples too large to fit in the sample holder of the

Soxhlet shall be reduced in size by means of a jaw crusher or

by hammering.

3.2.2 Extract chlorides from the sample using a Soxhlet extractor, a schematic of which is shown in Fig. A1. The Soxhlet

extractor consists of a heater, a lower flask to hold water, the

sample compartment, and a condenser. The extractor contains

approximately 100 ml of distilled water in the lower flask. Heat

is applied to this flask; vapor from the boiling water passes to

the condenser; and the condensate collects in the sample compartment. The sample is contained in a porous holder and the

hot condensate collects around the sample. When the condensate reaches a critical height, the liquid is siphoned back into the

lower flask and the process repeats. The nonvolatile components extracted from the sample accumulate in the lower flask,

while each extraction involves fresh hot distillate. The heat input shall be sufficient to give an extraction cycle about every 20

min. For convenience, suitable commercial equipment is available.**

4Reagents

4.1The reagents required for the chloride determination

are given in the test method for chloride of ASTM C 114.

5 Sampling

5.1Reduce the size of a minimum 300 gm sample as

specified in Section 6, and divide this sample to a minimum 30 gm representative sample for use in the chloride

For more information see The Determination of the Chloride Content of Concrete

by Brian B. Hope, John A. Page, and John S. Poland, Cement and Concrete Research, V. 15,

No. 5, Pergamon Press, New York, Sept. 1985, pp. 863-870.

ASTM Test Method C 114, Test Methods for Chemical Analysis of Hydraulic Cement.

ASTM C 42, Test Method for Obtaining and Testing Drilled Cores and Sawn

Beams of Concrete.

**Suitable Soxhlet extraction equipment is available from Fisher Scientific (Catalog

No. 09-551A) and other manufacturers.

Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=AL UMAIR, OMAR

Not for Resale, 06/13/2007 06:10:16 MDT

--``,`,,,`,```,,,,,``,,,```,```-`-`,,`,,`,`,,`---

measured is very dependent on the degree of fineness to

which the aggregates are ground during sample preparation.

The problem with the ASTM C 1218 test method is therefore

twofold: the test measures chlorides that are not generally

available for the corrosion reaction, and the test gives widely

variable results. The test method described herein should be

used when chloride-bearing aggregates influence the results

obtained using ASTM C 1218.

2.2Sulfides are known to interfere with the determination of chloride content. Blast-furnace slag aggregates

and cement contain sulfide sulfur in concentrations high

enough to cause significant interference and produce erroneous test results. Treatment with hydrogen peroxide,

as discussed in ASTM C 114, shall be used to eliminate

such interference.

TEST METHOD FOR WATER-SOLUBLE CHLORIDE

determination. If the sample is taken from concrete or

mortar then the concrete or mortar shall be at least 7 days

old before sampling.

Note 1Concrete cores taken in accordance with ASTM

C 42 or concrete cylinders cast from the proposed mix may

be cut longitudinally or laterally to provide the required 300

gm sample representative of the core or cylinder. Experience

has shown that the cooling water from core cutting will not

dissolve a significant amount of chloride.

6 Sample Preparation

6.1Using the jaw crusher or hammer, reduce the sample

so that it fits the sample holder using the minimum crushing necessary. The sample shall not be crushed to a powder since this would release chloride bound in some

aggregates which, as previously discussed, are known to

not contribute to corrosion.

a 250 ml conical flask. Add 3 drops of methyl orange indicator (prepared in accordance with ASTM C 114) and add dilute (1+1) nitric acid until the solution is acidified. Add 3.0

0.1 ml of hydrogen peroxide (30 percent solution) to the

solution. Proceed in accordance with the reference ASTM

C 114, starting with the procedure specified in Section

19.5.3 and continuing to the end of Section 19.5.8.

7.2.3 Make a blank determination by using the Soxhlet,

complete with thimble and glass wool, but containing no

sample of cementitious material.

8Calculation

8.1Calculate percent of chloride to the nearest 0.001

percent as the average chloride content of the triplicate samples,

each calculated as follows

N 500

Chloride, percent = 3.5453 ( V 1 V b ) ----- --------M V2

Copyright American Concrete Institute

Provided by IHS under license with ACI

No reproduction or networking permitted without license from IHS

(1)

where

V1 = ml of 0.05 N AgNO3 solution used for titration of

the sample (equivalence point)

Vb = mlof 0.05 N AgNO3 solution used for titration of

the blank (equivalence point)

N = normality of 0.05 N AgNO3 solution, calculated to

0.001

M = mass of concrete or mortar sample, g

V2 = volume of the 25 ml aliquot determined to 0.1 ml

(larger or smaller aliquots may be used depending on the

chloride concentrations present)

8.2Sufficient data are not available at this time to provide precision and bias statements.

--``,`,,,`,```,,,,,``,,,```,```-`-`,,`,,`,`,,`---

7Procedure

7.1A single test shall consist of determination of chloride contents of three individual 30 gm samples.

7.2Weigh each sample (30 g 5 g) to the nearest 0.01 g

and place in the porous sample holder of a Soxhlet extractor.

Add a wad of glass wool. Place approximately 100 ml of deionized water in the lower flask.

7.2.1 Assemble the condenser complete with cooling water supply pipes to the extractor and place on the heater. Turn

on both the heater and condenser cooling water and allow extraction to continue for 24 hr; adjust the heating rate to give

a cycle about every 20 min.

7.2.2 At the conclusion of the extraction stage, transfer the

solution to a 500 ml volumetric flask. Rinse the Soxhlet flask

three times with distilled water, transferring the washings to

the 500 ml volumetric flask; add distilled water to produce a

volume of 500 ml. With a pipette transfer a 25 ml aliquot to

222.1-3

Licensee=Fluor Corp no FPPPV per administrator /2110503106, User=AL UMAIR, OMAR

Not for Resale, 06/13/2007 06:10:16 MDT

You might also like

- AISC - Structral Steel ConnectionsDocument45 pagesAISC - Structral Steel ConnectionsHan Koko100% (10)

- Analysis of subcellular components experiment 1Document31 pagesAnalysis of subcellular components experiment 1eli pascualNo ratings yet

- How To Calculate Bearing Capacity of Soil From Plate Load TestDocument5 pagesHow To Calculate Bearing Capacity of Soil From Plate Load TestDEBOPRASAD BISWASNo ratings yet

- SP-1246 1Document31 pagesSP-1246 1Ahmad Zaid75% (4)

- ACI 334.1R-92 (R 2002) Concrete Shell Structures PDFDocument10 pagesACI 334.1R-92 (R 2002) Concrete Shell Structures PDFAhmad ZaidNo ratings yet

- ASTM C 204 Standard Test Method For Fineness of Hydraulic Cement by Air-Permeability Apparatus AADocument8 pagesASTM C 204 Standard Test Method For Fineness of Hydraulic Cement by Air-Permeability Apparatus AARyan LasacaNo ratings yet

- Half Cell Potential PDFDocument11 pagesHalf Cell Potential PDFCitiux CitiuxNo ratings yet

- Service Life DesignDocument16 pagesService Life Designapi-3766593No ratings yet

- PE Laboratory OverviewDocument50 pagesPE Laboratory Overviewsexyrusty100% (1)

- Aashto T-47Document3 pagesAashto T-47renzoNo ratings yet

- CALICUT UNIVERSITY M.SC PHYSICS NOTES - SEMESTER 3 - DIELECTRICS - JOYAL (STC)Document27 pagesCALICUT UNIVERSITY M.SC PHYSICS NOTES - SEMESTER 3 - DIELECTRICS - JOYAL (STC)Joyal Jain0% (2)

- ACI 303.1-97 Specification For Cast-in-Place Architectural Concrete PDFDocument10 pagesACI 303.1-97 Specification For Cast-in-Place Architectural Concrete PDFAhmad ZaidNo ratings yet

- Liquid Fuel Requirements For Ge Aeroderivative Gas TurbinesDocument5 pagesLiquid Fuel Requirements For Ge Aeroderivative Gas TurbinesMohammed ElarbedNo ratings yet

- Concrete Repair Terminology: (Extracted From Published by International Concrete Repair Institute, USA)Document53 pagesConcrete Repair Terminology: (Extracted From Published by International Concrete Repair Institute, USA)bvsubramanyamNo ratings yet

- C 1252 PDFDocument5 pagesC 1252 PDFAgatha ShirleyNo ratings yet

- Autogenous Self-Healing of ConcreteDocument23 pagesAutogenous Self-Healing of Concreteanon_650335530No ratings yet

- ASTM C110 - Ensaios Físicos Da Cal VirgemDocument25 pagesASTM C110 - Ensaios Físicos Da Cal VirgemThamirisAgmNo ratings yet

- Astm A615m PDFDocument12 pagesAstm A615m PDFAnonymous q8HhQ4w50% (2)

- Seismic Behaviour of Elevated Water TankDocument5 pagesSeismic Behaviour of Elevated Water TankFrederick TanNo ratings yet

- 2000 CALTRANS Bridge Design SpecificationsDocument14 pages2000 CALTRANS Bridge Design Specificationsrhonald2000No ratings yet

- Durability Test Methods For Service Life Design of Concrete Structures - Exposed To Coastal EnvironmentDocument13 pagesDurability Test Methods For Service Life Design of Concrete Structures - Exposed To Coastal EnvironmentBenharzallah KrobbaNo ratings yet

- Formulas para SpaDocument41 pagesFormulas para Spaeduardo100% (1)

- Norma Astm C33Document11 pagesNorma Astm C33EliasTalaAllcaNo ratings yet

- C76M 14Document11 pagesC76M 14diego rodriguezNo ratings yet

- Midlebrooks, T. & Bertram, G. (1942) - Soil Test For Design of Runway PavementsDocument42 pagesMidlebrooks, T. & Bertram, G. (1942) - Soil Test For Design of Runway PavementsRodrigo DíazNo ratings yet

- MicroencapsultionDocument20 pagesMicroencapsultionRaghuveer BheemshettyNo ratings yet

- Aashto M 6-13Document5 pagesAashto M 6-13Abu Alhassan A.No ratings yet

- Foundation Design and Construction in Hong KongDocument20 pagesFoundation Design and Construction in Hong KongXet Fat100% (1)

- SAES-H-002V Approved Saudi Aramco Data Sheets For The Pipeline Maintenance External Coatings PDFDocument23 pagesSAES-H-002V Approved Saudi Aramco Data Sheets For The Pipeline Maintenance External Coatings PDFAhmad Zaid33% (3)

- C 33 - 03 QZMZ PDFDocument11 pagesC 33 - 03 QZMZ PDFwafikmh4No ratings yet

- Fluid Loss of Clay Component of Geosynthetic Clay Liners: Standard Test Method ForDocument3 pagesFluid Loss of Clay Component of Geosynthetic Clay Liners: Standard Test Method ForDanZel DanNo ratings yet

- Vibration Standards For Different CountriesDocument7 pagesVibration Standards For Different CountriesNalla PerumalNo ratings yet

- Astm C143 C143MDocument4 pagesAstm C143 C143MhavalNo ratings yet

- Aci 209 R21Document44 pagesAci 209 R21Hao LuoNo ratings yet

- Schmidt Hammer Testing GuideDocument6 pagesSchmidt Hammer Testing Guideကိုနေဝင်းNo ratings yet

- Evavluation of The ..... Resilent ModulusDocument9 pagesEvavluation of The ..... Resilent ModulusAna Beatriz Postigo FarfanNo ratings yet

- c187 Normal ConsistencyDocument2 pagesc187 Normal ConsistencyJoshua Ian Gallardo Aban100% (1)

- Time of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForDocument3 pagesTime of Setting of Hydraulic Cement by Vicat Needle: Standard Test Method ForNazmus SakibNo ratings yet

- C869 1613807-1 PDFDocument2 pagesC869 1613807-1 PDFZiah KenNo ratings yet

- Design Calculation of Pc. Spun Pile: Specification ADocument3 pagesDesign Calculation of Pc. Spun Pile: Specification Aarsiteka binanusaNo ratings yet

- Astm D 1854 PDFDocument3 pagesAstm D 1854 PDFJohn Errol Saldevar MarcosNo ratings yet

- ASTM Standards for Corrosion, Erosion and Embrittlement TestingDocument3 pagesASTM Standards for Corrosion, Erosion and Embrittlement Testingabet_singkong8930No ratings yet

- Precast Corbel Design SpreadsheetDocument6 pagesPrecast Corbel Design SpreadsheetmukhleshNo ratings yet

- Monitoring Methods of Concrete From Early Age Strength Gain of Concrete A ReviewDocument8 pagesMonitoring Methods of Concrete From Early Age Strength Gain of Concrete A ReviewAmit Sharma IPS AcademyNo ratings yet

- rx087 PDFDocument21 pagesrx087 PDFYinna RuizNo ratings yet

- Model For Indirect Determination of The Tensile Stree-Strain Curve Carmona2012Document13 pagesModel For Indirect Determination of The Tensile Stree-Strain Curve Carmona2012MICHAEL MWONGANo ratings yet

- Astm d1752Document2 pagesAstm d1752Whitebeard RagnarokNo ratings yet

- D43 PDFDocument2 pagesD43 PDFArnold RojasNo ratings yet

- Astm D-5239 PDFDocument3 pagesAstm D-5239 PDFgtorrentes1No ratings yet

- Effect of Aggregate Gradations on Porous Friction Course Mix PropertiesDocument13 pagesEffect of Aggregate Gradations on Porous Friction Course Mix PropertiesBen Mur MarNo ratings yet

- D946D946M 15.pdf (EngPedia - Ir)Document2 pagesD946D946M 15.pdf (EngPedia - Ir)Baba Mountain Gem ServicesNo ratings yet

- FerrocementDocument25 pagesFerrocementAnonymous xC6bM4x6U6No ratings yet

- Assignment-2 Shear StrengthDocument3 pagesAssignment-2 Shear StrengthRabindraSubediNo ratings yet

- Section 5 Pedestal Axial Load Test: PurposeDocument1 pageSection 5 Pedestal Axial Load Test: PurposeSyerifaizal Hj. MustaphaNo ratings yet

- Astm C-88Document5 pagesAstm C-88Fernanda MenesesNo ratings yet

- 6 ASTM C138 Density Yield Air ContentDocument4 pages6 ASTM C138 Density Yield Air Contentdidavaran tejaratNo ratings yet

- Guidelines For The Design of Sediment ContainmentDocument10 pagesGuidelines For The Design of Sediment ContainmentBudi NadatamaNo ratings yet

- Plate Load Test: Principles and Case Histories of Deep Vibro TechniquesDocument25 pagesPlate Load Test: Principles and Case Histories of Deep Vibro TechniquesRifqi FirmansyahNo ratings yet

- A Comparative Evaluation of Various AdditivesDocument11 pagesA Comparative Evaluation of Various Additivesagus_ip3808No ratings yet

- Corrugated Steel Pipe, Metallic-Coated, For Sewers and DrainsDocument10 pagesCorrugated Steel Pipe, Metallic-Coated, For Sewers and DrainsFRANZ RICHARD SARDINAS MALLCONo ratings yet

- Astm C 62 04Document4 pagesAstm C 62 04Alex ContrerasNo ratings yet

- ACIDocument13 pagesACILuis GuerraNo ratings yet

- 6 Defects in Brickwork Due To Poor WorkmanshipDocument7 pages6 Defects in Brickwork Due To Poor WorkmanshipMichael Matshona100% (1)

- Aci 8Document89 pagesAci 8BartoFreitasNo ratings yet

- DCP To CBR 01 Materials Civil EngineeringDocument5 pagesDCP To CBR 01 Materials Civil EngineeringNandha Kumar100% (1)

- Astm - C 29 - C 29MDocument4 pagesAstm - C 29 - C 29MEnZo LPNo ratings yet

- BS - 4449-2005+a2-2009 10Document1 pageBS - 4449-2005+a2-2009 10Lee LaiHaaNo ratings yet

- 2221 96Document3 pages2221 96Luis LopezNo ratings yet

- ASTM C 1152C-97 - STD Tes Method Por Acid-Soluble CL in Mortar and ConcreteDocument3 pagesASTM C 1152C-97 - STD Tes Method Por Acid-Soluble CL in Mortar and ConcretemodulofrikiNo ratings yet

- Aashto TP 64 03 2007 PDFDocument15 pagesAashto TP 64 03 2007 PDFAmjad MalikNo ratings yet

- Iom - Declaration - Unisco 2014Document13 pagesIom - Declaration - Unisco 2014Ahmad ZaidNo ratings yet

- 00 Saip 06Document4 pages00 Saip 06YongBolitz Vbfz100% (1)

- Review QuizDocument10 pagesReview QuizAhmad Zaid100% (1)

- How Silica Fume WorksDocument1 pageHow Silica Fume WorksAhmad ZaidNo ratings yet

- ASTM A 194 Carbon and Alloy Steel Nuts PDFDocument13 pagesASTM A 194 Carbon and Alloy Steel Nuts PDFAhmad ZaidNo ratings yet

- ASTM A 47 M Ferritic Malleable Iron Castings PDFDocument5 pagesASTM A 47 M Ferritic Malleable Iron Castings PDFAhmad ZaidNo ratings yet

- Definitions ConcreteDocument42 pagesDefinitions ConcreteAhmad ZaidNo ratings yet

- ASTM A 283-03 Carbon Steel PlateDocument2 pagesASTM A 283-03 Carbon Steel PlateAhmad ZaidNo ratings yet

- ACI 304.2R-96 Placing Concrete by Pumping PDFDocument25 pagesACI 304.2R-96 Placing Concrete by Pumping PDFAhmad Zaid100% (1)

- ASTM A 36-02 Structural SteelDocument4 pagesASTM A 36-02 Structural SteelAhmad ZaidNo ratings yet

- A100-Hy9901021303 0Document1 pageA100-Hy9901021303 0Ahmad ZaidNo ratings yet

- A100-P9901012503 0Document1 pageA100-P9901012503 0Ahmad ZaidNo ratings yet

- Expat Attendance - 160715 To 150815Document615 pagesExpat Attendance - 160715 To 150815Ahmad ZaidNo ratings yet

- A100-P9901012502 0Document1 pageA100-P9901012502 0Ahmad ZaidNo ratings yet

- J-208 Petron Spool Cleared ListDocument2 pagesJ-208 Petron Spool Cleared ListAhmad ZaidNo ratings yet

- C100-BFW5401070613 0Document1 pageC100-BFW5401070613 0Ahmad ZaidNo ratings yet

- C100-P9901021605 0Document1 pageC100-P9901021605 0Ahmad ZaidNo ratings yet

- Welding SymbolsDocument1 pageWelding SymbolsAhmad ZaidNo ratings yet

- Osaka UniversityDocument24 pagesOsaka UniversityAhmad Ghaniy MuzakkiNo ratings yet

- Rep-05 Dated 30.06.2015Document1 pageRep-05 Dated 30.06.2015Ahmad ZaidNo ratings yet

- Ejemplos RT PlacasDocument4 pagesEjemplos RT PlacasNacho CajalNo ratings yet

- Asme B31.8Document8 pagesAsme B31.8deepndeepsi100% (1)

- Bruhaspati Kavacham Guru KavachamDocument1 pageBruhaspati Kavacham Guru KavachamAhmad ZaidNo ratings yet

- Itp For Pot Sheel Rev-0 Dated 09.12.2015Document4 pagesItp For Pot Sheel Rev-0 Dated 09.12.2015Ahmad ZaidNo ratings yet

- 31.5 Natural and Synthetic RubbersDocument3 pages31.5 Natural and Synthetic RubbersLakshmi PatreNo ratings yet

- Chem SureDocument2 pagesChem SureRxHughesNo ratings yet

- Kinetics: Rates and Mechanisms of Chemical Reactions Chapter 16 Multiple Choice QuestionsDocument18 pagesKinetics: Rates and Mechanisms of Chemical Reactions Chapter 16 Multiple Choice QuestionsJoanna QuintoNo ratings yet

- 0620 s03 QP 1Document20 pages0620 s03 QP 1Varun PanickerNo ratings yet

- BiochemistryDocument29 pagesBiochemistryamarizol_4124995No ratings yet

- Exp6 chm361 PDFDocument11 pagesExp6 chm361 PDFShafiqahFazyaziqahNo ratings yet

- MsdsDocument3 pagesMsdsFatmaNo ratings yet

- Degasser ResolutionSystemsDocument4 pagesDegasser ResolutionSystemsResolution Systems, Inc.No ratings yet

- CARBOXYLIC ACIDS & DERIVATIVESDocument3 pagesCARBOXYLIC ACIDS & DERIVATIVESMelody OngNo ratings yet

- Chemistry Holiday HomeworkDocument25 pagesChemistry Holiday HomeworkManisha GuptaNo ratings yet

- Comparison of Fenton and Foto-FentonDocument9 pagesComparison of Fenton and Foto-FentonNika Porubin DandelionNo ratings yet

- MKKKLDocument21 pagesMKKKLdaney67299No ratings yet

- Rowley Et Al 2024 Discovery and Sar Study of Boronic Acid Based Selective Pde3b Inhibitors From A Novel Dna EncodedDocument17 pagesRowley Et Al 2024 Discovery and Sar Study of Boronic Acid Based Selective Pde3b Inhibitors From A Novel Dna Encodedjufen98No ratings yet

- Desmodure-Rfe-Tds CROSSLİNKİNG AGENTDocument2 pagesDesmodure-Rfe-Tds CROSSLİNKİNG AGENTGİZEM DEMİRNo ratings yet

- The Punjab School: Give Them Accurate AnswersDocument35 pagesThe Punjab School: Give Them Accurate AnswersQulb e AbbasNo ratings yet

- Exploiting Wetting Phenomena To Tailor 1D Nano-And MicrostructuresDocument15 pagesExploiting Wetting Phenomena To Tailor 1D Nano-And Microstructuress1hahriarNo ratings yet

- Pyrolysis-GC/MS/IR Analysis of PolyethyleneDocument6 pagesPyrolysis-GC/MS/IR Analysis of PolyethyleneKung KleeNo ratings yet

- Test Series Schedule for NEET 2019Document2 pagesTest Series Schedule for NEET 2019Eshwar Subramanyam100% (1)

- General Equilibrium Notes CH 16 TroDocument13 pagesGeneral Equilibrium Notes CH 16 TroVincent AllamNo ratings yet

- Aluminium (Handout)Document2 pagesAluminium (Handout)s17m0582No ratings yet

- Handbook of Polymeric Foams and Foam Technology: HanserDocument10 pagesHandbook of Polymeric Foams and Foam Technology: Hanserfreidor0% (2)

- Amino Acids AnalysisDocument33 pagesAmino Acids Analysisfarida utamiNo ratings yet

- CHM243H5S April 2011 Special Deferred ExamDocument15 pagesCHM243H5S April 2011 Special Deferred ExamXiaohanJinNo ratings yet

- Click Chemistry and ATRP A Beneficial Union For The Preparation of Functional Materials 2007 PDFDocument19 pagesClick Chemistry and ATRP A Beneficial Union For The Preparation of Functional Materials 2007 PDFZhan FangNo ratings yet