Professional Documents

Culture Documents

The Matson Patent

Uploaded by

Minnesota Public RadioOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Matson Patent

Uploaded by

Minnesota Public RadioCopyright:

Available Formats

'

1,492,603

May 6, 1924.

F. G. MATSON

METHOD OF PRODUCING A FOOD PRODUCT

Filed Feb. 23, 1924

>

'

14

"(0

i5

.12

/

is

/

16

'

///////)V///////////V_////////(////

~~

.,

Francis ?i?fatson,

Patented May 6, 1924.

1,492,603

. '

UNITED STATES,

PATENT OFFICE.

FRANCIS G. MATSCN, OF WASHINGTON, DISTRICT OF COLUMBIA.

METHOD OF PRODUCING A FOOD PRODUCT.

Application ?led February 28, i924. Serial No. 694,707.

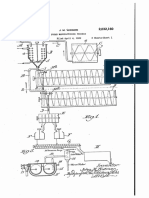

In the drawin , wherein for the purpose

To all whom it may concern:

Be it known thatI, FRANCIS G. MATSON, of illustration is shown a preferred em

a citizen of the United States, residing at bodiment of my invention, the numeral 10

Washington, in the District of Columbia, designates the lower member of the iron,

have invented certain new and useful Im

60

having a cavity or recess 11, of a generally

provements in Methods. of Producing a elliptical shape, for molding the product into

Food Product, of which the following 18 a the desired shape and size. The inner sur

face of this recess may have suitable inden

speci?cation.

My invention relates to an edible food tations and ribs formed therein, for effect=

product, and has particular reference to such ing the proper radiation of the heat to the

a product wherein a previously cooked batter and for producing an ornamental con

The numeral 12 designates the

upper coacting member of the iron having

An important object of the invention is a similarly shaped recess 13, with the ribs

to provide an edible food product of the and indentations, for a similar purpose.

65

sausage, such as a frankfurter, is enclosed ?guration.

in a casing of baked batter.

15

above

mentioned

character,

70

possessing Attention is called to the fact that the recess

marked advantages, such as a high degree 11 is substantially deeper than the recess 13.

of porosity in the enclosing casing of baked The numeral 14 designates a pair of sup

batter, whereby the same may be readily porting lugs or elements, arranged within

20

digested.

75

the recess 11, and cast integral with the

A further object of the invention is to member 10. These supporting lugs are

provide an edible food product of the above preferably disposed near the ends of the re- -

mentioned character having the enclosing cess, and extend in a generally vertical di

25

35

40

casing of baked batter of such a character rection. The previously cooked sausage or

that the same will not be injuriously af frankfurter 15, when ?rst introduced into

fected by the grease from the cooked sausage. the recess 11, rests upon the supporting ele

A further object of the invention is to ments 14, and is thereby held in spaced rela

provide an edible food product of the above tion from the bottom of the recess 11.

In the practice of the method in the pro

mentioned character, which may be cooked

quickly, having a highly porous or cellular duction of the edible product, the lower

enclosing casin of cooked batter, with the iron member 10 is arranged upon a stove

cellular forma ion extending inwardly into or the like and heated to a suiiiciently high

contacting relation with the cooked frank temperature to e?'ect a quick and thorough

cooking of the batter. The frankfurter or

furter, without becoming heavy or soggy.

86

In the accompanying drawings forming sausage 15- is previously completely cooked,

a part of this speci?cation, and in which like and this is an important feature of the in

numerals are employed to designate like vention. By this previous cooking, the ex

cess grease is removed from the frank

parts throughout the same,

_

_

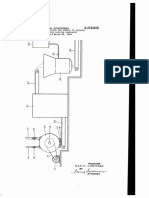

Figure 1 1s a central vertical longltudlnal furter, and further the frankfurter is in

section through the lower member of the a heated condition. This previously cooked

95

iron, prior to the introduction therein of frankfurter is now introduced in the recess

the batter, showing the previously cooked 11 and supported in spaced relation from.

frankfurter supported by the retaininglugs, its bottom, by resting upon the supporting

45

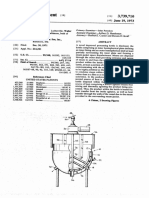

Figure 2 is a similar view, after the in elements 14. The batter is now properly

troduction of the batter into the iron, at poured into the recess 11 around, upon and

about the previously cooked sausage.

An important feature of the invention is

comp ete iron, showing the coacting member the employment of a batter su?iciently thin

to pour quickly and freely, and such a batter

in place,

Figure 4 is a perspective view of the prod must not be confused with a dough. Dough

100

the starting of the cooking operation,

Fi

50

re 3 is a similar view through the

uct, and,

105

is a product which must be kneaded, in or

'

Figure 5 is a central longitudinal section der to properly rise, and cannot ?ow, and

further bakes much slower than batter. The

.

Figure 6 is a transverse section through batter which is employed, as before stated,

through the same.

55 the complete iron showing'the frankfurter is su?iciently ?uid to pour readily and bake

and batter therein,

quickly, whereby a casing is obtained which

110

"

1,492,608

is highly cellular. As hereinbefore stated, frankfurter. The highly cellular character

the frankfurter is ?rst thoroughly or prop of the casing is due to the fact that I employ

a relatively thin batter, in counter distinc

tion to a dough. and secondly that the cook

ing is effected at a high temperature in a 70

rapid manner, which can only be carried out

batter, and any attempt to cook the frank by introducing the batter into the iron, in ~

furter while cooking the batter, would re the manner described.

A further advantage in the practice of

sult in failure. It has been attempted to

cook a frankfurter in dough, but this has not my method is that I produce a product Cl

erly cooked before being introduced into the

iron. This is essential, as the length of time

required to cook the frankfurter is consider

ably longer than that required to cook the.

10

roven satisfactory, as the grease from the which is highly sanitary.

By the method

ankfurter invariably. works into the above described,'the handling of the frank

dough, causing the inner portion of the furter, as ordinarily occurs in the making of

dough to become heavy and soggy. Further, a sandwich, as by passing the same into a

the

frankfurter cannot be properly cooked, split roll, is dispensed with. The usual han

15

even in dough, as it is too remote from the dling of the roll is also dispensed with.

action of heat, and the dough would burn Further, the .entire product may be produced

before the frankfurter was properly cooked. within three-fourths of a minute, in the

This?uid batter when poured into the re presence of the purchaser, assuring him that

20 cess 11, around, about or upon the previously the product is sanitary, and fresh, andalso

cooked frankfurter, at once passes beneath stimulating interest in the product.

It is to be understood that. the form of

the frankfurter, or the lower portion there

93

of. The top iron member 12 is now lowered my invention herewith shown and described ,

upon the lower iron member, whereby batter is to be taken as a preferred example of the

with the frankfur'ter embedded therein is same, and that various changes in the order 90

completely con?ned in a closed space having of the steps of the method, and in the shape

the desired shape and size of the ?nished and size of-parts of the product, may be

product. This ?uid batter, contains su?i resorted to, without departing from the

cient and proper baking powder to cause the spirit of my invention or the scope of the 95

.

'30 same to quickly rise, to produce a highly sub'oined claims.

aving thus described my invention, I

cellular structure. This rising of the batter

elevates the frankfurter, to some extent, claim:

1. The hereindescribed method of produc

from the supporting lugs so-that such frank

furter ?oats in the batter in a position ap ing an edible food product which consists 100

'35 proximately centrally of the cavity or the in ?oating a previously cooked frankfurter

25

product.

en the upper iron member is in a ?uid batter while con?ning the same

lowered in place,>_the rising batter immedi in an enclosed space, subjecting the batter

ately-?lls the entire cavity of the iron above thus con?ned to the action of a cooking heat

the frankfurter, which becomes entirely en to ?rst cause the batter to rise and, expand

closed in the casin of batter. The cooking and substantially completely surround the

40

105

for a suitable length of frankfurter within the enclosed space con

action is continue

time, such as for about one-half minute. tinuing the cooking action for completing

The entire iron is then inverted and the then the cooking of the expanded batter inv the

lower iron member is heated for approxi

form of an enclosing casing, and removing

mately one-half minute, until the cooking the cooked product from within the enclosed

110

sumed in introducing the cooked frankfurter furter in an enclosed space in the presence

into the iron, and pouring in the batter, is of a ?uid batter having the frankfurter

of course very little, such as a few seconds, partly or wholly embedded therein, subject

" with the result that the ?nished product can ing the ?uidbatter while thus con?ned in

115

45

action of the other side of the product is space.

2. The hereindescribed method of produc

completed. It has been found that the en

tire cooking operation can be effected in ing an edible food product, which consists

three-fourths of a minute. The time con in supporting a previously cooked frank

50

55

be produced in the presence of the purchaser, the enclosed space to the action of heat for

within a minute. After the cooking, the causing the same to expand and completely

product is of course ready to be removed ?ll the space around the frankfurter, con

tinuing the heating action for cooking the

from the iron, to be eaten. _

The product is obtained which has an edi expanded batter in the form of an enclosing

casing, and removing the cooked product

rounding and enclosing the previously from within the enclosed space.

- ble casing which is integral, completely sur

00

3. The hereindescribed method of produc

cooked sausage. This casing is indicated by

the numeral-16 in Figure 4:. As shown ing an edible food product, which consists

therein, the casing is highly porous or cel in introducing a previously cooked frank

lular, and this porous casin extends in furter into an enclosed space while main

wardlg7 into contacting relation with the taining the same spaced from the bottom

120

125

1,492,803

10

thereof, pouring a ?uid batter into thebot over the top of the frankfurter, continuing

tom of the space about the frankfurter, sub the heating action to effect the complete

jecting the batter while con?ned within the cookinrr of the batter, and removing the

enclosed space to the action of heat for caus cooked product from within the enclosed

ing the batter to rise and expand and ?ll the space.

enclosed space surrounding the frankfurter, 5. The hereindescribed method of produc

continuing the heating action to effect the ing an edible food product, which consists

complete cooking- of the batter. and remov in con?ning a previously cooked frankfurter

ing the cooked product from within the en in an enclosed space in the presence of a

closed space.

Y

?uid batter, causing the batter to expand

4. The hereindescribed method of produc and substantially completely surround the

ing an edible food product, which consists frankfurter within the enclosed space by

in holding, a ?uid batter in the lower por subjecting the batter to the action of heat,

'20

26

30

tion of an enclosed space in the presence of continuing the heating operation until the

a previously cooked frankfurter partly or batter is completely cooked. and removing

wholly embedded in the upper portion of the the cooked product from within the enclosed

batter, subjecting the batter to the action of space.

'

heat for causing it to rise and expand and In testimony whereof I a?ix my signature.

pass upwardly within the enclosed space

FRANCIS MATSON.

33

You might also like

- Mastering the Instant Vortex Plus: A Practical Guide to the 7-in-1 Air Fryer and All Its FunctionsFrom EverandMastering the Instant Vortex Plus: A Practical Guide to the 7-in-1 Air Fryer and All Its FunctionsNo ratings yet

- Preparing To Build A Masonry OvenDocument28 pagesPreparing To Build A Masonry OvenSteve B. SalongaNo ratings yet

- Architect's Pocket Book of Kitchen DesignDocument15 pagesArchitect's Pocket Book of Kitchen DesignJay RammaNo ratings yet

- Affordable Housing Recommendations To The Mayor ReportDocument30 pagesAffordable Housing Recommendations To The Mayor ReportMinnesota Public RadioNo ratings yet

- Convection Oven Cookbook: Easy Recipes With Essential Cooking Techniques To Roast, Grill And Bake In The Convection OvenFrom EverandConvection Oven Cookbook: Easy Recipes With Essential Cooking Techniques To Roast, Grill And Bake In The Convection OvenNo ratings yet

- Huawei E5885ls 93a Mobile Wifi DatasheetDocument22 pagesHuawei E5885ls 93a Mobile Wifi DatasheetMohammed ShakilNo ratings yet

- IGCSE Math (Worked Answers)Document22 pagesIGCSE Math (Worked Answers)Amnah Riyaz100% (1)

- F-500 Encapsulator TechnologyDocument6 pagesF-500 Encapsulator TechnologyBdSulianoNo ratings yet

- Evolution of Coffee RoastingDocument19 pagesEvolution of Coffee RoastingDavid_Normal_S_6934100% (4)

- ASME Fatigue Life CurvesDocument3 pagesASME Fatigue Life CurvesnamasralNo ratings yet

- Advisor Webcast Exadata Disk Management and Troubleshotting Tips FinalDocument84 pagesAdvisor Webcast Exadata Disk Management and Troubleshotting Tips FinalethenhuntNo ratings yet

- Efficient AFBC boiler cold start up and compartment transfer procedureDocument4 pagesEfficient AFBC boiler cold start up and compartment transfer procedureManimaran Guna100% (1)

- XML JavascriptDocument62 pagesXML Javascriptanon-506495No ratings yet

- Blockchain Unconfirmed Transaction Hack Script Docx PDF FreeDocument2 pagesBlockchain Unconfirmed Transaction Hack Script Docx PDF FreeHealing Relaxing Sleep Music100% (1)

- Reservoir Saturation ToolDocument19 pagesReservoir Saturation ToolAli Jay JNo ratings yet

- PFR Lime Kiln Process With Blast Furnace Gas and OxygenDocument4 pagesPFR Lime Kiln Process With Blast Furnace Gas and OxygenVitor Godoy100% (1)

- Another Corn Dog Machine PatentDocument14 pagesAnother Corn Dog Machine PatentMinnesota Public RadioNo ratings yet

- Patten Mechine CoffeeDocument10 pagesPatten Mechine CoffeeRoni NovisonNo ratings yet

- April 12, 1966. H. Sanders 3,245,800: Process of Producing Fried Chicken Under PressureDocument3 pagesApril 12, 1966. H. Sanders 3,245,800: Process of Producing Fried Chicken Under PressurezeldaikNo ratings yet

- Controlling holding time in infusion heating apparatusDocument26 pagesControlling holding time in infusion heating apparatusalejjavierdelgadoNo ratings yet

- April 29, 1947. M - Cqntesso 2,419,822Document3 pagesApril 29, 1947. M - Cqntesso 2,419,822sterlingNo ratings yet

- US patent for filled cookie that eruptsDocument7 pagesUS patent for filled cookie that eruptsDeisyNo ratings yet

- SILK REELING COOKING MANUALDocument6 pagesSILK REELING COOKING MANUALVipin Singh KandholNo ratings yet

- Process For Producing Granular Triple Superphosphate: F. DunbarDocument5 pagesProcess For Producing Granular Triple Superphosphate: F. DunbarOscar SobradosNo ratings yet

- Us 1505592Document4 pagesUs 1505592api-190559452No ratings yet

- Teal. A 2.É.: Aug. 7, 1945. W. J. Cotton 2,381,210Document4 pagesTeal. A 2.É.: Aug. 7, 1945. W. J. Cotton 2,381,210juzmailmaNo ratings yet

- Powder Filling Machine PatentDocument11 pagesPowder Filling Machine PatentDaniel VelasquezNo ratings yet

- SL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296Document7 pagesSL / y Tºš W: Feb. 2, 1965 H. R. Cowley 3,168,296lucasmosnaNo ratings yet

- Pressure cookers with improved venting systemDocument5 pagesPressure cookers with improved venting systemgobinath VPNo ratings yet

- United States Patent (19) : Fvtjggbmai L $132321?' Barley' Copson, Microwave Heating, Avi Publishing Co. LN.Document5 pagesUnited States Patent (19) : Fvtjggbmai L $132321?' Barley' Copson, Microwave Heating, Avi Publishing Co. LN.tmz1234No ratings yet

- US1153992 - Collumn StillDocument4 pagesUS1153992 - Collumn StilletyseNo ratings yet

- Machine for Forming and Packing Fish into ContainersDocument11 pagesMachine for Forming and Packing Fish into ContainersM Lukman HakimNo ratings yet

- Rotary kiln reactor design and operation for phosphoric acid productionDocument8 pagesRotary kiln reactor design and operation for phosphoric acid productionAram Nasih MuhammadNo ratings yet

- Wa0012.Document3 pagesWa0012.Ramos DavidNo ratings yet

- Measure cheese with this compact dispenserDocument5 pagesMeasure cheese with this compact dispenserRodrigoPomaNo ratings yet

- Rotary kiln reactor design and phosphoric acid productionDocument8 pagesRotary kiln reactor design and phosphoric acid productionAram Nasih MuhammadNo ratings yet

- Bussey v. Excelsior Mfg. Co., 110 U.S. 131 (1884)Document10 pagesBussey v. Excelsior Mfg. Co., 110 U.S. 131 (1884)Scribd Government DocsNo ratings yet

- Heating Baking Drying CookingDocument4 pagesHeating Baking Drying CookingPrashant RohillaNo ratings yet

- Heating Baking Drying CookingDocument4 pagesHeating Baking Drying CookingPrashant RohillaNo ratings yet

- Rotary dryer for aggregate with staggered lifting flights and cross bracesDocument5 pagesRotary dryer for aggregate with staggered lifting flights and cross bracesAhmadmartakNo ratings yet

- Apparatus For Treating Sewage.: No. 659,503. I Patented Oct. 9, I900Document4 pagesApparatus For Treating Sewage.: No. 659,503. I Patented Oct. 9, I900Abdullah SimpsonNo ratings yet

- Sorbitol Crystallization Process PatentDocument5 pagesSorbitol Crystallization Process PatentJosefogNo ratings yet

- Portable Rotary Grain DryerDocument13 pagesPortable Rotary Grain DryerJohn Carlos Moralidad CriticaNo ratings yet

- J. M. Widmer: Filed April 4, 19.52Document8 pagesJ. M. Widmer: Filed April 4, 19.52Kah MunNo ratings yet

- Method For Enhanced Recovery of Viscous Oil DepositsDocument5 pagesMethod For Enhanced Recovery of Viscous Oil DepositsRishel Mae VeraNo ratings yet

- United States Patent (19) : Assistant Examiner-Arthur O. HendersonDocument7 pagesUnited States Patent (19) : Assistant Examiner-Arthur O. HendersonDylan WielfredNo ratings yet

- A. A. Maccubbin E Tal: Filed Aug. 14, 1930Document7 pagesA. A. Maccubbin E Tal: Filed Aug. 14, 1930Gökhan Kürşat demirNo ratings yet

- Us2181099 PDFDocument4 pagesUs2181099 PDFAt ChecoNo ratings yet

- OvenDocument32 pagesOvenPrecylyn EvidorNo ratings yet

- United States Patent (191: McguganDocument6 pagesUnited States Patent (191: McguganJamesStenhouseNo ratings yet

- July 5, 1949. ' R. - Hasche - 2,475,282: Filed Jan. 21, 1946 ' 2 Sheets-Sheet 1Document5 pagesJuly 5, 1949. ' R. - Hasche - 2,475,282: Filed Jan. 21, 1946 ' 2 Sheets-Sheet 1Yanpiero BalladoresNo ratings yet

- United States Patent 0: Patented Dec. 20, 1955Document3 pagesUnited States Patent 0: Patented Dec. 20, 1955divyaNo ratings yet

- Pressure Cooker Regulator Title CounterDocument9 pagesPressure Cooker Regulator Title CounterThinesh KumarNo ratings yet

- US2727914Document3 pagesUS2727914Rian Pratama AkbaNo ratings yet

- Multi-functional cremation container for a cadaverDocument6 pagesMulti-functional cremation container for a cadavermetamorphosisgrNo ratings yet

- United States Patent (19) : B JornstadDocument4 pagesUnited States Patent (19) : B JornstadlfilippiniNo ratings yet

- Gage v. Herring, 107 U.S. 640 (1883)Document8 pagesGage v. Herring, 107 U.S. 640 (1883)Scribd Government DocsNo ratings yet

- Presentation Bakery and ConfectioneryDocument64 pagesPresentation Bakery and ConfectioneryJagan Babu67% (3)

- US1562093Document3 pagesUS1562093priyankaNo ratings yet

- Add 018746Document16 pagesAdd 018746john carterNo ratings yet

- Felling machine divides bulk materials into equal volumesDocument9 pagesFelling machine divides bulk materials into equal volumesCao Ngoc AnhNo ratings yet

- TREATMENT OF SLAG TO PRODUCE A LIGHT FOAM-LIKE STRUCTUREDocument6 pagesTREATMENT OF SLAG TO PRODUCE A LIGHT FOAM-LIKE STRUCTUREandresNo ratings yet

- Filed March 20, 1943Document8 pagesFiled March 20, 1943Andrés RamírezNo ratings yet

- Us4589264 PDFDocument6 pagesUs4589264 PDFRodrigoPomaNo ratings yet

- If WSSMW: UF Powder'Document3 pagesIf WSSMW: UF Powder'Zahoor Hussain RanaNo ratings yet

- High protein bread substitute made with milk, eggs, lipids and carbsDocument6 pagesHigh protein bread substitute made with milk, eggs, lipids and carbsRijad LičinaNo ratings yet

- Milliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaDocument4 pagesMilliam G. Airchhoff: SasaaaaaaaaaaaaaaaaaaaaaOscar Lora SiñaniNo ratings yet

- Pocket Lighter Patent from 1936 Describes Zippo DesignDocument3 pagesPocket Lighter Patent from 1936 Describes Zippo DesignRakeshNo ratings yet

- Steam Chest & Flaker Startup-R190723Document4 pagesSteam Chest & Flaker Startup-R190723BCPACKAGING SERVICENo ratings yet

- Rice Bran Oil Extraction ProcessDocument3 pagesRice Bran Oil Extraction Processteknik kimiaNo ratings yet

- Navigation Center FAQ FlyerDocument2 pagesNavigation Center FAQ FlyerMinnesota Public RadioNo ratings yet

- MUID Letter NAH-Encampment Dec2018Document2 pagesMUID Letter NAH-Encampment Dec2018Minnesota Public RadioNo ratings yet

- CAAPB Guardrail SlidesDocument7 pagesCAAPB Guardrail SlidesMinnesota Public RadioNo ratings yet

- Twin Cities Outperforms Peer Regions On Some Key Benchmarks Lags in OthersDocument3 pagesTwin Cities Outperforms Peer Regions On Some Key Benchmarks Lags in OthersMinnesota Public RadioNo ratings yet

- +hebda Statement On Accountability 8-31-18 FinalDocument2 pages+hebda Statement On Accountability 8-31-18 FinalMinnesota Public RadioNo ratings yet

- The Archdiocese of St. Paul and Minneapolis Disclosure StatementDocument78 pagesThe Archdiocese of St. Paul and Minneapolis Disclosure StatementMinnesota Public RadioNo ratings yet

- Minnesota Supreme Court Order On Audio and Video in Criminal CasesDocument14 pagesMinnesota Supreme Court Order On Audio and Video in Criminal CasesMinnesota Public RadioNo ratings yet

- +cozzens Statement On National Review Board 8-31-18 FinalDocument1 page+cozzens Statement On National Review Board 8-31-18 FinalMinnesota Public RadioNo ratings yet

- Hearing NoticeDocument1 pageHearing NoticeMinnesota Public RadioNo ratings yet

- Minneapolis 2040 Comprehensive Plan 9-27-2018Document481 pagesMinneapolis 2040 Comprehensive Plan 9-27-2018Minnesota Public RadioNo ratings yet

- The Archdiocese of St. Paul and Minneapolis' Reorganization PlanDocument198 pagesThe Archdiocese of St. Paul and Minneapolis' Reorganization PlanMinnesota Public RadioNo ratings yet

- Transcript of 911 Call Before The Fatal Police Shooting of Thurman BlevinsDocument4 pagesTranscript of 911 Call Before The Fatal Police Shooting of Thurman BlevinsMinnesota Public RadioNo ratings yet

- St. John's ComplaintDocument20 pagesSt. John's ComplaintMinnesota Public RadioNo ratings yet

- Faribault Letter To ACLU Dated June 11 2018.Document4 pagesFaribault Letter To ACLU Dated June 11 2018.Minnesota Public RadioNo ratings yet

- MPCA-MDH Joint Letter To EPA Science Transparency 5 15 18Document2 pagesMPCA-MDH Joint Letter To EPA Science Transparency 5 15 18Minnesota Public RadioNo ratings yet

- SPPS Board Priorities and Timeframe, Proposed in 2016Document2 pagesSPPS Board Priorities and Timeframe, Proposed in 2016Minnesota Public RadioNo ratings yet

- St. John's University Petition and ExhibitsDocument41 pagesSt. John's University Petition and ExhibitsMinnesota Public RadioNo ratings yet

- Plea AgreementDocument7 pagesPlea AgreementMinnesota Public RadioNo ratings yet

- Tenant Protection OrdinanceDocument7 pagesTenant Protection OrdinanceMinnesota Public RadioNo ratings yet

- Dayton's Emergency School AidDocument13 pagesDayton's Emergency School AidMinnesota Public RadioNo ratings yet

- Settlement Agreement Minnesota Attorney General Lori Swanson Reached With 3MDocument11 pagesSettlement Agreement Minnesota Attorney General Lori Swanson Reached With 3MMinnesota Public RadioNo ratings yet

- Attorney General Lori Swanson's Advisory OpinionDocument6 pagesAttorney General Lori Swanson's Advisory OpinionMinnesota Public Radio100% (1)

- Stine, Zelle's Letter To EPA ChiefDocument2 pagesStine, Zelle's Letter To EPA ChiefMinnesota Public RadioNo ratings yet

- Summary Judgement in Surly Class Action LawsuitDocument2 pagesSummary Judgement in Surly Class Action LawsuitMinnesota Public RadioNo ratings yet

- Lakes and Parks Alliance of Minneapolis V The Metropolitan Council, Order For Summary JudgmentDocument17 pagesLakes and Parks Alliance of Minneapolis V The Metropolitan Council, Order For Summary Judgmentdylanthmsyahoo.comNo ratings yet

- Good FungiDocument3 pagesGood FungiMinnesota Public RadioNo ratings yet

- Lawsuit Filed Against Reliance RecoveriesDocument16 pagesLawsuit Filed Against Reliance RecoveriesMinnesota Public RadioNo ratings yet

- Produce Distributions For Greater Minn., Summer 2017Document1 pageProduce Distributions For Greater Minn., Summer 2017Minnesota Public RadioNo ratings yet

- Produce Distributions For The Twin Cities Metro Area, Summer 2017Document3 pagesProduce Distributions For The Twin Cities Metro Area, Summer 2017Minnesota Public RadioNo ratings yet

- Chemical Composition, Properties, and Standards of Steel Grade 42CrMo4 (1.7225Document1 pageChemical Composition, Properties, and Standards of Steel Grade 42CrMo4 (1.7225ADITYA_PATHAK100% (1)

- PI ControllerDocument5 pagesPI Controllerdanuega1No ratings yet

- Faculty of Engineering Mechanical Engineering Program: Vibration Engineering Lab: KM31401: LAB IVDocument7 pagesFaculty of Engineering Mechanical Engineering Program: Vibration Engineering Lab: KM31401: LAB IVhasmikaNo ratings yet

- (Advanced Techniques For 4G Systems) : Name: Alaa Ashraf Abdelmoneim Elagrody Sec: 1 ID:1Document11 pages(Advanced Techniques For 4G Systems) : Name: Alaa Ashraf Abdelmoneim Elagrody Sec: 1 ID:1alaa elagrodiNo ratings yet

- Libro de FLOTACIÓN-101-150 PDFDocument50 pagesLibro de FLOTACIÓN-101-150 PDFIsaias Viscarra HuizaNo ratings yet

- PSE YRC1000micro 00Document25 pagesPSE YRC1000micro 00LiemNo ratings yet

- Adiabatic Logic: An Alternative Approach To Low Power Application CircuitsDocument6 pagesAdiabatic Logic: An Alternative Approach To Low Power Application CircuitsBibartan DasNo ratings yet

- Philippine Electronics Code - Volume 1Document28 pagesPhilippine Electronics Code - Volume 1Ishimaru Thor100% (1)

- Emc VNX Vnxe3300: Installation GuideDocument28 pagesEmc VNX Vnxe3300: Installation GuideAnkit JoshiNo ratings yet

- Unit 2 MineralogyDocument53 pagesUnit 2 MineralogyEashan Adil100% (1)

- Simple Backup/Restore Utility With SQL-: Introduction To SQL-DMODocument8 pagesSimple Backup/Restore Utility With SQL-: Introduction To SQL-DMOZaeni Marjiyanto, A.mdNo ratings yet

- (Altium Tutorial) PCB Symbol Naming ConventionDocument7 pages(Altium Tutorial) PCB Symbol Naming ConventionDefne AktemizNo ratings yet

- 20-SDMS-02 Overhead Line Accessories PDFDocument102 pages20-SDMS-02 Overhead Line Accessories PDFMehdi SalahNo ratings yet

- Sand, Salt, IronDocument1 pageSand, Salt, IronKevin ChoyNo ratings yet

- CNT SVX15D E4 1111Document60 pagesCNT SVX15D E4 1111Mihai IavorschiNo ratings yet

- 2011 Nov P1 Maths L2Document9 pages2011 Nov P1 Maths L2nhlanhlamhlambi3No ratings yet

- Carbohydrates Explained: Monosaccharides, Disaccharides and PolysaccharidesDocument21 pagesCarbohydrates Explained: Monosaccharides, Disaccharides and PolysaccharidesJhayce Christian S. CapanayanNo ratings yet

- AP+Bio 013+Photosynthesis++Respiration+Worksheet WLDocument2 pagesAP+Bio 013+Photosynthesis++Respiration+Worksheet WLVincent SuarezNo ratings yet

- S4M Service ManualDocument522 pagesS4M Service ManualRafał Krzysztof Kowalski100% (1)

- Experiment No 02Document5 pagesExperiment No 02Farhan AliNo ratings yet

- A B C D Supply I1 1 2 3 4 Deman D I1Document7 pagesA B C D Supply I1 1 2 3 4 Deman D I1Shaurya DewanNo ratings yet