Professional Documents

Culture Documents

Journal Paper RCPT

Uploaded by

Vennela VasupilliOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Journal Paper RCPT

Uploaded by

Vennela VasupilliCopyright:

Available Formats

Int. J. Electrochem. Sci.

, 11 (2016) 2297 - 2305

International Journal of

ELECTROCHEMICAL

SCIENCE

www.electrochemsci.org

Short Communication

Effect of Durability and Chloride Ion Permeability in Ternary

Cementitious Concrete with Additions of Fly Ash and Blast

Furnace Slag

W. Aperador1, *, A. Delgado1, J. Bautista-Ruiz2

1

School of Engineering, Universidad Militar Nueva Granada, Bogot-Colombia

Universidad Francisco de Paula Santander, San Jos de Ccuta, Colombia

*

E-mail: g.ing.materiales@gmail.com

2

Received: 1 January 2016 / Accepted: 19 January 2016 / Published: 1 February 2016

Ternary mixtures of concrete with Portland, fly ash and finely ground granulated slag were produced

to investigate their effects on the compressive strength and corrosion resistance. Portland cement was

partially replaced by alternative materials with water / cement ratio (w / c) of 0.50. The mechanical

strength it was evaluated by compression tests and the corrosion resistance using Half-cell potentials.

The results indicate that fly ash and blast furnace slag, greatly reduce the chloride permeability of

concrete and increases the corrosion resistance both short- and long- time evaluation. Therefore it is

concluded that to control the corrosion resistance in the presence of chloride ion, including pozzolan is

an effective method.

Keywords: Portland cement, fly ash steel slag, mechanical strength and corrosion.

1. INTRODUCTION

The use of concrete with additives has been widely used worldwide [1]. For example, in Asia,

the blast furnace slag has-been used as an Addition to cement and concrete [2]. So, this resource is

widely utilized. In contrast, production of fly ash worldwide is not utilized in full [3]. For example,

more than 88 million tons of fly ash are generated in India every year mostly Class F type (low

calcium), and its use is only 10% to 15% [4]. This scenario is also evident in Latin America, not being

reused these materials in the industrial sector and construction.

Since fly ash and blast furnace slag are employed in construction, the study of their properties

has been important [5]. However, cement fly ash in large volumes has some disadvantages such as low

resistance, high water requirements, and low resistance to carbonation [6]. Therefore, a good method

Int. J. Electrochem. Sci., Vol. 11, 2016

2298

the partial replacement of cement by fly ash in low volumes for producing compound. Moreover, when

mineral additives used additives can be added to the mixture to accelerate the hydration of fly ash slag

and improve the mechanical strength and the properties of the pore structure [7].

Slag reactions are significantly affected by the amount of free water available in the cement

hydration. Therefore, a difference between hydration characteristics of fly ash and slag occurs, fly ash

is a pozzolanic material, while the slag is a hydraulic material [8]. The blast furnace slag can react with

the plaster and produce etringita [9]. The heat release in said reaction it is related to the amount of slag

and the melting temperature of the specimens. In the cement-fly ash and cement-slag mixtures when

the reaction wheel fly ash or slag are interrupted by lack of Ca (OH)2 available stalled fly ash or slag

particles have a material effect on microllenante with clinker. When the percentage replacement of fly

ash or slag are high, the stagnation microllenante effect becomes significant [10].

Fly ash and blast furnace slag having different chemical compositions, such as the glassy

phase, the contents of SiO2 and CaO and generally different stoichiometry in the hydration reactions

[11]. In the interaction cement-fly ash, calcium hydroxide is produced by the hydration of cement and

the time consumed by the pozzolanic reaction [12].

This paper presents a laboratory study on the influence of the combination of fly ash, Portland

cement and blast furnace slag on the electrochemical properties of Ultra-High Performance Concrete.

The evaluation of the mechanical performance of concrete mixtures was made in the short and long

term. The experimental program comprises testing compressive strength and corrosion resistance. The

results showed that the combination of fly ash and blast furnace slag can improve the properties of

concrete short and long term, while concrete with high volume fly ash and steel slag they require long

periods for their beneficial effect.

2. EXPERIMENTAL METHOD

2.1 Materials

In this study commercial Type I Portland cement is used, Fly Ash from Thermal Power Plants

Sochagota and granulated blast furnace slag from the plant of Paz del Rio. Characterization of these

materials was performed by testing X-ray fluorescence and its chemical composition is summarized in

Table 1.

Table 1. Chemical composition of the cementitious materials.

Composed

SiO2

Al2O3

Fe2O3

CaO

MgO

Portland cement,

%

18.15

4.65

3.80

60.03

2.50

Fly Ash, %

Blast furnace slag, %

54.30

20.8

5.30

6.40

0.80

33.70

12.80

0.48

45.40

1.00

Int. J. Electrochem. Sci., Vol. 11, 2016

Na2O

K2O

P2O5

TiO2

MnO

SO3

SiO2/Al2O3

unburned

carbon

0.80

0.50

2.40

3.90

0.6

2299

0.90

0.70

0.70

1.20

0.01

0.92

2.61

8

0.12

1.50

0.50

2.63

-

As stony material fine aggregate was used type of river sand with fineness modulus of 3.04 and

absorption of 0.81%. As coarse aggregate fine gray gravel was used with nominal maximum size of 12

mm.

2.2 Concrete mixtures

All mixtures were designed to cementitious material content of 448 kg / m3 and a water /

cement ratio of 0.5. For this purpose, 4 ternary mixtures of varying composition with Portland cement

and partial replacement of fly ash and blast furnace slag are prepared. The abbreviations B, F and S are

used to identify materials Portland cement, fly ash and blast furnace slag, respectively. The proportions

of the blends are summarized in Table 2. Were also introduced to the nomenclature percentages

replacement main cementitious material for example B8-F1-S1 represents the mixture of 80% Portland

cement, 10% fly ash and 10% blast furnace slag; B4-F2-S2 represents the mixture of Portland cement

40%, 20% fly ash and 40% blast furnace slag [13].

Table 2. Proportions of concrete mixtures.

Gravel

Sodium

B

F

S

or

sand

Water

Identification

silicate

(kg/m3) (kg/m3) (kg/m3) Stone (kg/m3) (kg/m3)

(kg/m3)

(kg/m3)

B8-F1-S1

358.4

44.8

44.8

997.3

830.4

224

22.4

B-F2-S2

268.8

89.6

89.6

997.3

830.4

224

22.4

B4-F2-S4

179.2

89.6

179.2

997.3

830.4

224

22.4

B4-F4-S2

179.2

179.2

89.6

997.3

830.4

224

22.4

Plasticizers

(kg/m)3

0.5

0.5

0.6

0.8

2.3 Description of equipment and instrumentation

They conducted tests characterizing the mechanical properties of concrete with total and partial

replacement of Portland cement. These tests were performed in order to determine the effects of

additions of fly ash and slag on the properties of concrete is to say modification of its strength and

performance [14].

Int. J. Electrochem. Sci., Vol. 11, 2016

2300

2.4 Compressive strength

Compressive strength it is determined from the specimens in the form of cylinders having

dimensions of 15x30 cm at ages 28 and 90 days following the procedure of ASTM-C-39 standard. The

load is applied using a hydraulic press controlled by an automated system and load application speed

was 0.25 MPa/s. For proper application of the load without eccentricities is using metal discs and

neoprene. Additionally, to record the complete stress-strain curve and observe the maximum capacity

obtained in compression deformation, the longitudinal strain to failure by adapting a strain gauge on

the specimen is measured [15].

2.5 Electrochemical characterization

The electrochemical characterization was performed on a potentiostat / galvanostat, through the

techniques of half-cell potential, using a cell consisting of a graphite counter electrode, a reference

electrode, Cu/CuSO4 electrode and as structural steel work NTC 2289 was used with an exposed area

of 10 cm2. Electrochemical measurements were performed for the concrete at 0, 3, 6, 9 and 12 months

exposure to a solution composed of 3.5% Sodium Chloride Solution [16].

2.6 Chloride Ion Permeability

To evaluate the performance of concrete added with fly ash and steel slag against the

penetration of chloride ions, the test was performed rapid chloride permeability based on the ASTM

C1202 standard. These tests were performed after 28 days of curing.

3. RESULTS AND DISCUSSION

3.1 Compressive strength

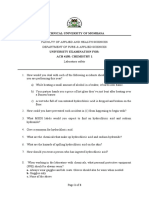

In Figure 1, the results of compressive strength, evaluated at 28 and 90 days are obtained,

where it is evident that at early ages (28 days) when no pozzolanic reaction, fly ash and steel slag

acting as an inert material, therefore, the effect of fly ash and steel slag on concrete strength is evident

with the curing and condition of the concrete, since they develop the pozzolanic reaction products and

thus increases the mechanical strength and refinement of the porous structure occurs, This last factor is

linked to the durability of concrete, especially reinforced concrete because the pore size reduced

carrying capacity of corrosive liquids and gases is limited through their porous system [17-19].

This is mainly because the pozzolanic activity of fly ash continues to develop, evidencing in

the corresponding graph at 90 days, because contributing to increase the mechanical strength at later

ages. The optimal values of the mixture corresponding to 10 and 20% fly ash and steel slag, because

the higher values of resistance is obtained, the effect of synergy between additions of fly ash and blast

furnace slag, it indicates that the increase in performance is due to be added in an appropriate ratio

Int. J. Electrochem. Sci., Vol. 11, 2016

2301

between the steel slag and fly ash. The value of compressive strength of this ternary mixture has the

highest values that mixtures; obtained only with fly ash or steel slag [Reference], implying that the

combination of fly ash and blast furnace slag has a higher activity, than each of these components

added separately [20].

Compressive strength (MPa)

25

20

B8F1S1

B6F2S2

B4F2S4

B4F4S2

15

10

0

28

90

Time (days)

Figure 1. Compressive strength of ternary mixtures evaluated at 28 and 90 days.

3.2 Half Cell Potential

In Figure 4 measurements of half-cell potential is observed where 2 different responses in

particular evaluated are obtained concrete with pozzolanic additions fewer B8F1S1, shows a high

probability of corrosion is because the ions have reached the steel have since found a continuous

conductive path because of the open porosity has the cement matrix, this because it has high content of

Portland cement the other answer corresponds to a discontinuous conductive path; and can generate an

area of insulation this behavior is because there is greater amount of pozzolanic material ranging

between 40 and 60% [21-22].

The half-cell potential; It is a technique commonly used to evaluate the interface steel concrete; when an ion penetration establishing a corrosive effect on metal embedded. From the results

it can be seen clearly that for the 4 mixtures analyzed there are two areas one with high likelihood of

Int. J. Electrochem. Sci., Vol. 11, 2016

2302

corrosion and the other with an uncertain region these regions are generated by contact with the NaCl

solution and the cement matrix. In Figure 2, it observed that as the evaluation time for mixtures with

Portland fewer (40%) cement potential is decreased, which indicates a decrease in the resistivity of the

system and also the diameter of the steel may increase because a corrosive behavior is generated at the

interface-specific matrix. To the mixture 60% cement Portlad (B6F2S2) the effect of the potential is

reversed in time because after the first measurement of the potential changes from an area of high

likelihood of corrosion in the zone of uncertainty [23].

Potential (mV) vs SCE

-0,16

Uncertainty of Corrosion

-0,24

B4F2S4

B4F4S2

B6F2S2

B8F1S1

-0,32

90% Probability of Corrosion

-0,40

0

12

Time / Months

Figure 2. Potential half-cell corresponding the 4 ternary mixtures evaluated versus time.

One of the parameters that influence protection against corrosion phenomena is the thickness

because in the concrete evaluated all have the same value this does not affect this assessment so the

study focuses on the permeability to aggressive agents in order to control the spread of chloride ions.

As mentioned in the experimental development simulates the evaluation means similar to a marine

environment so that corrosion is caused by chloride ions that come from the mixture generated, these

ions diffuse through the cement matrix from the outside until the reinforcing steel, these ions have the

ability to disrupt the stability of the passive film beginning the process of corrosion. In Figure 2 it

shows that the concrete with corrosion process is the one with a high amount of cementitious Portland

so from early loses its steel passivation generating an anode reaction where Fe releases two electrons

which diffuse through the concrete and react with water and oxygen, occurring cathodic reactions. The

problem created by this type of structures is that once the iron oxide hydrates, it becomes porous and

can reach increases the volume occupied by the steel which produces very high internal stresses

producing cracks and can cause material removal [24].

Int. J. Electrochem. Sci., Vol. 11, 2016

2303

3.3 Performance against chloride penetration

The results are interpreted according to Table 1, reported in the ASTM C1202 standard. This

rule refers to the classification of materials according increase or decrease its ion permeability chloride

these values are in Figure 3.

Table 3. Rating of chloride permeability of concrete

Charge

passing

(coulombs)

4000

2000-4000

1000-2000

100-1000

100

Chloride

permeability

High

Moderate

Low

Very Low

Negligible

According to Table 1, the concrete less amount of fly ash and steel slag it has moderate

permeability to chloride ion attack; concrete added with 20% slag and 20% fly ash had a low

permeability classification entering columbios the range 1000-2000, However mixtures with 40% of

Portland cement was the best performance record. As can be concluded the chloride ion permeability is

seriously affected by the rate of addition since the 10% higher load values were obtained while the

60% addition the lowest values were obtained this means that as the percentage of addition of ash and

steel slag is increased behaviour towards chlorides remarkably improved. The reduction in total charge

passed through the concrete the four mixes the best that behaviour with a higher content of fly ash that

is attributed to the effect remains lower porosity in concrete [25]. The saline environment directly

affects performance against corrosive phenomena and it is due to chloride ions coming from the sea

water and the sea breeze, these ions diffuse through the concrete structure from the outside until the

reinforcement and accumulate to reach the reinforcing steel, reaching a critical concentration, to which

this ion has the ability to disrupt the stability of the passive film beginning the process of corrosion

[26-27].

Chloride ions are present in this study is dissolved in water, these ions are retained in the pores

starting the dissolution of the pore, thereby generating a damage on reinforcing steel to correlate with

the mechanical test is determined that the ions do not have a significant influence on the concrete, but

about its rebar that can eventually cause corrosion reducing its area losing mechanical properties such

as compressive strength and fatigue they can reach disable the structure.

Int. J. Electrochem. Sci., Vol. 11, 2016

2304

B4F2S4

B4F4S2

B6F2S2

B8F1S1

500

1000

1500

2000

2500

3000

3500

Total charge passed/ Coulomb

Figure 3. Total charge passed corresponding to the last ternary mixtures evaluated.

4. CONCLUSIONS

Because the main problem of the armed structures is corrosion of the embedded armor a

solution with ternary mixtures which have a protective effect in terms of durability of constructions is

proposed this can reduce costly repairs and it allows for greater safety of structures near shorelines.

The microstructure obtained by mixing Portland cement, fly ash and steel slag, it is of

considerable importance that governs the mechanical and durability properties of concrete and it has a

significant influence on the performance against corrosion of steel reinforcement in concrete. The

resistance to chloride it was significantly higher as the cementitious Portland is decreased thus

increasing its durability properties.

ACKNOWLEDGEMENT

This research was supported by "Vicerrectora de investigaciones de la Universidad Militar Nueva

Granada" under contract ING 1760.

References

1.

2.

3.

M. Albitar, M.S. Mohamed Ali, P. Visintin, M. Drechsler, Constr. Build. Mater., 83 (2015) 128

C. Unluer, A. Al-Tabbaa, Constr. Build. Mater., 94 (2015)629

M.R. Karim, M.F.M. Zain, M. Jamil, F.C. Lai, Constr. Build. Mater., 49 (2013)894

Int. J. Electrochem. Sci., Vol. 11, 2016

4.

5.

6.

7.

8.

9.

10.

11.

12.

13.

14.

15.

16.

17.

18.

19.

20.

21.

22.

23.

24.

25.

26.

27.

2305

Z.T. Yao, X.S. Ji, P.K. Sarker, J.H. Tang, L.Q. Ge, M.S. Xia, Y.Q. Xi, Earth Sci. Rev., 141

(2015) 105

A.A. Malakhova, V.M. Mosina, D.A. Gorlushko, O.I. Nalesnik, N.V. Usoltseva, Procedia

Chem., 15 (2015) 27

M. Ahmaruzzaman, Prog. Energy Combust. Sci., 36 (2010)327

H.W. Kua, Energy Build., 101 (2015) 133

N.C. Collier, N.B. Milestone, Cem. Concr. Res, 40 (2010) 452

C.R. Panda, K.K. Mishra, K.C. Panda, B.D. Nayak, B.B. Nayak, Constr. Build. Mater., 49

(2013) 262

A Agrawal, K.K Sahu, B.D Pandey, Resour. Conserv. Recycl. Resources, 42 (2004) 99

M. Ahmaruzzaman, Adv. Colloid Interface Sci., 166 (2011) 36

E. Dourdounis, V. Stivanakis, G.N. Angelopoulos, E. Chaniotakis, E. Frogoudakis, D.

Papanastasiou, D.C. Papamantellos, Cem. Concr. Res., 34 (2004) 941

P. Van den Heede, N. De Belie, Cem. Concr. Compos., 34, (2012) 431

C. Chen, G. Habert, Y. Bouzidi, A. Jullien, A. Ventura, Resour. Conserv. Recycl. Resources,, 54

(2010) 1231

A. Nazari, J. G. Sanjayan, J. Cleaner Prod., 99 (2015) 297

R.A. Taha, A.S. Alnuaimi, K.S. Al-Jabri, A.S. Al-Harthy, Build. Environ., 42 (2007) 3366

E. Benhelal, G. Zahedi, E. Shamsaei, A. Bahadori, J. Cleaner Prod., 51 (2013) 142

C. Lampris, J.A. Stegemann, M. Pellizon-Birelli, G.D. Fowler, C.R. Cheeseman, J. Hazard.

Mater., 185 (2011) 1115

Kostas Komnitsas, Dimitra Zaharaki, Miner. Eng., 20 (2007) 1261

M. Abdul Quader, Shamsuddin Ahmed, Raja Ariffin Raja Ghazilla, Shameem Ahmed, Mahidzal

Dahari, Renewable Sustainable Energy Rev., 50 (2015) 594

H. W Song, V. Saraswathy, J. Hazard. Mater., 138 (2006) 226

E. Asuman Korkusuz, Meryem Bekliolu, Gksel N. Demirer, Ecol. Eng., 24 (2005) 185

F. Puertas, M. Palacios, H. Manzano, J.S. Dolado, A. Rico, J. Rodrguez, J. Eur. Ceram. Soc., 31

(2011) 2043

J.P. Castro-Gomes, Ablio P. Silva, Rafael P. Cano, J. Durn Suarez, A. Albuquerque, J. Cleaner

Prod., 25 (2012) 34

R. du Plooy, S. Palma Lopes, G. Villain, X. Drobert, NDT and E Int., 54 (2013) 27

G.K. Glass, J.R. Chadwick, Corros. Sci., 36 (1994) 2193

S.J. Jaffer, C.M. Hansson, Corros. Sci., 50 (2008) 3343

2016 The Authors. Published by ESG (www.electrochemsci.org). This article is an open access

article distributed under the terms and conditions of the Creative Commons Attribution license

(http://creativecommons.org/licenses/by/4.0/).

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Effect of Reinforcing Steel Debonding On RC Frame Performance in Resisting Progressive CollapseDocument13 pagesEffect of Reinforcing Steel Debonding On RC Frame Performance in Resisting Progressive CollapseVennela VasupilliNo ratings yet

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Puja Protocol 02 02 2020Document14 pagesPuja Protocol 02 02 2020Vennela Vasupilli100% (1)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- 1 s2.0 S1877705811013476 MainDocument9 pages1 s2.0 S1877705811013476 MainVennela VasupilliNo ratings yet

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (895)

- 1 s2.0 S187770581202526X MainDocument10 pages1 s2.0 S187770581202526X MainVennela VasupilliNo ratings yet

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (400)

- CPTDocument9 pagesCPTSougata DasNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Affecting Aspects On The Behaviour of Frame Joints: HBRC JournalDocument16 pagesAffecting Aspects On The Behaviour of Frame Joints: HBRC JournalVennela VasupilliNo ratings yet

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- ,M Journel Paper RCPTDocument5 pages,M Journel Paper RCPTVennela VasupilliNo ratings yet

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- 15 Conclusion Chapter 9Document17 pages15 Conclusion Chapter 9Vennela VasupilliNo ratings yet

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (588)

- Sika Concrete Handbook 2013Document262 pagesSika Concrete Handbook 2013Joseph Chen100% (1)

- Staad Pro TutorialDocument572 pagesStaad Pro TutorialSammish8383% (12)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Metakaolin A ReviewDocument5 pagesMetakaolin A ReviewSairam VenkatNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- Performance Evaluation of Sugarcane Bagasse Ash-Based Cement ForDocument7 pagesPerformance Evaluation of Sugarcane Bagasse Ash-Based Cement ForAnonymous ROtb6rVgjINo ratings yet

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Durability of Concrete With Different Mineral Admixtures A ReviewDocument12 pagesDurability of Concrete With Different Mineral Admixtures A ReviewVennela VasupilliNo ratings yet

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Staad Pro V8i Manual 2016Document775 pagesStaad Pro V8i Manual 2016Larry89% (9)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Sika Concrete HandbookDocument151 pagesSika Concrete HandbookFatjon ShahaNo ratings yet

- 13Vol66No2 JournalDocument11 pages13Vol66No2 JournalVennela VasupilliNo ratings yet

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- 50 58 Eng Concrete TestingDocument92 pages50 58 Eng Concrete TestingJimmy LopezNo ratings yet

- TWPCDocument9 pagesTWPCArief MaulanaNo ratings yet

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Article 29 Vol III Issue IV 2012Document4 pagesArticle 29 Vol III Issue IV 2012Vennela VasupilliNo ratings yet

- E0523539 Journal of Water Permeability Paper1Document5 pagesE0523539 Journal of Water Permeability Paper1Vennela VasupilliNo ratings yet

- 02 Water Permeability Test (2012 (1) .02.15)Document1 page02 Water Permeability Test (2012 (1) .02.15)Vennela VasupilliNo ratings yet

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Effect of Different Types of Steel Fibers With Metakaolin & FlyDocument7 pagesEffect of Different Types of Steel Fibers With Metakaolin & FlyIAEME PublicationNo ratings yet

- Concrete Blended Cement Concrete PDFDocument9 pagesConcrete Blended Cement Concrete PDFVennela VasupilliNo ratings yet

- Non-Linear Response of Two-Way Asymmetric Multistorey Building Under Biaxial ExcitationDocument7 pagesNon-Linear Response of Two-Way Asymmetric Multistorey Building Under Biaxial ExcitationVennela VasupilliNo ratings yet

- NonDestructive Testing NDT of Concrete in StructuresDocument4 pagesNonDestructive Testing NDT of Concrete in StructuresNurAtikahNo ratings yet

- Determination of Durability of Metakaoline Blend High Grade Concrete by Using Water Permeability Test JournalDocument6 pagesDetermination of Durability of Metakaoline Blend High Grade Concrete by Using Water Permeability Test JournalVennela VasupilliNo ratings yet

- 13Vol66No2 JournalDocument11 pages13Vol66No2 JournalVennela VasupilliNo ratings yet

- 02 Water Permeability Test (2012 (1) .02.15)Document1 page02 Water Permeability Test (2012 (1) .02.15)Vennela VasupilliNo ratings yet

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (121)

- Porosity PermeabilityDocument24 pagesPorosity PermeabilityVennela VasupilliNo ratings yet

- Buku Miller's Anesthesia BAB 20 Dan 21Document88 pagesBuku Miller's Anesthesia BAB 20 Dan 21Rahma TomuNo ratings yet

- Geopolymer Book Chapter1Document37 pagesGeopolymer Book Chapter1Aslam HutagiNo ratings yet

- Concentration (G/L) VS Absorbance (/) : ResultDocument3 pagesConcentration (G/L) VS Absorbance (/) : ResultasyharulNo ratings yet

- EML 3701 Quiz 2 SP2017 SolutionDocument3 pagesEML 3701 Quiz 2 SP2017 Solutionthez100% (3)

- METALS Structured Questions and Worked SolutionsDocument9 pagesMETALS Structured Questions and Worked SolutionsYoviNo ratings yet

- Intro AzoDyeDocument2 pagesIntro AzoDyejammNo ratings yet

- Emerging Solar Cell PDFDocument23 pagesEmerging Solar Cell PDFJaffar LoneNo ratings yet

- CBLM SampleDocument26 pagesCBLM SampleMaryjane Binag Gumiran100% (1)

- Biodegradation of Keratin Waste Theory and Practical AspectsDocument13 pagesBiodegradation of Keratin Waste Theory and Practical AspectsRodrigo Lara100% (1)

- Shell Rl3 MsdsDocument8 pagesShell Rl3 MsdsHitesh ShahNo ratings yet

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Cable Slickline 316 StainlessDocument1 pageCable Slickline 316 StainlessRafael EspinosaNo ratings yet

- Pinch TechnologyDocument7 pagesPinch TechnologyAakanksha MahajanNo ratings yet

- Orifice Flange Union Assembly and Orifice Run Installation and Operation ManualDocument8 pagesOrifice Flange Union Assembly and Orifice Run Installation and Operation ManualNithin CpNo ratings yet

- Laboratory SafetyDocument2 pagesLaboratory Safetyann wamburaNo ratings yet

- A Practical Study For New Design of Essential OilsDocument17 pagesA Practical Study For New Design of Essential OilsEmmanuel PlazaNo ratings yet

- Steel SAE O-Rings AdaptersDocument3 pagesSteel SAE O-Rings Adaptersgeav25653855No ratings yet

- Heat-Resistant Pressure-Vessel Steels: Mechanical Properties Available DimensionsDocument1 pageHeat-Resistant Pressure-Vessel Steels: Mechanical Properties Available DimensionsRamachandran SundararamanNo ratings yet

- Chemically Enriched UniverseDocument41 pagesChemically Enriched UniverseMark JamesNo ratings yet

- Mechanical Properties of Ultra-High-Performance Concrete Enhanced With Graphite Nanoplatelets and Carbon NanofibersDocument10 pagesMechanical Properties of Ultra-High-Performance Concrete Enhanced With Graphite Nanoplatelets and Carbon NanofibersRUSNA KPNo ratings yet

- Sizing Up The Valve Guide: by Dave MonyhanDocument4 pagesSizing Up The Valve Guide: by Dave MonyhanRidwanUsmanNo ratings yet

- Bulan AgustusDocument22 pagesBulan AgustusaristhanovyraNo ratings yet

- Module 1Document15 pagesModule 1venugopal_aeroNo ratings yet

- Drug Testing and Analysis - 2022 - Andrews - From JWH80 018 To OXIZIDS Structural Evolution of Synthetic Cannabinoids in TheDocument20 pagesDrug Testing and Analysis - 2022 - Andrews - From JWH80 018 To OXIZIDS Structural Evolution of Synthetic Cannabinoids in ThePelumi AshamuNo ratings yet

- Current Trends in Explosive Detection Techniques PDFDocument16 pagesCurrent Trends in Explosive Detection Techniques PDFSandra LuizNo ratings yet

- Elements Compounds and Mixtures Revision 1Document6 pagesElements Compounds and Mixtures Revision 1api-310569693No ratings yet

- The Calorific Value of A Fuel Is TheDocument4 pagesThe Calorific Value of A Fuel Is TheRana PrathapNo ratings yet

- FlotacionDocument2 pagesFlotacionJose Ariel TorrezNo ratings yet

- Daftar Obat Untuk BPJSDocument9 pagesDaftar Obat Untuk BPJSYulidar KhairaniNo ratings yet

- DocxDocument15 pagesDocxzhuzaiNo ratings yet

- Guidelines for Chemical Process Quantitative Risk AnalysisFrom EverandGuidelines for Chemical Process Quantitative Risk AnalysisRating: 5 out of 5 stars5/5 (1)

- The Things We Make: The Unknown History of Invention from Cathedrals to Soda CansFrom EverandThe Things We Make: The Unknown History of Invention from Cathedrals to Soda CansNo ratings yet

- Sodium Bicarbonate: Nature's Unique First Aid RemedyFrom EverandSodium Bicarbonate: Nature's Unique First Aid RemedyRating: 5 out of 5 stars5/5 (21)

- Composite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsFrom EverandComposite Structures of Steel and Concrete: Beams, Slabs, Columns and Frames for BuildingsNo ratings yet

- To Engineer Is Human: The Role of Failure in Successful DesignFrom EverandTo Engineer Is Human: The Role of Failure in Successful DesignRating: 4 out of 5 stars4/5 (138)