Professional Documents

Culture Documents

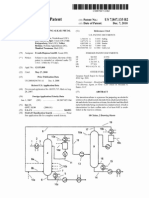

United States Patent 1191: Tu (45) Sep. 7, 1982

Uploaded by

AdyOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

United States Patent 1191: Tu (45) Sep. 7, 1982

Uploaded by

AdyCopyright:

Available Formats

United States Patent 1191

[111 .

Tu

[45]

[54]

Sep. 7, 1982

HYDROGEN UTILIZATION IN FLUID '

4,162,213

CATALYTIC CRACKING

4,268,376

5/1981

Foster

4,268,416

5/1981

Stine et a1. .................... .. 208/120 X

'

[75] Inventor. Hosheng Tu, Shorewood, Ill.

[73] Assigneei UOP, Inc Des Plalnes, 11L

[21] Appl' NOJ 170,373

[22] Filed:

51]

4,348,272

Int Cl 3

7/1979 .Zrinscak et a1. .................... .. 208/89

. . . . . . . . . . .

. . . . ..

208/120

Primay ExaminerDelbert E Gantz

Assistant Examiner-G. E1 Schmitkons

Attorney, Agent, or Firm-James R. Hoatson, Jr.; Louis

A. Morris; William H. Page, II

Jul. 21, 1980

C10G 47/20' C10G 47/30

[57]

'

ABSTRACT

isz] U.s'. ci. 11:11:13: ...... .. 208/111; 208/52 CT;_

A" FCC Process in which hydrogen Produced by water

208/56; 208/120; 252/420

thermolysis adheresto the catalyst and is used in the

' [58]

Field of Search ................ .. 208/120, 111, 52. CT,

203/56; 252/411 R, 420; 423/65Q_653

_

[56]

crystalline aluminosilicate cation exchanged with tran

References Clted

U.S. PATENT DOCUMENTS

sitional metal cations. The water thermolysis is carried

out in the circulating catalyst upstream of the reaction

3,413,212 11/1968 Weisz ................................ .. 208/120

3,844,973

3,963,830 10/1974

6/1976 Kasai

Stine et

et al.

al. ..

reaction Zone to achieve improved product selectivity

and reduced coke production. The catalyst used is a

111: at Water thmolysis nditins

.. 208/ 120 X

......... .. 423/579

6 Claims, N0 Drawings

4,348,272

HYDROGEN UTILIZATION IN FLUID

CATALYTIC CRACKING

cationic sitesof which have been ion-exchanged with

cations of a non-noble transitional metal, the catalyst

being cycled betwen a cracking zone, in which the

BACKGROUND OF

hydrocarbon feedstock, and a regeneration zone, in

catalyst is contacted at an elevated temperature with a

INVENTION

1. Field of the Invention

which carbon is oxidized and thereby removed from the

catalyst, the process comprising maintaining the cata

lyst under water thermolysis conditions prior to passing

the catalyst into the cracking zone, whereby hydrogen

The ?eld of art to which the claimed invention per

tains is the catalytic cracking of hydrocarbons. More

speci?cally, the claimed invention relates to a process

for the utilization of hydrogen obtained by water ther

molysis in a ?uid catalytic cracking process.

2. Description of the Prior Art

is produced and then adsorbed on the catalyst, thereby

making the hydrogen available in the cracking zone to

effect improved cracking selectivity and reduced coke

production.

There are a number of continuous cyclical processes

employing ?uidized solid techniques in which carbona

Other objectives and embodiments of my invention

ceous materials are deposited on the solids in the reac 15 encompass details about catalyst composition, ?ow

tion zone and the solids are conveyed during the course

schemes, and reaction conditions, all of which are here

of the cycle to another zone where carbon deposits are

inafter disclosed in the following discussion of each of

at least partially removed by combustion in an oxygen

the facets of the invention.

containing medium. The solids from the latter zone are

subsequently withdrawn and reintroduced in whole or 20

DESCRIPTION OF THE INVENTION

in part to the reaction zone.

. In a typical FCC process ?ow, ?nely divided regen

One of the more important processes of this nature is

erated catalyst leaves the regeneration zone at a certain

the ?uid catalytic cracking (FCC) process for the con

version of relatively high-boiling hydrocarbons to ligh

ter hydrocarbons boiling in the heating oil or gasoline

(or lighter) range. The hydrocarbon feed is contacted in

temperature, passes to the reactor via a dipleg and

25 contacts a feedstock in a lower portion of a reactor riser

zone. While the resulting mixture, which has a tempera

ture of from about 400 F. to about 1300 F., passes up

one or more reaction zones with the particulate crack

through the riser, conversion of the feed to lighter prod

ing catalyst maintained in a ?uidized state under condi

ucts occurs and coke is deposited on the catalyst. The

tions suitable for the conversion of hydrocarbons.

The selectivity to the desired gasoline fraction in the 30 ef?uent from the riser is discharged into a disengaging

space when additional conversion can take place. The

FCC process is limited by the overall hydrogen bal

hydrocarbon vapos, containing entrained catalyst, are

ance, i.e. the available hydrogen. Although the provid

then passed through one or more cyclone separation

ing of hydrogen gas from an outside source in the range

means to separate any spent catalyst from the hydrocar

of a few weight percent of the feed or even a few

weight ppm would greatly enhance the FCC process 35 bon vapor stream. The separated hydrocarbon vapor

stream is passed into a fractionation zone known in the

art as the main column wherein the hydrocarbon ef?u

selectivity, hydrogen is expensive and is generally not

considered for addition to that process. For example, in

U.S. Pat. No. 3,413,212 the advantages of hydrogen

ent is separated into such typical fractions as light gases

addition to the FCC process are shown, but reliance is

placed on expensive and impractical means such as

and gasoline, light cycle oil, heavy cycle oil and slurry

hydrogen donor materials added to the charge stock

from external sources or derived by partial hydrogena

tion of aromatic hydrocarbons in the charge stock.

In U.S. Pat. No. 3,963,830 it is disclosed that crystal

line zeolite structures, into which certain trivalent cati 45

ons are added by cation exchange procedures, are capa

oil. Various fractions from the main column can be

recycled along with the feedstock to the reactor riser.

Typically, fractions such as light gases and gasoline are

further separated and processed in a gas concentration

process located downstream of the main column. Some

of the fractions from the main column, as well as those

ble of thermochemically decomposing water (water

recovered from the gas concentration process may be

recovered as ?nal product streams. The separated spent

thermolysis) in a cyclic process which alternates the

production of oxygen and hydrogen. In one part of the

cycle the trivalent cations are reduced while interract

catalyst passes into the lower portion of the disengaging

space and eventually leaves that zone passing through

ing with water and the water molecules are decom

posed with the consequent evolution of oxygen. In the

other part of the cycle the bivalent metal cations are

reoxidized by imposing different operating conditions

also in the presence of water.

contacts the spent catalyst purging adsorbed and inter

stitial hydrocarbons from thecatalyst. The spent cata

lyst containing coke leaves the stripping zone and

passes into a regeneration zone, where, in the presence

55 of fresh regeneration gas and at a temperature of from

I have discovered a technique for utilizing water

thermolysis in the FCC process so as to make hydrogen

available in the cracking reaction and to achieve im

proved cracking selectivity and reduced coke produc

tion.

SUMMARY OF THE INVENTION

It is, accordingly, a broad objective of my process to

make hydrogen available in the cracking zone of an

FCC process.

stripping means in which a stripping gas, usually steam,

'

In brief summary, my invention is a ?uidized catalytic

cracking process wherein the catalyst employed com

prises a crystalline aluminosilicate the exchangeable

about 1150 F. to about 1400 F., combustion of coke

produces regenerated catalyst and ?ue gas containing

carbon monoxide, carbon dioxide, water, nitrogen and

perhaps a small quantity of oxygen. Usually, the fresh

regeneration gas is air, but it could be air enriched or

de?cient in oxygen. Flue gas is separated from en

trained regenerated catalyst by cyclone separation

means located within the regeneration zone and sepa

rated ?ue gas is passed from the regeneration zone,

65 typically, to a carbon monoxide boiler where the chemi

cal heat of carbon monoxide is recovered by combus

tion as a fuel for the production of steam, or, if carbon

monoxide combustion in the regeneration zone is com

4,348,272

mum thermal stability temperature of the catalyst, i.e.

that temperature above which the crystalline alumino

silicate structure 'of the catalyst tends to disintegrate.

An equally important condition is that the water con

plete, which is the preferred mode of operation, the ?ue

gas passes directly to sensible heat recovery means and

from there to a re?nery stack. Regenerated catalyst

which was separated from the ?ue gas is returned to the

lower portion of the regeneration zone which typically

is maintained at a higher catalyst density. A stream of

tent of the catalyst should be greater than about 0.1 wt.

%, but no greater than about 5.0 wt. % and preferably

regenerated catalyst leaves the regeneration zone via

the dipleg and, as previously mentioned, contact the

no greater thanabout 1.0 wt. %. Care, therefore, must

feedstock in the reaction zone.

lyst upstream of where the water thermolysis is to oc

cur, i.e. the dipleg, the usual source of such water being

be exercised in the amount of water added to the cata

Catalysts which can be used in the process of this

invention include those known to the art as fluidized

catalytic cracking catalysts. Speci?cally, the high activ

stripping and ?uidizing stream.

The following non-limiting examples are illustrative

ity aluminosilicate or zeolite-containing catalysts are to

be used, particularly X type zeolite, Y type zeolite or

of the principles and process of the present invention.

mordenite. The invention requires that the exchange

able cationic sites of the catalyst be ion exchanged, by

ion exchange techniques well-known to the art, with

EXAMPLE I

In this example, a Cr-Mordenite containing catalyst

was prepared by co-extruding Cr-Mordenite zeolite and

cations of a non-noble transitional metal, particularly a

metal included in the group comprising the polyvalent

metals such as copper, nickel, cobalt, iron, chromium,

alumina at a ratio of 75 wt. % mordenite to 25 wt. %

alumina on a volatile free basis. The Cr-mordenite had

20

molybdenum, tungsten, vanadium or titanium. It is es

sential that the cation be incorporated within the cata

nitrate solution to 0.75 wt. % Cr on mordenite powder.

The extrudate was calcined at 200 F. for 1 hour, after

which time it contained about 2- wt. % H2O. The cata

lyst by ion exchange rather than by other techniques

such as co-precipitation, co-gelling or impregnation,

because it is only ion exchange that will result in the

cation becoming part of the structure of the crystalline

lyst was coded Catalyst A.

Three hundred and nine grams of Catalyst A were

aluminosilicate which enables the electron sharingnec- .

loaded in a pilot plant for zeolite water thermolysis

evaluation. The plant was purged with nitrogen

essary for the thermolysis reaction. The non-noble tran

sitional metal will comprise from about 0.1 wt. % to

about 10.0 wt. % of the catalyst, and preferably from

throughout the test. The reactor temperature was raised

to 1000 F. over a period of about 5 hours. The amount

of oxygen evolved and collected was 106 ml at STP

about 0.1 wt. % to about 1.0 wt. %.

Without being limited to any theory, it is my hypoth

esis that the thermolysis reaction mechanism is as fol

lows (with chromium shown as the cation for illustra

tive purposes):

been prepared by ion-exchanging the Na-Mordenite

(supplied by Norton Chemical Co.) with chromium

(standard temperature @O C. and standard pressure

@1 atm conditions). It is apparent that chromium ion on

mordenite zeolites function as a reaction site for water

35

thermolysis.

2Cr3 + (zeolite) + H2O->2Cr2 + (zeolite) + Q

EXAMPLE II

In this example, a Cr-Y zeolite containing catalyst

Thus, the hydrogen species formed in the reaction ad

was prepared by co-extruding Cr-Y zeolite and alumina

heres to the zeolite in some manner, such as adsorption 40 at a ratio of 75 wt. % Y zeolite to 25 wt. % alumina on

or chemical combination, and is carried to the reaction

the volatile free basis. The Cr-Y zeolite had been pre

02 + 2H + (zeolite)

zone from the location from where the thermolysis

reaction occurs, which is upstream of the reaction zone

and preferably in the conduit or dipleg through which

the catalyst passes from the regeneration zone to the

cracking zone. The zeolite containing catalyst with the

' bound hydrogen species is then contacted with the

feedstock where, in addition to the normal cracking

reactions, the bound hydrogen is transferred to the

products which results in improved cracking selectivity

and reduced coke production. The catalyst is then rehy

drated, preferably in the steam stripping section follow

I ing the cracking zone, perhaps in accordance with the

following mechanism:

pared prior to extusion by ion exchanging the Na-Y

powder with chromium nitrate solution. The wt. % Cr

on the Y zeolite powder was 4.1 while the wt. % NazO

was 0.5 (both on a volatile free basis). The extrudate

was calcined at 1300 F. for % hour. The catalyst was

coded Catalyst B.

Three hundred and ?ve grams of Catalyst B were

loaded in the same pilot plant as shown in Example No.

I. The plant was purged with nitrogen throughout the

test. At the start of the test the catalyst contained about

2 wt. % H2O. The reactor temperature was raised from

room temperature to 1200 F. The amount of oxygen

55 evolved in this case was 395 ml at STP over a period of

about 5 hours.

To study the regenerability of a Cr-Y containing

catalyst (Catalyst B) the catalyst from the above test

The thermolysis and rehydration reactions are, there

was cooled to about 100 F. Steam was admitted to

fore, essentially the same as set forth in US. Pat. No. 60 oxidize the catalyst. Then nitrogen was used to purge

the reactor bed and the test was repeated to see if the

3,963,830, discussed above, with the important distinc

catalyst was still active in zeolite water thermolysis.

tion that in the process of this invention it is not the

The reactor temperature was raised slowly to 1200 F.

rehydration step that frees the hydrogen species, but the

while the water content of the catalyst was reduced to

contact with the hydrocarbon feed.

The catalyst of this invention must be maintained 65 about 2 wt. %. The amount of oxygen evolved in this

second test was 375 ml at STP. It is clear that the cata

under water thermolysis conditions for water thermoly

lyst of this invention could sustain the cycles of hydra

sis to occur. One of these conditions is a temperature

greater than about 900 F., but no higher than the maxi

tion-dehydration.

'

4,348,272

6

TABLE 2

EXAMPLE III

MAT RESULTS

In this example, a Cr-Y zeolite containing catalyst

was prepared following the same procedures as in Ex

Catalyst

Test No.

ample No. II. The composition included 25 wt. % of

alumina and 75 wt. % Y zeolite which contained about

Zeolite Water Thermolysis

No

Yes

Wt. % Conversion

Product Distribution

58.7

74.7

6.1 wt. % Cr on zeolite powder. The wet extrudate was

calcined at 1300 F. for 5 hour. This catalyst was coded

(Wt. % of product)

Catalyst C.

C2_

3.53

3.18 '

Total C3

Total C4

7.38

15.52

7.02

14.33

containing catalyst was prepared. This zeolite had 15.6

C5 - EP Gasoline

20.76

42.60

wt. % rare earths and 4.2 wt. % NazO. A catalyst with

25 wt. % alumina and 75 wt. % RE-Y zeolite was pre

pared following the same procedures as for Catalyst C.

This catalyst was coded Catalyst D.

Catalyst C and Catalyst D were evaluated in the same

450 + B.P.

36.47

20.51

Spent Catalyst Carbon

16.34

12.36

The MAT test results clearly indicate that the cata

lyst of this invention with proper water thermolysis

oxygen evolution pilot plant as shown in Example No.

I. The plant was purged with nitrogen gas throughout

conditions improves the FCC cracking selectivity, i.e.

higher gasoline selectivity and lower coke formation.

For comparison purposes, a Rare earth (RE)-Y zeolie

I claim as my invention:

the test. The reactor temperature was slowly raised to

1. A ?uidized catalytic cracking process employing a

1200 F. Both catalysts contained about 2 wt. % H2O at 20

catalyst comprising a crystalline aluminosilicate, the

the start of the evaluation. The results are shown in

exchangeable cationic sites of which have been ion

Table No. 1.

exchanged with cations of a non-noble transitional

TABLE 1

metal, said catalyst being cycled between a cracking

WATER THERMOLYSIS TEST

25 zone, in which said catalyst is contacted at an elevated

Catalyst

temperature with a hydrocarbon feedstock, and a re

Loading wt., g

Amount of Oxygen

Evolved, ml @ STP

184

520

246

9

generation zone, in which carbon is oxidized and

thereby removed from said catalyst, said process com

prising subjecting said catalyst, while in transit from

30 said regeneration zone to said cracking zone, to water

In this comparison, the rare earth Y clearly did not

thermolysis at a temperature from about 900 F. to a

function as an active component in zeolite water ther

molysis. The trace oxygen evolved may have been due

and a catalyst water content of from about 0.1 wt% to

maximum thermal stability temperature of said catalyst

FCC size of about 70 microns) was evaluated in an FCC

about 5.0%, thereby forming hydrogen which is re

tained by the catalyst, introducing said hydrogen to said

cracking zone with the catalyst, and releasing the hy

drogen from the catalyst by contact of the latter with

said hydrocarbon feedstock in the cracking zone to

effect improved cracking selectivity and reduced coke

mode microactivity test pilot plant (MAT). MAT uses

production.

to an impurity of transitional metals contaminating Cat

35

alyst D.

EXAMPLE IV

In this example, Catalyst C (ground and screened to

2. The process of claim 1 wherein said water content

is from about 0.1 wt. % to about 1.0 wt. %.

3. The process of claim-1 wherein said non-noble

transitional metal comprises from about 0.1 wt. % to

procedure without extensive catalyst preheating was

followed. Supposedly no excess hydrogen was gener 45 about 10.0 wt. % of said catalyst.

4. The process of claim 1 wherein said non-noble

ated on the catalyst due to insufficient water thermo1y~

transitional metal comprises a metal included in the

sis conditions, i.e. a water content of over 5 wt. %. The

group comprising copper, nickel, cobalt, iron, chro

MAT Test No. 2 utilized the same Catalyst C. How

mium, molybdenum, tungsten, vanadium or titanium.

ever, the catalyst was preheated in-situ to 1000" F. for

5. The process of claim 4 wherein said transitional

one hour under nitrogen purge to lower the catalyst 50

metal comprises chromium.

,

LOI down to zeolite water thermolysis conditions, i.e.

6. The process of claim 1 wherein said crystalline

about 2 wt. %. The evolved oxygen would be blown

4.0 grams of catalyst on a volatile free basis with 1.28

grams of vacuum gas oil as feedstock. The reactor tem

perature was 900 F. In the MAT Test No. l, a standard

aluminosilicate is included in the group comprising X

type zeolite, Y type zeolite or mordenite.

out along with the purge gas while the generated hy

drogen would stay on the zeolite sites of the Catalyst C.

The MAT test results are shown in Table No. 2.

60

65

You might also like

- Emulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingFrom EverandEmulsions and Oil Treating Equipment: Selection, Sizing and TroubleshootingRating: 5 out of 5 stars5/5 (3)

- Transition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesFrom EverandTransition Metal Catalyzed Furans Synthesis: Transition Metal Catalyzed Heterocycle Synthesis SeriesNo ratings yet

- Us 4377495Document5 pagesUs 4377495DWNLD USRMLNo ratings yet

- United States Patent (19) : Primary Examiner-Herbcrt Levine (54) Main Column Separation of FCCDocument7 pagesUnited States Patent (19) : Primary Examiner-Herbcrt Levine (54) Main Column Separation of FCCDuy Thanh NguyễnNo ratings yet

- Vapor-liquid phase separation of hydroconversion process effluentDocument6 pagesVapor-liquid phase separation of hydroconversion process effluentGalang Hanif AbdulahNo ratings yet

- Hydrocracking. Hydrocracking Is A Hydrogen-Consuming Reaction That Leads To Higher GasDocument4 pagesHydrocracking. Hydrocracking Is A Hydrogen-Consuming Reaction That Leads To Higher GasJefferson EndaraNo ratings yet

- FCC PosterDocument1 pageFCC PosterHai PhanNo ratings yet

- Lecture5 - Fludized Catalytic Cracking (FCC)Document3 pagesLecture5 - Fludized Catalytic Cracking (FCC)Bipradeep GhoshNo ratings yet

- Alhaji Massoud Juma - Petroleum AssignmentDocument9 pagesAlhaji Massoud Juma - Petroleum AssignmentAlhaj MassoudNo ratings yet

- United States Patent (19) : Daly Et Al. 11) 4,436,836Document9 pagesUnited States Patent (19) : Daly Et Al. 11) 4,436,836arif thoha bariklanaNo ratings yet

- Unit 3Document11 pagesUnit 3Shreyash UtekarNo ratings yet

- HDTB Sector Overview: Key Units and ProcessesDocument7 pagesHDTB Sector Overview: Key Units and ProcessesPartha AichNo ratings yet

- Cracking, Visbreaking, Coking and PropertiesDocument12 pagesCracking, Visbreaking, Coking and Propertiesteyiv23540No ratings yet

- UZ Petroleum Engineering Catalytic CrackingDocument9 pagesUZ Petroleum Engineering Catalytic CrackingSaMiHRNo ratings yet

- PETROLEUM REFINING AND PETROCHEMICALS: CATALYTIC CRACKING AND REGENERATIONDocument6 pagesPETROLEUM REFINING AND PETROCHEMICALS: CATALYTIC CRACKING AND REGENERATIONMilan MoradiyaNo ratings yet

- C H CL C H CL + HCL: Cracking EdcDocument5 pagesC H CL C H CL + HCL: Cracking Edczein2000No ratings yet

- Removing H2S from CO2-rich gas with CO2-containing solventDocument4 pagesRemoving H2S from CO2-rich gas with CO2-containing solventIveth RomeroNo ratings yet

- Process DescriptionDocument5 pagesProcess DescriptionGurunath EpiliNo ratings yet

- CHLORINE RECOVERY FROM HCLDocument5 pagesCHLORINE RECOVERY FROM HCLAnne Porter100% (1)

- Distillation Column Basics ExplainedDocument4 pagesDistillation Column Basics ExplainedTejas PatelNo ratings yet

- NHTDocument6 pagesNHTPadarthi Venkateswarlu50% (2)

- United States Patent (10) Patent N0.: US 6,743,952 B2Document8 pagesUnited States Patent (10) Patent N0.: US 6,743,952 B2Rizka AndhikaNo ratings yet

- Peigao Duan, Xiujun Bai, Yuping Xu, Aiyun Zhang, Feng Wang, Lei Zhang, Juan MiaoDocument9 pagesPeigao Duan, Xiujun Bai, Yuping Xu, Aiyun Zhang, Feng Wang, Lei Zhang, Juan MiaoyemresimsekNo ratings yet

- Hydro ProcessingDocument56 pagesHydro ProcessinggeorgiadisgNo ratings yet

- Cracking 151114162534 Lva1 App6891Document33 pagesCracking 151114162534 Lva1 App6891Truth SeekerNo ratings yet

- FCC UnitDocument28 pagesFCC UnitMohsin KhanNo ratings yet

- Hydrogen Gas Production by Partial OxidaDocument69 pagesHydrogen Gas Production by Partial OxidaChinwuba Samuel EbukaNo ratings yet

- United States Patent 1191: RedfordDocument6 pagesUnited States Patent 1191: Redfordhaddig8No ratings yet

- Kelompok 19 Tgb2018 Tugas#10Document8 pagesKelompok 19 Tgb2018 Tugas#10Aulia SiamandaNo ratings yet

- MANUFACTURING METHODS OF SULFURIC ACIDDocument11 pagesMANUFACTURING METHODS OF SULFURIC ACIDZamir Khan100% (3)

- Hydrogenation of hydrocarbons in trickle bed reactorsDocument11 pagesHydrogenation of hydrocarbons in trickle bed reactorsAram Nasih MuhammadNo ratings yet

- Q A BoilerDocument19 pagesQ A Boilerlavpandey8719No ratings yet

- Fluid Catalytic CrackingDocument9 pagesFluid Catalytic CrackingAntonitoNo ratings yet

- Combating Green Oil PDFDocument5 pagesCombating Green Oil PDFkulaspiroNo ratings yet

- Chlorine_Methods-2520of-2520ProductionDocument6 pagesChlorine_Methods-2520of-2520ProductionAditya KumarNo ratings yet

- Catalytic Cracking3Document12 pagesCatalytic Cracking3Abdurabu AL-MontaserNo ratings yet

- Steam ReformingDocument5 pagesSteam ReformingAshok S. PathakNo ratings yet

- Manufacture of Ethyl Benzene Using Zeolite CatalystDocument8 pagesManufacture of Ethyl Benzene Using Zeolite CatalystMario VensfiseCrewNo ratings yet

- ConocoPhillups GlossaryDocument7 pagesConocoPhillups GlossaryJesus MoralesNo ratings yet

- Petrochemical Technology: Boä Moân CNCB Daàu Khí, Khoa CNHH, ÑH Baùch Khoa Tp. HCMDocument25 pagesPetrochemical Technology: Boä Moân CNCB Daàu Khí, Khoa CNHH, ÑH Baùch Khoa Tp. HCMhatucdao2712No ratings yet

- Deisel Hydrotreating UnitDocument9 pagesDeisel Hydrotreating UnitRittu Paul100% (1)

- Hydro Treating CompleteDocument19 pagesHydro Treating CompleteFaiq Ahmad Khan100% (3)

- Lecture9 - Hydrogen Generation Unit (HGU)Document3 pagesLecture9 - Hydrogen Generation Unit (HGU)Bipradeep GhoshNo ratings yet

- CATALYTIC CONVERSION GUIDEDocument118 pagesCATALYTIC CONVERSION GUIDEAravind G100% (1)

- US3983180Document7 pagesUS3983180Agustina TriyaniNo ratings yet

- HydrodesulfurizationDocument7 pagesHydrodesulfurizationjcencicNo ratings yet

- OXIDATIONDocument36 pagesOXIDATIONMansab AliNo ratings yet

- Sulphur Recovery UnitDocument39 pagesSulphur Recovery UnitChetal Bhole100% (1)

- Petrochemical Technology: Boä Moân CNCB Daàu Khí, Khoa CNHH, ÑH Baùch Khoa Tp. HCMDocument21 pagesPetrochemical Technology: Boä Moân CNCB Daàu Khí, Khoa CNHH, ÑH Baùch Khoa Tp. HCMviettiennguyenNo ratings yet

- Diesel Hydrotreating ProcessDocument4 pagesDiesel Hydrotreating Processmynah_sim_eng100% (3)

- Us 4396789Document7 pagesUs 4396789Elias JúniorNo ratings yet

- Coke Steam ReformingDocument13 pagesCoke Steam ReformingmukthiyarsNo ratings yet

- Crude Distillation PosterDocument1 pageCrude Distillation Postervivek_rec100% (1)

- F. J. Klem 3,218,128 : Filed Sept. l0, 1962Document10 pagesF. J. Klem 3,218,128 : Filed Sept. l0, 1962Yourdan WijayaNo ratings yet

- DHT +corrosion +Document11 pagesDHT +corrosion +boscoNo ratings yet

- MANUFACTURING TOLUENE PROCESSESDocument4 pagesMANUFACTURING TOLUENE PROCESSESMiko Yee Teng100% (1)

- Claus process converts H2S to sulfurDocument5 pagesClaus process converts H2S to sulfurAshish SutariyaNo ratings yet

- Fluid Catalytic Craking Unit (Fccu)Document6 pagesFluid Catalytic Craking Unit (Fccu)Nitin VarshneyNo ratings yet

- MetoxidoDocument8 pagesMetoxidocessavelinoNo ratings yet

- BR 895970 r1 HyprecwjDocument12 pagesBR 895970 r1 HyprecwjAdyNo ratings yet

- Ncs DummyDocument45 pagesNcs DummyAdyNo ratings yet

- A Wavelet Based Approach For The Detection of Coupling in EEG SignalsDocument5 pagesA Wavelet Based Approach For The Detection of Coupling in EEG SignalsAdyNo ratings yet

- Electric and Magnetic Fields and Your HealthDocument36 pagesElectric and Magnetic Fields and Your HealthAnonymous hr7E1MNo ratings yet

- BiomedEngApplBasisComm17 p167 - Meditation EEG Interpretation Based On Novel Fuzzy-Merging Strategies and Wavelet FeaturesDocument9 pagesBiomedEngApplBasisComm17 p167 - Meditation EEG Interpretation Based On Novel Fuzzy-Merging Strategies and Wavelet FeaturesAdyNo ratings yet

- Bems1996 AbstractsDocument242 pagesBems1996 AbstractsAdyNo ratings yet

- A Local Neural Classifier For The Recognition of Eeg Patterns Associated To Mental TasksDocument9 pagesA Local Neural Classifier For The Recognition of Eeg Patterns Associated To Mental TasksAdyNo ratings yet

- Guide To Ista+Document30 pagesGuide To Ista+Guilherme PfeilstickerNo ratings yet

- EEG Signal Classification For Brain Computer Interface ApplicationsDocument72 pagesEEG Signal Classification For Brain Computer Interface Applicationsiolandadumitrescu4365No ratings yet

- Classification of Eeg Signals Using Neural Network and Logistic Regression PDFDocument13 pagesClassification of Eeg Signals Using Neural Network and Logistic Regression PDFAdyNo ratings yet

- Kural 2011 J. Phys.: Conf. Ser. 305 012088Document11 pagesKural 2011 J. Phys.: Conf. Ser. 305 012088AdyNo ratings yet

- Rubellus Petrinus Alchemy Journals Vol1Document10 pagesRubellus Petrinus Alchemy Journals Vol1travellerfellowNo ratings yet

- Chemical Resistance Guide EPDM & FKMDocument38 pagesChemical Resistance Guide EPDM & FKMnielhaywardgmailNo ratings yet

- 1009938Document222 pages1009938AdyNo ratings yet

- Audible Voice To Skull PDFDocument111 pagesAudible Voice To Skull PDFAnca Mihaela Vlas100% (1)

- Derby Homes JD Support Workers MilestoneDocument3 pagesDerby Homes JD Support Workers MilestoneAdyNo ratings yet

- CDSM - Winter Spring 2013-2014Document3 pagesCDSM - Winter Spring 2013-2014AdyNo ratings yet

- Dacia SarmisegetuzaDocument359 pagesDacia SarmisegetuzaCristian N ANTONESCU100% (3)

- Dacia SarmisegetuzaDocument359 pagesDacia SarmisegetuzaCristian N ANTONESCU100% (3)

- 06.02.2012 Comisioane Western UnionDocument1 page06.02.2012 Comisioane Western Unionloredana_tagartaNo ratings yet

- Metal Spinning Lathe TutorialDocument15 pagesMetal Spinning Lathe TutorialMike SullivanNo ratings yet

- Craigslist US Cities PageRank 7-19-2013Document8 pagesCraigslist US Cities PageRank 7-19-2013AdyNo ratings yet

- Geological Survey Professional PaperDocument89 pagesGeological Survey Professional PaperAdyNo ratings yet

- Basic Two-Stroke TuningDocument9 pagesBasic Two-Stroke TuningAdyNo ratings yet

- Atlas Copco ManualDocument152 pagesAtlas Copco ManualtatasrbaNo ratings yet

- Microfon 4 MiljeDocument3 pagesMicrofon 4 MiljetebrovacaNo ratings yet

- Drill Press TableDocument12 pagesDrill Press TableSuranga PierisNo ratings yet

- 25008Document13 pages25008AdyNo ratings yet

- HiLiftPresPt1 PDFDocument49 pagesHiLiftPresPt1 PDFAdyNo ratings yet

- 2stroke 18HP 4KG Da170 - Views PDFDocument1 page2stroke 18HP 4KG Da170 - Views PDFAdyNo ratings yet

- rt8205b Datasheet-06Document28 pagesrt8205b Datasheet-06André Hipnotista100% (1)

- EnergySRP Forms MatchingDocument2 pagesEnergySRP Forms Matchingeiad-mahmoudNo ratings yet

- SGP Chapter-1Document81 pagesSGP Chapter-1Shashank ReddyNo ratings yet

- Bomba Electrica 1500gpm 300HP (Medidas)Document1 pageBomba Electrica 1500gpm 300HP (Medidas)Fire ChileNo ratings yet

- Boundary Layer ThicknessDocument23 pagesBoundary Layer ThicknessPridhar ThiagarajanNo ratings yet

- Mantrac Egypt ProfileDocument9 pagesMantrac Egypt ProfilenabilredascribdNo ratings yet

- Three-Phase Induction MotorDocument21 pagesThree-Phase Induction MotorRajeev ValunjkarNo ratings yet

- Every Emergency.: C Safe Marine Generator SetsDocument4 pagesEvery Emergency.: C Safe Marine Generator SetsBrillyanNo ratings yet

- Waste Water-Sewage PumpDocument111 pagesWaste Water-Sewage Pumpcharadeg100No ratings yet

- India's Former President APJ Abdul Kalam on Leadership, Knowledge and Managing FailureDocument14 pagesIndia's Former President APJ Abdul Kalam on Leadership, Knowledge and Managing FailureHarsh TiwariNo ratings yet

- TMX53DC 1607 121 (Drawings Electric)Document13 pagesTMX53DC 1607 121 (Drawings Electric)ChristianNo ratings yet

- Makerere University Civil Engineering Assignment on Nalubaale DamDocument8 pagesMakerere University Civil Engineering Assignment on Nalubaale DamRobert WalusimbiNo ratings yet

- Xref 2010Document1 pageXref 2010Axel Mahya AvichenaNo ratings yet

- All Terrain Vehicle Wiring PDFDocument3 pagesAll Terrain Vehicle Wiring PDFVINAY KUMARNo ratings yet

- IGBTDocument22 pagesIGBTumeshgangwar100% (1)

- Fire Pump Installation GuideDocument3 pagesFire Pump Installation GuideJeff D. AgustinNo ratings yet

- Unit 1Document36 pagesUnit 1MonishNo ratings yet

- Aufbau PrincipleDocument4 pagesAufbau PrinciplecrbrumaNo ratings yet

- Q 1000Document24 pagesQ 1000Fredy Vázquez VelázquezNo ratings yet

- CH 3 Gas Refrigeration CycleDocument20 pagesCH 3 Gas Refrigeration CycleMeleseNo ratings yet

- Evaluating The Effectiveness of Retrofitting An Existing Hospitality Buildingsia in 2010-2014Document8 pagesEvaluating The Effectiveness of Retrofitting An Existing Hospitality Buildingsia in 2010-2014International Journal of Innovative Science and Research TechnologyNo ratings yet

- PG Parts Catalog1Document179 pagesPG Parts Catalog1Olivier ORMANNo ratings yet

- Question Paper Code:: Reg. No.Document2 pagesQuestion Paper Code:: Reg. No.tamilarasi87thulasiNo ratings yet

- 1004 Saiesh 1005 Brembley 1006 Russell 1007 MukeshDocument65 pages1004 Saiesh 1005 Brembley 1006 Russell 1007 MukeshbenonNo ratings yet

- Dose Complete CatalogueDocument272 pagesDose Complete CatalogueBerkan OranusNo ratings yet

- ME6502 Heat and Mass Transfer SyllabusDocument26 pagesME6502 Heat and Mass Transfer Syllabusamdeva0% (1)

- Dna60 PDFDocument15 pagesDna60 PDFAc IdNo ratings yet

- Connection TableDocument10 pagesConnection TableBepdjNo ratings yet

- Motor (ABB Type)Document50 pagesMotor (ABB Type)Rolando Nunez del Prado B.No ratings yet

- FMC Smith Meter 01 - Mesurement Product & SystemDocument70 pagesFMC Smith Meter 01 - Mesurement Product & SystemDucVikingNo ratings yet