Professional Documents

Culture Documents

Effect of Stabilization by Using GGBS On Black Cotto Soil PDF

Uploaded by

Er Sufyan AnsariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Effect of Stabilization by Using GGBS On Black Cotto Soil PDF

Uploaded by

Er Sufyan AnsariCopyright:

Available Formats

Effect of Stabilization Using GGBS on

Engineering Properties of Black Cotton Soil

Sufyan Ansari *

Student Final Year

ITM-College of Engineering

Nagpur, India

samfaizee007@gmail.com

Dushyant Yadav

Student Final Year

ITM-College of Engineering

Nagpur, India

dushyant.yadav2@gmail.com

Kavita S. Kene

Hemant V. Hajare

Asst. Professor

ITM-College of Engineering

Nagpur, India

kavitak@itmnagpur.ac.in

Principal

ITM-College of Engineering

Nagpur, India

hemanth@itmnagpur.ac.in

Akshaykumar Bhuyarkar

Student Final Year

ITM-College of Engineering

Nagpur, India

akshayb36@gmail.com

Akshata Lanjewar

Student Final Year

ITM-College of Engineering

Nagpur, India

akshatalanjewar832@gmail.com

Abstract: Soil stabilization can be explained as the alteration of the soil properties by chemical

or physical means in order to enhance the engineering quality of the soil. The main objectives

of the soil stabilization are to increase the bearing capacity of the soil, its resistance to

weathering process and soil permeability. Stabilization is a broad sense for the various

methods employed and modifying the properties of a soil to improve its engineering

performance and used for a variety of engineering works. In todays soil stabilization is the

major problem for civil engineers, either for construction of road and also for increasing the

strength or stability of soil and reduces the construction cost. Ground granulated blast

furnace slag (GGBS) material is used in the current work to stabilize soil (clay). The main

objectives of this paper were to investigate the effect of GGBS on the engineering property

(optimum moisture content and maximum dry density, plastic limit, liquid limit, compaction,

unconfined compressive strength, triaxial and California bearing ratio test) of the soil and

determine the engineering properties of the stabilized. Granulated shaped blast furnace slag is

most suitable for increasing the strength of the soil and for this we check the following

property of soil. GGBS are added from 0% to 40% by dry weight of soil, first of all check the all

soil property at 0 % (no GGBS) and then compare after addition of GGBS from 10% to 40%. On

the basis of Standard Proctor test & Unconfined Compressive Strength test the optimum

percentage of GGBS is 10%. Investigations showed that generally the engineering properties

which improved with the addition of GGBS. The California bearing ratio of soil increases as the

percentage of GGBS replaced in increase.

Keywords: California bearing ratio test, GGBS, Soil Stabilization, Unconfined Compression

test.

1.0 INTRODUCTION

lack clayey soil (BC Soil) represents a wellknown category of problematic from civil

engineering point of view. They exhibit large

volumetric changes shrinkage and swelling

behaviour if the moisture content changed. Due

to this nature this type of soil is susceptible to

damage to the structures and pavements

founded on it. In India expansive soils cover

about 0.8X10 km areas approximately 20% of

surface area. 40 to 60% of the Black clayey soil

(BC soil) has a size less than 0.001 mm. At the

liquid limit, the volume change is of the order of

200 to 300% and results in swelling pressure as

* Corresponding Author

high as 8 kg/cm to 10 kg/cm . As such Black

clayey soil (BC soil) has very low bearing

capacity and high swelling and shrinkage

characteristics. Soaked laboratory CBR values

of Black Clayey soils are generally found in the

range of 2 to 4%.Structures founded in areas

with soft or weak soil have need for

improvement of soil properties by using

additives.

Soil stabilization techniques are used to

improve shear strength, CBR, reducing

expansive characteristics, etc. For any landbased structure, The foundation is very

important and has to be strong to support the

entire structure. In order for the foundation to be

strong, the soil around it plays a very critical role.

The process of soil stabilization helps to achieve

the required properties in a soil needed for the

construction work. Stabilization has started to

take a new shape. With the availability of better

research, materials and equipment, it is

emerging as a popular and cost-effective

method for soil improvement.

Many waste materials are used to modify

the characteristics of soft soils. Traditionally the

soils are stabilized by lime, cement, etc. In

recent year the uses of waste materials like fly

ash, plastic, rice-husk ash, slag, etc. for soil

stabilization is gaining importance. Here, in this

project soil stabilization has been done with the

help of Ground Granulated Blast Furnace Slag

(GGBS or GGBFS) which is obtained by

quenching molten iron slag from a blast furnace

in water or steam. The GGBS we are using in

this project is obtained from the Uttam Galva

Steel Plant situated at Wardha, Maharashtra.

And the soil we are using for testing is from

behind Hanuman Mandir, ITM- college of

Engineering, Kamptee Campus. By physically

observing the soil we concluded that the soil is

of Black Cotton Soil. The real characteristic of

soil can be determined by doing the primary

tests on soil i.e. Sieve analysis, Atterberges

limit, etc.

[5]

Whitehurst and Yoder (1952) : Two

percent lime is insufficient to affect appreciably

the performance of the soils tested. Five percent

lime, or more significantly increased both

strength and durability of these soils. Increased

length of curing before testing was, in general,

beneficial. Of the soils tested, the gravel and the

least by the drift soil derived the greatest

benefits of adding lime. The dynamic test

employed seems to be quite adequate as a

measure of progressive deterioration and merits

further consideration.

3.0 MATERIALS AND METHODS

3.1.1 Black Cotton Soil

The soil we are using for testing is from

behind Hanuman Mandir, ITM- college of

Engineering, Kamptee Campus. By physically

observing the soil we concluded that the soil is

of Black Cotton Soil. The black cotton soil has

been used as a base material in this study. It

has been replaced partially by GGBS by weight

of dry soil. The clayey soil involved in this

research was collected from outside campus

wall, near main gate of ITM- College of

Engineering, Kamptee, Nagpur. The soil sample

was disturbed. The soil is classified as clay of

high plasticity (Gs = 2.27) with expansive

behaviour.

Table 1: Basic Properties of Soil

The main objective of this investigation to

improved the Engg. Properties of soil with

addition of GGBS.

Sr. No.

Description of item

Result

Natural water content

2.43%

2.0 LITERATURE REVIEW

Sieve analysis

Sand= 8.73%

The engineering properties of clayey subgrade soils may need to be improved to make

them suitable for construction using some sort of

stabilization methods. Stabilization of pavement

sub-grade soils has traditionally relied on

treatment with lime, cement, or waste materials

such as fly ash, slag, Silica Fume, GGBS, etc.

Many researchers are looking for alternative

materials for soil stabilization; fly ash is an

effective agent for chemical and mechanical

stabilization of soil.

[4]

Havelin and Kahn (1950) : The tests

showed that small amounts of lime with fly ash

develop considerable strength when mixed with

aggregates such as sandy soil, slag, and

crushed stone. Good resistance to wetting and

drying and freezing and thawing is also evident.

Resistance to freezing and thawing is greater in

specimens which have cured for longer periods.

The use of calcium chloride increases the early

strength.

Clay= 91.27%

3

Liquid limit

41.80%

Plastic limit

22.46%

Plasticity index

19.34%

Specific gravity

2.27

Type of soil

CL

3.1.2 Ground Granulated Blast Furnace Slag

(GGBS):

Source: Uttam Galva Steel Plant, Wardha

Maharashtra 442001. Granulated Blast Furnace

Slag is obtained by Rapidly chilling (quenching)

the molten ash from The furnace with the help of

water. During this Process, the slag gets

fragmented and Transformed into amorphous

granules (glass). The Granulated slag is ground

to desired fineness For Producing GGBS.

sectional area was calculated by dividing the

area by (1- ) and then the compressive stress

for each step was calculated by dividing the load

with the corrected area

3.1.5 Proctor compaction test

This experiment gives a clear relationship

between the dry density of the soil and the

moisture content of the soil. The equations used

in this experiment are as follows:

Fig.1: Ground Granulated Blast Furnace Slag

3.1 Methods of Testing

The laboratory tests carried out on the

Natural soil include Sieve analysis, Atterberges

Limits, Specific gravity, Free swell test, Standard

Proctor test, Unconfined Compressive strength

Test and California Bearing Ratio test.

3.1.3 California Bearing Ratio Test

The California Bearing Ratio test is

conducted for evaluating the stability of the sub

grade and the material used in sub base and

base of the flexile pavement. The plunger in the

CBR test penetrates the specimen in the mould

at the rate of 1.25 mm per minute. The loads

required for a penetration of 2.5mm and 5.00mm

are determined. The penetration load is

expressed as a percentage of the standard load

at the respective penetration level of 2.5mm or

5.0mm.

4.0 RESULTS AND DISCUSSION

4.1 Standard Proctor Test

Standard Proctor tests were used to

establish the dry density-moisture content

relationship and carried out the test of soil with

various amounts of GGBS added consider the

effect of GGBS on optimum moisture content

and maximum dry density the test of soil with 0

% to 40% by dry weight of soil.

Table 2: Effect of GGBS on OMC and MDD

GGBS (%)

OMC (%)

MDD (gm/cc)

23

1.57

10

19.5

1.6

20

19.5

1.57

30

19.5

1.58

40

18

1.57

CBR Value = (Penetration Load/Standard Load)

x 100

The

CBR

value

is

determined

corresponding to both penetration levels. The

greater of these values is used for the design of

the pavement.

This experiment is used to determine the

unconfined compressive strength of the soil

sample which in turn is used to calculate the

unconsolidated, undrained shear strength of

unconfined soil. The unconfined compressive

strength (qu) is the compressive stress at which

the unconfined cylindrical soil sample fails under

simple compressive test. The experimental

setup constitutes of the compression device and

dial gauges for load and deformation. The load

was taken for different readings of strain dial

gauge starting from = 0.005 and increasing by

0.005 at each step. The corrected cross-

Dry Density gm/cc

3.1.4 Unconfined compression test

1.62

1.59

1.56

1.53

1.50

1.47

1.44

1.41

1.38

1.35

11.00 16.00 21.00 26.00 31.00 36.00

Water Content %

Fig.1: OMC and MDD from 0% to 40 %

SG0

SG10

SG20

SG30

SG40

4.2. Effect of GGBS

Compressive Strength

on

Unconfined

Soil with various amounts of GGBS added

to determine the effect on compressive strength

of soil with 0 % to 40% by dry weight of soil.

Table 2: Effect of GGBS on Compressive

Strength of Soil

GGBS (%)

UCS (kg/cm2)

0.96

10

1.56

20

1.16

30

1.03

40

0.41

SG10

1.00

SG20

SG30

0.50

SG40

0.00

0.15

Fig.2: Unconfined compressive strength (0%

to 40%)

4.3. California Bearing Ratio Test

Soil with various amounts of GGBS added

to determine the effect on California bearing

ratio test of soil with 0 % to 40% by dry weight of

soil.

140.00

120.00

Load in Kg

2.13

10

2.13

20

1.42

30

2.13

40

3.55

the

following

1. C B R value increases with increases in

percentage of GGBS that show the

densification of soil takes place and more

suitable for pavement thickness.

SG0

0.1

CBR Value

By analysis of result

conclusions may be drawn:

1.50

0.05

GGBS (%)

5.0 CONCLUSION

2.00

Table3: Effect of GGBS on CBR Value

100.00

SG0

80.00

2. Densification of soil (clay) takes place with

increases in percentage of GGBS and

plasticity index is more than 17 % thus

making the soil suitable for embankment and

for pavement of light and medium traffic. The

pavement thickness will be reduced

considerably with increases in percentage of

GGBS With the increases in % of coarse

particles causes increases in permeability

and reducing the influence of pore water

pressure and enhance the self-strength of

soil, so stability of soil increases. On the

basis of the Standard proctor test &

Unconfined Compressive strength test the

optimum percentage of GGBS IS 10%.

6.0 ACKNOWLEDGEMENT

The authors are gratefully acknowledging

the support extended by the respective institute

in bringing out this article. We also thankful to

Final year project (B.E student), all teaching and

non teaching staff of civil engineering

department ITMCOE Kamptee, Nagpur and Mr.

Sanjay Wankhede CEO of GEOsystems

Research and Consultants (I) Pvt. Ltd and all of

his staff members.

SG10

60.00

SG20

40.00

SG30

20.00

SG40

0.00

0.0 3.0 6.0 9.0 12.0

Penetration in mm

Fig 3: CBR Value (0% to 40%)

References

[1] Prof.

Krishna

Reddy,

UIC,

2008,

Engineering Properties of Soils Based on

Laboratory Testing (9).

[2] http://www.engineeringtraining.tpub.com/140

70/css/14070_424.htm (8)

[3] Ashish Kumar Pathak et al Int. Journal of

Engineering Research and Applications

ISSN: 2248-9622, Vol. 4, Issue 5(Version 2),

May 2014, pg.164-171.

[4] L. J. Minnick, W. H. Carson, R. M. Miller,

Lime-Flyash Compositions for Use in

Highway Construction Proc. HRB Vol. 30

(1950) pg. 489.

[5] E. A. Whitehurst, E. J. Yoder, Durability

Tests on Lime-Stabilized Soils. Proceedings

HRB Vol. 31 (1952), pg. 529.

[6] Journal of Applied Sciences Research, 8(4)

(2012), pg. 2193-2196

[7] Effect of Stabilization Using Fly ash and

GGBS in Soil Characteristics, International

Journal of Engineering Trends and

Technology (IJETT) Volume 11 Number 6

- May 2014, pg. 284-289.

[8] J.M. Hoover, D.T. Davidson, Preliminary

Evaluation of Some Organic Cationic

Chemicals As Stabilizing Agents for Iowa

Loess , Iowa Eng. Exo. St.1956.

[9] Electronic

Journal

of

Geotechnical

Engineering, Vol. 17 (2012), pg. 2443-2461.

[10] Fly Ash Utilization Programme (FAUP),

TIFAC, Vol. VIII, pg. 5.1-5.10.

Authors Biography

Dr. H. V. Hajare has done his

B.E & PG from VNIT College

and doctorate degrees from

RTMUN. He has more than 26

year teaching Experience. He

has Published 27 research

papers

in

National

&

International Journals. Is a life member of

various professional bodies,

Prof. Kavita Kene obtained PG

degrees

from

RTMNU

University.

Her

area

of

specialization

is

Structural

Engineering. She has Published

06

research

papers

in

International Journals & 03

papers in international conferences.

Mr. Sufyan Ansari pursuing

B.E. in Civil Engineering from

RTM Nagpur University. His

area of interest is Geotechnical

Engineering. He has completed

Diploma in Civil engineering

from MSBTE.

You might also like

- Soil StabilizationDocument35 pagesSoil StabilizationVaish Navi100% (1)

- Stabilization of Clayey Soil by Lime & Coir: Shreyas.KDocument22 pagesStabilization of Clayey Soil by Lime & Coir: Shreyas.KAli Saleh Saad ALiSAWiNo ratings yet

- Report AbhiDocument14 pagesReport AbhiAshique PNo ratings yet

- Performance Characteristic Study of Weak Subgrade Soil and Improving The Strength of Subgrade Soil by Stabilization TechniquesDocument62 pagesPerformance Characteristic Study of Weak Subgrade Soil and Improving The Strength of Subgrade Soil by Stabilization TechniquesJagadisha AcharNo ratings yet

- SOIL STABLIZATIONBook FinalDocument57 pagesSOIL STABLIZATIONBook FinalMUUTHUKRISHNANNo ratings yet

- Stabilization of Sub-Grade Using Fly Ash and Geosynthetic MaterialDocument12 pagesStabilization of Sub-Grade Using Fly Ash and Geosynthetic MaterialSarabpreet SobtiNo ratings yet

- CBR For Black Cottan Soil With Coconut Shells' PDFDocument4 pagesCBR For Black Cottan Soil With Coconut Shells' PDFAnbu GanesanNo ratings yet

- Modification of Subgrade Properties Using Waste Generated From SandDocument8 pagesModification of Subgrade Properties Using Waste Generated From SandceanilNo ratings yet

- Stabilization of Black Cotton Soil by Admixtures PDFDocument19 pagesStabilization of Black Cotton Soil by Admixtures PDFSantosh NaikNo ratings yet

- STABILIZING SOIL WITH INDUSTRIAL WASTESDocument15 pagesSTABILIZING SOIL WITH INDUSTRIAL WASTESvikas chawlaNo ratings yet

- Improvement in Engineering Properties of Expansive Soils Using Ground Granulated Blast Furnace SlagDocument6 pagesImprovement in Engineering Properties of Expansive Soils Using Ground Granulated Blast Furnace SlagArham SheikhNo ratings yet

- Irjet V7i11143Document6 pagesIrjet V7i11143OwaisNo ratings yet

- IRC ProposalDocument50 pagesIRC ProposalashwinmjoshiNo ratings yet

- Stabilization of Expansive Soil Using Brick DustDocument8 pagesStabilization of Expansive Soil Using Brick DustRocky BhaiNo ratings yet

- Effect of Fiber On Fly-Ash Stabilized Sub Grade Layer ThicknessDocument8 pagesEffect of Fiber On Fly-Ash Stabilized Sub Grade Layer ThicknessEr Harshvardhan IngawaleNo ratings yet

- Effect of Polypropylene Fibers, Lime and Ceramic Additives On The Compressibility of Silty-Clay SoilDocument11 pagesEffect of Polypropylene Fibers, Lime and Ceramic Additives On The Compressibility of Silty-Clay SoilAsad HafudhNo ratings yet

- Stabilization of Black Cotton Soil Using Lime: Shailendra Singh, Hemant B. VasaikarDocument7 pagesStabilization of Black Cotton Soil Using Lime: Shailendra Singh, Hemant B. VasaikarPRADEEP100% (1)

- Soil Stabilization Methods and Cement StabilizationDocument31 pagesSoil Stabilization Methods and Cement StabilizationSiddharth RavuriNo ratings yet

- Stabilizing High Plastic Clayey Soil Using AdmixturesDocument15 pagesStabilizing High Plastic Clayey Soil Using Admixtureswaleed MalikNo ratings yet

- Ghobadi, M. H. Abdilor, Y. Babazadeh, R.Document9 pagesGhobadi, M. H. Abdilor, Y. Babazadeh, R.BRUNO KARASIAKNo ratings yet

- Stabilizing Black Cotton SoilDocument5 pagesStabilizing Black Cotton SoilDev SoniNo ratings yet

- An Experimental Study On Soil Strength E PDFDocument10 pagesAn Experimental Study On Soil Strength E PDFMarkanthony TatonNo ratings yet

- Paper 8Document7 pagesPaper 8RakeshconclaveNo ratings yet

- Civil Engineering Collaboration: Analisa Perbaikan Tanah Lempung Dengan Menggunakan Limbah Serbuk GergajiDocument5 pagesCivil Engineering Collaboration: Analisa Perbaikan Tanah Lempung Dengan Menggunakan Limbah Serbuk Gergajizul azmiNo ratings yet

- Review Paper On Study On Properties of Black Cotton Soil Using Stone Dust and Sisal FiberDocument3 pagesReview Paper On Study On Properties of Black Cotton Soil Using Stone Dust and Sisal FiberEditor IJTSRDNo ratings yet

- Study On Geotechnical Properties of Stabilized Expansive Soil-Quarry Dust MixesDocument7 pagesStudy On Geotechnical Properties of Stabilized Expansive Soil-Quarry Dust MixesRVNLPKG6B VBL-GTLMNo ratings yet

- 2012 USA, Mejora de Las Características de Los Suelos Expansivos de Suelos Expansivos Utilizando Cal y Cenizas VolantesDocument6 pages2012 USA, Mejora de Las Características de Los Suelos Expansivos de Suelos Expansivos Utilizando Cal y Cenizas VolantesEder RuizNo ratings yet

- Anil EditDocument10 pagesAnil EditEswar RoyalsNo ratings yet

- 03 Jul 20150207373Document4 pages03 Jul 20150207373Anonymous lMNXFwONo ratings yet

- Enhancing The Bearing Capacity of B.c.soil by Using Shredded Rubber TyreDocument5 pagesEnhancing The Bearing Capacity of B.c.soil by Using Shredded Rubber Tyremukesh poundekarNo ratings yet

- Determination of Optimum Cement Content For Stabilization of Soft Soil and Durability Analysis of Soil Stabilized With CementDocument5 pagesDetermination of Optimum Cement Content For Stabilization of Soft Soil and Durability Analysis of Soil Stabilized With CementHhowtobe YounesNo ratings yet

- IJEAS0303031Document6 pagesIJEAS0303031erpublicationNo ratings yet

- Soil Stabilization With Using Waste Materials Against Freezing Thawing EffectDocument3 pagesSoil Stabilization With Using Waste Materials Against Freezing Thawing EffectArham SheikhNo ratings yet

- Soil Stabilization Using Natural Fiber Coir: International Research Journal of Engineering and Technology (IRJET)Document5 pagesSoil Stabilization Using Natural Fiber Coir: International Research Journal of Engineering and Technology (IRJET)Ali Saleh Saad ALiSAWiNo ratings yet

- Soil Stablisation Using Coconut Coir Fibre & EggDocument12 pagesSoil Stablisation Using Coconut Coir Fibre & EggDeepansh YadavNo ratings yet

- Plastic Shreds in StabilizationDocument10 pagesPlastic Shreds in StabilizationRoshNa B SudhEerNo ratings yet

- Expansive Soil Stabilization Using Industrial Solid Wastes A ReviewDocument11 pagesExpansive Soil Stabilization Using Industrial Solid Wastes A ReviewTIZA MICHAEL B.Engr., BBS, MBA, Aff. M. ASCE, ASS.M. UACSE, M. IAENG. M.ITE.100% (1)

- Seminar Report 2020 1Document31 pagesSeminar Report 2020 1Sandesh KedarNo ratings yet

- Stabilization of Soil by Using Plastic Wastes: AbstractDocument6 pagesStabilization of Soil by Using Plastic Wastes: AbstractUmange Ranasinghe100% (1)

- Soil Stabilization Using PlasticDocument4 pagesSoil Stabilization Using PlasticHusna A SNo ratings yet

- Stabilizing Clay Soils with Volcanic Ash and TailingsDocument6 pagesStabilizing Clay Soils with Volcanic Ash and TailingsahmadNo ratings yet

- Ajaz PaperDocument20 pagesAjaz Papervikas chawlaNo ratings yet

- Stabilization of Sub Grade by Using Additives Cement LimeDocument5 pagesStabilization of Sub Grade by Using Additives Cement LimeKarien BesterNo ratings yet

- Ijs DR 2009016Document6 pagesIjs DR 2009016عبدالرحمن العليميNo ratings yet

- WJRR0404047Document4 pagesWJRR0404047Yoris R ChannelNo ratings yet

- 245 464 1 PBDocument10 pages245 464 1 PBRhesa Dian PratamaNo ratings yet

- Effect of Cement Treatment On Geotechnical Properties of Some Washington State SoilsDocument7 pagesEffect of Cement Treatment On Geotechnical Properties of Some Washington State Soilsherve JordanNo ratings yet

- Fyp Reinforced Soil by CH JunaidDocument26 pagesFyp Reinforced Soil by CH JunaidChaudary Junaid MughalNo ratings yet

- Dry Density ValuesDocument4 pagesDry Density ValuesNandakrishnan S LNo ratings yet

- Lime StabilizationDocument4 pagesLime StabilizationKshitija NadgoudaNo ratings yet

- Iaetsd-Jaras-Effect of Soil Stabilization by Consolid System OnDocument5 pagesIaetsd-Jaras-Effect of Soil Stabilization by Consolid System OniaetsdiaetsdNo ratings yet

- Granular piles improve expansive soil strength and reduce settlementDocument5 pagesGranular piles improve expansive soil strength and reduce settlementpkNo ratings yet

- Soil Stabilization Using Marble DustDocument6 pagesSoil Stabilization Using Marble DustnidsNo ratings yet

- Black Cotton Soil Stabilization MethodsDocument8 pagesBlack Cotton Soil Stabilization MethodsSudiptaNo ratings yet

- MIHIR 7th Sem. Civil ProjectDocument19 pagesMIHIR 7th Sem. Civil ProjectKUNAL SHAHNo ratings yet

- Influence of Geopolymers in The Stabilization of Clay SoilDocument13 pagesInfluence of Geopolymers in The Stabilization of Clay SoilAmmar AhmedNo ratings yet

- Investigative Study On Soil Stabilization Using Fiber Waste MaterialsDocument15 pagesInvestigative Study On Soil Stabilization Using Fiber Waste MaterialshariiNo ratings yet

- Stabilization of Soft Soil by A Sustainable Binder Comprises Ground Granulated Blast Slag (GGBS) and Cement Kiln Dust (CKD)Document18 pagesStabilization of Soft Soil by A Sustainable Binder Comprises Ground Granulated Blast Slag (GGBS) and Cement Kiln Dust (CKD)Shaker QaidiNo ratings yet

- Ground Improvement Case Histories: Compaction, Grouting and GeosyntheticsFrom EverandGround Improvement Case Histories: Compaction, Grouting and GeosyntheticsRating: 3.5 out of 5 stars3.5/5 (3)

- SeminalDocument4 pagesSeminalEr Sufyan AnsariNo ratings yet

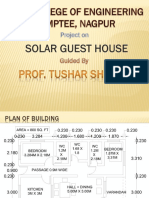

- Report On Solar Guest HouseDocument11 pagesReport On Solar Guest HouseEr Sufyan AnsariNo ratings yet

- Solar Guest HouseDocument11 pagesSolar Guest HouseEr Sufyan AnsariNo ratings yet

- IJRESTS Published Paper PDFDocument5 pagesIJRESTS Published Paper PDFEr Sufyan AnsariNo ratings yet

- Solar Guest HouseDocument11 pagesSolar Guest HouseEr Sufyan AnsariNo ratings yet

- Sufyan ResumeDocument2 pagesSufyan ResumeEr Sufyan AnsariNo ratings yet

- Hello EveryoneDocument1 pageHello EveryoneEr Sufyan AnsariNo ratings yet