Professional Documents

Culture Documents

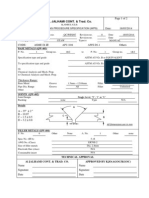

Form Qw-485 Suggested Format For Demonstration of Standard Welding Procedure Specifications (SWPS) (See Article V)

Uploaded by

durandm100 ratings0% found this document useful (0 votes)

14 views1 pagePROCEDURE SPECIFICATIONS Demonstration Test Record

Original Title

BPVC_IX_QW-485

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentPROCEDURE SPECIFICATIONS Demonstration Test Record

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

14 views1 pageForm Qw-485 Suggested Format For Demonstration of Standard Welding Procedure Specifications (SWPS) (See Article V)

Uploaded by

durandm10PROCEDURE SPECIFICATIONS Demonstration Test Record

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

FORM QW-485 SUGGESTED FORMAT FOR DEMONSTRATION OF STANDARD WELDING

PROCEDURE SPECIFICATIONS (SWPS)

(See Article V)

Identification of Standard Welding Procedure Specification Demonstrated

Demonstration Welding Variables

Specification and type/grade or UNS Number of Base Metal(s)

to Specification and type/grade or UNS Number of Base Metal(s)

Base Metal P-Number

to Base Metal P-Number

Thickness

Welding Process(es) used

Plate

Pipe (Enter Diameter of Pipe or Tube)

Groove Design (Single V, Double V, Single U, etc.)

Initial Cleaning Method

Backing (with/without)

Filler Metal Specification

Filler Metal or Electrode Classification

Filler Metal or Electrode Trade Name

Size of Consumable Electrode or Filler Metal

Tungsten Electrode Classification and Size for GTAW

Consumable Insert Class and Size for GTAW

Shielding Gas Composition and Flow Rate for GTAW or GMAW (FCAW)

Preheat Temperature

Position (1G, 2G, etc.) of Weld

Progression (Uphill or Downhill)

Interpass Cleaning Method

Measured Maximum Interpass Temperature

Approximate Deposit Thickness for Each Process or Electrode Type

Current Type/Polarity (AC, DCEP, DCEN)

Postweld Heat Treatment Time and Temperature

Visual Examination of Completed Weld (QW-302.4)

Bend Test (QW-302.1)

Type

Date of Test

Transverse Face and Root [QW-462.3(a)]

Result

Type

Side (QW-462.2)

Result

Type

Result

Alternative Radiographic Examination Results (QW-302.2)

Specimens Evaluated By

Title

Company

Welding Supervised By

Title

Company

Welder's Name

Stamp No.

We certify that the statements in this record are correct and that the weld described above was prepared, welded, and tested in accordance with

the requirements of Section IX of the ASME BOILER AND PRESSURE VESSEL CODE.

Organization

Signature

(07/13)

Date

Demonstration Number

You might also like

- Interactive Form QW-485 PDFDocument1 pageInteractive Form QW-485 PDFRama Krishna Reddy DonthireddyNo ratings yet

- Welding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Document5 pagesWelding Procedure Specification (WPS) (QW-482) : PPI/L&T/WPS/013Rajesh Owaiyar100% (1)

- BPVC Ix Qw-484aDocument1 pageBPVC Ix Qw-484aTC Capulcu Mustafa MNo ratings yet

- 2010 SECTION IX WPS FORMATDocument5 pages2010 SECTION IX WPS FORMATAjay ChodankarNo ratings yet

- Qw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )Document2 pagesQw-484A - Suggested Format A For Welder Performance Qualifications (WPQ) )essnelsonNo ratings yet

- BPVC Ix QW-483Document2 pagesBPVC Ix QW-483ganesh82No ratings yet

- 14033Document2 pages14033Priyanathan ThayalanNo ratings yet

- WPQ PDFDocument0 pagesWPQ PDFstanleyNo ratings yet

- P& E WPS Template Rev 00 - OfficialDocument3 pagesP& E WPS Template Rev 00 - OfficialRiaan PretoriusNo ratings yet

- Welder qualification record templateDocument1 pageWelder qualification record templateAnonymous 4e7GNjzGWNo ratings yet

- Automatic, Manual, Machine, or Semi-Auto.Document10 pagesAutomatic, Manual, Machine, or Semi-Auto.ChE_MattNo ratings yet

- QW 406 Asme CodeDocument3 pagesQW 406 Asme CodeMardeOpamenNo ratings yet

- QW-482 WPS FormatDocument2 pagesQW-482 WPS FormatMardeOpamen100% (1)

- WPS TITLEDocument2 pagesWPS TITLERichard Periyanayagam86% (14)

- BPVC Ix QW-482Document2 pagesBPVC Ix QW-482ganesh82No ratings yet

- Qw-482 Welding Procedure Specification (WPS)Document4 pagesQw-482 Welding Procedure Specification (WPS)Aldeline Sungahid100% (2)

- Sample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Document1 pageSample WPS Form (GTAW & SMAW) Welding Procedure Specification (WPS)Ehab HarbNo ratings yet

- Standard Welding Procedure Specification Demonstration FormDocument1 pageStandard Welding Procedure Specification Demonstration FormEmma DNo ratings yet

- Qw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)Document48 pagesQw-482 - Welding Procedure Specification: (Ref. Specification: Asme Section Ix)kamalakarsastry13530% (1)

- WPQ SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONSDocument1 pageWPQ SUGGESTED FORMAT A FOR WELDER PERFORMANCE QUALIFICATIONSMohamed Ahmed MaherNo ratings yet

- WELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELDocument4 pagesWELDING PROCEDURE SPECIFICATION FOR STAINLESS STEELAldeline SungahidNo ratings yet

- WELDING PROCEDURE AND QUALIFICATION RECORDSDocument4 pagesWELDING PROCEDURE AND QUALIFICATION RECORDSETSNo ratings yet

- WPS For Shaft of TG-9 ImpellerDocument17 pagesWPS For Shaft of TG-9 ImpellerRaymond de WeeverNo ratings yet

- QW-482 201.1Document2 pagesQW-482 201.1Barwin CruzNo ratings yet

- PQR TipsDocument4 pagesPQR TipsWaqas WaqasNo ratings yet

- Wps Format (Qw-482)Document2 pagesWps Format (Qw-482)Sebastian RajeshNo ratings yet

- Procedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingDocument6 pagesProcedure Qualification Records (PQR) : in Accordance With ASME SECTION IX For Power PippingNovita Dwi IsnaeniNo ratings yet

- Proposed Welding Procedure Specification FormatDocument2 pagesProposed Welding Procedure Specification FormatAli MoghiNo ratings yet

- PWPS For Piping-API 1104Document6 pagesPWPS For Piping-API 1104Nguyen Tien Luong100% (1)

- Form QW-482 Welding Procedure Specification FormatDocument4 pagesForm QW-482 Welding Procedure Specification FormatJesus Silva HenaoNo ratings yet

- WPS Format PDFDocument2 pagesWPS Format PDFHimansu Sekhar JenaNo ratings yet

- Valero Aruba Refinery Welding Procedure Specification: For Insert PatchesDocument3 pagesValero Aruba Refinery Welding Procedure Specification: For Insert PatchesRaymond de WeeverNo ratings yet

- Qw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageQw-484A Suggested Format A For Welder Performance Qualifications (WPQ) (See QW-301, Section IX, ASME Boiler and Pressure Vessel Code)Aries MarteNo ratings yet

- WPS GTAW pipe welding procedureDocument2 pagesWPS GTAW pipe welding procedureRichard PeriyanayagamNo ratings yet

- MRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDocument5 pagesMRPL Mangalore CDU VDU Heaters Welding Procedure SpecificationDeepak100% (1)

- All-in-One Manual of Industrial Piping Practice and MaintenanceFrom EverandAll-in-One Manual of Industrial Piping Practice and MaintenanceRating: 5 out of 5 stars5/5 (1)

- Pipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsFrom EverandPipeline Rules of Thumb Handbook: A Manual of Quick, Accurate Solutions to Everyday Pipeline Engineering ProblemsRating: 4.5 out of 5 stars4.5/5 (10)

- Applied Process Design for Chemical and Petrochemical Plants: Volume 1From EverandApplied Process Design for Chemical and Petrochemical Plants: Volume 1Rating: 3.5 out of 5 stars3.5/5 (3)

- Post Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&AFrom EverandPost Weld Heat Treatment PWHT: Standards, Procedures, Applications, and Interview Q&ANo ratings yet

- Fundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationFrom EverandFundamentals of Industrial Heat Exchangers: Selection, Design, Construction, and OperationNo ratings yet

- Which Process?: A Guide to the Selection of Welding and Related ProcessesFrom EverandWhich Process?: A Guide to the Selection of Welding and Related ProcessesNo ratings yet

- Heat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsFrom EverandHeat Exchanger Equipment Field Manual: Common Operating Problems and Practical SolutionsRating: 4 out of 5 stars4/5 (6)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Proceedings of the 8th International Symposium on Superalloy 718 and DerivativesFrom EverandProceedings of the 8th International Symposium on Superalloy 718 and DerivativesNo ratings yet

- Structural Steel Design to Eurocode 3 and AISC SpecificationsFrom EverandStructural Steel Design to Eurocode 3 and AISC SpecificationsNo ratings yet

- Metal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryFrom EverandMetal Valves & Pipe Fittings World Summary: Market Values & Financials by CountryNo ratings yet

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Welding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesFrom EverandWelding the Inconel 718 Superalloy: Reduction of Micro-segregation and Laves PhasesNo ratings yet

- Heating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsFrom EverandHeating Systems Troubleshooting & Repair: Maintenance Tips and Forensic ObservationsNo ratings yet

- Contractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerFrom EverandContractor's Guide for Installation of Gasketed PVC Pipe for Water / for SewerRating: 5 out of 5 stars5/5 (1)

- The Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationFrom EverandThe Handbook of Heating, Ventilation and Air Conditioning (HVAC) for Design and ImplementationRating: 1 out of 5 stars1/5 (1)

- Design Guidelines for Surface Mount TechnologyFrom EverandDesign Guidelines for Surface Mount TechnologyRating: 5 out of 5 stars5/5 (1)

- Nickel-Iron Electrode for Welding Gray Cast IronDocument1 pageNickel-Iron Electrode for Welding Gray Cast Irondurandm10No ratings yet

- Field Welding of Rail SpecificationsDocument4 pagesField Welding of Rail Specificationsdurandm10No ratings yet

- Pages From Rules For The Manufacture Testing and Certification of Materials July 2015-2Document1 pagePages From Rules For The Manufacture Testing and Certification of Materials July 2015-2durandm10No ratings yet

- Freedom Door Installation Guide and Template: SmallDocument1 pageFreedom Door Installation Guide and Template: Smalldurandm10No ratings yet

- Guardrail DesignDocument8 pagesGuardrail Designundf25No ratings yet

- Handrail DesignDocument5 pagesHandrail DesignMuhamadGustiMuharamaNo ratings yet

- Get Going ScoutingDocument2 pagesGet Going Scoutingdurandm10No ratings yet

- Area Efectiva de CorteDocument2 pagesArea Efectiva de CorteCarlos BernabeNo ratings yet

- 1000102Document4 pages1000102durandm10No ratings yet

- Die Safety Blocks WorksheetsDocument4 pagesDie Safety Blocks Worksheetsdurandm10No ratings yet

- Quality Control in Design and Supervision Can Eliminate Lamellar TearingDocument5 pagesQuality Control in Design and Supervision Can Eliminate Lamellar Tearingdurandm10No ratings yet

- Reference Guide Babbit BearingDocument21 pagesReference Guide Babbit BearingsnhmNo ratings yet

- Copper Design GuideDocument28 pagesCopper Design GuidevthiseasNo ratings yet

- Specification Writing Techniques - : Section Format OutlineDocument1 pageSpecification Writing Techniques - : Section Format Outlinedurandm10No ratings yet

- Roll FormingDocument16 pagesRoll FormingrafaelgomezmorenoNo ratings yet

- The Science of Cement and ConcreteDocument23 pagesThe Science of Cement and Concretemareymorsy2822No ratings yet

- Porosity in Castings AFS Transactions 2005Document28 pagesPorosity in Castings AFS Transactions 2005jlplazaolaNo ratings yet

- Coce Manufacturing PDFDocument5 pagesCoce Manufacturing PDFwakasensei99No ratings yet

- Asme Viii - Div.1 (2019)Document1 pageAsme Viii - Div.1 (2019)Ehsan ZiyaeiNo ratings yet

- International Welding Codes and StandardsDocument16 pagesInternational Welding Codes and StandardsRomeo Dela RosaNo ratings yet

- GHJDocument1 pageGHJAbdul Gafoor ShaikhNo ratings yet

- Carrier Fe4anb006l00 Article 1391689351370 en SM PDFDocument33 pagesCarrier Fe4anb006l00 Article 1391689351370 en SM PDFConstantin294No ratings yet

- Brochures - i-MTR2-G02-M0 012 - 018Document12 pagesBrochures - i-MTR2-G02-M0 012 - 018AGUNG SURYO ADI NUGROHONo ratings yet

- Unit-3 and Unit-4Document144 pagesUnit-3 and Unit-4Pragya JainNo ratings yet

- Welding Technology SyllabusDocument1 pageWelding Technology SyllabusShankaranarayanan100% (1)

- Bs en Iso 15607 2019 PDF FreeDocument23 pagesBs en Iso 15607 2019 PDF FreeEL-Hamra Terminal projectsNo ratings yet

- Under Water WeldingDocument16 pagesUnder Water Weldingsyed nadheemNo ratings yet

- Subjet IndexDocument14 pagesSubjet Indexapi-26723112No ratings yet

- STP 494-1971Document32 pagesSTP 494-1971ahmadmubarakaliasNo ratings yet

- Perfect Finishing with Steam and VacuumDocument22 pagesPerfect Finishing with Steam and VacuumUsama KhanNo ratings yet

- Inspection and Test Plan For Epc Gas Pipeline Project-X70mDocument15 pagesInspection and Test Plan For Epc Gas Pipeline Project-X70mFolarin Ayodeji100% (1)

- Practice 6 - Questions - CSWIPDocument12 pagesPractice 6 - Questions - CSWIPravichandran0506No ratings yet

- SF188 Rev 1 - Welder Qualification Test CertificateDocument1 pageSF188 Rev 1 - Welder Qualification Test CertificateMike BoyesNo ratings yet

- Weld Procedure Specification - PR - 0XXDocument7 pagesWeld Procedure Specification - PR - 0XXRAMAKRISHNANo ratings yet

- STD 1104 - Welding of Pipelines and Related FacilitiesDocument39 pagesSTD 1104 - Welding of Pipelines and Related FacilitiesJahidul IslamNo ratings yet

- List of Qualified WeldersDocument3 pagesList of Qualified WeldersRaghavan VenkatramanNo ratings yet

- Welded Connection-1Document23 pagesWelded Connection-1Ynah Marie BoragayNo ratings yet

- ISO 15614-1 Englisch PDFDocument1 pageISO 15614-1 Englisch PDFashrafNo ratings yet

- Qualification RangeDocument1 pageQualification RangeSARSAN NDTNo ratings yet

- Ke2 Evaporatorefficiency: Theory of OperationDocument8 pagesKe2 Evaporatorefficiency: Theory of OperationHoàngViệtAnhNo ratings yet

- Form WPS for MIG Welding ProcedureDocument10 pagesForm WPS for MIG Welding ProcedurePrakash PatelNo ratings yet

- Question 1 of 25Document7 pagesQuestion 1 of 25antonio larottaNo ratings yet

- Form Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Document1 pageForm Qw-482 Suggested Format For Welding Procedure Specifications (WPS) (See QW-200.1, Section IX, ASME Boiler and Pressure Vessel Code)Balkishan DyavanapellyNo ratings yet

- Iso 9606 4 1999Document11 pagesIso 9606 4 1999Lino Alves InácioNo ratings yet

- Asme Manual QuestionDocument4 pagesAsme Manual QuestionAjay SajeevNo ratings yet

- WELDING - Understanding Metal Fusion - Beginners GuideDocument31 pagesWELDING - Understanding Metal Fusion - Beginners GuideVash LengNo ratings yet

- ASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationDocument2 pagesASME Code Section IX - QW-360: Weldingoperator - Performance - QualificationAmit SharmaNo ratings yet

- What Is WeldingDocument50 pagesWhat Is WeldingvenkatNo ratings yet