Professional Documents

Culture Documents

Materials Ferrous

Uploaded by

johnson_regoCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Materials Ferrous

Uploaded by

johnson_regoCopyright:

Available Formats

Materials_General

Page 1 of 3

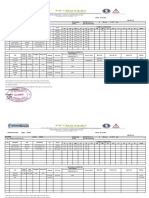

Ferrous Metals

1

CS1020, hot rolled

Mid Steel, hot rolled

Steel 250, hot rolled

structural

CS1020, cold rolled

CS1030, hot rolled

CS1040, hot rolled

CS1022, hot rolled

CS1045, hot rolled

CS1045, forging,

normalised

CS1055, forging,

normalised

ALLOY STEELS

AISI 4130 ChromeMoly, normalised

Steel ANSI 4340,

Oil/temp230

Spring Steel

SAE5150

(Also see Spring

Materials below)

CAST STEELS

Cast Steel, Grade C3

Cast Steel, Grade C41

Cast Steel, Grade C42

Cast Steel, Grade C5

Cast Steel, Grade C6

Cast Steel, Grade

L6B-1

GREY CAST

IRON

Grey Cast Iron Grade

150

Grey Cast Iron Grade

180

Grey Cast Iron

Meehanite

Grey Cast Iron Grade

220

Grey Cast Iron 250/35

Grey Cast Iron Grade

260

Grey Cast Iron Grade

300

Grey Cast Iron Grade

350

Grey Cast Iron Grade

400

DUCTILE IRON

AS1442 7870

AS1204 7870

200

200

80

80

0.29

0.29

200

200

400

410

AS1204 7870

200

80

0.29

250

410

AS1442

AS1442

AS1442

AS1442

AS1442

7870

7870

7870

7870

7870

200

200

200

200

200

80

80

80

80

80

0.29

0.29

0.29

0.29

0.29

300

250

270

330

300

420

500

540

550

570

AS1442 7870

200

80

0.29

620

185

0.29

700

200

Std

10

11

12

13

14 15

10Mpa MPa MPa MPa MPa MPa MPa MPa % 6

/C

kg/

GPa GPa

m3

CARBON

STEELS

ty tu ta cu ca n u y e

120

125

450

455

300

307

232

237

25

25

12

12

307

237

15

12

315

375

405

412

427

243

290

313

319

330

15

12

12

12

12

12

630

465

360

12

675

525

406

12

207

145

160

520

550

225

243

270

27

14

AISI

7850

200

80

Std

AISI

7850

200

80

0.29

415

615

360

310

28

12

ANSI

7850

200

80

0.30

1550

1855

835

700

12

12

SAE

7850

200

80

0.30

1290

1430

715

645

11

12

Std

ty tu ta cu ca n u y e

ty tu ta cu ca n u y e

AS2074 7870

200

80

0.29

430

128

470

14

AS2074 7870

200

80

0.29

460

128

492

14

AS2074 7870

200

80

0.29

490

128

518

14

AS2074 7870

AS2074 7870

200

200

80

80

0.29

0.29

540

620

128

128

550

630

14

14

AS2074 7870

200

80

0.29

860

128

765

14

AS1830 7150

115

45

0.29

150

41

360

195

AS1830 7150

115

45

0.29

180

53

400

234

Matweb 7060

89.6

38.3

0.27

207

12.4

AS1830 7150

115

45

0.29

286

Matweb 7150

115

45

0.29

AS1830 7150

115

45

0.29

260

87

510

338

AS1830 7150

115

45

0.29

300

100

560

390

AS1830 7150

115

45

0.29

350

115

630

455

AS1830 7150

115

45

0.29

400

130

700

520

Std

Std

ty tu ta cu ca n u y e

79.3

207

220

130

827

70

252

93

455

855

110

334

0.5

ty tu ta cu ca n u y e

http://www.learneasy.info/MDME/iTester/get-info/materials_ferrous.html

1/27/2014

Materials_General

Nodular Iron 400-17

Nodular Iron 400-12

Nodular Iron 500-7

Nodular Iron 600-3

Nodular Iron 700-2

Nodular Iron 800-2

Malleable Iron P450-6

Malleable Iron P500-4

Malleable Iron P550-4

Malleable Iron P700-2

Cast Iron Ductile

C3.7Si2.5

STAINLESS

STEELS

Page 2 of 3

AS1831

AS1831

AS1831

AS1831

AS1831

AS1831

AS1832

AS1832

AS1832

AS1832

7000

7000

7000

7000

7000

7000

172

172

172

172

172

172

0.275

0.275

0.275

0.275

0.275

0.275

Matweb 7000

172

0.275

Std

Stainless Steel 304,

Matweb 8000

annealed

Stainless Steel 304,

Matweb 8000

1/2 hard

Stainless Steel 316,

Matweb 8000

rolled

Stainless Steel 440C,

Azom 7650

annealed

Stainless Steel 440C,

Azom 7650

HT/Temp204C

345

400

400

500

600

700

800

450

500

550

700

132

136

146

160

185

197

55

78

90

145

496

130

468

478

506

554

630

666

480

515

540

650

290

400

400

500

600

700

800

450

500

550

700

17

12

7

3

2

2

12

12

12

12

12

12

496

18

12

ty tu ta cu ca n u y e

195

75

0.28

210

505

375

195

75

0.28

750

1030

770

195

75

0.28

415

620

195

77

0.28

448

195

77

0.28

1900

35

17.3

435

15

17.3

465

240

25

16

758

565

260

14

10

2030

1520

1100

10

122

Ref: Mechanical Design Hosking and Harris: 2nd Ed: p1.26 | Matweb | Values in Itallics derived from

Table 3 below | Key to Steels | Azom |

Key

Sym

Std

Name

Units

Reference, Australian Standard, ANSI or other

Density

kg/m3

E

G

Modulus of Elasticity

MPa

Modulus of Rigidity/Shear Modulus

MPa

ty

tu

ta

cu

ca

n

u

y

e

Poissons Ratio

Tensile Yield Stress

MPa

Ultimate Tensile Stress

MPa

Allowable Tensile Stress; by design rules

MPa

Ultimate Compressive Stress

MPa

Allowable Compressive Stress; by design rules

MPa

Fatigue Strength 100e6 cycles

MPa

Ultimate Shear Stress

MPa

Yield Shear Stress

MPa

Breaking Strain: Ductility

% of original length

http://www.learneasy.info/MDME/iTester/get-info/materials_ferrous.html

1/27/2014

Materials_General

Page 3 of 3

micons/metre per oC

Coeff of Thermal Expansion

Approximate Relationship between Shear and Tensile Stresses. Ref

Material

Hard drawn Spring Steels

Spring Steels

Wrought Steel & alloy steel

Ductile Iron

Malleable iron -Pearlitic

Wrought iron

Cast Iron

Copper & alloys

Aluminium & alloys

Shear from UTS

USS

USS

USS

USS

USS

USS

USS

USS

USS

0,45 x UTS

0,5 x UTS

0,75 x UTS

0,90 x UTS

1,0 x UTS

0,83 x UTS

1,3 x UTS

0,7 x UTS

0,65 x UTS

Shear from YS

SSY

SSY

SSY

SSY

SSY

0,45 x YS

0,5 x YS

0,58 x YS

0,75 x YS

0,55 x YS

http://www.learneasy.info/MDME/iTester/get-info/materials_ferrous.html

1/27/2014

You might also like

- Selecting Your Spanco Gantry Crane: Motorized Option AvailableDocument10 pagesSelecting Your Spanco Gantry Crane: Motorized Option AvailablewessamalexNo ratings yet

- Simmerrings PDFDocument152 pagesSimmerrings PDFGogyNo ratings yet

- Static Structural and Fatigue Analysis of SpannerDocument17 pagesStatic Structural and Fatigue Analysis of Spannerprashant kottalagiNo ratings yet

- BS-3031-1 Tyres Crane - TMPDocument12 pagesBS-3031-1 Tyres Crane - TMPgazaliNo ratings yet

- Star Core 6Document2 pagesStar Core 6jmur10No ratings yet

- Modeling of Welded Connections in SolidWorks SimulationDocument5 pagesModeling of Welded Connections in SolidWorks SimulationCleyton L. AlvesNo ratings yet

- AISI 1018 Mild/Low Carbon Steel Properties & UsesDocument4 pagesAISI 1018 Mild/Low Carbon Steel Properties & UsesFikri Rahim100% (1)

- Aac Spec 373001 PDFDocument13 pagesAac Spec 373001 PDFJakesNo ratings yet

- Critical Surface Preparation for Steel CoatingsDocument2 pagesCritical Surface Preparation for Steel CoatingsHIPAPNo ratings yet

- Training ModuleDocument44 pagesTraining ModulegereNo ratings yet

- Fatigue Life Analysis of Joint Bar of Insulated Rail JointDocument7 pagesFatigue Life Analysis of Joint Bar of Insulated Rail JointIJARP PublicationsNo ratings yet

- BoilerTubes - TechnitubeDocument24 pagesBoilerTubes - TechnitubeMMPAPNo ratings yet

- Prestressed Concrete Deflection CalculationsDocument7 pagesPrestressed Concrete Deflection CalculationsKamlesh DalavadiNo ratings yet

- Trapezoidal ThreadsDocument5 pagesTrapezoidal ThreadsSaraswantoNo ratings yet

- Wear Plate PDFDocument19 pagesWear Plate PDFNorma SalazarNo ratings yet

- V Groove WheelDocument3 pagesV Groove Wheelthirumalg1981No ratings yet

- Machine Elements Life and Design: Boris M. Klebanov David M. Barlam Frederic E. NystromDocument5 pagesMachine Elements Life and Design: Boris M. Klebanov David M. Barlam Frederic E. NystromRachu Raj100% (1)

- E1102m PDFDocument283 pagesE1102m PDFBhawani Singh RajawatNo ratings yet

- Bisalloy Technical Manual SectionsDocument65 pagesBisalloy Technical Manual Sectionsramaus100% (1)

- Monorails 4ed Bk180Document12 pagesMonorails 4ed Bk180harishram123456No ratings yet

- Eccentric Column BucklingDocument10 pagesEccentric Column BucklingMukeshChopraNo ratings yet

- Gantry and Jib CranesDocument28 pagesGantry and Jib CranesGogyNo ratings yet

- BS Iso 4992-2Document37 pagesBS Iso 4992-2Thomas ValoNo ratings yet

- DIN 17022-5 - Heat Treating of Ferrous Materials PDFDocument13 pagesDIN 17022-5 - Heat Treating of Ferrous Materials PDFFelipe FernandesNo ratings yet

- Austenitic Cast IronDocument2 pagesAustenitic Cast Ironkatchani123No ratings yet

- ROLLED STEEL BEAMS (Indian Standard) : DesignationDocument2 pagesROLLED STEEL BEAMS (Indian Standard) : DesignationdramiltNo ratings yet

- Stainless Steel Alloys Comparsion ChartDocument3 pagesStainless Steel Alloys Comparsion Chartsengcyan100% (1)

- Worm and Worm Wheel NomenclatureDocument1 pageWorm and Worm Wheel NomenclaturemuhdqasimNo ratings yet

- C P & C I .: Cema B4, B5, C5, C6, D6 & E7 Class IdlersDocument20 pagesC P & C I .: Cema B4, B5, C5, C6, D6 & E7 Class IdlersArdian20No ratings yet

- Spiral Springs PDFDocument18 pagesSpiral Springs PDFEngr Eze Chuklet ChukwumaNo ratings yet

- SKF Pillow Block HousingsDocument64 pagesSKF Pillow Block HousingsJulio Deyvis Ayala Gutierrez100% (1)

- AISI 12L14 Steel Analysis and PropertiesDocument2 pagesAISI 12L14 Steel Analysis and PropertiessyuepiNo ratings yet

- Dsc-Disc Springs To DIN 2093 UsDocument6 pagesDsc-Disc Springs To DIN 2093 UsYoe NoesNo ratings yet

- Design of Below-the-Hook Lifting Devices: ASME BTH-1-2014Document81 pagesDesign of Below-the-Hook Lifting Devices: ASME BTH-1-2014bytestefNo ratings yet

- AISI 1045 Medium Carbon Steel - AZoMDocument4 pagesAISI 1045 Medium Carbon Steel - AZoMLuis NunesNo ratings yet

- Carbon Steel Tee Rails: Standard Specification ForDocument7 pagesCarbon Steel Tee Rails: Standard Specification ForAAYNo ratings yet

- Deva - BM ENDocument24 pagesDeva - BM ENOscar CruzNo ratings yet

- Weld Repair AWS D1.1Document3 pagesWeld Repair AWS D1.1Hemant PatelNo ratings yet

- Design Guide, Spring, Pin, Coiled, SPIROLDocument24 pagesDesign Guide, Spring, Pin, Coiled, SPIROLDerekNo ratings yet

- BS Iso 1817-2011Document30 pagesBS Iso 1817-2011David JacksonNo ratings yet

- JIS G4801 SUP10 Steel GuideDocument2 pagesJIS G4801 SUP10 Steel GuideĐình Sỹ TTPNo ratings yet

- Suhm Spring Works-Spring Materials Issue 9a en US v1Document37 pagesSuhm Spring Works-Spring Materials Issue 9a en US v1DizzixxNo ratings yet

- Pre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsDocument3 pagesPre-Load and Tightening Torques For Steel Fasteners - Standard Metric ThreadsmukeshkumarjNo ratings yet

- Deva - Glide Din 1709Document20 pagesDeva - Glide Din 1709Daniel Matinez EsquivelNo ratings yet

- Brugg Catalog enDocument28 pagesBrugg Catalog enSinoj V AntonyNo ratings yet

- Standard External Circlips for Metric ShaftsDocument5 pagesStandard External Circlips for Metric Shaftschaitanya_kumar_13No ratings yet

- Finite Element Analysis of Engine Mounting Bracket by Considering Pretension Effect and Service LoadDocument7 pagesFinite Element Analysis of Engine Mounting Bracket by Considering Pretension Effect and Service LoadDevendra Kumar KumawatNo ratings yet

- As 4100Document1 pageAs 4100shiruhanNo ratings yet

- 1570 (Part II)Document20 pages1570 (Part II)Kaushik SenguptaNo ratings yet

- Properties s45cDocument3 pagesProperties s45ctomas duranNo ratings yet

- DIN 17100 STEELS GUIDEDocument7 pagesDIN 17100 STEELS GUIDEsardhan.rajender84No ratings yet

- Asme Sec Viii D2 Art D-2 PDFDocument10 pagesAsme Sec Viii D2 Art D-2 PDFDieguitoOmarMoralesNo ratings yet

- Csa-G40 350WLRDocument2 pagesCsa-G40 350WLRMario VenturaNo ratings yet

- ASTM A723 A723M Standard Specification For Alloy Forgings For High-Strength Pressure Component Application PDFDocument4 pagesASTM A723 A723M Standard Specification For Alloy Forgings For High-Strength Pressure Component Application PDFmitchialiNo ratings yet

- Metal Table JISDocument1 pageMetal Table JISNakkolopNo ratings yet

- Materials Properties DatabaseDocument40 pagesMaterials Properties DatabaseJuan Pablo ApazaNo ratings yet

- Metal Table-2865 - 2866Document1 pageMetal Table-2865 - 2866kastelaninNo ratings yet

- Mcode and Mname: Material - Cross - IndexDocument24 pagesMcode and Mname: Material - Cross - IndexSama UmateNo ratings yet

- Electrodes EnglishDocument139 pagesElectrodes Englishcostelino72No ratings yet

- Educating Engineers About Product Design MethodologyDocument8 pagesEducating Engineers About Product Design Methodologyjohnson_regoNo ratings yet

- Elastic Strength of Steel in Tension Compression and ShearDocument56 pagesElastic Strength of Steel in Tension Compression and Shearjohnson_regoNo ratings yet

- Cyclone PDFDocument34 pagesCyclone PDFRodrigo Florindo100% (1)

- NDM 13 ProceedingsDocument369 pagesNDM 13 Proceedingsjohnson_regoNo ratings yet

- Application of Instrumented Charpy Method in Characterisation of MaterialsDocument9 pagesApplication of Instrumented Charpy Method in Characterisation of Materialsjohnson_regoNo ratings yet

- Crossed Roller Paper WebDocument5 pagesCrossed Roller Paper WebMohamed Salah-EldinNo ratings yet

- Shaft and bearing design calculationsDocument24 pagesShaft and bearing design calculationsArul Gnana JohnNo ratings yet

- NorylDocument1 pageNorylAnonymous P8Bt46mk5INo ratings yet

- Shaft and bearing design calculationsDocument24 pagesShaft and bearing design calculationsArul Gnana JohnNo ratings yet

- Application of Instrumented Charpy Method in Characterisation of MaterialsDocument9 pagesApplication of Instrumented Charpy Method in Characterisation of Materialsjohnson_regoNo ratings yet

- CMA PresentationDocument44 pagesCMA Presentationjohnson_rego0% (1)

- Polymer Friction CoeffDocument14 pagesPolymer Friction Coeffhemant_durgawaleNo ratings yet

- Mtu Motoren-And Turbinen-Union Munchen GMBH Munich, GermanyDocument9 pagesMtu Motoren-And Turbinen-Union Munchen GMBH Munich, Germanyjohnson_regoNo ratings yet

- Failure Analysis of SwashplateDocument28 pagesFailure Analysis of Swashplatejohnson_regoNo ratings yet

- Eric Jaegle PDFDocument63 pagesEric Jaegle PDFjohnson_regoNo ratings yet

- Interzone 954Document4 pagesInterzone 954johnson_regoNo ratings yet

- Comparison of MaterialDocument4 pagesComparison of Materialjohnson_regoNo ratings yet

- Ductile Iron Data For Engineers PDFDocument135 pagesDuctile Iron Data For Engineers PDFGoran Bošković100% (1)

- En 10083Document3 pagesEn 10083johnson_regoNo ratings yet

- Main Shaft Tech PaperDocument15 pagesMain Shaft Tech Paperjohnson_rego100% (1)

- STR Relation For MetalDocument1 pageSTR Relation For Metaljohnson_regoNo ratings yet

- Cross Reference of Steel StandardsDocument4 pagesCross Reference of Steel StandardsNugroho Adhi SaputroNo ratings yet

- Fatigue CalculationDocument8 pagesFatigue CalculationMarcos NoronhaNo ratings yet

- CMMDocument12 pagesCMMjohnson_regoNo ratings yet

- Short and Smart Cuts For Your PCDocument10 pagesShort and Smart Cuts For Your PCRamprakash100% (5)

- IIM PresenationDocument7 pagesIIM Presenationmridulakhanna100% (3)

- T.O.S (Surface Active Structures)Document18 pagesT.O.S (Surface Active Structures)Riddhi Aggarwal100% (1)

- Cylinder Head - Install: Cerrar SIS Pantalla AnteriorDocument21 pagesCylinder Head - Install: Cerrar SIS Pantalla AnteriorReymundo Enrique Dominguez Hernandez100% (1)

- BVG4P 1 LOCK Parker Brass Ball ValveDocument2 pagesBVG4P 1 LOCK Parker Brass Ball ValveMROstop.comNo ratings yet

- Petrofast MTC 3.1 PO-400234 Anchor Bolts - Option FDocument2 pagesPetrofast MTC 3.1 PO-400234 Anchor Bolts - Option Fحسن صالح حسن المياحيNo ratings yet

- ASL 9095050303-Ed01 PDFDocument82 pagesASL 9095050303-Ed01 PDFMishra KewalNo ratings yet

- BS 3533 PDFDocument22 pagesBS 3533 PDFKarunakaran Nallasingam100% (2)

- 2019-05-28 - DA - RSLF Artillery Brigade - Volume 2 PDFDocument490 pages2019-05-28 - DA - RSLF Artillery Brigade - Volume 2 PDFDusngi MoNo ratings yet

- Product Catalog PDFDocument979 pagesProduct Catalog PDFa7mos0% (1)

- ASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 21Document1 pageASI Design Guide 10 - Bolted Moment End Plate Beam Splice Connections 21Anonymous 0x2pwMCWgjNo ratings yet

- Ps-x01 Nls InputdataDocument100 pagesPs-x01 Nls InputdatapckolNo ratings yet

- Instrument Manifold (Monoflange) : SpecificationsDocument1 pageInstrument Manifold (Monoflange) : Specificationshisaj4uNo ratings yet

- RK Pivot Doors AlbumDocument43 pagesRK Pivot Doors AlbumJafarNo ratings yet

- Spellnumber10m Bulo-NawoyDocument186 pagesSpellnumber10m Bulo-NawoyBeverly Nicole Dugao CutiNo ratings yet

- Geosynthetics ApplicationsDocument51 pagesGeosynthetics ApplicationsCharlotte TilburyNo ratings yet

- Portfolio 2013Document29 pagesPortfolio 2013mucupNo ratings yet

- Sika PDS - E - SikaGrout - 214-11 PDFDocument3 pagesSika PDS - E - SikaGrout - 214-11 PDFlwin_oo2435No ratings yet

- ABEL SH Solids Handling Pumps GB-web-02 2020Document6 pagesABEL SH Solids Handling Pumps GB-web-02 2020ha liNo ratings yet

- As 3571.2-2009 Plastics Piping Systems - Glass-Reinforced Thermoplastics (GRP) Systems Based On Unsaturated PDocument8 pagesAs 3571.2-2009 Plastics Piping Systems - Glass-Reinforced Thermoplastics (GRP) Systems Based On Unsaturated PSAI Global - APACNo ratings yet

- Bill of Quantity Pekerjaan Pengadaan Peralatan Utama Tata Udara Proyek Rpa Giritontro Wono Giri Jawa TengahDocument29 pagesBill of Quantity Pekerjaan Pengadaan Peralatan Utama Tata Udara Proyek Rpa Giritontro Wono Giri Jawa TengahSyahrulNo ratings yet

- Primavera Engineer To Order (ETO)Document9 pagesPrimavera Engineer To Order (ETO)ShriNo ratings yet

- Yanmar - 3tna72lDocument194 pagesYanmar - 3tna72lTiago Campos100% (1)

- Ots GRSH 250 00Document6 pagesOts GRSH 250 00ABC - Angela GomezNo ratings yet

- American Homes and Gardens 1905 Jul-DecDocument396 pagesAmerican Homes and Gardens 1905 Jul-DecNickiedeposieNo ratings yet

- PTS-1028 Ra FC Operation ManualDocument32 pagesPTS-1028 Ra FC Operation ManualOrlando PWRNo ratings yet

- Energy Recovery Ventilation System Type FHBQ: Air Handling Units, Chillers & FancoilsDocument6 pagesEnergy Recovery Ventilation System Type FHBQ: Air Handling Units, Chillers & FancoilsЈово КруљNo ratings yet

- Synaxis Prequalification (2018)Document82 pagesSynaxis Prequalification (2018)Synaxis ReadymixNo ratings yet

- Design of Steel Structures Formula Notes 59Document36 pagesDesign of Steel Structures Formula Notes 59Ayesha RubianaNo ratings yet

- CeracoatDerincoat Information SheetDocument5 pagesCeracoatDerincoat Information SheetMahesh MishraNo ratings yet

- Parts Explosion Diagram for Whirlpool 7MWT9601WW0 WasherDocument12 pagesParts Explosion Diagram for Whirlpool 7MWT9601WW0 WasherMARTIN CABRERANo ratings yet

- Automatic-Recirculation-Check Valve SSV 40-48Document3 pagesAutomatic-Recirculation-Check Valve SSV 40-48Herberth SilitongaNo ratings yet