Professional Documents

Culture Documents

Masonry: Cavity Wall Insulation: Partial Fill

Uploaded by

Bogdan MuresanCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Masonry: Cavity Wall Insulation: Partial Fill

Uploaded by

Bogdan MuresanCopyright:

Available Formats

Legend

Insulation zone

Air tightness barrier

(note: this can also

act as a vapour

control layer)

Blue text

Guidance on thermal

continuity

Red text

Guidance on air

tightness

Values used in psi calculations

Material

-values used

in calculations

(W/mK)

Plasterboard

Insulation (generic)

Plywood sheathing

Brick outer leaf

Mineral wool insulation

Concrete block

(dense) protected

0.21

0.04

0.13

0.77

0.044

1.13

Concrete block

(lightweight, high strength)

0.19

Timber frame

Concrete floor beam

Concrete screed

Render (cement/sand)

Gypsum plaster

(1000kg/m3)

0.13

2.3

1.15

1.0

0.4

Concrete roof tiles

EPDM membrane

Timber battens

Timber flooring

Chipboard

Floor joists

Aluminium

Steel

Stainless steel

Glass

Sarking felt

Insulation board

1.5

0.25

0.13

0.13

0.13

0.13

160

50

17

1

0.23

0.022

Plasterboard

Service void / protection

zone for air tightness

membrane (optional)

General guidance notes

Air tightness barrier

Alternative constructions

Insulation supported

within secondary timber

stud frame

Inner leaf (block shown)

Insulation

Wall ties

Cavity

Outer leaf (render

on block shown)

1. The thermal resistance of cavity

insulation needs to be greater than that

used in the inner leaf insulation, to

reduce the risk of interstitial

condensation.

2. Different constructions can be used to

provide an outer leaf but check that

there is sufficient ventilation provision

to prevent moisture from being trapped

within the wall.

Sealing membrane junctions

3. All membranes should be taped,

stapled or bedded in adhesive as

identified by manufacturer. Repair all

tears in membranes before

commencing next stage of work.

Psi-value calculations

4. For details of all thermal conductivity

values of materials used in the psi-value

calculations, see also Appendix B of the

Introduction.

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

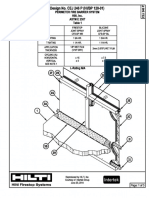

Masonry: Cavity Wall Insulation: Partial Fill

Isometric cut-away view

Detail 2.00

Thermal continuity checklist

Air tightness checklist

Ventilation gap equivalent to 5mm

minimum continuous opening at ridge

is required where the roof pitch is

1. Ensure that insulation layers in roof are

fitted perpendicularly, to cover junctions

2. Check that roof insulation butts against the

cavity wall insulation, with minimum of

50mm overlap at narrowest point

3. Install cavity barrier at the top of the wall.

1. Check that any air tightness barrier

used in the ceiling overlaps with the

layer in the wall

more than 10m

Proprietary cross flow

ventilator to maintain

minimum 25mm air gap

Timber batten to provide fixing

for plasterboard sheet

Vapour control layer

in wall and ceiling

Minimising condensation risk

Ventilation gap equivalent to

10mm minimum continuous

opening is required where

or

ventilation gap equivalent to

25mm minimum continuous

opening is required where

1. Check ventilation paths are clear before

installing insulation above the ceiling

Insulation between the studs

in addition to the cavity insulation.

This insulation to be tightly fitted

against the wall, leaving no gaps

Cavity barrier giving 30

minute fire resistance ensure cavity barrier is not

breeched by inappropriate

rigid sheathing insulation

material

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

Design advice

Thermal Resistance of insulation used in

details:

Note: See detail numbers 2.02 and 2.21 for

other junctions using this roof construction

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.0392W/mK Pitched Roof: Ventilated Roofspace - Eaves

Detail 2.01

Thermal continuity checklist

Air tightness checklist

1. Ensure that insulation layers in roof are

fitted perpendicularly, to cover junctions

2. Ensure that roof insulation butts against

the gable wall

3. Install cavity barrier at the top of the wall.

1. Check that any air tightness barrier

used in the ceiling overlaps with the

layer in the wall

Cavity insulation continued

full height of gable or to the

top of the loft insulation

Insulation between

the last truss and

the gable wall

Design advice

Cavity barrier giving

30 minute fire

resistance - ensure

cavity barrier is not

breeched by

inappropriate rigid

sheathing insulation

material

Timber batten to provide fixing

for plasterboard sheet

Vapour control layer

in wall and ceiling

Insulation between the studs

in addition to the cavity insulation.

This insulation to be tightly fitted

against the wall, leaving no gaps

Minimising condensation risk

1. Check ventilation paths are clear before

installing insulation above the ceiling

Thermal Resistance of insulation used in

details:

Note: See detail numbers 2.01 and 2.21 for

other junctions using this roof construction

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.0918W/mK Pitched Roof: Ventilated Roofspace - Gable

Detail 2.02

Thermal continuity checklist

Air tightness checklist

Minimum 50mm ventilation path over insulation

1. Ensure that insulation layers in roof are

fitted perpendicularly, to cover junctions

2. Ensure that roof insulation butts against

the gable wall

3. Install cavity barrier at the top of the wall.

1. Check that any air tightness barrier

used in the ceiling overlaps with the

layer in the wall

Insulation

between joists

and covering

cavity insulation

Cavity barrier

giving 30 minute

fire resistance thin calcium silicate

board or similar

across top of wall

Design advice

Where two insulation types are

used together see

supplementary guidance

Timber runner to provide fixing

for plasterboard sheet

Minimising condensation risk

1. Check ventilation paths are clear before

installing insulation above the ceiling

Thermal Resistance of insulation used in

details:

Vapour control layer

in wall and ceiling

Note: this

construction is

typically used

where there are

habitable rooms

within the roof

construction

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

Insulation between the studs in

addition to the cavity insulation.

This insulation must be tightly

fitted, leaving no gaps

Note: See detail numbers 2.04, 2.05 and 2.22

for other junctions using this roof construction

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.0206W/mK Pitched Roof: Ventilated Rafter Void - Gable

Detail 2.03

Thermal continuity checklist

1. Ensure that insulation layers in roof are

fitted perpendicularly, to cover junctions

2. Ensure that roof insulation butts against

the cavity wall insulation, with minimum of

50mm overlap at narrowest point

3. Install cavity barrier at the top of the wall

Air tightness checklist

Ventilation gap equivalent to

5mm minimum continuous

opening is required at ridge

to batten space

1. Check that any air tightness barrier

used in the ceiling overlaps with the

layer in the wall

Rigid insulation used as sarking

Insulation to be vapour permeable

Vapour permeable membrane

(with a vapour resistance of

not more than 0.25MN.s/g)

Lap roof and wall insulation

minimum 150mm thickness at

narrowest point

Proprietary over

fascia ventilator

Ventilation to

batten void

Timber batten to

provide fixing for

plasterboard sheet

Vapour control layer

in wall and ceiling

Alternative air barrier

- parge coat of plaster

finish on blockwork

Cavity barrier giving 30 minute

fire resistance - ensure cavity

barrier is not breeched by

inappropriate rigid sheathing

insulation material

Insulation between the

studs in addition to the

cavity insulation. This

insulation must be tightly

fitted, leaving no gaps

Note: this construction is

typically used where there

are habitable rooms within

the roof construction

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

Psi value = 0.034W/mK

Design advice

Minimising condensation risk

1. Check ventilation paths are clear before

installing insulation above the ceiling

Thermal Resistance of insulation used in

details:

Note: See detail numbers 2.03, 2.05 and 2.22

for other junctions using this roof construction

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Pitched Roof: Ventilated Batten Void (warm roof) - Eaves

Detail 2.04

Thermal continuity checklist

Air tightness checklist

50mm ventilation path over insulation

1. Ensure that insulation layers are fitted

perpendicularly, to cover junctions

2. Ensure that roof insulation butts against

the gable wall

3. Install cavity barrier at the top of the wall.

1. Check that any air tightness barrier

used in the ceiling overlaps with the

layer in the wall

Vapour

permeable

membrane

(with a vapour

resistance of

not more than

0.25 MN.s/g)

Design advice

Insulation between

joists and inner face

of the wall

Cavity barrier giving

30 minute fire

resistance - ensure

cavity barrier is not

breeched by

inappropriate rigid

sheathing insulation

material

Note: this construction

is typically used where

there are habitable

rooms within the roof

construction

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

Minimising condensation risk

Where two insulation types are

used together see

supplementary guidance

1. Check ventilation paths are clear before

installing insulation above the ceiling

Timber runner to provide fixing

for plasterboard sheet

Thermal Resistance of insulation used in

details:

Vapour control layer

in wall and ceiling

Insulation between the studs in

addition to the cavity insulation.

This insulation must be tightly

fitted, leaving no gaps

Note: See detail numbers 2.03, 2.04 and 2.22

for other junctions using this roof construction

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.0552W/mK Pitched Roof: Ventilated Batten Void (warm roof) - Gable

Detail 2.05

Thermal continuity checklist

1. Ensure that insulation layers in roof are

fitted perpendicularly, to cover junctions

2. Ensure that roof insulation butts against

the gable wall

3. Install cavity barrier at the top of the wall.

Air tightness checklist

1. Check that any air tightness barrier

used in the ceiling overlaps with the

layer in the wall

Vapour control layer turned up edge

of roof insulation, lapped with roof

waterproofing layer and sealed

Eaves - fix full height blocking

piece and tightly fit insulation into

void and under deck

Membrane roof construction

Verge option - tightly fit

insulation into void over

wall and under deck to

maintain thermal

continuity

Design advice

Cavity barrier giving 30

minute fire resistance ensure cavity barrier is not

breeched by inappropriate

rigid sheathing insulation

material

Vapour control

layer in ceiling

Timber runner to provide fixing

for plasterboard sheet

Vapour control layer

Insulation between the studs in

addition to the cavity insulation.

This insulation must be tightly

fitted, leaving no gaps

Minimising condensation risk

1. Check ventilation paths are clear before

installing insulation above the ceiling

2. A vapour control layer is required at

ceiling level, to prevent moisture from

entering into the roof construction

3. The option shown here includes a vapour

control layer and insulation as part of a

membrane roof construction. Similar

details could be used for a profiled metal

decking roof but consult with

manufacturer regarding ventilation

requirements.

Thermal Resistance of insulation used in

details:

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.0695W/mK Timber Flat Roof

Detail 2.06

Thermal continuity checklist

Air tightness checklist

1. Ensure that insulation layers in roof are

fitted perpendicularly, to cover junctions

3. Ensure that roof insulation butts against

the gable wall

4. Install cavity barrier at the top of the wall

1. Check that any air tightness barrier

used in the ceiling overlaps with the

layer in the wall

Compressible filler

Roofing membrane to be taken minimum

150mm above finished roof level

Vapour control layer turned up edge

of parapet, lapped over top of

blockwork and sealed

Membrane roof construction

Design advice

Minimising condensation risk

Vapour control layer in

wall and roof

Insulation between the studs in addition

to the cavity insulation. This insulation must

be tightly fitted, leaving no gaps

1. Check ventilation paths are clear before

installing insulation above the ceiling

2. A vapour barrier is required at ceiling

level, to prevent moisture from entering

into the roof construction

3. The option shown here includes a vapour

control layer and insulation as part of a

membrane roof construction. Similar

details could be used for a profiled metal

decking roof but consult with

manufacturer regarding ventilation

requirements.

Thermal Resistance of insulation used in

details:

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.0811W/mK Timber Flat Roof with Parapet

Detail 2.07

Thermal continuity checklist

Air tightness checklist

1. Check that there is no debris in the cavity

2. Install cavity barrier around opening

3. Install insulation in the window reveal

1. Install window to overlap with outer leaf of

wall finish.

Alternative:

If window lines through with the bottom of

the opening in the external finish, some

means of preventing a direct line of air

infiltration will be required

2. Install air tightness seal between the

inside face of the window and the

structural finish of the window opening.

Cavity tray with

minimum

upstand of

140mm and

stop ends

Insulation to

be tightly fixed

back to inner

leaf of wall

30 minute fire

resisting

proprietary

insulating cavity

barrier with

integral DPC ensure cavity

barrier is not

breeched by

inappropriate

rigid sheathing

insulation

material

Sealant at window frame

If position of window head is

lower than or level with the

underside of the lintol, a larger

compressible filler will be

required to stop up a potential

air infiltration route

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

Vapour control

layer

Lintol any type

Compressible

fill

Detail shows window fixed to plywood

frame set into window opening

Insulate the window reveal

Air tightness tape

Sealant to back of frame

Design advice

Minimising condensation risk

1. Alternative internal finish at window

reveal - use insulation backed

plasterboard

General notes

2. The window head and jamb details

shown have used a plywood box lining

around the window opening in the internal

leaf of the wall, to allow for window

fixings. Alternative details are possible

but the continuity of insulation and air

tightness should be considered.

Thermal Resistance of insulation used in

details:

Note: the timber batten in window reveal is shown smaller

than actual size, to allow the membrane corner strip to be seen

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.1302W/mK Lintel at Window Head

Detail 2.08

Thermal continuity checklist

1. Check that there is no debris in the cavity

2. Install cavity barrier around opening

3. Install insulation in the window reveal

Air tightness checklist

30 minute fire resisting

proprietary insulating cavity

barrier with integral DPC

1. Install window to overlap with outer leaf of

wall finish.

Alternative:

If window lines through with the external

jamb, some means of preventing a direct

line of air infiltration will be required

2. Install air tightness seal between the

inside face of the window and the

structural finish of the window opening.

Sealant at window frame

Air tightness tape and

sealant to back of frame

Insulate the window reveal

Detail shows window fixed

to plywood frame set into

window opening

Jamb detail

Air tightness barrier in wall

Compressible filler

between window and cill

Solid cill acts as cavity

closer. If pressed cill is

used, a 30 minute fire

rated thermally insulated

cavity closer will be

required

DPC lapped

behind cill and

below window

30 minute fire

rated thermally

insulated

cavity barrier

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

Psi value (jamb) =0.2224W/mK

Psi value (cill) =-0.02W/mK

Design advice

Air tightness tape and

sealant to back of frame

Insulate the window reveal

Note: the timber battens in

the window reveal and cill are

shown smaller than actual

size, to allow the membrane

corner strip to be seen

Vapour control layer in wall

Insulation between the studs in

addition to the cavity insulation.

This insulation must be tightly

fitted, leaving no gaps

Minimising condensation risk

1. Alternative internal finish at window

reveal - use insulation backed

plasterboard

General notes

2. The window head and jamb details

shown have used a plywood box lining

around the window opening in the internal

leaf of the wall, to allow for window

fixings. Alternative details are possible

but the continuity of insulation and air

tightness should be considered.

Thermal Resistance of insulation used in

details:

Cill detail

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Windows and Doors - Jambs and Cills

Detail 2.09

Thermal continuity checklist

Air tightness checklist

1. Use a perimeter strip of insulation where

the concrete slab abuts the concrete

blockwork wall

2. Ensure that insulation level in external

wall overlaps with the insulation at the

floor slab

1. Check that any air tightness barrier used

in the wall overlaps with the layer in the

floor

Vapour control layer

Seal between the wall and floor

membrane with a flexible sealant or

seal the gap between skirting board

and floor using a flexible sealant

Vapour control layer below

timber floor finish

The wall insulation installed

below the wall dpc must be

fit for purpose with regards

to water absorption

External ground level

Design advice

Minimising condensation risk

Damp proof membrane

above or below slab

20mm strip of perimeter

insulation with thermal

conductivity ( value) not

exceeding 0.025 W/mK around

slab and any screed

1. Check that concrete slab is level and

clear of debris before fitting the insulation

at floor level

2. If a screed finish is used instead of a

timber floor, use a strip of perimeter

insulation with a minimum R value of

Alternative detail

3. Using lightweight blockwork (e.g. with

value of 0.19W/mK) to improve the

thermal performance at the junction where

the external wall and ground floor

constructions meet will change the psi

value

Thermal Resistance of insulation used in

details:

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.0744W/mK Ground Bearing Floor: Insulation Above Slab

Detail 2.10

Thermal continuity checklist

Air tightness checklist

1. Use a perimeter strip of insulation where

the concrete slab abuts the concrete

blockwork wall

2. Ensure that insulation level in external

wall overlaps with the insulation at the

floor slab

Vapour control layer

1. Check that any air tightness barrier used

in the wall overlaps with the layer in the

floor

Seal between the wall and

floor membrane with a flexible

sealant or seal the gap between

skirting board and floor using a

flexible sealant

The wall insulation installed

below the wall dpc must be

fit for purpose with regards

to water absorption

External ground level

Design advice

Damp proof membrane

20mm strip of perimeter

insulation with thermal

conductivity ( value) not

exceeding 0.025 W/mK around

slab and any screed

Minimising condensation risk

1. If a screed finish is used instead of a

timber floor, use a strip of perimeter

insulation with a minimum R value of

Alternative detail

2. Using lightweight blockwork (e.g. with

value of 0.19W/mK) to improve the

thermal performance at the junction

where the external wall and ground floor

constructions meet will change the psi

value

Thermal Resistance of insulation used in

details:

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

Psi value = 0.175W/mK

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Ground Bearing Floor: Insulation Below Slab

Detail 2.11

Thermal continuity checklist

Air tightness checklist

1. Use a perimeter strip of insulation

between the floor joists and blockwork

wall

2. Ensure that insulation level in external

wall overlaps with the insulation at the

floor construction

Vapour control layer

Use air tightness tape at junction of air

barrier in wall and floor. Seal between the

wall and floor membrane with a flexible

sealant or seal the gap between skirting

board and floor using a flexible sealant

Air tightness barrier

below timber floor finish

Minimum 50mm strip of

insulation with thermal

conductivity ( value) not

exceeding 0.025 W/mK

should be installed between

wall and the last joist

External ground level

Solum

1. Check that any air tightness barrier used

in the wall overlaps with the layer in the

floor

Floor joist ends supported on joist

hangers or using scarcement wall

Insulation directly under flooring supported on netting draped over joists

and stapled at the required depths

Design advice

Minimising condensation risk

1. Check that all ventilation paths are clear

before installing the floor insulation

Alternative detail

Damp proof membrane

Sub floor ventilation should be

per run of external wall or

2. Using lightweight blockwork (e.g.

with value of 0.19W/mK) to improve

thermal performance at the junction

where the external wall and ground floor

constructions meet will change the psi

value

3. If there are concerns about damaging the

air tightness membrane in the floor finish

during construction, an additional services

void can be created using timber battens

on top of the floor joists

Thermal Resistance of insulation used in

details:

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.0978W/mK Timber Suspended Ground Floor

Detail 2.12

Thermal continuity checklist

Design stage

1. Install thermally insulated cavity barrier in

line with separating wall

2. Check that there is no debris in the cavity

Air tightness checklist

Cavity barrier giving 30 minute

fire resistance - ensure cavity

barriers are not breeched by

inappropriate insulation material

1. Check that any air tightness barrier used

in the internal wall overlaps with the layer

in the external wall

Vapour control layer

Minimum specification of

8kg/m2 gypsum based

plasterboard required if

13mm plaster not used, to

comply with acoustic

requirements

Air tightness layer,

13mm plaster shown

Design advice

Minimising condensation risk

1. Check that insulation is fitted tightly to

concrete block wall at corner junctions

Thermal Resistance of insulation used in

details:

For more information

on acoustic details see

guidance in Section 5 of

the Technical Standards

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.0508W/mK Separating Wall

Detail 2.13

Thermal continuity checklist

Air tightness checklist

Design stage

1. Check that there is no debris in the cavity

Vapour control layer

1. Check that any air tightness barrier used

in the external wall is secured onto the

floor slab

2. If plaster is use as an air tightness barrier

seal over junction at floor with barrier tape

Vapour barrier lapped over

corner junction and taped to

surface of floor construction

Vapour control layer

below timber floor finish

Vapour control layer lapped

over corner junction and taped to

underside of floor construction

Vapour control layer

Insulation between the studs in addition

to the cavity insulation. This insulation

must be tightly fitted, leaving no gaps

Alternative air barrier - parge coat

of plaster finish on blockwork

Design advice

Minimising condensation risk

1. Check that insulation is tightly fixed into

the studs adjacent to the floor junction,

leaving no gaps

Thermal Resistance of insulation used in

details:

Separating floors require

to comply with Section 2:

Fire and Section 5: Noise

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.0541W/mK Concrete Separating Floor

Detail 2.14

Thermal continuity checklist

Air tightness checklist

1. Check that there is no debris in the cavity

1. Check that any air tightness barrier used

in the internal wall overlaps with the layer

in the floor or ceiling

Alternative:

If the air tightness barrier is installed onto

the face of the blockwork wall and runs

continuously through the floor

construction, infill any gaps where floor

fixing is made to external wall

Vapour control layer lapped

over corner junction and taped

to air tightness barrier

Air tightness barrier corner

strip lapped over top of

joists and joist hangers

Minimum 50mm

strip of rigid

insulation with

thermal conductivity

( value) not

exceeding 0.025

W/mK should be

installed between

joists

Joists shown supported

on joist hangers

Air tightness barrier to be

continuous behind joists

Vapour control layer in wall

Insulation between the studs in addition

to the cavity insulation. This insulation

must be tightly fitted, leaving no gaps

Alternative air barrier - parge coat

of plaster finish on blockwork

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

Design advice

Minimising condensation risk

1. Check that insulation is tightly fixed into

the studs adjacent to the floor junction,

leaving no gaps

Thermal Resistance of insulation used in

details:

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.0109W/mK Timber Intermediate Floor

Detail 2.15

Thermal continuity checklist

Air tightness checklist

Air tightness barrier in wall (plaster option shown)

Use air tightness tape at junction of air barrier in wall

and floor. Seal between the wall and floor membrane

with a flexible sealant or seal the gap between skirting

board and floor using a flexible sealant

Air tightness layer below

timber floor finish

1. Ensure that insulation is tightly fitted to the

back of the masonry wall

1. Check that any air tightness barrier used

in the wall overlaps with the layer in the

floor

2. Consider gluing joints between floor

boards

Insulation directly under flooring supported on netting draped over joists

and stapled at the required depths

Solum

Damp proof membrane

Design advice

Minimising condensation risk

1. Check that all ventilation paths are clear

before installing the floor insulation

Sub floor ventilation should be

per run of external wall or

Alternative Detail

2. Lightweight thermal blockwork can be

used in the separating wall to improve the

thermal performance but this will also

reduce the acoustic performance of the

wall. If this alternative is used then

additional elements will be required to

meet Section 5 of the Technical

Standards.

Thermal Resistance of insulation used in

details:

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.2365W/mK Ground Floor / Separating Wall junction - Timber susp. floor

Detail 2.16

Thermal continuity checklist

Air tightness checklist

1. Ensure that insulation is tightly fitted

against the separating wall

Tape corner strip of air

tightness membrane

over wall / floor junction

Air tightness barrier in wall (plaster shown)

Seal between the wall and floor

membrane with a flexible sealant or

seal the gap between skirting board

and floor using a flexible sealant

Minimum 50mm strip of insulation

with thermal conductivity ( value)

not exceeding 0.025 W/mK should be

installed between wall and the slab

Vapour control layer in floor

1. Check that there are no gaps between the

wall and floor constructions

2. Check that any air tightness barrier used

in the wall overlaps with the layer in the

floor

Design advice

Damp proof membrane

Minimising condensation risk

1. If a screed finish is used instead of a

timber floor, use a strip of perimeter

insulation with a minimum R value of

Alternative Detail

2. Lightweight thermal blockwork can be

used in the separating wall to improve the

thermal performance but this will also

reduce the acoustic performance of the

wall. If this alternative is used then

additional elements will be required to

meet Section 5 of the Technical

Standards.

Thermal Resistance of insulation used in

details:

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.2736W/mK Concrete Ground Floor/ Separating Wall: Insulation Below Slab Detail 2.17

Thermal continuity checklist

Air tightness checklist

1. Ensure that insulation is tightly fitted

against the separating wall

Tape corner strip of air

tightness membrane

over wall / floor junction

Air tightness barrier in wall (plaster option shown)

Seal between the wall and floor

membrane with a flexible sealant or

seal the gap between skirting board

and floor using a flexible sealant

Minimum 20mm strip of insulation

with thermal conductivity ( value)

not exceeding 0.025 W/mK should be

installed between wall and the slab

Vapour control layer in floor

1. Check that there are no gaps between the

wall and floor constructions

2. Check that any air tightness barrier used

in the wall overlaps with the layer in the

floor

Design advice

Damp proof membrane

Minimising condensation risk

1. Check that concrete slab is level and

clear of debris before fitting the insulation

at floor level

2. If a screed finish is used instead of a

timber floor, use a strip of perimeter

insulation with a minimum R value of

Alternative Detail

3. Lightweight thermal blockwork can be

used in the separating wall to improve the

thermal performance but this will also

reduce the acoustic performance of the

wall. If this alternative is used then

additional elements will be required to

meet Section 5 of the Technical

Standards.

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Thermal Resistance of insulation used in

details:

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.2822W/mK Concrete Ground Floor/ Separating Wall: Insulation Above Slab Detail 2.18

Thermal continuity checklist

Air tightness checklist

1. Ensure that there are no gaps between

floor slabs or between the top of the wall

and the underside of the floor slab.

2. Ensure that the insulation is tightly fitted to

the top of the floor slab.

1. Check that any air tightness barrier used

in the internal wall overlaps with the layer

in the floor or ceiling

Air tightness barrier in wall

(plaster option shown)

Cavity barrier is

used in to

prevent thermal

bypass.Use

dense insulation

or proprietary

cavity barrier in

sleeve

5mm minimum resilient flanking

strip to be used at floor junction. See

Technical Standards Guidance

Notes for Section 5 for details

If membrane used, seal onto top of

screed. If render or plaster used as

airtightness layer, add a corner strip

of membrane to cover junction

before applying finish

Design advice

Air tightness barrier lapped

over corner junction

Air tightness barrier in

wall (plaster shown)

Minimising condensation risk

1. Check that concrete slab is level and

clear of debris before fitting the insulation

at floor level

Separating floors require

additional layers and components

to comply with Section 2: Fire

and Section 5: Noise

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.0133W/mK Concrete Separating Floor / Separating Wall junction

Detail 2.19

Thermal continuity checklist

Air tightness checklist

1. Check that there are no gaps between the

floors and the separating wall.

1. Check that any air tightness barrier used

in the internal wall overlaps with the layer

in the floor or ceiling

Alternative:

If the air tightness barrier is installed onto

the face of the blockwork wall and runs

continuously through the floor

construction, infill any gaps where floor

fixing is made to the wall

Air tightness barrier in

wall (plaster shown)

Seal between the wall and floor

membrane with a flexible sealant or

seal the gap between skirting board

and floor using a flexible sealant

Air tightness barrier in to be

continuous behind joists

Design advice

Minimising condensation risk

See general guidance notes

Air tightness barrier in

wall (plaster shown)

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.1053W/mK Timber Intermediate Floor / Separating Wall junction

Detail 2.20

Thermal continuity checklist

Air tightness checklist

1. Install a cavity barrier at the top of the wall

2. Ensure that insulation layers in roof are

fitted perpendicularly, to cover junctions

1. Check that there are no gaps between

the top of the masonry wall and the

underside of the roof

2. Check that the air tightness barrier

used in the ceiling overlaps with the

layer in the wall

Design advice

Vapour control layer in

wall and ceiling

Minimum 50mm strip of

rigid insulation with

thermal conductivity (

value) not exceeding

0.025 W/mK should be

installed between wall

and the last joist

Cavity barrier is used in to

prevent thermal bypass.Use

low or soft density insulation

wrapped in plastic or

membrane

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

Minimising condensation risk

1. Check ventilation paths are clear before

installing insulation above the ceiling

Thermal Resistance of insulation used in

details:

Note: See detail numbers 2.01 and 2.02 for

other junctions using this roof construction

For more information

on acoustic details see

guidance in Section 5 of

the Technical Standards

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.2008W/mK Pitched Roof: Cold Roof / Separating Wall junction

Detail 2.21

Thermal continuity checklist

Minimum 50mm ventilation path over insulation

1. Install a cavity barrier at the top of the wall

2. Ensure that insulation layers are fitted

perpendicularly, to cover junctions

Air tightness checklist

1. Check that there are no gaps between

the top of the masonry wall and the

underside of the roof

2. Check that the air tightness barrier

used in the ceiling overlaps with the

layer in the wall

Design advice

Cavity barrier giving 30

minute fire resistance ensure cavity barrier is not

breeched by inappropriate

rigid sheathing insulation

material

Cavity barrier is used in to

prevent thermal bypass.Use low

or soft density insulation

wrapped in plastic or membrane

Separating walls require

additional layers and components

to comply with Section 2: Fire

and Section 5: Noise

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

Minimising condensation risk

Where two insulation types are

used together see

supplementary guidance

1. Check ventilation paths are clear before

installing insulation above the ceiling

Thermal Resistance of insulation used in

details:

Air tightness barrier in

wall and ceiling (plaster

shown on wall)

Note: this construction is

typically used where there

are habitable rooms within

the roof construction

Note: See detail numbers 2.03, 2.04 and 2.05

for other junctions using this roof construction

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.2247W/mK Pitched Roof: Ventilated Batten Void/ Separating Wall junction

Detail 2.22

Thermal continuity checklist

Air tightness checklist

1. Check that there is no debris in the cavity.

2. Check that there are no gaps in insulation

fitted at the corner junction in the cavity

1. Check that any air tightness barrier used

in the external walls overlaps at the

corner

Insulation between the

studs in addition to the

cavity insulation. This

insulation must be

tightly fitted, leaving no

gaps

Vapour control layer

Design advice

Minimising condensation risk

1. Check that insulation is tightly fixed into

the studs at the corner junction, leaving

no gaps

Thermal Resistance of insulation used in

details:

Plan view

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = 0.0607W/mK Wall Junction

Detail 2.23

Thermal continuity checklist

Air tightness checklist

1. Check that there is no debris in the cavity

1. Check that any air tightness barrier used

in the external walls overlaps at the

corner

Vapour control layer

Insulation between

the studs in addition to

the cavity insulation.

This insulation must be

tightly fitted, leaving

no gaps

Design advice

Minimising condensation risk

1. Check that insulation is tightly fixed into

the studs at the corner junction, leaving

no gaps

Thermal Resistance of insulation used in

details:

Plan view

HEAT 2.7 software image of isotherms

through junction detail.

For illustrative purposes only.

This example should be read in conjunction with the guidance in the introduction to this document. It illustrates the reduction

of unwanted infiltration in buildings and provides a Psi value for this junction situation which can be used in calculation

provided the principles outlined and any identified component specification are followed.

Masonry: Cavity Wall Insulation - Partial fill

Psi value = -0.0826W/mK Wall Junction - Inward Corner

Detail 2.24

You might also like

- Masonry Cavity Wall Insulation IllustrationsDocument0 pagesMasonry Cavity Wall Insulation IllustrationsGonzalo Luque GarcíaNo ratings yet

- Cavity Wall InsulationDocument29 pagesCavity Wall InsulationOlivia Safer100% (1)

- BOQ Canteen BlockDocument80 pagesBOQ Canteen BlockyogeshNo ratings yet

- Ceresit Ceretherm External Wall InsulationDocument22 pagesCeresit Ceretherm External Wall InsulationGeorge KeithNo ratings yet

- BoqDocument24 pagesBoqsrinivasmantry88No ratings yet

- Architect's PocketbookDocument67 pagesArchitect's Pocketbookdavisley28No ratings yet

- GFA Definition Part 2Document45 pagesGFA Definition Part 2letuananhbNo ratings yet

- Hilti Firestop DesignDocument3 pagesHilti Firestop DesignAristo OnanNo ratings yet

- HDB SOR - Jul 2013Document260 pagesHDB SOR - Jul 2013kokuei100% (1)

- Check Points For Labour Contract House ConstructionDocument1 pageCheck Points For Labour Contract House ConstructionKarthik KarunanidhiNo ratings yet

- Advantage Disadvangtage of Suspended Vs Open CeilingDocument5 pagesAdvantage Disadvangtage of Suspended Vs Open CeilingAre OnezNo ratings yet

- Suspended Ceilings Construction DetailsDocument4 pagesSuspended Ceilings Construction DetailsHassan RahilNo ratings yet

- RoofDocument9 pagesRoofHakim AkemNo ratings yet

- 4.1 BsorDocument103 pages4.1 BsorRichard TaiNo ratings yet

- Sequence of WorksDocument5 pagesSequence of WorksmohdNo ratings yet

- Gewan Island Qatar concrete BOQDocument7 pagesGewan Island Qatar concrete BOQabid hamzaNo ratings yet

- KLCC & KLCC Convention Centre Fire Safety TourDocument13 pagesKLCC & KLCC Convention Centre Fire Safety TourXin Min ChongNo ratings yet

- Tropical DesignDocument69 pagesTropical DesignbbhNo ratings yet

- BoqDocument2 pagesBoqemonwreNo ratings yet

- Roofing Styles in Traditional Nigerian SocietyDocument15 pagesRoofing Styles in Traditional Nigerian SocietyOluwaseyi AdegokeNo ratings yet

- Summary Sheet (Annexure F1 & F2)Document5 pagesSummary Sheet (Annexure F1 & F2)Ajay Malik100% (1)

- External Wall Insulation Irish CertificationDocument19 pagesExternal Wall Insulation Irish CertificationTj GilliganNo ratings yet

- Finishing Schedule S.No. Description Flooring Skirting Walls Internal Ceiling Doors Windows/ Ventilators Frame Shutter Frame ShutterDocument1 pageFinishing Schedule S.No. Description Flooring Skirting Walls Internal Ceiling Doors Windows/ Ventilators Frame Shutter Frame ShutterAnonymous Of0C4dNo ratings yet

- IS Codes For Building Construction PracticeDocument5 pagesIS Codes For Building Construction Practicepraj24083302No ratings yet

- IGBC Model Exam ResultDocument36 pagesIGBC Model Exam ResulttrishankaNo ratings yet

- Bathrooms Waterproofing: Method StatementDocument3 pagesBathrooms Waterproofing: Method StatementsohanpmeharwadeNo ratings yet

- Trakhees EHS Green Building Regulations for Villas & Residential Developments up to 3 floorsDocument21 pagesTrakhees EHS Green Building Regulations for Villas & Residential Developments up to 3 floorsjagvishaNo ratings yet

- Materials and Techniques Used in Expansion JointsDocument1 pageMaterials and Techniques Used in Expansion JointsSunidhi VermaNo ratings yet

- Civil, Structure and Water - Proofing WorksDocument2 pagesCivil, Structure and Water - Proofing WorksAditi Agrawal100% (1)

- Modes of Measurement and Cement ConsumptionDocument11 pagesModes of Measurement and Cement ConsumptionAnand BabuNo ratings yet

- MASONRY TESTING GUIDEDocument19 pagesMASONRY TESTING GUIDEDona Mae BayoranNo ratings yet

- Item IN Place Comments A. Exterior ItemsDocument7 pagesItem IN Place Comments A. Exterior ItemsILydia HernzNo ratings yet

- 11 HDB Requirements For A&a Work On HDB PremisesDocument16 pages11 HDB Requirements For A&a Work On HDB PremisesasdasNo ratings yet

- Timber WindowsDocument52 pagesTimber WindowsNuwan Wasantha RupasingheNo ratings yet

- 7.1 SSIS Preamble of Tender B.Q - Piling enDocument1 page7.1 SSIS Preamble of Tender B.Q - Piling enHector PhamNo ratings yet

- Level Flat No.: Cold & Hot Water Services Feed Pipe Calculation ScheduleDocument2 pagesLevel Flat No.: Cold & Hot Water Services Feed Pipe Calculation ScheduleMario B. DaluNo ratings yet

- Celotex BBA - Cavity WallsDocument12 pagesCelotex BBA - Cavity Wallsfaber1972No ratings yet

- Microsoft Word - Floor FinishesDocument9 pagesMicrosoft Word - Floor FinisheskokueiNo ratings yet

- NEA - Code of Practice Environmental HealthDocument43 pagesNEA - Code of Practice Environmental HealthJackson TanNo ratings yet

- Tender B - Architectural SpecficationsDocument188 pagesTender B - Architectural SpecficationsJe M'appelle NofreNo ratings yet

- Take Off List Framed Structure. WestgatecghhhiDocument11 pagesTake Off List Framed Structure. WestgatecghhhiTashamiswa MajachaniNo ratings yet

- Annex V - Bills of QuantitiesDocument12 pagesAnnex V - Bills of QuantitiesAl Arafat RummanNo ratings yet

- 01 35 29 - Health, Safety, and Emergency Response ProceduresDocument3 pages01 35 29 - Health, Safety, and Emergency Response ProceduresSteve LezamaNo ratings yet

- Al Ahli Sports - Curtain WallDocument7 pagesAl Ahli Sports - Curtain WallHaneefa ChNo ratings yet

- PSB Singapore Bs5234 Part 2 - 100mm s3 Aac Block Wall - (PSB 7191102720-Mec15-Yx)Document30 pagesPSB Singapore Bs5234 Part 2 - 100mm s3 Aac Block Wall - (PSB 7191102720-Mec15-Yx)Chimmy GonzalezNo ratings yet

- Topic 7 Maintenance Schemes For Private Buildings in Hong Kong (Part 3)Document12 pagesTopic 7 Maintenance Schemes For Private Buildings in Hong Kong (Part 3)YUK LAM WONG100% (2)

- Sample BOQDocument17 pagesSample BOQThushan MaduNo ratings yet

- Roof Insulation: Southern California Gas Company New Buildings Institute Advanced Design Guideline SeriesDocument31 pagesRoof Insulation: Southern California Gas Company New Buildings Institute Advanced Design Guideline Seriesapi-19789368100% (1)

- How To Calculating Floor Area RatioDocument2 pagesHow To Calculating Floor Area RatioNisha AgnihotriNo ratings yet

- Presentation Wall FinDocument67 pagesPresentation Wall FinManju Navin KumarNo ratings yet

- Layers of A Floor - Anatomy, and Parts (Illustrated)Document8 pagesLayers of A Floor - Anatomy, and Parts (Illustrated)Melaine A. FranciscoNo ratings yet

- Plant schedule and planting specificationDocument1 pagePlant schedule and planting specificationlaNo ratings yet

- Standard Bracing For Simple Roofs PDS PDFDocument4 pagesStandard Bracing For Simple Roofs PDS PDFusername_imanNo ratings yet

- Inspection Report: Property Address: 1001 Tokedokey Trail Connestee Falls Brevard NC 28712Document33 pagesInspection Report: Property Address: 1001 Tokedokey Trail Connestee Falls Brevard NC 28712api-143032247No ratings yet

- Trane Decorative Split / Hi Wall Split UnitDocument31 pagesTrane Decorative Split / Hi Wall Split UnitdreamagiczNo ratings yet

- Timber Frame Isometric ViewDocument25 pagesTimber Frame Isometric ViewsertackcdgNo ratings yet

- CMHC2000-Rigid Air Barrier AssembliesDocument4 pagesCMHC2000-Rigid Air Barrier Assemblieskulov1592No ratings yet

- SBI Direction 189 External Walls Edition OCWDocument18 pagesSBI Direction 189 External Walls Edition OCWAlexandra TotoianuNo ratings yet

- Heat Control Technology of Building EnvelopesDocument24 pagesHeat Control Technology of Building Envelopesch4nt333No ratings yet

- GUTEX en BR Construction 2014-09Document48 pagesGUTEX en BR Construction 2014-09Ioana BarsanNo ratings yet

- CPU Computer Power User Buyer's Guide Vid CardsDocument112 pagesCPU Computer Power User Buyer's Guide Vid CardsMac TabilisNo ratings yet

- Exhibitors ECS2013Document39 pagesExhibitors ECS2013Bogdan MuresanNo ratings yet

- Billboard Magazine - 12 May 2012Document52 pagesBillboard Magazine - 12 May 2012Bogdan MuresanNo ratings yet

- Success Story 2015Document2 pagesSuccess Story 2015Bogdan MuresanNo ratings yet

- Exxsol d40 Fluid Product Safety Summary en PDFDocument3 pagesExxsol d40 Fluid Product Safety Summary en PDFBogdan MuresanNo ratings yet

- Jointing Solutions GuideDocument44 pagesJointing Solutions GuideBogdan MuresanNo ratings yet

- Color CardDocument1 pageColor CardDiplomamunkaNo ratings yet

- Antimicrobial Products-Test For Antimicrobial Activity and EfficacyDocument14 pagesAntimicrobial Products-Test For Antimicrobial Activity and EfficacyherfuentesNo ratings yet

- Acticide MbsDocument10 pagesActicide MbsBogdan MuresanNo ratings yet

- Digital Indicator Quick Start Manual: 32x SeriesDocument36 pagesDigital Indicator Quick Start Manual: 32x SeriesFroylan De la CerdaNo ratings yet

- On-Board Diagnostics (OBD) IIDocument59 pagesOn-Board Diagnostics (OBD) IIBogdan MuresanNo ratings yet

- How To Ensure The Quality of ETICSDocument16 pagesHow To Ensure The Quality of ETICSBogdan MuresanNo ratings yet

- Leistungsspektrum Krankenhäuser, Kliniken Und PflegeeinrichtungenDocument46 pagesLeistungsspektrum Krankenhäuser, Kliniken Und PflegeeinrichtungenBogdan MuresanNo ratings yet

- Digital Indicator Quick Start Manual: 32x SeriesDocument36 pagesDigital Indicator Quick Start Manual: 32x SeriesFroylan De la CerdaNo ratings yet

- Energy-Effi Cient InsulationDocument16 pagesEnergy-Effi Cient InsulationBogdan MuresanNo ratings yet

- Fire FightingDocument20 pagesFire Fightingnywd806033No ratings yet

- Samsung Dishwasher User ManualDocument60 pagesSamsung Dishwasher User ManualBogdan MuresanNo ratings yet

- The New Declaration of Performance (Description)Document39 pagesThe New Declaration of Performance (Description)Bogdan MuresanNo ratings yet

- 2012 Product Catalogue 2012Document222 pages2012 Product Catalogue 2012Bogdan MuresanNo ratings yet

- Cad Drawings Bi IntDocument82 pagesCad Drawings Bi IntBogdan MuresanNo ratings yet

- Guideline For Planning and Executing WaterproofingDocument40 pagesGuideline For Planning and Executing WaterproofingBogdan MuresanNo ratings yet

- 030Document12 pages030Bogdan MuresanNo ratings yet

- Facade MagazinestyleDocument205 pagesFacade MagazinestyleBogdan Muresan100% (2)

- Vapour Resistances and μ-Values ExplainedDocument6 pagesVapour Resistances and μ-Values ExplainedGilberto Ortiz RomeroNo ratings yet

- 2012 Product Catalogue 2012Document222 pages2012 Product Catalogue 2012Bogdan MuresanNo ratings yet

- 11 Ceramics... (pp.322-326)Document5 pages11 Ceramics... (pp.322-326)Bogdan MuresanNo ratings yet

- Experiment 1 RefrigerationDocument18 pagesExperiment 1 RefrigerationAdamu GinyanNo ratings yet

- WWW - Ubakus.de: AcoperisDocument4 pagesWWW - Ubakus.de: AcoperisAlexandru-SorinRizea100% (1)

- Determine Molar Mass by Vapor Density MethodDocument3 pagesDetermine Molar Mass by Vapor Density MethodRA MemijeNo ratings yet

- Storage, Intallation, and MaintenancDocument16 pagesStorage, Intallation, and MaintenancRuben GutierrezNo ratings yet

- DampAid UK - Avoiding Condensation ProblemsDocument3 pagesDampAid UK - Avoiding Condensation ProblemsGillian KirbyNo ratings yet

- Lesson Plan No. 1Document4 pagesLesson Plan No. 1Pineda RenzNo ratings yet

- 1 s2.0 S0263876299717624 MainDocument7 pages1 s2.0 S0263876299717624 Mainryan123459No ratings yet

- Aectp 200Document569 pagesAectp 200fithri_np8030No ratings yet

- Astm D-2247Document5 pagesAstm D-2247Avinash ChauhanNo ratings yet

- Building and Environment: Y.L. Yin, R.Z. Wang, X.Q. Zhai, T.F. IshugahDocument9 pagesBuilding and Environment: Y.L. Yin, R.Z. Wang, X.Q. Zhai, T.F. IshugahTheen BadhushNo ratings yet

- Lesson Plan On Water CycleDocument3 pagesLesson Plan On Water CycleShirly BasilioNo ratings yet

- ATDC (Science4) - Components of WeatherDocument38 pagesATDC (Science4) - Components of WeatherMa. Elena A. MacasayonNo ratings yet

- Cool FactsDocument36 pagesCool FactsOmar SangronaNo ratings yet

- 2 Comparative Analysis of Moisture RemovingDocument7 pages2 Comparative Analysis of Moisture Removing15472No ratings yet

- Melyza Funes - Cycles of Matter VocabularyDocument3 pagesMelyza Funes - Cycles of Matter Vocabularyapi-450782149No ratings yet

- Troubleshooting - Guide Activated Sludge ProcessesDocument61 pagesTroubleshooting - Guide Activated Sludge ProcessesRoberto GoncalvesNo ratings yet

- Optimal Design of An Air-Cooled Condenser For Flue Gas From A PowDocument316 pagesOptimal Design of An Air-Cooled Condenser For Flue Gas From A PowJimmy Nuñez VarasNo ratings yet

- Condensation MDocument35 pagesCondensation MSumedh MahekarNo ratings yet

- Key Stage 3 Ks3 Science MarkScheme 2005Document56 pagesKey Stage 3 Ks3 Science MarkScheme 2005odysseym1No ratings yet

- PHE As CondensersDocument50 pagesPHE As CondensersHelga Ines BenzNo ratings yet

- Condensation and Cloud FormationDocument17 pagesCondensation and Cloud FormationIyah Macam100% (1)

- Peter Cox Condensation Control Whole House Ventilation PDFDocument3 pagesPeter Cox Condensation Control Whole House Ventilation PDFPaul LawlessNo ratings yet

- Condensation in Switchgears and Anti Condensation Heater PDFDocument2 pagesCondensation in Switchgears and Anti Condensation Heater PDFKok WaiNo ratings yet

- Moisture Control Guidance For Building Design, Construction and Maintenance (2013)Document144 pagesMoisture Control Guidance For Building Design, Construction and Maintenance (2013)Schreiber_Dieses100% (1)

- COT 1 - Science 8 (Matter)Document4 pagesCOT 1 - Science 8 (Matter)joan marie Pelias100% (1)

- Science Lesson Plan ImbDocument4 pagesScience Lesson Plan Imbapi-2822466080% (1)

- Explanation TextDocument6 pagesExplanation TextTerserah SayaNo ratings yet

- Cavity Wall Insulation ProblemsDocument7 pagesCavity Wall Insulation Problemsfriska_arianiNo ratings yet

- Geography 37 - Daily Class Notes - UPSC Sankalp HinglishDocument7 pagesGeography 37 - Daily Class Notes - UPSC Sankalp Hinglishanuraghavsingh01No ratings yet

- Redubar A Register of All Gas RegulationsDocument64 pagesRedubar A Register of All Gas RegulationsMilos BajicNo ratings yet