Professional Documents

Culture Documents

Variable Valve Timing and Lifting Technologies in Different Automobiles Companies

Uploaded by

Awais AnwarOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Variable Valve Timing and Lifting Technologies in Different Automobiles Companies

Uploaded by

Awais AnwarCopyright:

Available Formats

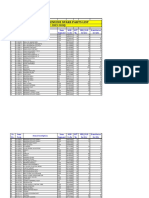

Variable Valve Timing And Lifting Technologies In

Different Automobiles Companies

Automobile Company Name

Technology Used

Subaru

AVCS

Subaru

AVLS

Proton

CPS

Nissan, Infiniti

CVTCS

Alfa Romeo, Citron, Geely, Hyundai,

Iran Khodro, Kia, Peugeot, Renault,

Volvo

CVVT

General Motors

DCVCP

Daihatsu

DVVT

Mitsubishi

MIVEC

Fiat

MultiAir

Nissan

N-VCT

Mazda

S-VT

Ford

Ti-VCT

BMW

VANOS

Porsche

VarioCam

Ford, Yamaha

VCT

Honda, Acura

VTEC

MG Rover

VVC

Nissan

VVL

Audi

Valvelift

Nissan, Infiniti

VVEL

Chrysler, General Motors, Proton,

Suzuki, Volkswagen Group

VVT

Toyota, Lexus

VVT-i

Hyundai, Kia

VTVT

Active valve control system

The active valve control system (AVCS) is an automobile variable valve

timing technology used by Subaru. It varies the timing of the intake

valves by using hydraulic oil pressure to rotate the camshaft in order to

provide optimal air flow in and out of the engine. The system is closed

loop using camshaft sensors, crankshaft sensors, air flow meter, throttle

position as well as oxygen sensors and/or Air-Fuel ratio sensors in order to

calculate engine load. The ECU is programmed to operate control valves

that adjust the delivery of the hydraulic pressure in order to move the

camshaft into the position that will provide the engine with the best

performance while minding emissions standards

Active valve lift system

The I-Active Valve Lift System (i stands for intelligence) or i-AVLS is a valve

train technology implemented by Subaru in the 2.5L naturally aspirated

engines SOHC to improve emissions, efficiency and performance. Note

that AVLS is different from AVCS used on other Subaru engines. AVLS

improves performance and efficiency by changing which camshaft is

operating which of the two intake valves. The camshafts on all AVLS

Subaru engines have specially designed lobes for intake valves. They

feature two different cam profiles: a low/mid lift profile or a high lift profile.

The two intake valves in each cylinder are operated by a rocker arm with

its own cam lobe.

CamPro engine

The nameCamPro is short for Cam Profiling. This engine powers the Proton

Gen-2, Proton Satria Neo, Proton Waja Campro, Proton Persona,Proton

Saga, Proton Exora, Proton Preve, Proton Suprima S and Proton Iriz. The

CamPro engine was created to show Proton's ability to make its own

engines that produce good power output and meet newer emission

standards.

CVTCS

Continuous

Variable

Valve

Timing

Control,

which

is

known

as CVTC or CVTCS, is an automobile variable valve timing technology

developed by Nissan, similar to Toyota's VVT-i system. It is also used in a

twin

CVTC

configuration

on

engines

such

as

the Nissan

Juke's MR16DDT engine. CVTCS is the successor to Nissan's earlier valve

timing implementation NVCS.

MIVEC

MIVEC (Mitsubishi Innovative Valve timing Electronic Control system) is

the brand name of a variable valve timing (VVT) engine technology

developed by Mitsubishi Motors. MIVEC, as with other similar systems,

varies the timing of the intake and exhaust camshafts which increases the

power and torque output over a broad engine speed range while also

being able to help spool a turbocharger more quickly.

MultiAir

Multiair is a hydraulically-actuated variable valve timing (VVT) engine

technology enabling "cylinder by cylinder, stroke by stroke control of

intake air directly via a gasoline engine's inlet valves. Developed by Fiat

Powertrain Technologies, the technology bypasses a primary engine

inefficiency: pumping losses caused by restriction of the intake passage by

the throttle plate, used to regulate air feeding the cylinders.

N-VCT

Nissan

Variable

Cam

Timing or Nissan

Valve

Timing

Control

System (commonly

known

as N-VCT, VCT, NVCS or NVTCS)

is

an automobile variable valve timing technology developed by Nissan. NVCT was first introduced in 1987 on the VG30DE and VG20DET engine.

N-VCT varies valve timing by rotating the affected camshaft(s) relative to

the sprocket; valve lift and duration are not altered. This rotation is

achieved when an electric solenoid, controlled by the car's ECU, allows

pressurized engine oil to flow into and through the cam and into a slave

mechanism, axially advancing cam timing relative to the sprocket. Valve

to crank angle timing varies depending on whether engine speed is high

or low and changes at fixed intervals. NVTCS is hydraulically actuated

similar to Hondas VTECsystem, but adjusts a different aspect of the valve

train, so it is more like the I part of I-VTEC.

S-VT

S-VT, or Sequential Valve Timing, is an automobile variable valve

timing technology developed by Mazda. S-VT varies the timing of

the intake valves by using hydraulicpressure to rotate the camshaft. S-VT

was introduced in 1998 on the ZL-VE engine

the B-, Z-, MZR- and J-families of engines.

and

is

used

in

VANOS

VANOS (abbr.

from

German variable Nockenwellensteuerung)

an automotive variable valve timing system produced by BMW.

is

VANOS is a variator system that varies the timing of the valves by moving

the position of the camshafts in relation to the drive gear. The relative

timing between inlet and exhaust valves is changed.

At lower engine speeds, the position of the camshaft is moved so the

valves are opened later, as this improves idling quality and smooth power

development. As the engine speed increases, the valves are opened

earlier: this enhances torque, reduces fuel consumption and lowers

emissions. At high engine speeds, the valves are opened later again,

because this allows full power delivery

VarioCam

VarioCam is an automobile variable valve timing technology developed

by Porsche. VarioCam varies the timing of the intake valves by adjusting

the

tension

on

the

timing

chain

connecting

the

intake

and exhaust camshafts.

Porsche's more recent VarioCam Plus combines variable valve timing with

two-stage lift on the intake side. The two-stage valve-lift function is

performed by electro-hydraulically operated switchable tappets.

Variable Cam Timing

Variable Camshaft Timing (VCT) is an automobile variable valve

timing technology developed by Ford. It allows for more optimum engine

performance, reduced emissions, and increased fuel efficiency compared

to engines with fixed camshafts. It uses electronically controlled hydraulic

valves that direct high pressure engine oil into the camshaft phaser cavity.

These oil control solenoids are bolted into the cylinder heads towards the

front of the engine near the camshaft phasers. The powertrain control

module (PCM) transmits a signal to the solenoids to move a valve

spool that regulates the flow of oil to the phaser cavity. The phaser cavity

changes the valve timing by rotating the camshaft slightly from its initial

orientation, which results in the camshaft timing being advanced or

retarded.

VTEC

VTEC (Variable Valve Timing and Lift Electronic Control) is a system

developed by Honda to improve the volumetric efficiency of a fourstroke internal combustion engine (i.e. improved economy). The VTEC

system uses two camshaft profiles and hydraulically selects between

profiles. It was invented by Honda engineer Ikuo Kajitani. It is distinctly

different from standard VVT (variable valve timing) which advances the

valve timing only and does not change the camshaft profile or valve lift in

any way.

Variable Valve Control

VVC (Variable Valve Control) is an automobile variable valve

timing technology developed by Rover and applied to some high

performance variants of the company's K Series 1800cc engine.

Nissan VVL engine

Nissan Ecology Oriented Variable Valve Lift and Timing (commonly known

as VVL & VVT) is an automobile variable valve timing technology

developed by Nissan. VVL varies the duration, and lift of valves by

using hydraulic pressure

switch

between

two

different

sets

of camshaft lobes. VVT varies the valve timing throughout the RPM range.

Together they function similarly to Honda's VTEC system.

Variable Valve Event and Lift

Nissan Variable Valve Event and Lift (commonly abbreviated as "VVEL") is

an automobile variable valve timing technology developed by Nissan.

Nissan VVEL was first introduced to the US market in late-2007 on the

2008 Infiniti G37 Coupe sporting the new "VVEL" VQ37VHR engine.

VVT-i

VVT-i, or Variable Valve Timing with intelligence, is an automobile variable

valve timing technology developed by Toyota. The Toyota VVT-i system

replaces the Toyota VVT offered starting in 1991 on the 5-valve per

cylinder 4A-GE engine. The VVT system is a 2-stage hydraulically

controlled cam phasing system.

You might also like

- Energysuspension CatalogDocument76 pagesEnergysuspension CatalogwillyhuaNo ratings yet

- Fuel InjectionDocument18 pagesFuel InjectionAshutoshSharmaNo ratings yet

- 00 GeneralDocument24 pages00 Generalcrysttina100% (1)

- 2010 Ginn Motor Company HHR Atlanta GADocument8 pages2010 Ginn Motor Company HHR Atlanta GAatlantachevroletNo ratings yet

- 3s Engine - MechanicalDocument175 pages3s Engine - MechanicalTiTi En GalaxyNo ratings yet

- ValeoDocument4 pagesValeographmashNo ratings yet

- 2013 FIAT 500 - 500C OM 5th PDFDocument413 pages2013 FIAT 500 - 500C OM 5th PDFzavalaoNo ratings yet

- Title 07 Training ManualDocument436 pagesTitle 07 Training ManualtgaNo ratings yet

- Multi Air Engine Technology BenefitsDocument19 pagesMulti Air Engine Technology BenefitsMahaManthra0% (2)

- Carte Tehnica Alfa RomeoDocument66 pagesCarte Tehnica Alfa RomeoIndianaJones2000No ratings yet

- 4 Throttles' Vacuum From Toyota Corolla Levin AE101 4A-GE 20vDocument6 pages4 Throttles' Vacuum From Toyota Corolla Levin AE101 4A-GE 20vTobyNo ratings yet

- Service Manual: 320 & 320L ExcavatorDocument30 pagesService Manual: 320 & 320L ExcavatorSri hartati100% (1)

- Proton S4 PHAutomotive TrainerDocument1 pageProton S4 PHAutomotive TrainerAzre mohd nor100% (1)

- Rearend Gear GuideDocument18 pagesRearend Gear GuideJam BabNo ratings yet

- OverlapDocument24 pagesOverlapA7MED 7ALEMNo ratings yet

- VARIABLE VALVE TIMING GUIDED BY ANOOP KUMAR GDocument25 pagesVARIABLE VALVE TIMING GUIDED BY ANOOP KUMAR GCochintu Radu100% (1)

- Ford 2.4, 2.8 and 2.9 Litre V6 EnginesDocument22 pagesFord 2.4, 2.8 and 2.9 Litre V6 Enginesjorge Angel LopeNo ratings yet

- D9R DescriptionDocument154 pagesD9R DescriptionMekdim Bogale100% (1)

- 2006 Cclass Clkclass Sclass Clclass SlclassDocument79 pages2006 Cclass Clkclass Sclass Clclass Slclassopenid_nHbxM2cxNo ratings yet

- Valve Seat Installation InstructionsDocument10 pagesValve Seat Installation InstructionscpaolinodNo ratings yet

- Engine Fundamentals QuizDocument315 pagesEngine Fundamentals QuiztrishaNo ratings yet

- BW 211 D 3Document3 pagesBW 211 D 3Oecox Cah DjadoelNo ratings yet

- c6.6 Parts Catalog Sebp4314-30Document2,242 pagesc6.6 Parts Catalog Sebp4314-30Галина КарташоваNo ratings yet

- GCP and 4G Diagnostic ManualDocument305 pagesGCP and 4G Diagnostic ManualRolando Gonzalez ArmasNo ratings yet

- 3.0L EngineDocument523 pages3.0L EnginenifftinessNo ratings yet

- Gas Engine Maintenance ScheduleDocument14 pagesGas Engine Maintenance SchedulerajeshNo ratings yet

- Manual Motor Hyundai Elantra - Unlocked PDFDocument164 pagesManual Motor Hyundai Elantra - Unlocked PDFloky13100% (1)

- Combustion Engines: An Introduction to Their Design, Performance, and SelectionFrom EverandCombustion Engines: An Introduction to Their Design, Performance, and SelectionNo ratings yet

- PT Pgt25 Dle Description VCNGDocument30 pagesPT Pgt25 Dle Description VCNGolegprikhodko2809100% (1)

- Parts List For S4Document3 pagesParts List For S4Alessandro SouzaNo ratings yet

- Mivec: MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)Document5 pagesMivec: MIVEC (Mitsubishi Innovative Valve Timing Electronic Control System)alibababujanglapokNo ratings yet

- Variable Valve Timing ExplainedDocument9 pagesVariable Valve Timing ExplainedDivya Chaudhary100% (1)

- VVTDocument3 pagesVVTraumilNo ratings yet

- Variable Valve Timing (VVT)Document32 pagesVariable Valve Timing (VVT)Ali HamzaNo ratings yet

- Proton Saga: Navigation SearchDocument9 pagesProton Saga: Navigation SearchatiqeeraNo ratings yet

- CH 08 - Four-Wheel-Drive SystemsDocument36 pagesCH 08 - Four-Wheel-Drive SystemsRevanth BhattaramNo ratings yet

- Engine Performance Optimization - GT PowerDocument2 pagesEngine Performance Optimization - GT Powermanoj262400/2No ratings yet

- Volvo - My05 07B5254T S40V50C70C30Document30 pagesVolvo - My05 07B5254T S40V50C70C30sharck04100% (1)

- Duratec Camshaft TimingDocument2 pagesDuratec Camshaft TimingKNOBERYNo ratings yet

- Vincard16 Car 08-23-16 r1.12Document29 pagesVincard16 Car 08-23-16 r1.12rahulNo ratings yet

- 350Z ECU Resetting ProceduresDocument2 pages350Z ECU Resetting Proceduresr3belzNo ratings yet

- Valvetrain Feature ETM107 Mechadyne TechnologiesDocument4 pagesValvetrain Feature ETM107 Mechadyne Technologiesseva0No ratings yet

- Catalogo Fuel Pumps Air Flow 17122009135336Document88 pagesCatalogo Fuel Pumps Air Flow 17122009135336evailson2No ratings yet

- Auto WikiDocument313 pagesAuto WikijhpandiNo ratings yet

- 275 HP 6-Cylinder Automotive Engine Specs and Performance CurvesDocument2 pages275 HP 6-Cylinder Automotive Engine Specs and Performance CurvesopytnymoryakNo ratings yet

- Project Report On Power Transmission in AutomobilesDocument74 pagesProject Report On Power Transmission in AutomobilesRahul Yargattikar100% (1)

- Ev1 PDFDocument11 pagesEv1 PDFGerardo Alex Gz DzNo ratings yet

- Cylinder Head InstallDocument2 pagesCylinder Head InstallMiguel Moreno FernándezNo ratings yet

- Oil Pump Overhaul GuideDocument3 pagesOil Pump Overhaul GuideHenry SilvaNo ratings yet

- AU TO M OT I V E & T R U C K / S U V APPLICATIONS, SPECIFICATIONS & DISTRIBUTOR PRICE GUIDEDocument60 pagesAU TO M OT I V E & T R U C K / S U V APPLICATIONS, SPECIFICATIONS & DISTRIBUTOR PRICE GUIDEArif WidayuniNo ratings yet

- 08XKDocument510 pages08XKscribd2162No ratings yet

- WossnerPistons 2014 Auto Catalog PDFDocument140 pagesWossnerPistons 2014 Auto Catalog PDFAlin IordacheNo ratings yet

- CP7818 - Fuel Pressure Tester Kit Instructions: Vehicle Application ListDocument4 pagesCP7818 - Fuel Pressure Tester Kit Instructions: Vehicle Application ListEngine Tuning UpNo ratings yet

- VTECDocument15 pagesVTECAnkit Singh0% (1)

- Toyota CamryDocument2 pagesToyota CamryJon WestNo ratings yet

- Valve Stem SealsDocument2 pagesValve Stem SealsBinny Samuel Christy100% (1)

- 1 - 208129978 Hemi EnginesDocument18 pages1 - 208129978 Hemi EnginesBoya Raj NaikNo ratings yet

- Engine Diagnostics Guide for B5254TDocument30 pagesEngine Diagnostics Guide for B5254TFlorin AgaiNo ratings yet

- Camshaft Design For An Inlet-Restricted FSAE Engine: September 2008Document10 pagesCamshaft Design For An Inlet-Restricted FSAE Engine: September 2008emanuelNo ratings yet

- Double CV Joint Lada NivaDocument7 pagesDouble CV Joint Lada NivaLaurentiu PopaNo ratings yet

- Iafm EngineDocument2 pagesIafm EngineAdhitya IndrawanNo ratings yet

- 12 - LE9 EcotecDocument4 pages12 - LE9 EcotecakirafactorNo ratings yet

- Swedish hypercar maker KoenigseggDocument11 pagesSwedish hypercar maker KoenigseggAzizul Anwar0% (1)

- Manual Linkage System Kia Sephia 98-01 (1997-2001)Document5 pagesManual Linkage System Kia Sephia 98-01 (1997-2001)Jose PichinteNo ratings yet

- Suspension Trasera 97-98Document6 pagesSuspension Trasera 97-98kilofome05No ratings yet

- TREMEC TR-6070 Transmission: 7-Speed RWD Manual TransmissionDocument2 pagesTREMEC TR-6070 Transmission: 7-Speed RWD Manual TransmissionAngelNo ratings yet

- Impulse Turbine and Reaction TurbineDocument5 pagesImpulse Turbine and Reaction Turbinerahul100% (1)

- Complete Bajaj Genuine Spare Parts ListDocument546 pagesComplete Bajaj Genuine Spare Parts Listনোমান100% (4)

- EFI System ExplainedDocument14 pagesEFI System ExplainedMd zakirNo ratings yet

- F004-P006-Gfpi Guia de ApreDocument165 pagesF004-P006-Gfpi Guia de Aprejuan perezNo ratings yet

- Additional Instructions MHC-1 J1939Document7 pagesAdditional Instructions MHC-1 J1939PljjkjNo ratings yet

- J312V202 enDocument4 pagesJ312V202 enMartin KratkyNo ratings yet

- 20231020price From Lisa For Yuchai EngineDocument6 pages20231020price From Lisa For Yuchai Enginedenny saputraNo ratings yet

- Rudder Repeatback Rudder Angle Transmitter.Document469 pagesRudder Repeatback Rudder Angle Transmitter.Nutriologa Adriana LazaroNo ratings yet

- Lycoming 580 Series - MOTORESDocument2 pagesLycoming 580 Series - MOTORESmangegenNo ratings yet

- Turbine Engine FundamentalsDocument72 pagesTurbine Engine FundamentalsASHIS MAHARANANo ratings yet

- Automotive Acronyms and AbbreviationsDocument4 pagesAutomotive Acronyms and AbbreviationsHasnain AftabNo ratings yet

- 303-04F+Fuel+Charging+and+Controls+-+TurbochargerDocument9 pages303-04F+Fuel+Charging+and+Controls+-+TurbochargerP HandokoNo ratings yet

- kr115 Fox PR enDocument6 pageskr115 Fox PR enMohd NazriNo ratings yet

- Tap Man CatalogueDocument60 pagesTap Man CatalogueFilipposNo ratings yet

- Repair N67 Series Industrial EnginesDocument20 pagesRepair N67 Series Industrial Enginesmanuel segoviaNo ratings yet

- PGM FiDocument57 pagesPGM FiMiko KeefeNo ratings yet

- Qubepower Parts Manual V10Document35 pagesQubepower Parts Manual V10Sandeep Singh ChaudharyNo ratings yet

- Continuous Variable Valve Timing System CVVT System: Click!Document75 pagesContinuous Variable Valve Timing System CVVT System: Click!Cristiam QuispeNo ratings yet

- Puch E50 Engine Tune Up SheetDocument1 pagePuch E50 Engine Tune Up SheetwiscadNo ratings yet

- Loco BoilerDocument9 pagesLoco Boilersahil bansal100% (1)