Professional Documents

Culture Documents

The Clutch

Uploaded by

Ana Maria AvadaneiCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

The Clutch

Uploaded by

Ana Maria AvadaneiCopyright:

Available Formats

Avdnei Ana-Maria, AE, 1731

The clutch

Definition

The clutch is a mechanism that uses pads impregnated with a friction

material to transfer the power from the engine to the axle tractors. It is used

for the gear shifting. The clutch is also used to isolate rotating components

against fixed ones , reducing shock loads. Vehicles with manual transmission

use the clutch to transfer the power from the gearbox to the wheels .

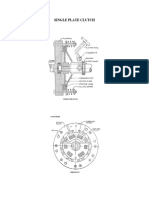

The monodisc clutch with diaphragm

central spring

At this type of clutch, the function of compression springs and

decoupling levers is accomplished by a special central spring shape.

The diaphragm central spring is a thin disc made of steel, in a

truncated shape, having a serie of elastic arms formed by radial cuts.

The monodisc clutch with diaphragm central spring, depending on

the direction of actioning of release force, we can discuss about two types of

clutches:

- mechanical clutch with diaphragm central spring released by

compression;

- mechanical clutch with diaphragm central spring released by traction.

On most cars and light commercial vehicles, the clutch used is the

one released by compression.

Avdnei Ana-Maria, AE, 1731

The

monodisc clutch with peripheral

springs

This type of clutch is still used in cars and trucks because it has the

lowest weight and the simplest construction.

The weight of this type of clutch (without book) is 0,30,6% of weight

of the truck and 0,40,8% of weight of the car production.

Its use is limited by the maximum momentum which can be

transmitted and which should not be bigger than 7080 daN.m.

The peripheral springs are arranged equidistant on the periphery of

the pressure disc. These are helical springs made from pulled wire with linear

characteristic.

In normal state the clutch is "coupled". This condition is the effect of

the compression springs, which mounted prestressed between housing and

pressure plate, in trend of expansion, driven disc collection will be done

between the flywheel and pressure plate.

The decoupling of the clutch is obtained when in the command part is

developed a force Fd. The decoupling collar, under the action of this force,

moved axially to the left, will rotate the decoupling levers in a clockwise

direction. Simultaneously with the release levers takeover by elastic forces of

2

Avdnei Ana-Maria, AE, 1731

the springs through additional compression springs, pressure plate is axially

displaced to the left until loosen frictional contact between the driving and

driven parts. This is how the state of declutching is achieved. The clutching

after declutching is obtained by canceling force Fd.

Disadvantages:

- pressing the friction disc on the friction surface is nonuniform;

- mounting springs impose a constructive series of special provisions;

- decoupling levers require laborious adjustment operations;

- due to structural characteristics of the springs increases the axial gauge;

- reliability is lower because of a large number of parts and joints mobile

friction clutch mechanism contained inside;

- actioning is more difficult because the force required in maintaining the

clutch disengaged position is disengaged is higher in this type of clutch.

Therefore, after 1980 it was gradually dropped from use in favor of

The monodisc clutch with diaphragm central spring.

The bidisc clutch

Friction linings dimensions are limited by the dimensions of the

flywheel and the coefficient of friction is also limited. Also downforce springs

can not exceed a certain value, because with cresetrea they increase the

3

Avdnei Ana-Maria, AE, 1731

size of the springs and the specific pressure of the disc may exceed the

allowable limit. In these conditions becomes cumbersome clutch drive and

clutch sizes grow considerably if you have sent a great moment.

For these reasons, the transmission of greater than 80 daN moments:

m resorting to increasing the number of surface friction clutches by using

multiple discs. Of these the most used are twin disc clutch. The weight of

such a clutch can reach about 0.7% by weight of the car.

Decoupling clutch is done by moving to the right disc pressure using

the clutch levers, screws through June, led freeing disk (figure below).

Meanwhile, the pressure plate is far from disc springs led by mounted

between disc and flywheel.

To limit axial displacement of the disc pressure so as not to produce a

click of the disc driven by the pressure plate, between the two pressure

plates are provided three screws supporting 12 fixed in housing.

Bearing pressure spring 16 returns to its initial position after releasing

the clutch.

Clutch levers are fixed to the outer ends of the pressure plate via

screws nut 6. 7 serves to adjust the clearance between the bearing pressure

and the inner ends of the clutch levers.

The clutch is fitted at the bottom with a hole to drain the oil. In this

slot game is introduced with the pin 14, which vibrations occurring during the

course of the car does not enable the port to clog with dirt.

Avdnei Ana-Maria, AE, 1731

References:

5

Avdnei Ana-Maria, AE, 1731

http://www.rasfoiesc.com/inginerie/tehnica-mecanica/AMBREIAJUL41.php

You might also like

- The Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementFrom EverandThe Book of the Singer Junior - Written by an Owner-Driver for Owners and Prospective Owners of the Car - Including the 1931 SupplementNo ratings yet

- Automobile Clutch: Aim To Study and Prepare Report On The Constructional Details, Working Principles andDocument4 pagesAutomobile Clutch: Aim To Study and Prepare Report On The Constructional Details, Working Principles andசிவ சங்கர்No ratings yet

- Construction and Manufacture of AutomobilesFrom EverandConstruction and Manufacture of AutomobilesRating: 5 out of 5 stars5/5 (1)

- ClutchDocument5 pagesClutchyudhisthar0110% (1)

- Plymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceFrom EverandPlymouth and Chrysler-built cars Complete Owner's Handbook of Repair and MaintenanceNo ratings yet

- Galgotias University: Laboratory ManualDocument52 pagesGalgotias University: Laboratory ManualAgnivesh SharmaNo ratings yet

- Auto Transmission - NotesDocument34 pagesAuto Transmission - Notesvandanaharikumar100% (2)

- Vacuum ClutchDocument8 pagesVacuum Clutchprithvi mannNo ratings yet

- Transmission Systems OverviewDocument168 pagesTransmission Systems Overviewriyaz ahmedNo ratings yet

- Automobile Suspension Detailed Analysis PDFDocument19 pagesAutomobile Suspension Detailed Analysis PDFalpNo ratings yet

- Clutch & Gearbox Guide in 38 CharactersDocument30 pagesClutch & Gearbox Guide in 38 CharactersManjunath Shettar100% (1)

- ClutchDocument22 pagesClutchIsaiah LuleNo ratings yet

- CLUTCHES All DetailsDocument36 pagesCLUTCHES All DetailsArunavNo ratings yet

- Power Units and TransmissionDocument42 pagesPower Units and TransmissionAmarjeet RaiNo ratings yet

- Mechanism and Types of ClutchesDocument41 pagesMechanism and Types of Clutchessarath100% (1)

- AT6501 UwDocument132 pagesAT6501 UwAjithNo ratings yet

- Automotive Transmission NewDocument147 pagesAutomotive Transmission NewhodvmkvecautoNo ratings yet

- Automotive TransmissionDocument146 pagesAutomotive TransmissionTony Neal100% (1)

- Internal Expanding BrakeDocument11 pagesInternal Expanding BrakeGirish Sahare100% (1)

- Brake System - HMCDocument69 pagesBrake System - HMCDani HidayatulohNo ratings yet

- What Does The Clutch Pressure Plate Do?Document10 pagesWhat Does The Clutch Pressure Plate Do?Kem Docenos Yam-ocNo ratings yet

- Clutch PDFDocument60 pagesClutch PDFAyush Kumar50% (2)

- Single Plate ClutchDocument4 pagesSingle Plate Clutchsaffrin0% (2)

- Unit 3 ClutchesDocument54 pagesUnit 3 Clutchesswapnil pandeNo ratings yet

- INTERNAL EXPANDING BRAKE DESIGN AND WORKING (39Document5 pagesINTERNAL EXPANDING BRAKE DESIGN AND WORKING (39Karansingh KhatriNo ratings yet

- Automotive Brake Efficiency Formulas & Hydraulic Brake System DesignDocument45 pagesAutomotive Brake Efficiency Formulas & Hydraulic Brake System DesignAjit100% (1)

- Assignment ClutchDocument624 pagesAssignment ClutchSubhash KNo ratings yet

- CLUTCHES AND COUPLINGS: PNEUMATIC, MECHANICAL, AND FLEXIBLE TYPESDocument11 pagesCLUTCHES AND COUPLINGS: PNEUMATIC, MECHANICAL, AND FLEXIBLE TYPESSangharsh RathoreNo ratings yet

- Unit-2-Automobile EnggDocument23 pagesUnit-2-Automobile EnggPrashant BhumireddyNo ratings yet

- Manual Transmission CouplerDocument1 pageManual Transmission Couplerpkjhan1353No ratings yet

- Automotive (2) Lab: EXP1: ClutchesDocument7 pagesAutomotive (2) Lab: EXP1: ClutchesMohammad YahyaNo ratings yet

- Steering and Braking SystemDocument70 pagesSteering and Braking SystemPatrick MAZIMPAKANo ratings yet

- EXPERIMENT No 3 - Clutch SystemDocument4 pagesEXPERIMENT No 3 - Clutch SystemVaibhav RathoreNo ratings yet

- Slipper clutch improves motorcycle controlDocument27 pagesSlipper clutch improves motorcycle controljeyNo ratings yet

- Clutch: Chapter-1 IntroductionDocument6 pagesClutch: Chapter-1 IntroductionNikhil DixitNo ratings yet

- CLUTCHDocument48 pagesCLUTCHhaymanotNo ratings yet

- AT6501 (R-13) Notes PDFDocument131 pagesAT6501 (R-13) Notes PDFAashiq NawinNo ratings yet

- DoME Report (009 & 019)Document9 pagesDoME Report (009 & 019)Muhammad WaleedNo ratings yet

- 92 Automotive Power Train Service RevisedDocument92 pages92 Automotive Power Train Service Reviseddmc constructionNo ratings yet

- Diaphragm ClutchDocument13 pagesDiaphragm Clutchravi0% (1)

- ClutchesDocument25 pagesClutchesAtharva ShahaneNo ratings yet

- AE Unit 3 Transmission System NotesDocument15 pagesAE Unit 3 Transmission System Notessemmat1802No ratings yet

- Cert Drive TrainDocument30 pagesCert Drive TrainOKIDI Thomas BecketNo ratings yet

- Drum Brake System Components and OperationDocument0 pagesDrum Brake System Components and OperationPushpendra Singh RathoreNo ratings yet

- Chapter 2: The Transmission SystemDocument47 pagesChapter 2: The Transmission SystemJayvin RossNo ratings yet

- Mechanics of Textile Machinery ContentDocument59 pagesMechanics of Textile Machinery ContentPARAMASIVAM SNo ratings yet

- Goldwing InstructionsDocument5 pagesGoldwing InstructionsVanadia NohanNo ratings yet

- Brakes and ClutchesDocument20 pagesBrakes and ClutchesHuzaifa YousafNo ratings yet

- C.K. Pithawalla College of Engg. and Technology: Types of Brakes B26Document24 pagesC.K. Pithawalla College of Engg. and Technology: Types of Brakes B26RevanKumarBattuNo ratings yet

- Ae Unit 2Document25 pagesAe Unit 2Iyyappan SivalingamNo ratings yet

- Independent Front Suspension SystemDocument6 pagesIndependent Front Suspension SystemChetan SomashekarNo ratings yet

- Unit 17 - 02 - Starting & ManoeuvringDocument16 pagesUnit 17 - 02 - Starting & ManoeuvringAisha ZaheerNo ratings yet

- Hydraulic BrakeDocument6 pagesHydraulic BrakeHemantha DalugamaNo ratings yet

- Automobile clutch design and functionDocument7 pagesAutomobile clutch design and functionsreenu mNo ratings yet

- Power SteeringDocument3 pagesPower Steeringautomobile kmctptcNo ratings yet

- Drum Brake System Backing Plate: Braking PrincipleDocument3 pagesDrum Brake System Backing Plate: Braking PrincipleSamiullah QureshiNo ratings yet

- Brake ClassificationDocument9 pagesBrake Classificationmamnd tahaNo ratings yet

- It Is The Total Mechanism That Transmit The Power Developed of The Engine Going To The Drive Wheels of The VehicleDocument90 pagesIt Is The Total Mechanism That Transmit The Power Developed of The Engine Going To The Drive Wheels of The VehicleManny AnacletoNo ratings yet

- Aen QBDocument7 pagesAen QBKundan PednekarNo ratings yet

- Diaphragm Spring ClutchDocument3 pagesDiaphragm Spring ClutchEka Puspita AliNo ratings yet

- Philip Larkin: The Art of Poetry 30Document32 pagesPhilip Larkin: The Art of Poetry 30Telmo RodriguesNo ratings yet

- SPSS-TEST Survey QuestionnaireDocument2 pagesSPSS-TEST Survey QuestionnaireAkshay PatelNo ratings yet

- Ultimate Guide To Construction SubmittalsDocument10 pagesUltimate Guide To Construction SubmittalsDavid ConroyNo ratings yet

- STS Syllabus 2020Document27 pagesSTS Syllabus 2020AndreaDimaculangan100% (1)

- 2.7.3 Lab Use Steganography To Hide Data Answer KeyDocument3 pages2.7.3 Lab Use Steganography To Hide Data Answer KeyVivek GaonkarNo ratings yet

- Effect of Dust On The Performance of Wind Turbines PDFDocument12 pagesEffect of Dust On The Performance of Wind Turbines PDFJallal ArramachNo ratings yet

- De Thi HK 2 Tieng Anh 9 de 2Document17 pagesDe Thi HK 2 Tieng Anh 9 de 2Lê Thu HiềnNo ratings yet

- Sight Reduction Tables For Marine Navigation: B, R - D, D. SDocument12 pagesSight Reduction Tables For Marine Navigation: B, R - D, D. SGeani MihaiNo ratings yet

- HCCM System Technical Specification v1Document12 pagesHCCM System Technical Specification v1Ankita ChowdhuryNo ratings yet

- Quality Management - QuestionDocument4 pagesQuality Management - QuestionLawzy Elsadig SeddigNo ratings yet

- Re: Laparoscopic Myomectomy: A Review of Alternatives, Techniques and ControversiesDocument1 pageRe: Laparoscopic Myomectomy: A Review of Alternatives, Techniques and ControversiesMayada OsmanNo ratings yet

- Ifatsea Atsep Brochure 2019 PDFDocument4 pagesIfatsea Atsep Brochure 2019 PDFCondor GuatonNo ratings yet

- Powers of Central Govt under Environment Protection ActDocument13 pagesPowers of Central Govt under Environment Protection Actsirajudeen INo ratings yet

- Science SimulationsDocument4 pagesScience Simulationsgk_gbuNo ratings yet

- FED - Summer Term 2021Document18 pagesFED - Summer Term 2021nani chowdaryNo ratings yet

- TOS 22402 Winter 19th I SCHEME Paper Model Answer PaperDocument25 pagesTOS 22402 Winter 19th I SCHEME Paper Model Answer Paperirshadmirza753No ratings yet

- YSUUSYs NiCd Battery RepairDocument6 pagesYSUUSYs NiCd Battery Repairrwesseldyk50% (2)

- Figures of Speech ExplainedDocument5 pagesFigures of Speech ExplainedDarenJayBalboa100% (1)

- RA For Installation & Dismantling of Loading Platform A69Document15 pagesRA For Installation & Dismantling of Loading Platform A69Sajid ShahNo ratings yet

- Falling Weight Deflectometer Bowl Parameters As Analysis Tool For Pavement Structural EvaluationsDocument18 pagesFalling Weight Deflectometer Bowl Parameters As Analysis Tool For Pavement Structural EvaluationsEdisson Eduardo Valencia Gomez100% (1)

- E.bs 3rd-Unit 22Document46 pagesE.bs 3rd-Unit 22DUONG LE THI THUYNo ratings yet

- Rethinking Classification and Localization For Object DetectionDocument13 pagesRethinking Classification and Localization For Object DetectionShah Nawaz KhanNo ratings yet

- Short Answers Class 9thDocument14 pagesShort Answers Class 9thRizwan AliNo ratings yet

- Test Fibrain RespuestasDocument2 pagesTest Fibrain Respuestasth3moltresNo ratings yet

- Expt 1 Yarn Formation (Sherley Trash Analyser)Document7 pagesExpt 1 Yarn Formation (Sherley Trash Analyser)Yashdeep Sharma0% (1)

- Activities/Assessments 2:: Determine The Type of Sampling. (Ex. Simple Random Sampling, Purposive Sampling)Document2 pagesActivities/Assessments 2:: Determine The Type of Sampling. (Ex. Simple Random Sampling, Purposive Sampling)John Philip Echevarria0% (2)

- TEI - of - Microsoft - Business Central - FINALDocument23 pagesTEI - of - Microsoft - Business Central - FINALMarketing ComesaNo ratings yet

- Kanavos Pharmaceutical Distribution Chain 2007 PDFDocument121 pagesKanavos Pharmaceutical Distribution Chain 2007 PDFJoao N Da SilvaNo ratings yet

- 02 - Order Quantities When Demand Is Approximately LevelDocument2 pages02 - Order Quantities When Demand Is Approximately Levelrahma.samyNo ratings yet

- S 212 Pre Course WorkDocument5 pagesS 212 Pre Course Workafiwierot100% (2)

- A Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesFrom EverandA Poison Like No Other: How Microplastics Corrupted Our Planet and Our BodiesRating: 5 out of 5 stars5/5 (1)

- The Invisible Rainbow: A History of Electricity and LifeFrom EverandThe Invisible Rainbow: A History of Electricity and LifeRating: 4.5 out of 5 stars4.5/5 (21)

- Functional Safety from Scratch: A Practical Guide to Process Industry ApplicationsFrom EverandFunctional Safety from Scratch: A Practical Guide to Process Industry ApplicationsNo ratings yet

- Introduction to Petroleum Process SafetyFrom EverandIntroduction to Petroleum Process SafetyRating: 3 out of 5 stars3/5 (2)

- Chemical Process Safety: Learning from Case HistoriesFrom EverandChemical Process Safety: Learning from Case HistoriesRating: 4 out of 5 stars4/5 (14)

- Guidelines for Implementing Process Safety ManagementFrom EverandGuidelines for Implementing Process Safety ManagementNo ratings yet

- Incidents That Define Process SafetyFrom EverandIncidents That Define Process SafetyNo ratings yet

- Inherently Safer Chemical Processes: A Life Cycle ApproachFrom EverandInherently Safer Chemical Processes: A Life Cycle ApproachRating: 5 out of 5 stars5/5 (1)

- Rules of Thumb for Maintenance and Reliability EngineersFrom EverandRules of Thumb for Maintenance and Reliability EngineersRating: 4.5 out of 5 stars4.5/5 (12)

- Radium Girls: Women and Industrial Health Reform, 1910-1935From EverandRadium Girls: Women and Industrial Health Reform, 1910-1935Rating: 4.5 out of 5 stars4.5/5 (4)

- Trevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationFrom EverandTrevor Kletz Compendium: His Process Safety Wisdom Updated for a New GenerationNo ratings yet

- Safety Fundamentals and Best Practices in Construction IndustryFrom EverandSafety Fundamentals and Best Practices in Construction IndustryNo ratings yet

- Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisFrom EverandGuidelines for Initiating Events and Independent Protection Layers in Layer of Protection AnalysisRating: 5 out of 5 stars5/5 (1)

- Practical Industrial Safety, Risk Assessment and Shutdown SystemsFrom EverandPractical Industrial Safety, Risk Assessment and Shutdown SystemsRating: 4 out of 5 stars4/5 (11)

- Nutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeFrom EverandNutritional and Therapeutic Interventions for Diabetes and Metabolic SyndromeNo ratings yet

- Guidelines for Auditing Process Safety Management SystemsFrom EverandGuidelines for Auditing Process Safety Management SystemsNo ratings yet

- 3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionFrom Everand3D Printing of Concrete: State of the Art and Challenges of the Digital Construction RevolutionArnaud PerrotNo ratings yet

- Safety and Intelligent Transport Systems Development in the People’s Republic of ChinaFrom EverandSafety and Intelligent Transport Systems Development in the People’s Republic of ChinaNo ratings yet

- A Complete Guide to Safety Officer Interview Questions and AnswersFrom EverandA Complete Guide to Safety Officer Interview Questions and AnswersRating: 4 out of 5 stars4/5 (1)

- Exercise, Sport, and Bioanalytical Chemistry: Principles and PracticeFrom EverandExercise, Sport, and Bioanalytical Chemistry: Principles and PracticeNo ratings yet

- Safety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849From EverandSafety Critical Systems Handbook: A Straight forward Guide to Functional Safety, IEC 61508 (2010 EDITION) and Related Standards, Including Process IEC 61511 and Machinery IEC 62061 and ISO 13849Rating: 4 out of 5 stars4/5 (5)

- Electrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70EFrom EverandElectrical Safety Code Manual: A Plain Language Guide to National Electrical Code, OSHA and NFPA 70ERating: 3 out of 5 stars3/5 (6)

- One Health: Integrated Approach to 21st Century Challenges to HealthFrom EverandOne Health: Integrated Approach to 21st Century Challenges to HealthJoana C. PrataNo ratings yet

- Fire Protection Engineering in Building DesignFrom EverandFire Protection Engineering in Building DesignRating: 4.5 out of 5 stars4.5/5 (5)