Professional Documents

Culture Documents

Stainless Steels Duplex

Uploaded by

Jason Zhao FuCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Stainless Steels Duplex

Uploaded by

Jason Zhao FuCopyright:

Available Formats

Stainless Steels: Duplex

As their name implies, duplex stainless steels are

stainless steels containing two primary phases, f.c.c

austenite and b.c.c. ferrite. These alloys were first

observed in the 1920s as an outgrowth of studies on

austenitic stainless steels. Their balance of good

corrosion and mechanical properties has made them

an important part of the stainless steel family of alloys.

1. Development of Microstructure

The development of a duplex microstructure is a

natural outgrowth of the metallurgy of the FeCrNi

system, which is the basis of all stainless steels. This is

illustrated in Fig. 1, which shows the 70 wt.% Fe

isopleth for the FeCrNi system, which is approximately the amount of iron present in most stainless

steels. The austenite is referred to as the phase and

the ferrite as . (In wrought ferritic stainless steels, the

ferrite is typically referred to as , and this nomenclature is also often used in the duplex stainless steel

literature.) The more chromium in the alloy, the more

ferrite will be present, and the more nickel, the more

austenite will be present. Figure 2 shows a typical

microstructure for a duplex stainless steel. Here the

ferrite is etched darker than the austenite and is

denoted as .

Most duplex stainless steels initially solidify as ,

with the phase developing on cooling or during

working in the j phase field. The amount and

morphology of austenite and ferrite depends upon the

exact composition of the alloy, the cooling rate after

solidification, the annealing temperature, and the

processing conditions. Alloying elements in addition

to iron, chromium, and nickel also play a role in

determining the amount of ferrite that can be developed. The exact effectiveness of any element in

stabilizing ferrite or austenite varies from study to

study, depending upon the exact alloy composition,

processing, and heat treatment. Molybdenum, silicon,

niobium, aluminum, and titanium stabilize ferrite, and

manganese, copper, carbon, and nitrogen stabilize

austenite. Carbon and nitrogen are particularly potent

austenite stabilizers, being 1535 times more effective

than nickel (on a wt.% basis). The weighing factors for

the other elements, for austenite or ferrite stabilization,

are about 0.253.0 (also on a wt.% basis relative to

nickel or chromium).

Duplex stainless

steels typically

contain

2070 vol.% ferrite. They can exist in either wrought

or cast forms. In addition, castings which are

nominally considered as being austenitic often contain

540 vol.% ferrite, and are thus strictly speaking

duplex stainless steels, although they are generally not

referred to as such. Austenitic stainless steel weld metal

is also almost always duplex, typically containing

520 vol.% ferrite. In the case of castings and weld

metal, the ferrite is present primarily to prevent hot

cracking during solidification. In the case of those

alloys that are termed duplex, the ferrite is present

because of its influence on corrosion and mechanical

properties.

2. Development of Additional Phases

Figure 1

Pseudobinary diagram showing the 70% isoplethal section

of the FeCrNi phase diagram (reproduced by permission

of EDP Sciences from Stainless Steels, 1993, pp. 61359).

Duplex stainless steels can contain many phases in

addition to austenite and ferrite. The development of

these phases, and the way various alloying elements

influence this development, is illustrated in Fig. 3. For

the most part, the phases shown in Fig. 3 embrittle the

alloy without strengthening it and should therefore be

avoided. This is particularly true for and phases.

The exception is the h phase, which is a chromiumrich b.c.c. phase that strengthens the ferrite as well as

reduces its ductility. As such, duplex stainless steels are

sometimes deliberately heat treated to produce some

1

Stainless Steels: Duplex

annealing is also required to prevent undesirable

precipitates from developing.

3. Alloy Properties and Uses

Figure 2

Typical duplex microstructure (reproduced by permission

of ASM International from Duplex Stainless Steels, 1983,

pp. 693756).

Figure 3

Schematic representation of the possible precipitates in

duplex stainless steels (reproduced by permission of EDP

Sciences from Duplex Stainless Steels 91, 1991, pp.

348).

h. This phase can develop by either nucleation and

growth or by spinodal decomposition, depending

upon the composition of the alloy. The spinodal

decomposition into chromium- and iron-rich regions

also strengthens the ferrite.

Many of the phases illustrated in Fig. 3 develop in

the ferrite or at the ferrite\austenite boundaries, so the

amount and morphology of the ferrite determine the

degree to which the alloy properties are degraded.

Figure 3 shows the temperature ranges at which these

phases form, and this sets limits on the temperature

ranges at which these alloys can be fabricated or used.

Rapid cooling from high-temperature processing or

2

The chief reasons for using duplex stainless steels are

their good resistance to oxidation, corrosion, and

stress corrosionall this while maintaining superior

mechanical properties. These alloys generally exhibit

the same, or lower, general corrosion rates as austenitic stainless steels in dilute sulfuric acid. This is also

true in dilute hydrochloric acid, and in the caustic

solutions encountered in the pulp and paper industry.

Some of these alloys are also applicable for exposure

to organic acids. Many of these alloys possess superior

pitting and crevice corrosion resistance, compared

with austenitic stainless steels. Duplex stainless steels

possess superior resistance to both transgranular and

intergranular stress corrosion cracking. The exact

degree to which any of these alloys is resistant to any

form of corrosion or stress corrosion depends upon its

composition, microstructure, and the exact nature of

the solution and solution temperature to which it is

exposed.

Duplex stainless steels also possess excellent mechanical properties, and are consequently sometimes

utilized instead of austenitic or ferritic stainless steels.

Duplex steels generally possess higher yield and

ultimate tensile strengths than most austenitic or

ferritic stainless steels. The degree to which this is so

depends not only on the alloy composition, but also on

the way that it is processed. This improved strength is

generally achieved without compromising the toughness of the alloy, providing that the alloy does not

contain any of the deleterious phases shown in Fig. 3.

The toughness of ferrite is decreased with decreasing

temperatures but, being present only as a constituent

of a two-phase alloy, this not does not produce as

sharp a ductile-to-brittle transition as in ferritic stainless steels. The higher the ferrite content, the sharper

the ductile-to-brittle transition.

Ferrite has a smaller expansion coefficient and larger

thermal conductivity than austenite, so the more

ferrite that is present, the lower will be the coefficient

of expansion and the greater the thermal conductivity

of the duplex stainless steel. Duplex stainless steels are

generally very weldable; in fact, austenitic stainless

steels utilize duplex weld metal.

See also: Stainless Steels: Martensitic; Ferritic

Stainless Steels; Austenitic Stainless Steels; Stainless

Steels: Cast

Bibliography

Charles J, Bernhardsson S (eds.) 1991 Duplex Stainless Steels

91. Les Editions de Physique, Les Ulis, France

Charles J 1991 The duplex stainless steels: materials to meet your

Stainless Steels: Duplex

needs. In: Charles J, Bernhardsson S (eds.) Duplex Stainless

Steels 91. Les Editions de Physique, Les Ulis, France, pp.

348

Desestret A, Charles J 1993 The duplex stainless steels. In:

Lacombe P, Baroux B, Beranger G (eds.) Stainless Steels. Les

Editions de Physique, Les Ulis, France, pp. 61359

Duplex Stainless Steels 94 1994 TWI, Glasgow, UK

Duplex Stainless Steels 86 1986 Nederlands Instituut voor

Lastechniek, The Hague

Gunn R N 1997 Duplex Stainless Steels. Abington Publishing,

Cambridge, UK

Lula R A (ed.) 1983 Duplex Stainless Steels. American Society

for Metals, Metals Park, OH

Solomon H D, Devine T M Jr. 1983 Duplex stainless steelsa

tale of two phases. In: Lula R A (ed.) Duplex Stainless Steels.

American Society for Metals, Metals Park, OH, pp. 693756

H. D. Solomon

Copyright ' 2001 Elsevier Science Ltd.

All rights reserved. No part of this publication may be reproduced, stored in any retrieval system or transmitted

in any form or by any means : electronic, electrostatic, magnetic tape, mechanical, photocopying, recording or

otherwise, without permission in writing from the publishers.

Encyclopedia of Materials : Science and Technology

ISBN: 0-08-0431526

pp. 88028804

3

You might also like

- In Situ Testing of Flexible ElectronicsDocument3 pagesIn Situ Testing of Flexible ElectronicsJason Zhao FuNo ratings yet

- FinlandDocument140 pagesFinlandJason Zhao FuNo ratings yet

- Harvard Referencing ManualsDocument29 pagesHarvard Referencing ManualsUdithaKekulawalaNo ratings yet

- Harvard Referencing ManualsDocument29 pagesHarvard Referencing ManualsUdithaKekulawalaNo ratings yet

- Austenite Stainless SteelDocument5 pagesAustenite Stainless SteelJason Zhao FuNo ratings yet

- High Entropy AlloysDocument57 pagesHigh Entropy AlloysJason Zhao FuNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- ASTM A960-Common Requirements For Wrought Steel Piping Fittings PDFDocument9 pagesASTM A960-Common Requirements For Wrought Steel Piping Fittings PDFvendry mofuNo ratings yet

- A Superior Alternative To Carbon or Low Alloy Steels: Sandvik 3R12/4L7Document4 pagesA Superior Alternative To Carbon or Low Alloy Steels: Sandvik 3R12/4L7Saravanan MariNo ratings yet

- KL Jack Fasteners-Technical Data and ChartsDocument32 pagesKL Jack Fasteners-Technical Data and ChartsGufran AhmadNo ratings yet

- Stainless Steel Tube SpecificationsDocument7 pagesStainless Steel Tube Specificationsgkamesh84No ratings yet

- COBALT - FACTS-Metallurgical - UsesDocument15 pagesCOBALT - FACTS-Metallurgical - UsesMarlon BombiNo ratings yet

- Weldability Testing For Advanced MaterialsDocument8 pagesWeldability Testing For Advanced MaterialsJim BetsingerNo ratings yet

- Industrial Fan ApplicationsDocument24 pagesIndustrial Fan Applicationsmshah222No ratings yet

- Seal Material and Arrangement GuideDocument48 pagesSeal Material and Arrangement Guideleo100% (1)

- 3M DC Series Cartridge Filter HousingsDocument4 pages3M DC Series Cartridge Filter HousingsRichard Franklin Pacheco QuiscaNo ratings yet

- 03c EIL MR 3002 dd1059Document146 pages03c EIL MR 3002 dd1059Kalai Selvan100% (1)

- Bartec Datasheet PDS001rev24 - BF PDFDocument26 pagesBartec Datasheet PDS001rev24 - BF PDFSaidi NadjimNo ratings yet

- TECHNICAL DATA FUSE LINK TYPE K (15 38 KV) WEBDocument1 pageTECHNICAL DATA FUSE LINK TYPE K (15 38 KV) WEBSantiago EspitiaNo ratings yet

- Chemical Engineering Equipment DesignDocument55 pagesChemical Engineering Equipment Designabdo magdy100% (1)

- Criterios Higienicos para El Diseño de Equipos PDFDocument13 pagesCriterios Higienicos para El Diseño de Equipos PDFLuisa MontoyaNo ratings yet

- Angle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesDocument14 pagesAngle Style, Pressure Relief Valves For Steam, Gas, and Liquid ServicesCHRISTIAN ZAVALANo ratings yet

- 6 - HiAce - Acidic WearDocument2 pages6 - HiAce - Acidic WearNguyên NguyễnNo ratings yet

- 2017 Scheerder AFA Catastrophic Failure and Near Misses in Urea Plants Due To CorrosionDocument15 pages2017 Scheerder AFA Catastrophic Failure and Near Misses in Urea Plants Due To CorrosionTalal MehfoozNo ratings yet

- Rocketdyne Chlroine Tryfluorine ManualDocument59 pagesRocketdyne Chlroine Tryfluorine ManualCider WaltNo ratings yet

- Nace Index PDFDocument8 pagesNace Index PDFluisantoniocoy100% (1)

- Borrelly Catalogue en BDDocument36 pagesBorrelly Catalogue en BDAL_B_RTONo ratings yet

- MSS SP-43 (1991) (Reaffirmed 2001)Document16 pagesMSS SP-43 (1991) (Reaffirmed 2001)Allan SousaNo ratings yet

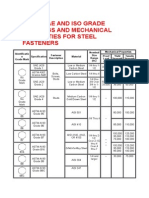

- Bolt Grade Markings and Strength Chart: Head Marking Grade and Material Nominal Size Range Mechanical PropertiesDocument2 pagesBolt Grade Markings and Strength Chart: Head Marking Grade and Material Nominal Size Range Mechanical PropertiesDeepakGawasNo ratings yet

- Catalogo Ilustrativo Filtros Bolsa EatonDocument12 pagesCatalogo Ilustrativo Filtros Bolsa EatonLuz Angela Diaz GuevaraNo ratings yet

- Feroxyle Test Procedur eDocument9 pagesFeroxyle Test Procedur esanrexiNo ratings yet

- Anodic Passivation Electroless Nickel Plating TanksDocument12 pagesAnodic Passivation Electroless Nickel Plating Tanks薇薇No ratings yet

- Datasheet For Steel Grades Specialsteel 06Cr25Ni20Document3 pagesDatasheet For Steel Grades Specialsteel 06Cr25Ni20nagmech07No ratings yet

- WOM Magnum Gate Valve BrochureDocument8 pagesWOM Magnum Gate Valve BrochuresjongejongeNo ratings yet

- Valve Materials - Kitz CorporationDocument2 pagesValve Materials - Kitz Corporationibnuhary100% (1)

- Steel, Stainless: Supply Setwice, General Sewices Administration, AgenciesDocument9 pagesSteel, Stainless: Supply Setwice, General Sewices Administration, Agencies杜文欽No ratings yet

- Bolts GradesDocument9 pagesBolts GradesMachineryengNo ratings yet