Professional Documents

Culture Documents

Fence Line Feed Bunk

Uploaded by

Afan Syafi'i0 ratings0% found this document useful (0 votes)

187 views4 pagesFence Line Feed Bunk

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFence Line Feed Bunk

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

187 views4 pagesFence Line Feed Bunk

Uploaded by

Afan Syafi'iFence Line Feed Bunk

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Beef Cattle Handbook

Product of Extension Beef Cattle Resource Committee

BCH-9701

Fence Line Feedbunk Design

T. Wendling, Extension Agricultural Engineering, Kansas State University - Manhattan, KS

The fence line feedbunk is the typical feeder of cattle

feedlots in the Great Plains Region. This type of feeder

works well with the mechanical feed wagon delivery system. Experience has shown the shape, size, construction,

location and orientation of these feedbunks can affect

feed losses, ease of feed distribution and feedbunk

cleaning, feeding system maintenance, feedlot rodent

control and feedlot fly control. All of these factors can

have an eco- nomic impact on a feedlot operation. This

fact sheet pres- ents fence line feedbunk design and construction information as it relates to the open feedlot

application of this type feeder.

Location and Orientation

A key consideration in feedbunk location is drainage. Place

feedbUnks so feedlot or adjacent area runoff water drains

away from feeder. Grade and shape the area if necessary

to secure good drainage. A 2% slope away from the feedbunk on both the lot and road side of the feedbunk is minimum. Slopes of up to 8% are commonly used. Slopes over

8% may create erosion and maintenance problems. (See

Figure 1.) When feeding is from only one side of the feeding road, placing feeders along the high side of the pens

will usually minimize earth shaping work to secure

drainage. When it is desirable to feed along both sides of a

feeding road, running the fence line feeders perpendicular

to the land contour (up or down the slope) usually minimizes earth shaping requirements. The maximum desirable

grade on feeding roads running with the slope of the land

is around 8%. Lot cross slope drainage, roadway maintenance due to erosion, and occasionally mud or ice can be a

problem on steeper slopes.

Orientation or lengthwise direction of a feeding

bunk is another item to consider when locating bunks.

Drifting snow, frozen manure pack build-up, wind blown

feed losses, and rate of drying after a wet period are

some of the factors affected by feedbunk orientation.

The importance of these factors varies some with your

location in the Great Plains region. In colder areas of the

region where drifting snow and frozen manure pack

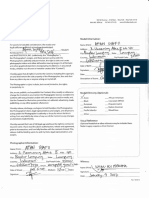

Figure 1. Feedbunk Grade and Drainage Section

BCH-9701

Figure 2. Typical Fenceline Feedbunk Sections.

build-up is a greater prob- lem, feedlot sites with south

or southeasterly slopes are generally preferred. With the

possible exception of wind blown feed losses, orienting

bunks with a N-S or near N-S length-wise direction is

preferred. Snow drifting from pre- vailing northerly

winds is minimized and sun shining on the feeding

floors at least 1/2 of each day aids in drying the area and

minimizes frozen manure pack problems. E-W bunk orientation are best adapted to southern areas of the

region or sites with natural or tree-belt windbreak protec- tion to the north.

Space and Capacity

Feeding space and bunk capacity is a function of animal

size, feed ration, and feeding time interval. Feed- bunk

space requirements for feeding programs where all animals need to eat at once such as limited grain feeding on

a once a day schedule are:

18 to 24 calves up to 600#

24 to 26 calves 600# to market

26 to 30 mature cows and bulls

For these feeding systems, a bunk capacity of 1-1/2

to 2-1/2 cu. ft. per foot of bunk length is needed. A

recent survey of over 60 Texas feedlots sponsored by the

Texas Cattle Feeders Association report over 90% of the

feeders feed two or more times per day. Bunk space

requirements of 600 pound to market weight cattle on

finishing rations fed twice daily or more ranges from 9

to 12 inches of bunk length per head. A bunk capacity of

1 to 1-1/2 cu. ft. per foot of bunk length is adequate for

this kind of the feeding program.

include:

Durability and maintenance

Ease of filling _ Ease of cleaning

Feed loss characteristics

Concrete is the building materials most commonly

used in feedbunk construction. Other suitable materials

include wood and metal or some combination of these

materials. Concrete used for feeding bunks should be a

high quality concrete to resist the corrosive effect of

salts and minerals in the feeds. A mix of 7 sacks of air

entrained cement per cu. yd. of cement with not over 5

gallons total water per sack of cement is recommended.

Sealing the concrete with a water seal, boiled linseed oil treatment, or epoxy resin paint prior to use will

in- crease the life of the concrete and reduce erosion of

the bunk floor. Lumber used for outside feeding bunk

con- struction should be pressure, preservative treated.

Rec- ommended treatments include creosote, 10 pcf

(pounds per cubic foot); penta, 0.50 pcf; ACA or CCA

(Type A or B) salts 0.40 pcf. A short weathering period or

wash down of freshly preserved timber may be desirable prior to use.

Typical Feeding Bunk Cross-Section Dimensions: (Figure 2)

Throat Height:

18 to 22

Feedbunk Bottom Width:

16 to 18

Bunk Floor Height Above Slab:

4 to 12

Neck Rail Height Clearance:

16 to 20

Adjustable Feed Road Bunk Wall Height Above Feed Road 30

Width of Feed Delivery Top Opening

30

Feedbunk Design

Factors to consider in feedbunk design and selection

2

Beef Cattle Handbook

Figure 3. Typical Feeding Floor Sections

A feedbunk drain for rainwater discharge is needed

for each lot or 100 to 150 lineal feet of fence line bunk.

Drains should be at least 1-1/2 inches in diameter to

minimize plugging problems. Discharging the bunk

drains on to the feedbunk apron is the preferred discharge location. Bunk cleaning is easier when the feeding fence posts are in or on the lot side of the bunk not

in the feedbunk floor. (Figure 2). Rounding sharp corners

within the feeding bunk bottom will make cleaning easier and reduce the problem of feed lodging in these

areas and becoming stale or sour. Increasing the slope

of the feed- bunk apron to 8% or inserting a step along

the bunk (Figure 3) reduces in bunk manure problems.

When one considers the fact 64% of the feeders surveyed in the Texas study clean their feed bunks at least

weekly and 81% report at least partial manual labor

cleaning the value of easy to clean bunks and designs

which reduce the need for cleaning becomes obvious.

Rodent, fly and odor problems associated with feedlot operations are often magnified by poor feedbunk

base design or construction. If possible, eliminate open

areas under the bunks where manure, spilled feed and

similar trash can collect. Make sure the concrete at the

edge of a concrete feeding apron or feedbunk foundaBCH-9701

tion are at least 12 deep. This will keep rodents from

burrowing under the slabs and establishing a safe

haven next door to a plentiful supply of feed and water.

The feedbunk base construction designs (Figure 2) minimizes bunk rodent and fly problems. They will also aid

in odor control and reduce the clean-up and maintenance labor requirements. The neck rail on the feedbunk

fence provides easy access to feed and keeps cattle out

of the bunk and in the pen. To accommodate varying

sizes of cattle neck rails with a 16 to 20 adjustable

opening between the bunk throat height and the neck

rail will accommodate cattle from around 500# to market weight. To reduce pressures on the neck rail from

cattle leaning against it as they reach for feed in the

bunks neck rails are often supported by small brackets

attached to the posts which set the rail 3 to 4 in from

the fence line over the feeding bunk. To complete the

feedbunk fence, one or two rails are placed above the

neck rail with the top rail located ap- proximately 5 ft.

above the feeding apron level. Support posts for the

feedbunk fence are spaced approximately 8 on center.

Two inch pipe posts 8 ft. long or pressure treated wood

posts 4 minimum top diameter are recommended.

Feeding Floor Design

Feeding floors or feedbunk aprons are essential to fenceline feedbunk feeding systems. Concrete is the most satisfactory feeding floor material. When properly placed, a

concrete feeding floor should provide the owner at least

20 years of dependable service with very little maintenance.To get this kind of a feeding floor, the builder

must:

1) Prepare the site properly for concrete placement.

2) Use quality concrete, reinforced as specified.

3) Place, finish and cure the concrete properly.

Site preparation for feeding floors involves.

Cleaning or clearing the surface of any organic or unstable mate- rials. Shaping the surface to the desired grade

and thoroughly compacting fill areas. Fills of over 12

depth should be compacted in layers. Feeding floors

over poorly drained or heavy clay soils should have a 4

to 6 sand or gravel bed. A recommended concrete mix

for feeding floors is use at least 6 sacks of cement per

cu. yd. of concrete and not over 6 gal. total water per

sack of cement. Use air en- trained cement. When ordering ready mix, specify a 6 sack mix with a maximum

slump of 2 in lieu of the 6 gallons of water limitation.

When mixed on-the-job, (1) be sure all ingredients go

through the mixer, avoid adding field stones and old

scrap iron; (2) use only clean aggre- gate; (3) the water

used should be clean enough to drink; (4) aggregate size

should not exceed 1/4 the floor thickness.

To prepare for concrete placement prior to concrete

delivery: (1) Place and level the 4 to 6 sand or gravel

slab base. (2) Set brace and stake forms to the design

finish grade. (3) Place and tie or support reinforcing

steel at the specified location in the slab and footings.

(4) Sprinkle or moisten the sand or gravel base material

until thoroughly compacted.

When the concrete arrives: (1) Spread, level and

vibrate or spade the concrete into the forms to insure

complete filling, (2) Strike or level the concrete surface

off at the proper grade. (3) Finish the surface to the

desired texture. (4) Be prepared to protect and cure the

finished concrete for at least 6 days after placement.

The texture preferred for feeding floors is a rough nonskid surface. A wood float or broom will usually provide

the finish wanted. If concrete is placed during freezing

weather, take special care to protect it from freezing for

at least 24 hours. During Hot weather take special

care to keep the surface moist for at least 24 hours after

placement. Typical feeding floor sections are illustrated

in Fig- ure 3. Section (1 and 2) fit locations where lot

drainage is away from the feeding bunk. Section 3 illustrates a double slope feeding floor design. This is a

good option for feed lot sites with little natural drainage

or lots where natural lot drainage may be toward the

feedbunk. One advantage of this design is it eliminates

the deep mud area that com- monly develops at the

end of a feeding floor. The step along the bunk (section

2) is optional for any feeding floor. Its purpose is to

reduce animal defecation into the bunks. The step is

most effective for feeding floors with slopes of less

than 1/2 per foot.

Feeding Roads

A stabilized all-weather road capable of supporting feeding trucks is needed to service the fenceline feedbunk.

Commonly used feed road surfacing materials include

crushed rock, gravel and sand. The local county engineer

or road department is a good resource to consult to

locate the best local road surfacing materials. Road

materials vary widely over the region. The feed road surface should be at least 14 ft. wide and shaped to drain

with a minimum slope of 2% away from the feedbunk. A

6 to 8 inch thick rock or gravel base with a 1 to 2 surface covering of finer material such as chat or sand is

generally adequate for road surfacing on well drained

soils. A 12 thick base may be needed on poorly drained

soils to get the needed stability. A road shaping program

that maintains good road surface drainage at all times

will minimize road repair and reconstruction costs.

Author:

By Leo. T. Wendling, Extension Agricultural Engineering, Kansas State University - Manhattan, KS

This publication was prepared in cooperation with the Extension Beef Cattle Resource Committee and its member states and produced in

an electronic format by the University of Wisconsin-Extension, Cooperative Extension. Issued in furtherance of Cooperative Extension

work, ACTS of May 8 and June 30, 1914.

BCH-9701 Fence Line Feedbunk Design

4

Beef Cattle Handbook

You might also like

- Top 10 Masturbation Tips From WomenDocument3 pagesTop 10 Masturbation Tips From WomengmeadesNo ratings yet

- UV-5R MenusDocument4 pagesUV-5R MenusRikardoviskiNo ratings yet

- WP - High Efficiency Axial Flux Machines - Whitepaper v1.5Document21 pagesWP - High Efficiency Axial Flux Machines - Whitepaper v1.5unknown234uNo ratings yet

- Creating A Water Garden Retreat (Brochure)Document32 pagesCreating A Water Garden Retreat (Brochure)manda_manuNo ratings yet

- Wicking Bed Gardening For Drought GardeningDocument5 pagesWicking Bed Gardening For Drought GardeningU8x58No ratings yet

- Building A Model Steam Engine From Scratch Chapter 1, 150 121Document19 pagesBuilding A Model Steam Engine From Scratch Chapter 1, 150 121Liam Clink100% (2)

- River Protection Design GuideDocument13 pagesRiver Protection Design GuideEm MarNo ratings yet

- Pond Construction:: Some Practical ConsiderationsDocument4 pagesPond Construction:: Some Practical ConsiderationsGeorge AtaherNo ratings yet

- Precast Catch BasinDocument4 pagesPrecast Catch BasinJanetCablaoNo ratings yet

- Beef Cattle Housing and Feedlot FacilitiesDocument23 pagesBeef Cattle Housing and Feedlot FacilitiesCabdalla Niyo100% (1)

- How To Build A Wicking Bed 13pagesDocument0 pagesHow To Build A Wicking Bed 13pagestherootsNo ratings yet

- The Success of Freshwater Fishpond Farming Depends On The Selection of Ideal Fishpond SiteDocument4 pagesThe Success of Freshwater Fishpond Farming Depends On The Selection of Ideal Fishpond SitecarmineNo ratings yet

- Porous Asphalt Association Guidance DocumentDocument10 pagesPorous Asphalt Association Guidance DocumentwillypraviantoNo ratings yet

- Rftmdc6a PDFDocument17 pagesRftmdc6a PDFShakeebNo ratings yet

- Hoshin Policy Deployment TemplatesDocument8 pagesHoshin Policy Deployment Templatesjcruz909No ratings yet

- Effect of Impurities On Freezing and Boiling PointsDocument6 pagesEffect of Impurities On Freezing and Boiling PointssakthivelNo ratings yet

- Grain, Forage and Feed StructuresDocument4 pagesGrain, Forage and Feed StructurespaaryNo ratings yet

- Orca Share Media1541759628568 PDFDocument12 pagesOrca Share Media1541759628568 PDFJuneNeilBalacuitNo ratings yet

- MLA Feedlot ManualDocument87 pagesMLA Feedlot ManualFajar GrafNo ratings yet

- 3D1 Feedlot LayoutsDocument7 pages3D1 Feedlot LayoutsSofik SampurnoNo ratings yet

- Concrete On The Farm - tcm45-341269Document5 pagesConcrete On The Farm - tcm45-341269shivas34regalNo ratings yet

- NatnaelDocument4 pagesNatnaelAzahir AbharishNo ratings yet

- Wastewater Pond Design and ConstructionDocument4 pagesWastewater Pond Design and ConstructionBrian RussoNo ratings yet

- Check Dams SE-4: Description and PurposeDocument5 pagesCheck Dams SE-4: Description and PurposeAziz Khan KakarNo ratings yet

- Water and Sediment ControlDocument5 pagesWater and Sediment ControlAmalina YaniNo ratings yet

- Breather PipeDocument13 pagesBreather PipeMarie PeneyraNo ratings yet

- Check DamDocument7 pagesCheck Damahtan99No ratings yet

- River Banks Design PDFDocument15 pagesRiver Banks Design PDFpk100% (1)

- A Low Cost Floating Upweller Shellfish Nursery SystemDocument6 pagesA Low Cost Floating Upweller Shellfish Nursery SystemUsman MadubunNo ratings yet

- Production of Fish ZasDocument10 pagesProduction of Fish ZasMichelle KanokangaNo ratings yet

- Boardwalk DesignDocument9 pagesBoardwalk DesignOwen Francis Arles MaongatNo ratings yet

- Types of Subsurface Drainage SystemsDocument12 pagesTypes of Subsurface Drainage SystemsRajesh Khadka100% (1)

- Grassed W TR WayDocument3 pagesGrassed W TR WayjonkreakNo ratings yet

- Check DamDocument13 pagesCheck DamAE TRS SEC 2No ratings yet

- Pond Construction and Management Fish Pond Design and ConstructionDocument9 pagesPond Construction and Management Fish Pond Design and Constructionpatelrt8No ratings yet

- C. System Installation.: D. BackfillingDocument1 pageC. System Installation.: D. BackfillingObaidUrRehmanNo ratings yet

- Sediment Control: Silt FencesDocument7 pagesSediment Control: Silt FencesShah ImaNo ratings yet

- Water Pan For Runoff Water Harvesting PDFDocument4 pagesWater Pan For Runoff Water Harvesting PDFmulwa2009No ratings yet

- Sediment Traps Sediment Traps: Design Criteria Design CriteriaDocument10 pagesSediment Traps Sediment Traps: Design Criteria Design CriterialokescNo ratings yet

- Culvculvculvculvculv Ererererer T Uset Uset Uset Uset Use, Installa, Installa, Installa, Installa, InstallaDocument16 pagesCulvculvculvculvculv Ererererer T Uset Uset Uset Uset Use, Installa, Installa, Installa, Installa, Installaralfaro2288No ratings yet

- Rock-Plant Filter Design and Construction For Home Wastewater SystemsDocument14 pagesRock-Plant Filter Design and Construction For Home Wastewater Systemsvikdev100% (1)

- Erosion Control BMPs Silt FencingDocument5 pagesErosion Control BMPs Silt FencingCORALationsNo ratings yet

- Tilapia Farming Guide 2Document12 pagesTilapia Farming Guide 2Shiela SalvosaNo ratings yet

- Recommended Zero Grazing Housing PlanDocument3 pagesRecommended Zero Grazing Housing PlanAsman Osiche AmaundaNo ratings yet

- Guidelines For Culverts FactDocument4 pagesGuidelines For Culverts FactrajeevNo ratings yet

- Typical Engineering Features For Feedlot Design - PpsDocument18 pagesTypical Engineering Features For Feedlot Design - PpsIvan DiazNo ratings yet

- Poultry Layer Production Facility Manure Management: Undercage Flush - Lagoon ManagementDocument8 pagesPoultry Layer Production Facility Manure Management: Undercage Flush - Lagoon ManagementLineth DomingoNo ratings yet

- Wayne Winchell', Norm Bird: Site SelectionDocument7 pagesWayne Winchell', Norm Bird: Site SelectionCarlos MukasaNo ratings yet

- Ubsurface Rain: Eneral DvantagesDocument2 pagesUbsurface Rain: Eneral DvantagesGorak NathNo ratings yet

- The Most Basic Need For Each and Every Living Being On EarthDocument20 pagesThe Most Basic Need For Each and Every Living Being On EarthKaushik GhoshNo ratings yet

- Aquaponic System ComponentsDocument4 pagesAquaponic System ComponentsTravis BobrowskiNo ratings yet

- Guidelines For Planning Cattle Feedlots MF3392Document2 pagesGuidelines For Planning Cattle Feedlots MF3392DendenGalitNo ratings yet

- Drip Irrigation Guide For Onion Growers in The Treasure ValleyDocument8 pagesDrip Irrigation Guide For Onion Growers in The Treasure ValleyNelson PucheNo ratings yet

- Technical Commentary Standard Plan B-10.20: For Catch Basin Type 2Document3 pagesTechnical Commentary Standard Plan B-10.20: For Catch Basin Type 2Sabina ShresthaNo ratings yet

- EC07-777 Planning A New Cattle FeedlotDocument18 pagesEC07-777 Planning A New Cattle FeedlotDendenGalitNo ratings yet

- Dewatering Revised Oct 98Document11 pagesDewatering Revised Oct 98Mahmoud BreamaNo ratings yet

- Wash Plant GuideDocument2 pagesWash Plant GuideAnfield GeNk ToMiNo ratings yet

- Improving The Productivity of Landscapes With Little or No TopsoilDocument4 pagesImproving The Productivity of Landscapes With Little or No TopsoilbaakicaaNo ratings yet

- Forestry Note, How To Install A Forest Road CulvertDocument4 pagesForestry Note, How To Install A Forest Road CulvertTony GallacherNo ratings yet

- 2016 Guideline WashPlantDocument2 pages2016 Guideline WashPlantHerliani HerlianiNo ratings yet

- Back FillingDocument2 pagesBack FillingpuldamaNo ratings yet

- Ea CattleDocument5 pagesEa Cattleanthonius70No ratings yet

- Managing Soils in Pecan OrchardsDocument4 pagesManaging Soils in Pecan OrchardszzzxxccvvvNo ratings yet

- Well DesignDocument17 pagesWell DesignabdulazizNo ratings yet

- Cattle Dehorning - Questions and AnswersDocument5 pagesCattle Dehorning - Questions and AnswersAfan Syafi'iNo ratings yet

- Model Release On Stock PhotographyDocument1 pageModel Release On Stock PhotographyAfan Syafi'iNo ratings yet

- Effect of Weaning Date (Normal vs. Late) On Performance of Young and Mature Beef Cows and Their Progeny in A Fall Calving System in The Southern Great PlainsDocument11 pagesEffect of Weaning Date (Normal vs. Late) On Performance of Young and Mature Beef Cows and Their Progeny in A Fall Calving System in The Southern Great PlainsAfan Syafi'iNo ratings yet

- Calving System and Weaning Age Effects On Cow and Preweaning Calf Performance in The Northern Great PlainsDocument13 pagesCalving System and Weaning Age Effects On Cow and Preweaning Calf Performance in The Northern Great PlainsAfan Syafi'iNo ratings yet

- Feeding and Management of The Dairy Calf - Birth To 6monthsDocument8 pagesFeeding and Management of The Dairy Calf - Birth To 6monthsAfan Syafi'iNo ratings yet

- SDFC AdminDocument8 pagesSDFC AdminYashpal SinghNo ratings yet

- Urethane UB-7 Catalog 2013Document32 pagesUrethane UB-7 Catalog 2013yfontalvNo ratings yet

- KSB KWP: Non-Clogging Centrifugal PumpsDocument12 pagesKSB KWP: Non-Clogging Centrifugal PumpsalfredNo ratings yet

- 10 Famous Shipping Canals of The WorldDocument7 pages10 Famous Shipping Canals of The Worldparth_upadhyay_1No ratings yet

- Vray Material Settings: COMP 423: Cadd For ArchitectureDocument18 pagesVray Material Settings: COMP 423: Cadd For ArchitectureMarvin GonzalesNo ratings yet

- Maryland Institute of Technology and Management, Jamshedpur Theory of Machine-Module: IIIDocument12 pagesMaryland Institute of Technology and Management, Jamshedpur Theory of Machine-Module: IIISourabh PradhanNo ratings yet

- Date Code - Osram - 1994-PresentDocument2 pagesDate Code - Osram - 1994-PresentMuzeul LampilorNo ratings yet

- Chemical - Reactions - Balancing - Equations by JSS Feb 2019Document34 pagesChemical - Reactions - Balancing - Equations by JSS Feb 2019Maria Alyssa MagallonNo ratings yet

- P45-69Z V3.0 Schematic DiagramDocument10 pagesP45-69Z V3.0 Schematic DiagramAhmed El SharkawyNo ratings yet

- Craftsman 73754 ManualDocument24 pagesCraftsman 73754 Manualjkchromy945No ratings yet

- Instrument and Control Designer Rev01Document5 pagesInstrument and Control Designer Rev01masilamaniNo ratings yet

- Sec1 1 1Document2 pagesSec1 1 1rajfmc100% (1)

- What We Offer.: RemunerationDocument8 pagesWhat We Offer.: Remunerationsurabhi mandalNo ratings yet

- Projects Need To Upload Online. Use The Standard Format. Use Any EDA Tool For The SimulationDocument2 pagesProjects Need To Upload Online. Use The Standard Format. Use Any EDA Tool For The SimulationAjay DuranNo ratings yet

- Comparacion Planta Meg - TegpdfDocument18 pagesComparacion Planta Meg - TegpdfJulian RomeroNo ratings yet

- gp30mpc 150Document27 pagesgp30mpc 150locomotoras.slpNo ratings yet

- Owners Manual Dominar 250Document52 pagesOwners Manual Dominar 250RaghavNo ratings yet

- Modelsim TutorialDocument26 pagesModelsim Tutorialsachinshetty001No ratings yet

- 33003788K01000 PDFDocument472 pages33003788K01000 PDFAji SukumaNo ratings yet

- Actividad 1 Lorena GuerreroDocument4 pagesActividad 1 Lorena GuerreroAlfonso GutierrezNo ratings yet

- Centrifugal PumpsDocument6 pagesCentrifugal Pumpsjerome fajardoNo ratings yet

- Altapail Ii: 20-Liter or 5-Gallon Pail MeltersDocument2 pagesAltapail Ii: 20-Liter or 5-Gallon Pail MeltersjorgeramosvasNo ratings yet