Professional Documents

Culture Documents

Softstarter Specifications

Uploaded by

JAY PARIKHCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Softstarter Specifications

Uploaded by

JAY PARIKHCopyright:

Available Formats

General Specifications for Soft Starter.

1.01

SOFT STARTER:

General:

This specification describes the requirements for a solid-state torque controlled

starter (Controller) used to provide linear ramp starting and stopping of three-phase

AC induction motors. The requirement is for a stand-alone unit that negates the

need for further equipment in terms of protection, viewing and controlling.

A.

Electrical ratings

a)

b)

c)

B.

The Controller shall provide as standard, the following starting modes:

a)

b)

c)

d)

e)

f)

g)

h)

i)

j)

k)

l)

m)

C.

200 525 +/- 10% 200-690 +5%/- 10% Volts AC mains

50-60 Hz +/- 10%

100-240/380-500 +/- 10% Volts control voltage

Linear Torque control for Start

Quadratic Torque control for Start

Pump Control

Current Limit Start

Voltage ramp Start

Voltage ramp with current limit Start

Full Voltage DOL Start

Remote analogue control

Soft Start with Selectable Torque Boost

Slow Speed time controlled

Slow Speed external controlled

Dual Ramp Start

Bypass control

The Controller shall provide as standard, the following stopping modes:

a)

b)

c)

d)

e)

f)

g)

h)

i)

j)

k)

Linear Torque control for Stop

Quadratic Torque control for Stop

Pump Control

Voltage ramp Stop

DOL/Coast to stop

Remote analogue control Stop

Dynamic DC-Brake and Soft brake (reverse brake)

Slow Speed time controlled

Slow Speed external controlled

DC-Brake at slow speed

Dual Ramp Stop

{PAGE }

Tangent Technologies

105, Ambica Complex, Near Alembic Nagar, Gorwa Refinary Road, Vadodara - 390016, Phone: 91-265-2291264, Fax: 91-265-2291568,

Email: anurag.gupta@tangent.in, Website: www.emotron.com

l) Accurate positional stop control

m) Bypass control

D.

The Controller shall provide as standard, the following Additional features

a)

b)

c)

d)

Jogging forward and reverse

4 parameter sets

Analog output

Built in Display

E.

The Controller shall provide as standard, the following Operation features

a) Keyboard

b) Remote

F.

The Controller shall provide as standard, the following Protection

features:

a)

b)

c)

d)

e)

f)

g)

h)

i)

j)

k)

l)

m)

G.

Motor Thermal Overload

Soft Start thermal overload

PTC input

Motor Shaft Torque (Max) machine process protection.

Motor Shaft Torque (Min) machine process protection.

Phase imbalance

Phase reversal

Over voltage

Under voltage

Locked Rotor

Excessive Starts per hour for application

Phase loss input / output

Motor output loss

The Controller shall provide as standard, the following Viewing functions:

a)

b)

c)

d)

e)

f)

g)

h)

i)

j)

Three Phase Current

Three Phase Voltage

Current in L1, L2, L3

Voltage between L1-L2, L1-L3, L2-L3

Shaft Power in kW / HP (selectable)

Motor thermal capacity

Motor Energy consumption (kWh)

Power factor

Run time in hours

Torque in Lbs./ft or Nm (selectable)

{PAGE }

Tangent Technologies

105, Ambica Complex, Near Alembic Nagar, Gorwa Refinary Road, Vadodara - 390016, Phone: 91-265-2291264, Fax: 91-265-2291568,

Email: anurag.gupta@tangent.in, Website: www.emotron.com

H.

The Controller shall provide as standard, the following Fault Indication

functions:

a)

n)

b)

c)

d)

e)

f)

g)

h)

i)

j)

k)

l)

m)

n)

o)

1.02

Line failure

Phase imbalance

Over temperature motor

Over temperature Soft Starter

Shorted Thyristor

Open Thyristior

Locked Rotor

Motor output loss

Overload - Shaft Torque

Underload Shaft Torque

Phase imbalance

Over voltage

Under voltage

Excessive Starts

Phase reversal

Event List of 15 latest fault indications/occurrence

CONSTRUCTION:

a) The Controller shall be of modular construction, consisting of a Power Control

Board (PCB) and Power Structure.

b) The PCB shall be compatible the full range of power structures.

c) In the sizes from 17-1400 Amps all phases should be controlled during

start/stop.

d) The power structure shall consist of six SCRs mounted on a heatsink for ratings

up to and including 1400 Amps.

e) The Controller shall be DIN Rail mountable up to 250 A.

f) DIN Rail mountable units should be mountable without space at side.

1.03

CODES AND STANDARDS:

The controller shall be designed to meet the applicable requirements of:

a)

b)

c)

d)

1.04

EN 60204-1, EN 50081-1 (-2 from 170 A) EN 50082-2

IEC 947-4-2

UL 508

cUL

CONTROL MODULE DESIGN FEATURES:

A.

MECHANICAL:

{PAGE }

Tangent Technologies

105, Ambica Complex, Near Alembic Nagar, Gorwa Refinary Road, Vadodara - 390016, Phone: 91-265-2291264, Fax: 91-265-2291568,

Email: anurag.gupta@tangent.in, Website: www.emotron.com

B.

a)

The PCB module shall consist of a power supply, logic control

circuitry, silicon controlled rectifier (SCR) firing circuitry. I/O circuitry, a

digital programming keypad, dual LED Displays and a serial

communication port.

b)

The PCB shall be designed for integral mounting on the power

structure and shall be compatible with the full range of current ratings17 Amps to 1400 Amps.

c)

The PCB shall be easily removed from the power structure, without

the need to disassemble associated printed circuit board assembles.

d)

Control terminals shall be easily accessible and located on the front

bottom of the device. The terminals shall be UL rated for 300 Volts,

15 Amps maximum and accept a maximum of two wires, 0,2-4mm2

(#30-#12 AWG).

e)

Digital parameter adjustment shall be provided through a built-in

keypad. Analog potentiometer adjustments are not acceptable.

f)

Dual built-in alphanumeric, LED displays shall be provided for

controller set-up, diagnostics, status and monitoring. The Control

Keypad and Display shall have the option for remote mounting.

g)

For safety reasons the controller should have 2 green lights for

running and start/stop.

ELECTRICAL:

a)

The PCB shall provide digital microprocessor control and supervision

of all controller operation, including SCR pulse firing control.

b)

The PCB power supply shall be self-tuning to accept control power

input from 100 to 240 or 380 to 500 VAC, 50/60 Hz.

c)

The SCR firing circuitry shall incorporate an RC snubber network to

prevent false SCR firing.

d)

The logic circuitry shall incorporate a latch circuit for three-wire

control.

e)

Reverse operation of the motor shall be standard in the jog mode

without the use of a reversing contactor.

{PAGE }

Tangent Technologies

105, Ambica Complex, Near Alembic Nagar, Gorwa Refinary Road, Vadodara - 390016, Phone: 91-265-2291264, Fax: 91-265-2291568,

Email: anurag.gupta@tangent.in, Website: www.emotron.com

C.

D.

USER ADJUSTMENTS:

a)

The two acceleration start ramp timers shall have individual

adjustments from 1 to 60 seconds.

b)

The two acceleration stop ramp timers shall have individual

adjustments from 2 to 120 seconds.

c)

The initial torque setting shall be adjustable from 0 to 250% of motor

torque.

d)

The end torque setting shall be adjustable from 50 to 250% of motor

torque.

e)

Current limit starting shall be adjustable from 150% to 500% of the

motors full load current.

f)

Slow speed shall be adjustable up to 60 seconds or up to 100 external

pulses.

PROTECTION AND DIAGNOSTICS:

a)

Overload protection shall be as follows:

1)

2)

3)

4)

5)

b)

E.

Meets applicable standards as a motor thermal protection

device.

Shaft Power measurement without the use of external electromechanical sensors.

Electronic thermal memory shall be provided for enhanced

motor protection.

Shaft Overload and Underload protection shall be available

through the controller, even in a bypass configuration.

Protections should be available if bypass is made.

When fault conditions are detected, the controller shall inhibit starting

or shut down SCR pulse firing.

PUMP CONTROL (standard feature):

a)

The standard feature pump control shall be implemented to provide

closed loop control of a motor to match the specific torque

requirements of centrifugal pumps for both starting and stopping. This

shall aid in eliminating the phenomena commonly referred to as water

hammer. Methods utilizing Soft Start with Soft Stop shall not be

{PAGE }

Tangent Technologies

105, Ambica Complex, Near Alembic Nagar, Gorwa Refinary Road, Vadodara - 390016, Phone: 91-265-2291264, Fax: 91-265-2291568,

Email: anurag.gupta@tangent.in, Website: www.emotron.com

acceptable. The soft start and soft stop programming should be

independent of each other.

F.

b)

Pump stop shall be initiated without the need for a dedicated Pump

Stop input. A coast-to-rest stop shall still be possible with a stop input.

c)

The Pump Stop times shall be user adjustable from 0 to 120 seconds.

POWER STRUCTURE DESIGN FEATURES:

Electrical:

a)

Back-to-back SCR pairs shall be the only power-switching

semiconductor means acceptable. Diode0SCR combinations shall not

be acceptable.

b)

There shall be separate power sections to operate from 200V to 525 V

and 200V to 690V, 50/60 Hz.

c)

Semi conductor fuses should not be required for warranty in sizes171400 Amps.

d)

Softstarter should be built for continuous operation without need of by

pass for any reason.

e)

SCRs shall have the following minimum repetitive peak inverse

voltage ratings:

1.

2.

200 to 525V: 1600 V

200 to 690V: 1800V

Transient Protection: 17 Amps to 1400 Amps

G.

a)

For controllers rated 17 Amps to 1400 Amps, transient protection with

snubber circuit including RC-net shall be standard.

b)

Capacitors against electrical noise should be integrated as standard.

ENERGY SAVER:

a)

The Energy Saver feature shall operate to automatically cause the

output voltage from the controller to be reduced when a motor is

unloaded or lightly loaded.

b)

Customer adjustments shall not be required.

{PAGE }

Tangent Technologies

105, Ambica Complex, Near Alembic Nagar, Gorwa Refinary Road, Vadodara - 390016, Phone: 91-265-2291264, Fax: 91-265-2291568,

Email: anurag.gupta@tangent.in, Website: www.emotron.com

H.

c)

The Energy Saver feature shall be defeatable.

d)

Additional mounting space or wiring shall not be required.

ENVIRONMENTAL RATINGS:

a)

Temperature Ratings

1)

2)

3)

b)

Humidity Range

1)

c)

The Controller shall deliver its rated current in ambient

temperature ranging from 0.C to +50C.

The controller should be able to operate up to 50 C.

The ambient storage temperature shall range from 25C to

+70C.

The controller shall be operable in relative humidity of 5 to 95%,

non-condensing.

Altitude Rating

1)

The controller shall be suitable for operation up to altitudes of

1,000 meters without derating.

{PAGE }

Tangent Technologies

105, Ambica Complex, Near Alembic Nagar, Gorwa Refinary Road, Vadodara - 390016, Phone: 91-265-2291264, Fax: 91-265-2291568,

Email: anurag.gupta@tangent.in, Website: www.emotron.com

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Company Logo: Cable Size CalculationDocument7 pagesCompany Logo: Cable Size Calculationahmadgce04No ratings yet

- AC For Mechanical EngineeringDocument77 pagesAC For Mechanical EngineeringHasen Yunne ShemsiNo ratings yet

- Procedure For Calculation of Efficiency-1Document7 pagesProcedure For Calculation of Efficiency-1JAY PARIKHNo ratings yet

- Boiler Water TreatmentDocument7 pagesBoiler Water TreatmentJAY PARIKH100% (1)

- MX3EG1A Automatic Synchronizer Technical ManualDocument38 pagesMX3EG1A Automatic Synchronizer Technical Manualsgshekar30No ratings yet

- SC CalculationsDocument112 pagesSC CalculationsJAY PARIKHNo ratings yet

- GRE Word ThesaurusDocument137 pagesGRE Word ThesaurusPhanidhar GubbalaNo ratings yet

- GRE Word ThesaurusDocument137 pagesGRE Word ThesaurusPhanidhar GubbalaNo ratings yet

- Irr - Pa & Id Fan - Boiler 1Document14 pagesIrr - Pa & Id Fan - Boiler 1Jay Rameshbhai ParikhNo ratings yet

- CableDocument2 pagesCableJAY PARIKHNo ratings yet

- CT Testing at ERDA & HALOLDocument3 pagesCT Testing at ERDA & HALOLJAY PARIKHNo ratings yet

- CT Testing at ERDA & HALOLDocument3 pagesCT Testing at ERDA & HALOLJAY PARIKHNo ratings yet

- CableInstallation PDFDocument8 pagesCableInstallation PDFJAY PARIKHNo ratings yet

- CEA Battery ManagementDocument112 pagesCEA Battery ManagementJAY PARIKHNo ratings yet

- Keeping SafeDocument3 pagesKeeping SafeJay Rameshbhai ParikhNo ratings yet

- Hindalco Routine Test Report Page No. 4 & 5Document2 pagesHindalco Routine Test Report Page No. 4 & 5JAY PARIKHNo ratings yet

- 3AH1 Operating InstrDocument29 pages3AH1 Operating InstrJAY PARIKHNo ratings yet

- 011-23340000 / 23344787 / 23344773 / 23345500 / 23345800 or Mail To: Care@irctc - Co.inDocument1 page011-23340000 / 23344787 / 23344773 / 23345500 / 23345800 or Mail To: Care@irctc - Co.inJAY PARIKHNo ratings yet

- 3AH3 Circuit Breaker DetailsDocument28 pages3AH3 Circuit Breaker Details2003vinayNo ratings yet

- 3AH Catalog PDFDocument75 pages3AH Catalog PDFalsilva2014100% (1)

- Improve Primary Air Heater EfficiencyDocument4 pagesImprove Primary Air Heater EfficiencyJAY PARIKHNo ratings yet

- Best PracticesDocument28 pagesBest PracticesJAY PARIKHNo ratings yet

- SynchroniserDocument21 pagesSynchroniserJAY PARIKHNo ratings yet

- SynchroniserDocument21 pagesSynchroniserJAY PARIKHNo ratings yet

- Voltage Regulator DECS-100 ManuelDocument81 pagesVoltage Regulator DECS-100 Manuelctsak100% (1)

- Boiler DraftDocument22 pagesBoiler DraftJAY PARIKHNo ratings yet

- Air CompressorsDocument10 pagesAir CompressorsJAY PARIKHNo ratings yet

- WoodwardDocument4 pagesWoodwardKUNALJAYNo ratings yet

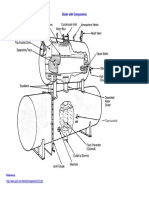

- 0507BoilerwithComponents PDFDocument1 page0507BoilerwithComponents PDFJAY PARIKHNo ratings yet

- Boiler TechnologiesDocument5 pagesBoiler TechnologiesSubhabrata SahaNo ratings yet

- Statement Showing Cost & Profitability of Power Generated - Cogeneration PlantDocument19 pagesStatement Showing Cost & Profitability of Power Generated - Cogeneration PlantJAY PARIKHNo ratings yet

- Unit 2 Notesm UuoiDocument72 pagesUnit 2 Notesm UuoiTeacher JAY-AR LAGMANNo ratings yet

- Aakash Medical Batch Test Schedule 2021-2022Document1 pageAakash Medical Batch Test Schedule 2021-2022akilan gurumurthyNo ratings yet

- Soft Hand Exoskeleton for Adaptive GraspingDocument17 pagesSoft Hand Exoskeleton for Adaptive GraspingJagannath Prasad SahooNo ratings yet

- DGT Surface ChemistryDocument34 pagesDGT Surface ChemistryDalu KinzelaNo ratings yet

- Triple Harmonics in Transformers: by G. FaccioliDocument9 pagesTriple Harmonics in Transformers: by G. FaccioliWaruna RasanjayaNo ratings yet

- Series of Frequency Inverter: Yantai Huifeng Electronics Co.,LtdDocument6 pagesSeries of Frequency Inverter: Yantai Huifeng Electronics Co.,LtdEzequiel Victor HugoNo ratings yet

- Rishabh Instruments Pvt. LTD.: Test CertificateDocument1 pageRishabh Instruments Pvt. LTD.: Test CertificateSufiyan KhedekarNo ratings yet

- Acetoacetic and malonic esters reactionsDocument10 pagesAcetoacetic and malonic esters reactionsМария МановаNo ratings yet

- Ficha Tecnica Cat 6a CableDocument3 pagesFicha Tecnica Cat 6a CableVictor Guevara GarciaNo ratings yet

- The Capacity of The Noisy Quantum ChannelDocument19 pagesThe Capacity of The Noisy Quantum ChannelElisabeth OrtegaNo ratings yet

- Becker 6019 Aux Input Retrofit ModDocument2 pagesBecker 6019 Aux Input Retrofit ModSh Medo MedoNo ratings yet

- EDC Unit-4Document23 pagesEDC Unit-4laxmanabcdNo ratings yet

- I MX200Document2 pagesI MX200Omar Fabra RiveraNo ratings yet

- Ignition System - Inspection Check PDFDocument4 pagesIgnition System - Inspection Check PDFMark Evan SalutinNo ratings yet

- Industrial Safety Syllabus Anna UnivDocument20 pagesIndustrial Safety Syllabus Anna UnivSourabh DuttaNo ratings yet

- Mineral Silikat: Mineralogi - 8Document21 pagesMineral Silikat: Mineralogi - 8RosellaNo ratings yet

- Grammatikou+Fardis - Flexural Rotation Capacity Models Fitted To Test Results Using DifferentDocument17 pagesGrammatikou+Fardis - Flexural Rotation Capacity Models Fitted To Test Results Using DifferentMelo PereiraNo ratings yet

- 1 s2.0 S0927024815001075 MainDocument8 pages1 s2.0 S0927024815001075 MainPEDRO REYNALDO MARTINEZ MANUELNo ratings yet

- Question-1050712 231107 193531Document15 pagesQuestion-1050712 231107 193531Anikjot SinghNo ratings yet

- QuicksandDocument3 pagesQuicksandalyssaNo ratings yet

- JEE Main 2020 Question Paper Solutions 9 January MorningDocument45 pagesJEE Main 2020 Question Paper Solutions 9 January MorningDishant ShahNo ratings yet

- Positive Displacement Meter SpecificationsDocument3 pagesPositive Displacement Meter SpecificationsYohanes AzzisNo ratings yet

- Rechargeable Sealed Lead-Acid Battery: 12 Volt 18.0 Amp. HrsDocument2 pagesRechargeable Sealed Lead-Acid Battery: 12 Volt 18.0 Amp. HrsJuan EsNo ratings yet

- Appnote 15Document6 pagesAppnote 15meteohrNo ratings yet

- Stal9781607500315 1088Document3 pagesStal9781607500315 1088Tariq SufianNo ratings yet

- MBHTE-ALMS SCIENCE 8 - Quarter3wk2Document14 pagesMBHTE-ALMS SCIENCE 8 - Quarter3wk2Aisha Manuban100% (1)

- Geometry: A Timeline of The Development On The Field of GeometryDocument25 pagesGeometry: A Timeline of The Development On The Field of GeometryARIANNE JASMINE ADRIANONo ratings yet

- Asset - 325848 Stahl 8008 PDFDocument11 pagesAsset - 325848 Stahl 8008 PDFErnesto DenisNo ratings yet

- NTTF Press Tool Standards Ebook GeneralDocument207 pagesNTTF Press Tool Standards Ebook GeneralRagunathan GNo ratings yet