Professional Documents

Culture Documents

Operation Power Trian Electrical Control System

Uploaded by

sayeed younis sadaatCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Operation Power Trian Electrical Control System

Uploaded by

sayeed younis sadaatCopyright:

Available Formats

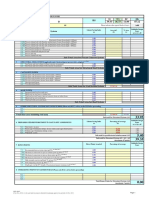

Service Information System

Page 1 of 21

Systems Operation

966G Series II Wheel Loader and 972G Series II Wheel Loader Power Train

Media Number -RENR4386-05

Publication Date -01/05/2003

Date Updated -19/05/2003

i01774797

Power Train Electronic Control System

SMCS - 4800; 7610-DTN

The main functions of the power train electronic control system follow: "Neutral Start Function",

"Manual Shift Function", "Automatic Shift Function", "Transmission Neutralizer Function", "Parking

Brake Function", "Backup Alarm Function", "Secondary Steering (If Equipped)", "Ride Control

Function (If Equipped)", "Speed Limiter (If Equipped)" and "Diagnostic Operation".

Neutral Start Function

View Image

Illustration 1

Start Relay

g00329538

The start relay is an output of the power train electronic control module (ECM). The start relay turns the

start solenoid on and off. The start solenoid controls the starting motor. When the operator turns the key

start switch to the START position and the power train ECM decides that all the starting conditions are

satisfied, the power train ECM energizes the start relay with a +battery signal. The power train ECM

will not allow the engine to be started unless the transmission direction and speed control lever (if

equipped) is in the NEUTRAL position. The power train ECM will not allow the engine to be started

unless the transmission direction control switch (if equipped) is in the NEUTRAL position. If the

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Page 2 of 21

transmission direction and speed control lever (if equipped) or the transmission direction control switch

(if equipped) is in the NEUTRAL position, the power train ECM activates the start relay. The start relay

allows the starting motor to turn. The power train ECM will not allow the starter to activate if the engine

is running.

The start relay has a connector with two contacts. One contact receives power from connector contact

J1-8 of the power train ECM. The other contact returns power to connector contact J2-3 of the power

train ECM.

Terminal 3 of the start relay connects to a +battery source. Terminal 4 connects to the start solenoid.

Reference: For more information on the key start switch, refer to the Service Manual module Systems

Operation, "Switches" for the machine that is being serviced.

Reference: For more information on the power train electronic control module (ECM), refer to the

Service Manual module Systems Operation, "Electronic Control Module (Power Train)" for the machine

that is being serviced.

Manual Shift Function

Table 1

Modulating Valve (Transmission Clutch)

Fourth Speed Forward

3 and 2

Third Speed Forward

4 and 2

Second Speed Forward

5 and 2

First Speed Forward

6 and 2

Neutral

First Speed Reverse

6 and 1

Second Speed Reverse

5 and 1

Third Speed Reverse

4 and 1

Fourth Speed Reverse

3 and 1

Conventional Steering

View Image

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Illustration 2

(1) Autoshift switch

Page 3 of 21

g00823325

(2) Manual position

View Image

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Illustration 3

(3) Transmission downshift switch.

Page 4 of 21

g00823334

View Image

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Illustration 4

(4) Transmission direction and speed control lever.

Page 5 of 21

g00823383

In order to manually shift the transmission, the autoshift switch (1) must be in the MANUAL position

(2). Shifting the transmission is the main function of the power train electronic control module (ECM).

The power train ECM interprets the changes in the switch position. After the power train ECM interprets

the changes in the switch position, the power train ECM shifts the transmission.

Transmission direction and speed control lever (4) is a sealed unit. The transmission direction and speed

control lever is mounted on the steering column. The transmission direction and speed control lever

allows the operator to select a speed range by rotating the control lever. The operator can select a

direction by moving the transmission direction and speed control lever forward or backward. The

transmission will remain in the selected direction until the transmission direction and speed control lever

is moved forward or backward. The transmission will remain in the selected speed until the transmission

direction and speed control lever is rotated to a different speed.

When transmission downshift switch (3) is depressed, the transmission downshift switch signals the

power train ECM to downshift the transmission by one speed. If second speed forward or second speed

reverse are selected, the transmission will shift to first speed by depressing transmission downshift

switch (3). The transmission will remain in first speed until transmission direction and speed control

lever (4) is shifted into the opposite direction or to the NEUTRAL position.

When the key start switch is turned from the OFF position to ON position, the power train ECM is

activated. When the power train ECM is first activated all of the clutch solenoid modulating valves are

de-energized. The clutch solenoid modulating valves are de-energized regardless of the position of

transmission direction and speed control lever (4). The power train ECM then determines if the

transmission direction and speed control lever is in the NEUTRAL position. The power train ECM

disables the transmission if the NEUTRAL position is NOT selected. If the NEUTRAL position is NOT

selected, the transmission direction and speed control lever must be returned to the NEUTRAL position

before a direction can be selected. The power train ECM activates the start relay and the power train

ECM allows the engine to start if the transmission direction and speed control lever is in the NEUTRAL

position. The power train ECM allows the initial selected speed to be changed if the transmission

direction and speed control lever is in the NEUTRAL position.

Note: Transmission direction and speed control lever (4) must be in the NEUTRAL position when the

key start switch is turned to the START position. If the transmission direction and speed control lever is

not in the NEUTRAL position, the start relay will not be activated when the key start switch is turned.

For additional information on the neutral start function, refer to "Neutral Start Function".

Reference: For more information on the switches for the transmission direction and speed control lever,

refer to the Service Manual module Systems Operation, "Switches" for the machine that is being

serviced.

Reference: For more information on the key start switch, refer to the Service Manual module Systems

Operation, "Switches" for the machine that is being serviced.

Reference: For more information on the power train electronic control module (ECM), refer to the

Service Manual module Systems Operation, "Electronic Control Module (Power Train)" for the machine

that is being serviced.

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Page 6 of 21

Command Control Steering

Table 2

Normal Shifting Sequence

Speed

Range and

Direction

REVERSE

Position

Transmission

Shift

NEUTRAL

Position

Transmission

Shift

FORWARD

Position

Transmission

Shift

UP SHIFT

Position

Transmission

Shift

DOWN

SHIFT

Position

Transmission

Shift

4F

4R

Neutral(1) (4N)

No Change

No Change

3F

3F

3R

Neutral(1) (3N)

No Change

4F

2F

2F

2R

Neutral(1) (2N)

No Change

3F

1F

1F

1R

Neutral(1) (1N)

No Change

2F

No Change

Last(2)

Next(3)

Prior(3)

Neutral(1)

(1N, 2N,

3N, 4N)

Last(2)

No Change

1R

No Change

Neutral(1) (1N)

1F

2R

No Change

2R

No Change

Neutral(1) (2N)

2F

3R

1R

3R

No Change

Neutral(1) (3N)

3F

4R

2R

4R

No Change

Neutral(1) (4N)

4F

No Change

3R

(1) The

speed and the direction that is shown in bold print is the gear readout.

(2) A

directional shift out of neutral will cause a speed shift to the last speed that was selected in either forward or reverse.

(3) Speed shifts are allowed when neutral is selected. The gear readout will change the speed that is shown when neutral is

selected and a speed shift is made. However, none of the solenoids are activated until forward or reverse is selected.

View Image

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Illustration 5

(5) Autoshift switch

Page 7 of 21

g00823503

(6) Manual position

View Image

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Illustration 6

(7) Transmission direction control switch

Page 8 of 21

g00823455

(8) Transmission speed selector switch

The autoshift switch (5) tells the power train ECM of the desired shift mode, AUTO mode or MANUAL

mode. In order to manually shift the transmission, the autoshift switch must be in the MANUAL (6)

position. Shifting the transmission is the main function of the power train electronic control module

(ECM). The power train ECM interprets the changes in the switch position. After the power train ECM

interprets the changes in the switch position, the power train ECM shifts the transmission.

The transmission direction control switch (7) and the transmission speed selector switch (8) are located

on the steering wheel. The transmission direction control switch is a three-position switch that selects

either forward, neutral, or reverse.

The operator selects a direction by moving transmission direction control switch (7) to one of three

positions. The transmission direction control switch tells the power train ECM of the desired direction of

travel.

The transmission speed selector switch (8) is a momentary rocker switch. The transmission speed

selector switch allows the operator to select the speed range of the transmission. Press the top of the

transmission speed selector switch in order to increase the speed of the transmission. The power train

ECM will upshift the transmission to the next higher gear. Press the bottom of the transmission speed

selector switch in order to decrease the speed of the transmission. The power train ECM will downshift

the transmission to the next lower gear. Transmission speed selector switch has four input connections at

the power train ECM on connector J1.

Note: The correct status of the four input connections is required. This will allow the power train ECM

to decide when the power train ECM should make each shift.

Note: The normally closed (N/C) circuit and normally open (N/O) circuit of the transmission downshift

switch are used for diagnostic purposes. The normally closed (N/C) circuit and normally open (N/O)

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Page 9 of 21

circuit of the transmission upshift switch are used for diagnostic purposes. If the normally closed (N/C)

circuit and normally open (N/O) circuit are open at the same time, the power train ECM records a fault.

If the normally closed (N/C) circuit and normally open (N/O) circuit are grounded at the same time, the

power train ECM records a fault.

When the key start switch is turned from the OFF position to ON position, the power train ECM is

activated. When the power train ECM is first activated all of the clutch solenoid modulating valves are

de-energized. The clutch solenoid modulating valves are de-energized regardless of the position of

transmission direction control switch (5). The power train ECM then determines if transmission

direction control switch (7) is in the NEUTRAL position. The power train ECM disables the

transmission if the NEUTRAL position is NOT selected. If the transmission direction control switch is

in the NEUTRAL position, the power train ECM selects the current speed and the current direction as

neutral. The power train ECM activates the start relay if the transmission direction control switch is in

the NEUTRAL position. When the start relay is activated, the engine is allowed to start.

Note: Transmission direction control switch (7) must be in the NEUTRAL position when the key is

turned to the START position. If the transmission direction control switch is not in the NEUTRAL

position, the start relay will not be activated. For additional information on the neutral start function,

refer to "Neutral Start Function".

Reference: For more information on the Caterpillar Monitoring System, refer to the Service Manual

module Systems Operation, "Monitoring System (Power Train Functions)" for the machine that is being

serviced.

Reference: For additional information on the transmission direction control switch and the transmission

speed selector switch, refer to the Service Manual module Systems Operation, "Switches" for the

machine that is being serviced.

Reference: For more information on the key start switch, refer to the Service Manual module Systems

Operation, "Switches" for the machine that is being serviced.

Reference: For more information on the power train electronic control module (ECM), refer to the

Service Manual module Systems Operation, "Electronic Control Module (Power Train)" for the machine

that is being serviced.

Automatic Shift Function

Conventional Steering

View Image

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Illustration 7

(1) Autoshift switch

Page 10 of 21

g00823628

(2) "2-4" position

(3) "1-4" position

View Image

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Illustration 8

(4) Downshift switch.

Page 11 of 21

g00823640

The transmission can be shifted automatically. There are two modes of automatic operation: (2) 1-4

position and (3) 2-4 position.

The automatic mode of operation is represented by two numbers that are separated by a dash. The first

number indicates the speed of the transmission when the transmission is placed into gear. The second

number indicates the highest speed of the transmission when the machine is travelling.

For example, place the autoshift control switch into the 2-4 position. The machine will automatically

shift into second gear when the transmission is placed into gear. The transmission will automatically

upshift into fourth gear as the machine accelerates.

Use the transmission downshift switch (4) that is located on the lift lever on the right side of the

operator's compartment in order to downshift the transmission. This switch is normally used to

downshift from second speed to first speed in order to load a bucket. The transmission will remain in the

downshifted gear for three seconds after the switch is released. Then, automatic shifting will resume. If

the transmission is downshifted to first speed, the machine remains there until there is a direction

change.

Note: If a downshift would cause an engine overspeed condition, the power train ECM will prevent the

downshift from occurring.

Note: The setting of the transmission direction and speed control lever will limit the top gear.

Command Control Steering

View Image

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Illustration 9

(5) Autoshift switch

Page 12 of 21

g00823631

(6) 2-4 position

(7) 2-3 position

(8) 2 position

(9) 1-4 position

View Image

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Illustration 10

(10) . (11) .

Page 13 of 21

g00823646

(10) Transmission direction control switch

(11) Transmission speed selector switch

The autoshift switch is used to select the top speed for the transmission when the transmission is in the

AUTO mode.

The transmission can be shifted automatically. There are four modes of automatic operation: (6) 2-4

position, (7) 2-3 position, (8) 2 position and (9) 1-4 position.

The automatic mode of operation is represented by two numbers that are separated by a dash. The first

number indicates the top speed of the transmission when the transmission is placed into gear. The

second number indicates the highest speed of the transmission when the machine is travelling.

For example, place the autoshift switch into the 2-3 position. The machine will automatically shift into

second gear when the transmission is placed into gear. The transmission will automatically upshift into

third speed when the machine accelerates.

When the machine is operating in "AUTO" mode, the transmission speed selector switch (11) can be

used in order to downshift the transmission. This switch is normally used to downshift from second

speed to first speed in order to load a bucket. The transmission will remain in the downshifted gear for

three seconds after the switch is released. Then, automatic shifting will resume. If the transmission is

downshifted to first speed, the machine remains there until there is a direction change or a manual

upshift.

Note: If a downshift would cause an engine overspeed condition, the power train ECM will prevent the

downshift from occurring.

Transmission Neutralizer Function

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Page 14 of 21

View Image

Illustration 11

(1) Left pedal position sensor.

g00823991

Left pedal position sensor (1) is located in the cab in the left brake pedal assembly. The left pedal

position sensor is a pulse width modulated (PWM) sensor. The left pedal position sensor informs the

power train ECM of the position of the left brake pedal. When the left brake pedal is depressed, the left

pedal position sensor sends a PWM signal to the power train ECM. The power train ECM uses the

PWM input in order to neutralize the transmission.

View Image

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Illustration 12

Transmission neutralizer override switch

Page 15 of 21

g00739087

The transmission neutralizer override switch is an input of the power train ECM. The input is used by

the power train ECM to decide if the transmission neutralizer should be disabled. The transmission

neutralizer override switch is a momentary rocker switch.

Left pedal position sensor (1) signals the power train ECM to neutralize the transmission if the

transmission neutralizer is enabled. When the machine is started, the transmission neutralizer is enabled.

When the transmission neutralizer override switch is depressed and released, the transmission

neutralizer is alternately enabled or disabled.

The transmission is neutralized by de-energizing the selected direction clutch solenoid. The selected

speed clutch solenoid is still energized. The engine rpm will increase when the transmission is

neutralized due to the no-load condition from the transmission. This allows full hydraulic power for

bucket operation.

Note: When the transmission is neutralized, the readout on the Caterpillar Monitoring System continues

to show the speed that is selected but the direction will read neutral.

Note: When the transmission neutralizer is disabled, the neutralizer disable indicator on the dash is

activated.

Reference: For more information on the left pedal position sensor, refer to the Service Manual module

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Page 16 of 21

Systems Operation, "Switches" for the machine that is being serviced.

Reference: For more information on the transmission neutralizer override switch, refer to the Service

Manual module Systems Operation, "Switches" for the machine that is being serviced.

Reference: For more information on the power train electronic control module (ECM), refer to the

Service Manual module Systems Operation, "Electronic Control Module (Power Train)" for the machine

that is being serviced.

Parking Brake Function

The parking brake function prevents the operator from operating the machine while the parking brake is

engaged. Driving through the parking brake causes accelerated wear to the friction components of the

parking brake.

When the parking brake control is disengaged, the transmission will shift normally. When the parking

brake control is engaged, the transmission will not shift out of neutral to first speed forward or first

speed reverse. If the transmission is in first speed forward or in first speed reverse and the parking brake

is moved to the engaged position, the transmission will shift into neutral. All of the modulating valves

(transmission clutch) are de-energized. If the transmission is in second speed forward or in third speed

forward, the transmission will remain engaged.

The parking brake function activates a warning category 1 or a warning category 3 on the Caterpillar

Monitoring System.

Warning category 1 is activated whenever the parking brake is engaged. The parking brake indicator

will flash.

While the parking brake is engaged and the machine is in gear, warning category 3 will be activated.

This will occur if the operator places the transmission direction control lever (if equipped) or the

transmission direction control switch (if equipped) in the FORWARD position or the REVERSE

position. The parking brake indicator will flash and the action light will flash. The action alarm will

sound.

When the parking brake is engaged and the transmission is in first speed, the power train ECM shifts the

transmission to neutral. The power train ECM also sends the parking brake status to the Caterpillar

Monitoring System via the CAT Data Link. When the parking brake is engaged, the alert indicator for

the parking brake flashes on the Caterpillar Monitoring System. If the operator selects the FORWARD

position or the REVERSE position and the parking brake is engaged, the Caterpillar Monitoring System

initiates a Warning Category 3. A Warning Category 3 causes the parking brake indicator and the action

lamp to flash. The action alarm will also sound.

Reference: For more information on the Caterpillar Monitoring System, refer to the Service Manual

module Systems Operation, "Monitoring Systems (Power Train Functions)" for the machine that is

being serviced.

Reference: For more information on the parking brake pressure switch, refer to the Service Manual

module Systems Operation, "Switches" for the machine that is being serviced.

Reference: For more information on the power train electronic control module (ECM), refer to the

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Page 17 of 21

Service Manual module Systems Operation, "Electronic Control Module (Power Train)" for the machine

that is being serviced.

Driving Through the Parking Brake

The power train ECM will allow the operator to drive through the parking brake. The machine should be

moved only for a short distance.

In order to drive through the parking brake, the operator must select first speed forward or first speed

reverse. The operator must then move the transmission direction control lever (if equipped) or the

transmission direction control switch (if equipped) to the NEUTRAL position. The operator must then

move the transmission direction control lever (if equipped) or the transmission direction control switch

(if equipped) to the previous direction that was selected.

Reference: For more information on the power train electronic control module (ECM), refer to the

Service Manual module Systems Operation, "Electronic Control Module (Power Train)" for the machine

that is being serviced.

Backup Alarm Function

The backup alarm function alerts surrounding personnel that the machine is backing up. The backup

alarm is an output of the power train electronic control module (ECM). The power train ECM activates

the backup alarm relay when the transmission direction control lever (if equipped) or the transmission

direction control switch (if equipped) is in the REVERSE position. The backup alarm relay then

activates the backup alarm. The backup alarm receives a +battery signal from the power train ECM

when the backup alarm is activated.

The backup alarm has two terminals for electrical connections. One terminal receives power from

connector contact J2-37 of the power train ECM. The other contact returns power to connector contact

J2-3 and J1-7 of the power train ECM.

Reference: For more information on the power train electronic control module (ECM), refer to the

Service Manual module Systems Operation, "Electronic Control Module (Power Train)" for the machine

that is being serviced.

Secondary Steering (If Equipped)

The optional secondary steering system provides steering control of the machine when the primary

steering system is disabled. The secondary steering system is intended for emergency use only.

Reference: For more information on the secondary steering system, refer to the Service Manual module

Systems Operation, "Secondary Steering System" for the machine that is being serviced.

Ride Control Function (If Equipped)

View Image

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Illustration 13

(1) Ride control switch.

Page 18 of 21

g00824031

View Image

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Illustration 14

Indicator display

Page 19 of 21

g00824038

(2) Ride control ON

(3) Ride control AUTO

Ride control is an optional function that is enabled by a programmable parameter via the Caterpillar

Electronic Technician (ET). Ride control can also be enabled by the calibration mode of the Caterpillar

Monitoring System. Ride control is enabled when the operator places the ride control switch (1) in the

ON position or the AUTO position. In the ON position, ride control is activated at all times and the

power train ECM continuously energizes the ride control solenoid. In the AUTO position, ride control is

activated when the machine ground speed increases above approximately 6 mph. In the AUTO position,

ride control is deactivated when the machine ground speed is below approximately 5.5 mph. The default

speed can be changed with the configuration screen of the Caterpillar Electronic Technician (ET). As

ride control is activated and deactivated the ride control solenoid is energized and de-energized.

The two ride control solenoids for the ride control are outputs of the power train ECM. The ride control

solenoids turn the ride control system on and off. When ride control is disabled, the number one ride

control solenoid is de-energized and the number two ride control solenoid is energized. When ride

control is enabled, the number one ride control solenoid is energized 5 seconds after the number two ride

control solenoid is de-energized. The delay time can be changed with the ride control equalization

pressure time parameter of the Caterpillar Electronic Technician (ET). Both of the ride control solenoids

have a connector with two contacts. The number one ride control solenoid receives power from the

connector contact J1-18 of the power train ECM. The number two ride control solenoid receives power

from the connector contact J1-12 of the power train ECM. Both of the ride control solenoids return

power to connector contact J2-3 of the power train ECM.

Reference: For more information on the Caterpillar Monitoring System, refer to the Service Manual

module Systems Operation, "Monitoring Systems (Power Train Functions)" for the machine that is

being serviced.

Reference: For more information on the power train electronic control module (ECM), refer to the

Service Manual module Systems Operation, "Electronic Control Module (Power Train)" for the machine

that is being serviced.

Speed Limiter (If Equipped)

The optional speed limiter software allows the operator to set the maximum ground speed for a machine

that is operating on a level surface. The speed limiter software uses the following inputs to control the

ground speed of the machine: engine speed, machine acceleration and ground speed.

Note: The maximum ground speed can be set to a maximum of 20 km/h (12.5 mph).

Note: The speed limiter software will not prevent a machine from exceeding the speed limit during

downhill travel.

Diagnostic Operation

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Page 20 of 21

The power train electronic control module (ECM) detects faults that occur in most of the input circuits

and the output circuits. A fault is detected when the signal at the contact of the power train ECM is

outside a valid range. The power train ECM then records the fault. If the fault goes away, the fault

information remains stored for future reference.

The diagnostics of the power train ECM are available to assist with the troubleshooting of detected

faults. A service code is used to specify each fault. These service codes are shown in the display area of

the Caterpillar Monitoring System. Service codes consist of three identifiers: MID, CID and FMI.

Module Identifier (MID) - The MID is a three-digit code that is shown on the display area. The MID is

shown for approximately one second before the service code that is shown in the same area. The power

train ECM that has diagnosed the fault is logged by the MID. The following examples are of some

MID's.

Caterpillar Monitoring System ... 030

Power Train ECM ... 081

Note: The MID of the power train control is "081". Before troubleshooting the power train, make sure

that "081" is the service code of the fault. The Caterpillar Monitoring System also shows service codes

of the faults that are not related to the power train system. MID 081 identifies the power train ECM as

the source of the service code.

Component Identifier (CID) - The components that are faulty are noted by the CID. The following

components are examples: start relay and reverse solenoid. The CID is a four digit code that is shown on

the display area. The CID and the FMI are shown together after the MID has been displayed.

Reference: For a list of the CID codes for the power train ECM, refer to the Service Manual module

Testing And Adjusting, "Troubleshooting Diagnostic Codes" for the machine that is being serviced.

Failure Mode Identifier (FMI) - The FMI tells the type of failure that has occurred. The following

situations are examples: voltage above normal, current below normal and abnormal frequency. The FMI

is a two digit code that is shown on the display area. The CID and the FMI are shown together after the

MID has been displayed. A decimal point "." precedes the FMI.

Reference: For a list of the FMI codes for the power train ECM, refer to the Service Manual module

Testing And Adjusting, "Troubleshooting Diagnostic Codes" for the machine that is being serviced.

The power train ECM does not have a display area for displaying diagnostic information to service

personnel. Diagnostic information concerning the power train system is sent on the CAT Data Link to

the Caterpillar Monitoring System. Service personnel must be familiar with the Caterpillar Monitoring

System in order to troubleshoot the power train system.

The service mode of the Caterpillar Monitoring System allows service personnel to see the faults that

were detected by the power train ECM. The service mode of the Caterpillar Monitoring System allows

service personnel to troubleshoot the faults that were detected by the power train ECM. While the

Caterpillar Monitoring System is in the service mode, the service code for any detected fault of the

power train electronic control system is shown in the display area of the Caterpillar Monitoring System.

When the service mode is first entered, all service codes for any detected faults scroll in the display area.

For troubleshooting and clearing, the particular service code must be placed on hold. The display area

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

Service Information System

Page 21 of 21

continuously alternates between showing the MID, and then showing both the CID and the FMI of the

particular service code for the fault that is on hold.

The Caterpillar Monitoring System enters service mode when ground is removed from the service input

and the clear input. The mode number 3 for service mode is shown in the display area of the Caterpillar

Monitoring System. To place a service code for a fault on hold, ground the service input. To clear a

service code for a fault on hold, ground the clear input. The Caterpillar Monitoring System exits service

mode when ground is added to the service input and the clear input.

Note: The time that is needed to clear a fault and the time that is needed to set a fault can last less than 1

second up to 60 seconds.

Reference: For more information on the CAT Data Link, refer to the Service Manual module Systems

Operation, "CAT Data Link" for the machine that is being serviced.

Reference: For more information on the power train electronic control module (ECM), refer to the

Service Manual module Systems Operation, "Electronic Control Module (Power Train)" for the machine

that is being serviced.

Reference: For more information on the Caterpillar Monitoring System, refer to the Service Manual

module Systems Operation, "Monitoring Systems (Power Train Functions)" for the machine that is

being serviced.

Note: The Service Manual modules Systems Operation, Testing and Adjusting, "Caterpillar Monitoring

System" should only be used as a reference to the display of the faults of the power train electronic

control system.

Copyright 1993 - 2011 Caterpillar Inc.

All Rights Reserved.

Private Network For SIS Licensees.

Tue Apr 5 14:51:45 UTC+0430 2011

https://sis.cat.com/sisweb/sisweb/techdoc/content.jsp?calledpage=/sisweb/sisweb/mediasear... 4/5/2011

You might also like

- Forex Drag SystemDocument1 pageForex Drag Systemsayeed younis sadaatNo ratings yet

- Forex TMchart2Document1 pageForex TMchart2sayeed younis sadaatNo ratings yet

- Forex Bull BarrDocument1 pageForex Bull Barrsayeed younis sadaatNo ratings yet

- Sensors SystemDocument5 pagesSensors SystemSayed Younis SadaatNo ratings yet

- Curso HEUI PDFDocument168 pagesCurso HEUI PDFeng_ebrahim_200088% (8)

- Forex OrbexDocument1 pageForex Orbexsayeed younis sadaatNo ratings yet

- Forex Social TradingDocument1 pageForex Social Tradingsayeed younis sadaatNo ratings yet

- Switches For Engine StartingDocument18 pagesSwitches For Engine Startingsayeed younis sadaatNo ratings yet

- RENR8077RENR8077 - 01 - SIS Emcp 2 + PDFDocument4 pagesRENR8077RENR8077 - 01 - SIS Emcp 2 + PDFsayeed younis sadaat100% (1)

- 3412 Peec Emcp2Document4 pages3412 Peec Emcp2Pedro Zafra100% (1)

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- Logged Event Codes - C 18 Engine.Document1 pageLogged Event Codes - C 18 Engine.sayeed younis sadaatNo ratings yet

- Trim Code Old & New Position MasterDocument1 pageTrim Code Old & New Position Mastersayeed younis sadaatNo ratings yet

- Caterpillar Solenoids For Electronic Fuel InjectionDocument6 pagesCaterpillar Solenoids For Electronic Fuel Injectionsayeed younis sadaatNo ratings yet

- Renr7885renr7885 03 Sis CMCDocument2 pagesRenr7885renr7885 03 Sis CMCsayeed younis sadaatNo ratings yet

- Switches For Engine StartingDocument18 pagesSwitches For Engine Startingsayeed younis sadaatNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Minimum - Sat - Scores - 2020-2021 - KopyaDocument1 pageMinimum - Sat - Scores - 2020-2021 - KopyaUlvin Gaming100% (1)

- CAD and CAM (Module)Document81 pagesCAD and CAM (Module)Arjun Pratap SinghNo ratings yet

- Subject Code: GE2025 Unit I: Subject Name: Professional Ethics in EngineeringDocument2 pagesSubject Code: GE2025 Unit I: Subject Name: Professional Ethics in Engineeringmuralimano06No ratings yet

- Orientation: 2. Student HandbookDocument3 pagesOrientation: 2. Student HandbookRonalyn ManzanoNo ratings yet

- Town Planning Lectures by Ravindar KumarDocument10 pagesTown Planning Lectures by Ravindar KumarMalik ZainNo ratings yet

- Contacts: Sylvester Otieno OumaDocument6 pagesContacts: Sylvester Otieno OumaZuma SylvesterNo ratings yet

- Buildability Score CalculationDocument4 pagesBuildability Score CalculationtangkokhongNo ratings yet

- (Tambahan) Tolerances - FitsDocument25 pages(Tambahan) Tolerances - FitsMuhammad Fachry RamadhanyNo ratings yet

- Basharat CVDocument2 pagesBasharat CVBasharat HussainNo ratings yet

- Water Distribution SystemDocument45 pagesWater Distribution SystemSrihari DasariNo ratings yet

- IEC 60445-2017-Basic and Safety Principles For Man-Machine Interface, Marking and Identification - Identification of Equipment Terminals, Conductor Terminations and ConductorsDocument17 pagesIEC 60445-2017-Basic and Safety Principles For Man-Machine Interface, Marking and Identification - Identification of Equipment Terminals, Conductor Terminations and ConductorsSrihari Mandava33% (6)

- Revisions To BS8006 For Reinforced Soil Technical NoteDocument5 pagesRevisions To BS8006 For Reinforced Soil Technical NoteTanNo ratings yet

- Bukit Merah c39b PDF File (Non Cast-In) 28.11.2022Document15 pagesBukit Merah c39b PDF File (Non Cast-In) 28.11.2022kk. yulwinnNo ratings yet

- Natural Language Processing Using Artificial IntelligenceDocument3 pagesNatural Language Processing Using Artificial IntelligenceInternational Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- Ford ExampleDocument22 pagesFord ExampleMohamad GhaliNo ratings yet

- Laminated Elastomeric Bearing DesignDocument4 pagesLaminated Elastomeric Bearing DesignGanesh PrabuNo ratings yet

- Replacement of Existing Railway BridgeDocument9 pagesReplacement of Existing Railway BridgeIrwan JoeNo ratings yet

- Water Supply Sanitary Engineering by Rangwala Tg74oufb PDFDocument2 pagesWater Supply Sanitary Engineering by Rangwala Tg74oufb PDFsivasai rakkasi0% (1)

- Renderoc LaxtraDocument2 pagesRenderoc LaxtraBalasubramanian AnanthNo ratings yet

- 3090 Slope Build Up NH PDFDocument2 pages3090 Slope Build Up NH PDFTodd St. GeorgeNo ratings yet

- Result - Bteupexam.in Year Oddresult - Aspx Roll No E1712732800021 PDFDocument1 pageResult - Bteupexam.in Year Oddresult - Aspx Roll No E1712732800021 PDFDipanshu NagarNo ratings yet

- As 3990-1993Document9 pagesAs 3990-1993Difa Liu0% (1)

- Att-3 Test & Inspection SewageDocument4 pagesAtt-3 Test & Inspection SewageFaries Jati SampurnoNo ratings yet

- DM BrochureDocument88 pagesDM Brochurethomas1313No ratings yet

- NEW AGE - Civil Engineering Catalogue 2013 - 2014Document6 pagesNEW AGE - Civil Engineering Catalogue 2013 - 2014Anonymous fFsGiyNo ratings yet

- Skyscraper CTF Finance CenterDocument9 pagesSkyscraper CTF Finance CenterAvilayyina ANo ratings yet

- General NotesDocument1 pageGeneral NotesGodino ChristianNo ratings yet

- Semester MarksheetDocument1 pageSemester MarksheetSiddharth SatyarthiNo ratings yet

- Aluminum plate punching force calculationDocument16 pagesAluminum plate punching force calculationAvijit SahaNo ratings yet