Professional Documents

Culture Documents

Kertas Penerangan 1 - Truss-Out (Spur) Scaffold Erection, Alteration and Dismantling

Uploaded by

Dasb ScaffoldingOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Kertas Penerangan 1 - Truss-Out (Spur) Scaffold Erection, Alteration and Dismantling

Uploaded by

Dasb ScaffoldingCopyright:

Available Formats

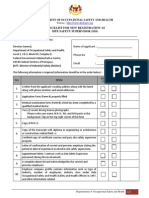

LEMBAGA PEMBANGUNAN INDUSTRI PEMBINAAN

MALAYSIA (CIDB)

TINGKAT 10, MENARA DATO ONN, PUSAT

DAGANGAN DUNIA PUTRA (PWTC),

NO. 45, JLN TUN ISMAIL, 50480 KUALA LUMPUR

KERTAS PENERANGAN

(INFORMATION SHEET)

KOD DAN NAMA

PROGRAM /

PROGRAMS CODE &

NAME

BC-061-2:2015

BASIC SCAFFOLD ERECTION, ALTERATION AND

DISMANTLING

TAHAP / LEVEL

NO. DAN TAJUK UNIT

KOMPETENSI /

BC-061-2:2015-C02

COMPETENCY UNIT NO.

AND TITLE

TRUSS-OUT (SPUR) SCAFFOLD ERECTION, ALTERATION

AND DISMANTLING

NO. DAN PENYATAAN

AKTIVITI KERJA / WORK

ACTIVITIES NO. AND

STATEMENT

1. COMPLY WITH SAFETY, HEALTH AND ENVIRONMENT

REQUIREMENTS

2. PERFORM SCAFFOLD DESIGN SKETCHING

3. PREPARE SCAFFOLD SITE

4. ERECT FRAME SCAFFOLD

5. ERECT TUBULAR SCAFFOLD

6. ERECT MODULAR SCAFFOLD

7. PERFORM HOUSEKEEPING

NO. KOD / CODE NUM.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page :1

Drp / Of : 13

TAJUK / TITLE:

TRUSS-OUT (SPUR) SCAFFOLD ERECTION, ALTERATION AND DISMANTLING

TUJUAN / PURPOSE:

This Information Sheet is intended to describe on tubular, modular and frame scaffold

so the trainee able to ensure the Truss-Out (Spur) Scaffold erected, altered and

dismantled safely and correctly.

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 2

Drpd/of : 16

PENERANGAN / INFORMATION:

1. INTRODUCTION

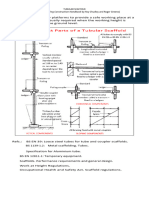

Figure 1: Truss Out (Spur) Scaffold

A truss out (spur) scaffold is an independent tied scaffold, constructed projecting from

the face of a building or structure. The supporting structure is known as a truss-out with

needles or cantilever tubes strengthened by spurs to support the outside scaffold

structure.

This type of scaffold is generally used where it is impractical and not advisable to build

up from ground level, for example, for repairs to a parapet wall, or for work on upper

storey in a tall building on a busy street or relevant.

However, a Professional Engineer experienced in structural design, must verify such a

design before the truss out (spur) scaffold is handed over for use.

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 3

Drpd/of : 16

Figure 2: Components of Truss-Out Scaffold

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

2. TYPE OF TRUSS-OUT SCAFFOLD

Sample No 2

Figure 3: Sample No. 1

Muka Surat / Page : 4

Drpd/of : 16

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Figure 2: Sample No. 2

Muka Surat / Page : 5

Drpd/of : 16

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Figure 4: Sample No 3

Muka Surat / Page : 6

Drpd/of : 16

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Figure 5: Sample No 4

Muka Surat / Page : 7

Drpd/of : 16

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 8

Drpd/of : 16

3. DESIGN, LOADING, WALL TIES AND BRACING FOR TRUSS OUT (SPUR)

SCAFFOLD

The truss-out scaffold should be designed to support the dead weight of the scaffold

and the total superimposed loads, including wind loading.

Truss out (Spur) scaffold can be built for light duty, medium duty or heavy duty with

the spacing and positions of members as set out in Figure 6.

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 9

Drpd/of : 16

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 10

Drpd/of : 16

Figure 6: Truss-Out Scaffold

4. TERMINOLOGY USED FOR TRUSS OUT (SPUR) SCAFFOLD

4.1. Toms

Toms are fixed between floor and ceiling at proper spacing to suit the

puncheons of the scaffold to be erected on the outside of the building.

A suitable headstock is to be provided at the top of each tom to spread the load

to the ceiling. At the base of the tom a base plate and reveal screw or an

adjustable base is required to firmly secure the tom between the floor and

ceiling. When the toms are in position, they shall be adequately tied together

with ledger and transom and braced.

4.2. Needles or Cantilever Tubes

Needles or cantilever tubes are secured to the toms with right angle couplers.

These cantilever tubes shall be adequately supported and project the required

distance beyond the outside face of the wall. A scaffold tube is fixed, with right

angle couplers, to the toms and hard down on top of the cantilever tubes. This

ties the toms together and acts as a safety measure for any uplift in this end of

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 11

Drpd/of : 16

the needles. A scaffold tube is secured, with right angle couplers to the

cantilevers and hard against the inside face of the wall. Safety fittings are

secured to the cantilevers hard against the right angle couplers securing the

tube to the cantilevers. This scaffold tube and safety fittings prevent any outthrust of the scaffold occurring. Care must be taken to ensure that this tube is

supported by the wall and not by architraves or other fixtures.

4.3. Bracing

Bracing tubes fixed with right angle couplers to cantilever tubes and transoms

must be provided to provide rigidity and prevent swaying of the scaffold

structure.

4.4. Facade Bracing

Facade bracing runs parallel to the building and examples of faade bracing

include:

a) A series of parallel diagonal tubes placed one above the other

b) In long facades, a continuous diagonal tube from bottom to top

The recommended facade brace spacing for some system scaffolds ranges

from a maximum of 3 un-braced bays to a maximum of 8 un-braced bays,

depending on the system, Tube and fitting scaffolds should braced at least

every alternate bays or maximum distance of 30m, unless movement along the

building is prevented by other means. Bracing should be fixed as near to the

standards and ledger intersections as possible. The bracing should extend from

bottom to top of the scaffold with no breaks.

4.5. Spurs

Spurs (a load bearing inclined standard/tube) should be set at an angle

generally not exceeding 35 from the vertical. Spurs must be provided to

support all needles/cantilever tubes to which puncheon for the outside scaffold

structure are attached. Their lower ends should be secured against

displacement and bases suitably packed. The upper ends of the spurs should

be fixed to the outer ledgers as close as possible to the cantilever tubes

(leading into or from building). A check coupler should be fixed on to the spur

immediately underneath and in contact with the ledger coupler. The un-braced

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 12

Drpd/of : 16

length of rakers should never exceed 3m. For longer length knee braces must

be provided to strengthened spurs.

Only right angle couplers (load bearing couplers) should be used in the

construction of a truss-out (spur) scaffold. Special attention should be given to

the numbers and positioning of spurs, ties and check couplers.

4.6. Plan Bracing

Plan bracing should be installed on those horizontal planes of the scaffold

which are not stabilized against lateral distortion. The bracing should be

connected from standard to standard, forming a complete series of triangles.

Where wall tie can not be installed at the manufacturers recommended

spacing, plan bracing may be used to help span the extended distance

between the adjacent ties to cover maximum distance of 6 bays. Note that the

loading on the ties will be increased.

Figure 7: Figures showing installation of plan bracing

5. ERECTION AND DISMANTLING PROCEDURE FOR TRUSS OUT (SPUR)

SCAFFOLD

a) The supporting scaffolding structure shall be erected first.

This supporting

scaffold is the scaffold WITHIN the internal of the building.

b) The supporting scaffold shall be butted using base jacks against the suffix of the

slab and the dead load of the supporting scaffold shall be supported by the base

jacks.

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 13

Drpd/of : 16

c) The supporting scaffold shall be treated like an independent scaffold and it is

used only as a support & counterweight to the trussout scaffold which is fixed

OUTSIDE of the building or structure.

d) As the supporting scaffold is being fixed, needle transoms (the tubes extending

to the outside of the building) will be fixed as a base for the truss-out scaffold.

e) Upon the completion of the needle transoms, the faade/angle tubes shall be

fixed.

f) The truss-out scaffold shall then commence (to be constructed as an

independent scaffold) on top of the needle transoms and the faade/angle

tubes/bracings.

g) The dismantling procedure shall be the reverse of the Erection Procedure.

h) It must be noted that the truss-out scaffold shall be dismantled first followed by

the needle transoms and finally the supporting scaffold shall be dismantled.

i) The supporting scaffold must NOT be dismantled first.

6. SPECIAL NOTES FOR MODULAR SYSTEM

As for modular scaffolds, the same erection and dismantling procedures are

followed as per the erection and dismantling procedures of the tubular system and

manufacturers recommendation.

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 14

Drpd/of : 16

7. SAFE ERECTION, ALTERATION AND DISMANTLING OF TRUSS-OUT (SPUR)

SCAFFOLD (TUBULAR)

7.1. Erection

Erection procedures should be such that an unstable is not reached at any time.

This applies to both low and high scaffoldings.

The ties for the scaffold should be fixed in place as the scaffold is erected and

reached each tie position. No portion of the scaffold should be used unless that

portion is fully checked, braced and tied.

i) Step of erection

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Step 1

Dimulakan dengan membuat

pemasangan perancah

didalam bangunan.

Perlu pasang needle

transoms terjulur keluar.

Step 2

Pasang tiub ledger pada

bahagian bawah dihujung

Needle transoms.

Pasang tiub Bracing

Safety clamp dipasang pada

bahagian dalam Bracing

Muka Surat / Page : 15

Drpd/of : 16

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Step 3

Pasang middle spur diantara

Bracing sudut 45 darjah

Step 4

Selepas pemasangan needle

transoms disusuli dengan

pemasangan faade brace.

Muka Surat / Page : 16

Drpd/of : 16

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Step 5

Pasang Standard pada

Needle transoms dengan

Right Angle Cuopler

Step 6

Pasang Putlog diatas Needle

transoms disusuli dengan

pemasangan Putlog Cuopler.

Step 7

Siapkan Working Platform .

Muka Surat / Page : 17

Drpd/of : 16

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 18

Drpd/of : 16

7.2. Alteration

All alteration to existing scaffoldings should be carried out in such a way that the

stability of the scaffold is not impaired. As a general rule, supplementary

components should be added before those which have to be removed are

uncoupled and taken away.

Step 1

Buka grandrail dan teoboard jika

menghalang process barang atau

material masuk

Step 2

Pasangkan semua grandrail and

teoboard setelah barang itu telah

dipasang.

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 19

Drpd/of : 16

7.3. Dismantling Procedures

i) During dismantling, no component which endangers the stability of the

remaining structure should be removed. If the scaffold is defective, it

should be made good before dismantling. The procedure for dismantling

should proceed generally from top in horizontal section. Scaffold should

never be dismantled in vertical sections from one end towards the other.

ii) Materials should be lowered to the ground as the scaffold is dismantled

progressively. They should not be staked on scaffold. Components should

not be thrown down to ground; they should be lowered hand to hand in an

orderly fashion or brought down by crane, gin wheel or other suitable

means.

iii) When dismantling:

The order in which a scaffold is dismantled is not necessarily the reverse

of the order of erection. Generally, scaffolds should be taken down lift by

lift and not from one end to the other.

Step 1

Buka teoboard and

guardrail .

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Step 2

Buka Putlog diatas

Needle transoms disusuli

dengan Standard.

Step 3

Buka Middle Spur

diantara Bracing

Step 4

Buka Bracing

Muka Surat / Page : 20

Drpd/of : 16

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 21

Drpd/of : 16

Step 4

Buka needle transom.

8. SAFE ERECTION, ALTERATION AND DISMANTLING OF TRUSS-OUT (SPUR)

SCAFFOLD (MODULAR)

8.1. Erection

Erection procedures should be such that an unstable is not reached at any time.

This applies to both low and high scaffoldings.

The ties for the scaffold should be fixed in place as the scaffold is erected and

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 22

Drpd/of : 16

reached each tie position. No portion of the scaffold should be used unless that

portion is fully checked, braced and tied.

ii) Step of erection

Step 1

Pasang needle transoms

bersama dengan bracing.

dan Starting collar

Step 2

Pasang Platform

Step 3

Pasang Ledger

Step 4

Pasang Edge protection

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 23

Drpd/of : 16

8.2. Alteration

All alteration to existing scaffoldings should be carried out in such a way that the

stability of the scaffold is not impaired. As a general rule, supplementary

components should be added before those which have to be removed are

uncoupled and taken away.

Step 1

Buka grandrail dan teoboard

jika

menghalang

process

barang atau material masuk

8.3. Dismantling Procedures

iv) During dismantling, no component which endangers the stability of the

remaining structure should be removed. If the scaffold is defective, it

should be made good before dismantling. The procedure for dismantling

should proceed generally from top in horizontal section. Scaffold should

never be dismantled in vertical sections from one end towards the other.

v) Materials should be lowered to the ground as the scaffold is dismantled

progressively. They should not be staked on scaffold. Components should

not be thrown down to ground; they should be lowered hand to hand in an

orderly fashion or brought down by crane, gin wheel or other suitable

means.

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 24

Drpd/of : 16

vi) When dismantling:

The order in which a scaffold is dismantled is not necessarily the reverse

of the order of erection. Generally, scaffolds should be taken down lift by

lift and not from one end to the other.

Step 1

Buka Edge protection

Step 2

Buka Ledger

Step 3

Buka Platform

Step 4

Buka needle transoms

bersama dengan bracing.

dan Starting collar

NO. KOD / CODE NO.

BC-061-2:2015C02/P(1/1)

Muka Surat / Page : 25

Drpd/of : 16

SOALAN/QUESTION:

1. What is the truss out (spur) scaffold?

2. Define terminology for:

a) Toms

b) Spurs

RUJUKAN/REFERENCE :

1. Basic Scaffolding Certificate, Holmesglen Institute of Tafe, National Occupational

Health and Safety Certification Standard for Users and Operators of Industrial

Plant, July 1995

2. Course Of Scaffolding, The Design Specifications Of A Scaffold Can Either Be A

Comple Set Of Drawings Or Held In Mind Of The Responsible Scaffolder,

AS/NZS 4576:1995 Guideline For Scaffolding

3. Scaffolding Inspection Course

4. WA Skill Training, Knowledge and Safety, CPCCLSF2001A , Licence To Erect,

Alter And Dismantle Scaffolding Basic Level

You might also like

- Kertas Penerangan 1 - Independent 2Document27 pagesKertas Penerangan 1 - Independent 2Dasb ScaffoldingNo ratings yet

- Kertas Tugasan 1Document9 pagesKertas Tugasan 1Dasb ScaffoldingNo ratings yet

- Module 1Document31 pagesModule 1kevin291100% (1)

- Scaffolding Level 1Document9 pagesScaffolding Level 1Alan Bentley50% (2)

- Access Birdcage ScaffoldsDocument22 pagesAccess Birdcage ScaffoldsJitendra Kumar AnandNo ratings yet

- Kertas Tugasan 1 (1) 2Document9 pagesKertas Tugasan 1 (1) 2Dasb Scaffolding100% (1)

- Tubular ScaffoldingDocument17 pagesTubular Scaffoldingfoxsins226100% (1)

- Prosedur ScaffoldingDocument38 pagesProsedur ScaffoldingFafa seyza100% (3)

- NASC Scaffold SpecificationDocument15 pagesNASC Scaffold Specificationstephen155100% (2)

- Hse Training Basic ScaffoldingDocument49 pagesHse Training Basic ScaffoldingRosli Bin Abdul Shukor100% (1)

- Method Statement Scaffolding DraftDocument64 pagesMethod Statement Scaffolding DraftAnonymous BzGb2fnfE100% (7)

- Scaffolding Management Solutions: Welcome To The World of SafeDocument15 pagesScaffolding Management Solutions: Welcome To The World of SafeVEERKUMAR GNDECNo ratings yet

- SCAFFOLD DESIGNDocument13 pagesSCAFFOLD DESIGNMohd Zahariy100% (6)

- Building Construction Scaffolding TypesDocument11 pagesBuilding Construction Scaffolding TypesGarima MehtaNo ratings yet

- Scaffold Tube Storage Racks: 1 of 6 August 2021Document6 pagesScaffold Tube Storage Racks: 1 of 6 August 2021Matthew PowellNo ratings yet

- Design Project1Document19 pagesDesign Project1Syed Munawar Ali100% (1)

- ScaffoldsDocument1 pageScaffoldsmzmameen11No ratings yet

- Scaffold Erection GuidanceDocument14 pagesScaffold Erection GuidanceRauf Akchurin67% (3)

- Scaffolding Design Calculation (Timber)Document3 pagesScaffolding Design Calculation (Timber)KH Chung100% (1)

- 3 MS ScaffoldingDocument32 pages3 MS Scaffoldingpaansaeng94% (16)

- Scaffolding Safety TrainingDocument37 pagesScaffolding Safety Trainingsaasim_1100% (1)

- Layher Scaffolding CouplersDocument1 pageLayher Scaffolding CouplersALex ABerlyn RodriguezNo ratings yet

- 04 Scaffolding (GG)Document79 pages04 Scaffolding (GG)Hafizah Ayob100% (6)

- ScaffoldingDocument91 pagesScaffoldingyzza100% (4)

- BNJ21102 Osha ScaffoldingDocument18 pagesBNJ21102 Osha ScaffoldingWee Soon Chai100% (1)

- BS 2482 1981 Specification For Timber Scaffold BoardsDocument17 pagesBS 2482 1981 Specification For Timber Scaffold BoardsZulham Surbakti100% (1)

- Site Safety Supervisor FormDocument3 pagesSite Safety Supervisor FormSati Sivan100% (1)

- Advanced Scaffolding Knowledge QuestionsDocument4 pagesAdvanced Scaffolding Knowledge QuestionsBike To Work67% (3)

- Build 145 30 Build Right Scaffolding in The FrameDocument3 pagesBuild 145 30 Build Right Scaffolding in The Frameanon_657324417100% (2)

- ScaffoldingDocument86 pagesScaffoldingAristotel C. Cabais, RN100% (6)

- Scaffolding Training Module 2Document62 pagesScaffolding Training Module 2HILAL ALSAMANo ratings yet

- User Manual Cuplok (10-2006)Document51 pagesUser Manual Cuplok (10-2006)humaidjafri60% (5)

- TG4 - 17 Anchorage Systems For ScaffoldingDocument24 pagesTG4 - 17 Anchorage Systems For ScaffoldingDerek ReddinNo ratings yet

- ScaffoldCouplers14Document8 pagesScaffoldCouplers14Guatemalan1979No ratings yet

- Scaffolding TrainingDocument81 pagesScaffolding TrainingSanjana Ganesh100% (1)

- SG28:17 Safe System of Work for ScaffoldingDocument24 pagesSG28:17 Safe System of Work for ScaffoldingMohammed HafizNo ratings yet

- Scaffold Specification Template PDFDocument20 pagesScaffold Specification Template PDFDiki FirmansahNo ratings yet

- Scaffolding GuidanceDocument19 pagesScaffolding Guidanceabogadie100% (1)

- Laws of Malaysia BowecDocument21 pagesLaws of Malaysia BowecAbah Harris Hafizh60% (5)

- National Scaffolding Guidance UpdateDocument5 pagesNational Scaffolding Guidance UpdateHari Haran100% (5)

- CISRS Scaffolding Supervisor - CITBDocument4 pagesCISRS Scaffolding Supervisor - CITBManda Khel Apna Des100% (1)

- TG20 21 An Introduction For ScaffoldersDocument20 pagesTG20 21 An Introduction For ScaffoldersAaa Bbbb100% (3)

- Cuplok Scaffold System: User GuideDocument11 pagesCuplok Scaffold System: User Guideezzularab100% (1)

- Scaffolding CalculationDocument2 pagesScaffolding CalculationReza FurqonNo ratings yet

- Module 2Document20 pagesModule 2kevin291100% (2)

- Tank Erection ProcedureDocument13 pagesTank Erection ProcedureAshokkumar ThangarajNo ratings yet

- LANL EngDocument3 pagesLANL EngNaNo ratings yet

- Column Internals CheckpointsDocument3 pagesColumn Internals CheckpointsMasoodMiyanNo ratings yet

- Method StatementDocument15 pagesMethod StatementKrushna RamaNo ratings yet

- Spare Parts, Instruction and Maintenance Manual For Spanco Model 300 Jib CranesDocument16 pagesSpare Parts, Instruction and Maintenance Manual For Spanco Model 300 Jib CranesAndres LopezNo ratings yet

- Tank Erection ProcedureDocument15 pagesTank Erection Procedurejohney294% (16)

- KochDocument181 pagesKochRichard FelipNo ratings yet

- RHOSW (Short) / RHOLW (Long) Wall Mount: Installation GuideDocument4 pagesRHOSW (Short) / RHOLW (Long) Wall Mount: Installation GuideRita CaselliNo ratings yet

- Spare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib CranesDocument20 pagesSpare Parts, Instruction and Maintenance Manual For Spanco Model 301 Jib CranesGuillermoNo ratings yet

- J-76-1 IKS Wellhead Installation and Operation ManualDocument72 pagesJ-76-1 IKS Wellhead Installation and Operation Manualmam100% (1)

- Iso Hydraulic Assembly ProcedureDocument9 pagesIso Hydraulic Assembly ProcedureV_SanthanakrishnanNo ratings yet

- Digitilt Horizontal Probe Manual 2006Document17 pagesDigitilt Horizontal Probe Manual 2006Mahesh JalluNo ratings yet

- Flange Ductwork Jointing System PDFDocument35 pagesFlange Ductwork Jointing System PDFKhánh DươngNo ratings yet

- Manual de Mantenimiento de Gruas Jib PDFDocument20 pagesManual de Mantenimiento de Gruas Jib PDFalejandroaleman53No ratings yet

- Captive Air Commercial Kitchen Exhaust Vent ManualDocument31 pagesCaptive Air Commercial Kitchen Exhaust Vent ManualGiann CarlosNo ratings yet

- Scaffold Erection Theory Lesson PlanDocument1 pageScaffold Erection Theory Lesson PlanDasb ScaffoldingNo ratings yet

- Scaffold Erection Theory Lesson PlanDocument1 pageScaffold Erection Theory Lesson PlanDasb ScaffoldingNo ratings yet

- Cu5 Wa4-5-6-7Document14 pagesCu5 Wa4-5-6-7Dasb ScaffoldingNo ratings yet

- Kertas Tugasan 1 (1) 2Document9 pagesKertas Tugasan 1 (1) 2Dasb Scaffolding100% (1)

- Jadual Pembahagian Bahan Pengajaran Bertulis c02Document1 pageJadual Pembahagian Bahan Pengajaran Bertulis c02Dasb ScaffoldingNo ratings yet

- Cu5 Wa4-4Document5 pagesCu5 Wa4-4Dasb ScaffoldingNo ratings yet

- Reviewed Scaffolding Documents and AssignmentsDocument2 pagesReviewed Scaffolding Documents and AssignmentsDasb ScaffoldingNo ratings yet

- All Employer e Directory 1Document1,167 pagesAll Employer e Directory 1Dasb Scaffolding100% (1)

- Microsoft Word - I'm Secretly Married To A Big S - Light DanceDocument4,345 pagesMicrosoft Word - I'm Secretly Married To A Big S - Light DanceAliah LeaNo ratings yet

- Fta Checklist Group NV 7-6-09Document7 pagesFta Checklist Group NV 7-6-09initiative1972No ratings yet

- Galvanize Action donation instructionsDocument1 pageGalvanize Action donation instructionsRasaq LakajeNo ratings yet

- Service Culture Module 2Document2 pagesService Culture Module 2Cedrick SedaNo ratings yet

- Configuration Rationale Document - Personnel StructureDocument11 pagesConfiguration Rationale Document - Personnel Structurepkank09100% (1)

- Mobile phone controlled car locking systemDocument13 pagesMobile phone controlled car locking systemKevin Adrian ZorillaNo ratings yet

- Aero T RopolisDocument9 pagesAero T RopolisZeynep çetinelNo ratings yet

- Ombudsman Complaint - TolentinoDocument5 pagesOmbudsman Complaint - TolentinoReginaldo BucuNo ratings yet

- Drought in Somalia: A Migration Crisis: Mehdi Achour, Nina LacanDocument16 pagesDrought in Somalia: A Migration Crisis: Mehdi Achour, Nina LacanLiban SwedenNo ratings yet

- Agreement For Consulting Services Template SampleDocument6 pagesAgreement For Consulting Services Template SampleLegal ZebraNo ratings yet

- Hue University Faculty Labor ContractDocument3 pagesHue University Faculty Labor ContractĐặng Như ThànhNo ratings yet

- Network Marketing - Money and Reward BrochureDocument24 pagesNetwork Marketing - Money and Reward BrochureMunkhbold ShagdarNo ratings yet

- List LaguDocument13 pagesList LaguLuthfi AlbanjariNo ratings yet

- Courtroom Etiquette and ProcedureDocument3 pagesCourtroom Etiquette and ProcedureVineethSundarNo ratings yet

- ThangkaDocument8 pagesThangkasifuadrian100% (1)

- How a Dwarf Archers' Cunning Saved the KingdomDocument3 pagesHow a Dwarf Archers' Cunning Saved the KingdomKamlakar DhulekarNo ratings yet

- UCPB Violated Truth in Lending Act in Loan to SpousesDocument4 pagesUCPB Violated Truth in Lending Act in Loan to SpousesMark Xavier Overhaul LibardoNo ratings yet

- Cruise LetterDocument23 pagesCruise LetterSimon AlvarezNo ratings yet

- People of The Philippines vs. OrsalDocument17 pagesPeople of The Philippines vs. OrsalKTNo ratings yet

- Mind Map All in One PBA-2021-08-20 12-38-51Document1 pageMind Map All in One PBA-2021-08-20 12-38-51MikosamirNo ratings yet

- DIN EN ISO 12944-4 071998-EnDocument29 pagesDIN EN ISO 12944-4 071998-EnChristopher MendozaNo ratings yet

- Building Security in Maturity Model: (Bsimm)Document2 pagesBuilding Security in Maturity Model: (Bsimm)cristiano.vs6661No ratings yet

- Company Profile-SIPLDocument4 pagesCompany Profile-SIPLShivendra SinghNo ratings yet

- Types of Electronic CommerceDocument2 pagesTypes of Electronic CommerceVivek RajNo ratings yet

- Notice WritingDocument2 pagesNotice WritingMeghana ChaudhariNo ratings yet

- Nursing Care Plan: Assessment Planning Nursing Interventions Rationale EvaluationDocument5 pagesNursing Care Plan: Assessment Planning Nursing Interventions Rationale Evaluationamal abdulrahman100% (2)

- Lancaster University: January 2014 ExaminationsDocument6 pagesLancaster University: January 2014 Examinationswhaza7890% (1)

- Anthony VixayoDocument2 pagesAnthony Vixayoapi-533975078No ratings yet

- Reading Comprehension and Vocabulary PracticeDocument10 pagesReading Comprehension and Vocabulary Practice徐明羽No ratings yet

- The Constitution of The Student Council of Pope John Paul II Catholic High SchoolDocument4 pagesThe Constitution of The Student Council of Pope John Paul II Catholic High Schoolapi-118865622No ratings yet