Professional Documents

Culture Documents

Assessment of Safety Practices in Construction Industry

Uploaded by

Nasir Mehmood AryaniOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Assessment of Safety Practices in Construction Industry

Uploaded by

Nasir Mehmood AryaniCopyright:

Available Formats

International Journal On Engineering Technology and Sciences IJETS

ISSN (P): 2349-3968, ISSN (O): 2349-3976

Volume 2 - Issue 5, May 2015

ASSESSMENT OF SAFETY PRACTICES IN

CONSTRUCTION INDUSTRY

ASHLY BABU

ME- Construction Engineering and Management,

RVS College of Engineering, Coimbatore, Anna University

ABSTRACT

In both developed and developing countries, the construction industry is considered to be one of the most

significant industries in terms of its impact on health and safety of the working population. Construction

industry is both economically and socially important. However, the construction industry is also recognized

to be the most hazardous. The objectives of this research is to investigate the safety performance in the

construction sites. The data were collected from the contractors, consultant, and owners by using

questionnaire to evaluate the safety performance in the construction sites. The results show that there was

still a lack of commitment from the government, the insurance company, the labour ministry, the owners,

consultants, and also the contractors to improving safety performance on the construction sites. The

suggestion is to improve the safety performance on the construction sites. The government should follow up

the safety performance by visiting the construction sites. The insurance company should be more active in

visiting the construction sites. The owners should be more active towards the safety by controlling, visiting

the process in the construction sites. The contractors have to train the workers and promote the safety

culture and follow up the safety performance. The consultants should control all the tools in the construction

sites to insure that those tools are safe.

KEYWORDS: Safety, construction project, risk, accidents ,safety management, safety policy.

1.INTRODUCTION

The safety performance of the construction

industry has been improving. Health and safety

has been recognized as an important business

performance subject. The factors causing

construction site accidents have been addressed

by several researchers. These are lack of proper

training, deficient enforcement of safety, lack of

safety equipment, unsafe methods or sequencing,

unsafe site conditions, not using provided safety

equipment, poor attitude toward safety, and

isolated, sudden deviation from prescribed

behaviour. The state of the safety in the

construction industry is poor. In the past five

years, the numbers of people injured or even died

in the construction projects has been increasing

.The authority, however, has not been able to keep

up with the huge increase in number of

construction projects. Many safety issues in the

construction projects were overlooked by the

authority due to ignorance. This is because the

main concern for the authority there has been how

to finish as many projects possible to make up for

the lost time the country suffered as results of the

economic sanctions.

2.CONSTRUCTION ACCIDENTS

The importance of the use of plant and equipment

in construction works seems to be increasing on

daily basis. Manual methods are fast giving way

to mechanical methods in the effort to increase

productivity,

meet

increasing

complex

specifications, construct or actualize the growing

complexity of modern designs, utilize the

numerous new construction materials that are

being introduced into the industry, meet the tight

schedules and targets placed by clients demands,

implement control measures required to bring

projects on track and ensure effective and efficient

utilization of the numerous resources involved in

the construction of projects. New plant and

equipment are being developed and produced

regularly in response to the needs of the industry.

Asserts that increases mechanization of

construction work can speed up construction and

reduce the overall cost of construction. In

appreciation of the important role that plant and

equipment play in achieving project objectives,

clients are placing greater emphasis on the use

89

International Journal On Engineering Technology and Sciences IJETS

ISSN (P): 2349-3968, ISSN (O): 2349-3976

Volume 2 - Issue 5, May 2015

Using a safety committee or plant council.

Specific policies of the organization (violence to

staff).

4. ROLE

OF

THE

GOVERNMENT

TOWARDS SAFETY

plant and equipment even that before by

identifying possession of plant and equipment of

prospective contractors as a major criterion for the

award of contracts. In response to this

development, contractors often embark on efforts

to own construction plant and equipment in order

to be able to compete favourably with their

counterparts during tendering. They do not stop

there; hay also stipulate mechanized methods in

their production methods statement during

tendering. They are also competed to implement

the methods stipulated in their tenders when

eventually contracts are won and have to be

executed. Mechanization goes with hazards as the

use of plant and equipment is prone to accidents

and injuries. Research studies have confirmed that

the construction industry is one of the most

hazardous industries all over the world . In most

countries, the rates of accident and injury

prevailing in the industry are higher that what

prevail in other industries.

Every contractor is required to contact the safety

department of the concerned municipality when

starting new projects and submit necessary

documents such as building permit, area location.

The safety department provides safety information

regarding the proposed job or activity, and a

safety representative conducts a site visit to ensure

safe places for storage, temporary site offices, and

services. Safety posters with major instructions

are given to the contractor to be hung at the job

site, in addition to safety interaction procedures

and accident prevention methods for each activity

related to the proposed job. The municipality

charges a certain fee as insurance for safety and

work completion. This amount is returned to the

contractor at the completion date of the project

along with a clearance .The practice of safety in

construction in the USA is regulated by

governmental agencies such as the occupational

safety and health administration (OSHA), which

provides strict rules and regulations to enforce

safety and health standards on job sites.

3.SAFETY MANAGEMENT AND SAFETY

POLICY

Management and planning is one way to avoid

unplanned events. Since accidents are unplanned

events, an effective safety management can help

avoid job injuries. Safety management must be

through, and it must be applicable to all aspects of

the job, from the estimating phase of the project

until the last worker has left the premise at the

completion of the project. All parties to a

construction project must be included in some

way in the safety program every party is

responsible.

5. INSURANCE COMPANIES TOWARDS

SAFETY

Insurance companies play an important role in the

improvement of health and safety standards. Since

1969, it has been a legal requirement for

employers to insure against liability for injury or

disease to their employees arising out of their

employment. This is called employers liability

insurance. Certain public sector organizations are

exempted from this requirement because any

compensation is paid from public funds. Other

forms of insurance include fire insurance and

public liability insurance (to protect members of

the public). Premiums for all these types of

insurance are related to levels of risk which is

related to standards of health and safety. In recent

years, there has been a considerable increase in

the number and size of compensation claims and

this has placed further pressure on insurance

companies. Insurance companies are becoming

effective health and safety regulators by weighing

the premium offered to an organization according

to its safety and/or fire precaution record .

The following points should be included or

considered when a health and safety policy

statement is being drafted:

The aims should cover health and safety, welfare

and relevant environmental issues.

The position of the senior person in the

organization or company who is responsible for

health and safety (normally the chief executive).

The names of the health and safety adviser and

any safety representatives.

A commitment to the basic requirements of the

health and safety at work Act (access

egress, risk assessments, safe plant and systems of

work, use handing, transport and

handing of articles and substances, information,

training and supervision).

90

International Journal On Engineering Technology and Sciences IJETS

ISSN (P): 2349-3968, ISSN (O): 2349-3976

Volume 2 - Issue 5, May 2015

Structured interviews were supplemented where

necessary. Finally, the results of the questionnaire

were analysed by sorting them using tables and

the results were used to form basis for

recommendations as well as areas for further

research. The following methods of analysis were

used in analysing the data:

a. Relative Importance Index (RII)

6. ADVANTAGES OF APPLYING SAFETY

ON CONSTRUCTION SITES.

Applying safety on the construction projects has

many advantages, as summarized below:

Reduce the accidents on the construction

sites.

Help end projects in the early time.

Increase employee morals

Increased productivity.

Decreased the number of compensation.

b. Weighted Average

8.1 RELATIVE

TECHNIQUE:

IMPORTANCE

INDEX

Relative Importance Index method is used to

determine the relative importance of the various

causes and effects of the factors considered. The

same method is adopted in this study within

various groups (i.e. clients, consultants or

contractors). The five-point scale ranged from 1

(not important) to 5 (extremely important) which

will be adopted and will be transformed to relative

importance indices (RII) for each factor as

follows:

7. DATA COLLECTION

7.1 PRIMARY DATA

The source of the primary data is in the form of

questionnaire and structured interviews, designed

together.

A

large volume of data from

Consultants, building contractors , site engineers

as well as insurance companies were collected.

The primary function of the survey is to collect

information that can be analysed, and inference

made to produce conclusion about major risk

factors in construction, the importance of safety in

the construction industry, the interactions between

construction players and insurance companies

with

respect

to

risk

management.

RII =

( W) / ( S x N)

; 0 INDEX 1

Where ,

7.2 SECONDARY DATA

W = the summation of the weighting given to

each factor

Secondary data which involves information from

published text such as academics periodicals,

research journals, government publications,

dictionaries, past dissertations and Internet

resources were used to compliment the primary

data.

S = maximum score = 5

N = total number of firms that responded in the

sample

7.3 SAMPLING

The RII value had a range from 0 to 5 (0 not

inclusive), higher the value of RII, more important

was the factor. The RII was used to rank (R) the

different causes. These rankings made it possible

to cross-compare the relative importance of the

factors as perceived by the different groups of

respondents (i.e. clients, consultants and

contractors). Each individual causes RII

perceived by all respondents should be used to

assess the general and overall rankings in order to

The questionnaires were sent to randomly selected

Contractors, site engineers ,Consultants and

insurance companies in the Construction industry

.The type and size of projects they have handled,

which were normally involved with high risks as

well as insurance covers.

8. TECHNIQUES USED FOR RANKING

THE SELECTED FACTORS FROM THE

SURVEY

91

International Journal On Engineering Technology and Sciences IJETS

ISSN (P): 2349-3968, ISSN (O): 2349-3976

Volume 2 - Issue 5, May 2015

give an overall picture of the risk factors in the

construction industry in India.

industry .A sample of the questionnaire can be

seen in the . The questionnaires were sent to

different

organizations in the construction

industry. These include Consultants, Insurance

Companies, Site engineers and Contractors.

8.2 WEIGHTED AVERAGE

An average in which each quantity to

be averaged is assigned a weight. These

weightings determine the relative importance of

each quantity on the average. Weightings are the

equivalent of having that many like items with the

same value involved in the average.

9.1 ANALYSIS OF RESPONSE

A total of 25 questionnaires were sent to the four

groups of respondents in the construction industry

of which 13 were collected. The 13 uestionnaires

collected comprised of 5 from client / consultants,

4 from owners, 2 from site engineers and 2 from

contractors. This gives a responds rate of 52%.

Below is the breakdown of responses from the

various sample groups.

For each factor the weighted average

was achieved by adding the products of

(a) The RII of each group and

9.1.1 The Contractors

(b) The proportion of the total respondents

A total of 6 questionnaires were sent out to the

various contractors in the building construction

industry of which 2 were returned. Three of these

questionnaires were considered invalid and

therefore rejected on grounds that they were not

adequately completed. This puts the total number

of valid questionnaires at 2, representing 33.33%

of total number of questionnaires sent out.

Weighted average = n1 X RII (1) / N +

n2 X RII (2)/ N + n3 X RII (3) / N + n4

X RII (3) / N +..

Where ;

n1 = No of respondents for contractors

n2 = No of respondents for consultants

9.1.2 The Consultants

n3 = No of respondents for owners

Out of a total of 7 questionnaires sent out to the

consultants , about 5 questionnaires were received

and considered valid for analysis. Thus the total

survey response comes to 71.42 %from

consultants which served the highest contribution

for the analysis.

n4 = No of respondents for site engineers

RII = Relative importance index for

contractors

RII = Relative importance index for

consultants

9.1.3 The Owners

A total of 6 questionnaires were sent out to the

various Owners in the building construction

industry of which 4 were returned. This represents

a total 66.66% of total number of questionnaires

sent out. This served the second highest

contribution for the analysis.

RII = Relative importance index for

owners

RII = Relative importance index for site

engineers.

9. SURVEY RESULTS, ANALYSIS AND

DISCUSSION

9.1.4 Site engineers

Out of a total of 6 questionnaires sent out to the

consultants , only 2 questionnaires were received

A total of 25 questionnaires were sent to a

selected sample of respondents in the construction

92

International Journal On Engineering Technology and Sciences IJETS

ISSN (P): 2349-3968, ISSN (O): 2349-3976

Volume 2 - Issue 5, May 2015

and considered valid for analysis. Thus, the total

survey response comes to 33.33% from site

engineers.

Only owner had an experience of 21 to 30

years .

This was an important question raised to

the respondents and their responses were as

follows

9 out of 13 responded that lack of safety

knowledge was an important factor for the

accidents happening in the construction site .

8 respondents reported that careless

workers attitude is the main reason .

4 of them found out the reason to be lack

of legislation.

9.1.5 Insurance firms

Few questionnaires were sent out to the Insurance

fraternity. Out of which no firms responded . The

reason was found to be genuine as they said they

couldnt reveal the number or cause of the

accident claims. But they contributed to this

survey by giving data about important risk factors

in the construction industry and the commonly

used insurance policies in this sector.

Question was raised about the experience of the

respondents in years . The response was as

follows 2 respondents each with experience of less than 1

year , 3 years and between 5 -10 years were

there.

1 respondent had experience of 5 years.

There were 6 respondents who had experience of

more than 10 years .

Contractors 2 respondents had an experience of

more than 10 years .

Consultants 2 respondents had experience of

less than 1 year , 1 respondent with 3 years

and between 5 to 10 years and 1 with more

than 10 years of experience in the

construction industry.

Owners 1 respondent with experience of 5 to 10

years and 3 respondents had experience of

more than 10 years.

Site engineers 1 respondents each with 3 and 5

years of experience.

3 respondents each were of the opinion that

management carelessness and carelessness of the

consulting are the reasons for construction

accidents.

Certain

factors or faults from the

management part can lead to accidents on site

, they are as follows7 respondents found that reason to be lack of

employing a safety officer and lack of safety

training.

While 2 responded that the reason is due to

lack of a safety policy.

Only 1 responded that the reason is due to lack of

a safety motivation.

Apart from the management reasons,

certain faults from workers can also lead to

accidents

10 out of 13 respondents found the reason

to be lack of training.

8 of them said that accidents occur due to

lack of safety culture.

While 4 of them said that it can happen

due to lack of experience in using equipment.

Only 2 among 13 said that the reason is

found to be lack of safety motivation.

7 out of 13 said that the workers on site

are responsible for industrial accidents.

While 5 of them said that contractors are

responsible for accidents during construction

on site,

The number of projects executed by the various

groups in the construction industry in the last five

years 6 respondents executed less than 10 number of

projects.

5 respondents handled 11- 20 projects .

1 each respondents handled 21 to 30 projects

and more than 30 .

Only 1 consultant had an experience of more

than 30 years.

1 contractor, 3 consultants and

2 site

engineers have an experience of less than 10

years.

1 contractor , 1 consultant and 3 owners had an

experience of 11 to 20 years.

93

International Journal On Engineering Technology and Sciences IJETS

ISSN (P): 2349-3968, ISSN (O): 2349-3976

Volume 2 - Issue 5, May 2015

1 each responded that government and

owners are responsible for this act.

Whereas, 3 out of 13 responded that all

people mentioned above are responsible for

this act and it does not belong to a single

individuals fault.

4 responded that the cost for safety

considerations can be 0.5 % - 1%.

While 3 each responded it can be less

than 0.5 % and between 1% - 2%.

Only 1 responded telling that it can be

between 2% to 3 %.

2 respondents were of the opinion From

the above table it is clear that first aid bag and

emergency telephone numbers are the only

essentials found in a work site .

Hard hats and safety footwear are used

sometimes in the site depending on the work

undertaken.

Least importance is given to eye

protection and fire protection that it can go

beyond 3 %.

Question was raised about the regularity

of safety meetings during the execution of

projects

Majority conducted safety meetings

depending on the nature of accidents.ie; 5

respondents.

3 of them organised monthly meetings.

1 each of the respondents organised

meetings weekly and only after an accident.

Rank 1 - Lack of employing a safety officer

Rank 2 - Careless workers attitude

Rank 3 - Lack of safety motivation

Rank 4 - Lack of safety policy

Major reasons that the workers are

short of Rank 1 - Lack of training

Rank 2 - Lack of safety culture

Rank 3 lack of experience in using

equipment

Rank 4 - Lack of safety motivation

People responsible for industrial

accidentsRank 1 Workers

Rank 2 Contractors

Rank 3 All

Rank 4 - Government

Rank 5 Owners

Suggested expense in implementing

safety expensesRank 1 0.5%-1%

Rank 2 Less than 0.5%

Rank 3 1%-2%

Rank 4 2%-3%

Rank 5 - More than 3%

Below are the results of various questions that

were included in the questionnaire. Here are the

ranks allotted for various factors by majority of

the construction players

Major reasons that the management is

short of

Regularity of safety meetings

Rank 1 Depending on the nature of accident

Rank 2 Monthly

Rank 3 Other

Degree of injury

Rank 1 - light injury

Rank 2 - partial injury

Reason for high accident rates

Rank 4 - Weekly

Rank 5 After an accident

Rank 1 - Lack of safety

Rank 2 - Careless workers attitude

Rank 3 - Lack of legislation

Rank 4 - Management carelessness

Rank 5 - Carelessness of the consulting

10. FUTURE RESEARCH

Construction insurance plays an important role in

transferring risks in the construction industry.

Future research can focus on the issues of motives

for construction insurance purchase, special risk

94

International Journal On Engineering Technology and Sciences IJETS

ISSN (P): 2349-3968, ISSN (O): 2349-3976

Volume 2 - Issue 5, May 2015

8.Godwin I, I, (2011), Effect of Mechanisation on

Occupational Health and Safety performance in the

Nigerian construction industry, Journal of Construction

in Developing Countries, (2011).

considerations, changing environment, interaction

to risk management, and alternative risk transfer

solutions. They will contribute a better

understanding for both industries, i.e. the

insurance industry and especially the construction

industry because the changing business

environment needs the construction industry to

improve its ability to manage construction risks.

9.Hassouna,M,A,(2005)

Improving

Safety

Performance In Construction Projects In Gaza Strip

Thesis (98),(2005).

10.Huang,X.,& Fang,D.,(2003),Construction

Training and Education in china IEJC,China.

Safety management in the construction industry is

also an important factor to be considered . In this

survey, details have been collected and analysed

from various construction groups . This could

help to provide an awareness to various groups

regarding how much safety measures are being

practised in the industry. This clearly shows that

construction safety and construction insurance are

interlinked which together can help in mitigating

the risk involved in this sector

Safety

11.Hassanein and Ragaa S, H, (2007), Safety Programs

in Large Size Construction Firms Opertaing in

EgyptJounal of SH&E Resarch(2007), Vol.4, Num1.

12.Jannadi,M.,Assaf,S.,(1998),Safety Assessment In

The Built Environment of Saudi Arabia,Safety Science

29 (1998)15-24.

REFERENCES

1.Ajay singh and Krish .H (2008),Critical success

factors influencing safety program performance in

construction projects, Saftey Science,Volume

46,pp 709-727(2008).

2.Aksorn

,T,&

Bonaventura,(2009),Measuring

effectiveness of Safety programmers in Thailand

Construction industry,25 November,(2009).

3. Abdul Rahim A, H, Muhd, Z, Abd Majid, B, S,

(2008), Malaysian journal of Civil Engineering

20(2):242-259(2008).

4. D.P.Fang, F.Xiea, X.Y. Huang ,H.Lic,(2004),Factor

Analysis-Based Studies on Construction Workplace

Safety Management in China, international Journal of

projects Management 22 (2004)43-49.

5.Dingsdag,D.P.,Biggs,H.C.and

Sheahan,V.L.(2008),Understanding

and

defining

OH&S

competency for construction site position:Worker

perceptions,Saftey Science ,Volume 46,pp(2008) 619633.

6.Enshassi,A,Peter, E, Mohamed ,S,and EL-Masri,F

(2007),The

International

Journal

Constriction

Management (2007) 41-51.

7.Farooqi R.U.,(2008), Safety Performance In

Construction Industry of Pakistan, first International

Conference on Construction Education ,Research&

Practice August 4-5,(2008),Karachi, Pakistan.

95

You might also like

- 3 Working Safely With MachinesDocument20 pages3 Working Safely With MachinesNasir Mehmood AryaniNo ratings yet

- Standard Normal Cumulative Probability TableDocument2 pagesStandard Normal Cumulative Probability TableNasir Mehmood AryaniNo ratings yet

- TI30XIIS Guidebook PDFDocument5 pagesTI30XIIS Guidebook PDFNasir Mehmood AryaniNo ratings yet

- OSHA Scaffold RegulationDocument1 pageOSHA Scaffold RegulationNasir Mehmood AryaniNo ratings yet

- Train The Trainer Manual 2Document48 pagesTrain The Trainer Manual 2Khoso AijazNo ratings yet

- Hot Work SafetyDocument3 pagesHot Work SafetyNasir Mehmood Aryani100% (1)

- Using Q Methodology To Explore College Students ConceptualizatioDocument145 pagesUsing Q Methodology To Explore College Students ConceptualizatioNasir Mehmood AryaniNo ratings yet

- What Is Hypothesis TestingDocument32 pagesWhat Is Hypothesis TestingNasir Mehmood AryaniNo ratings yet

- General Requirements. - 1926Document14 pagesGeneral Requirements. - 1926Nasir Mehmood AryaniNo ratings yet

- General Requirements. - 1926Document14 pagesGeneral Requirements. - 1926Nasir Mehmood AryaniNo ratings yet

- The Inevitable Organizational Politics'Document7 pagesThe Inevitable Organizational Politics'IAEME PublicationNo ratings yet

- Basic Electrical SafetyDocument64 pagesBasic Electrical Safetydaltongifty100% (3)

- Definition of Hazard and RiskDocument1 pageDefinition of Hazard and RiskNasir Mehmood AryaniNo ratings yet

- UWSup GHS Haz Com Label Poster2013 PDFDocument1 pageUWSup GHS Haz Com Label Poster2013 PDFNasir Mehmood AryaniNo ratings yet

- Crane Safety V0911.1Document1 pageCrane Safety V0911.1Nasir Mehmood AryaniNo ratings yet

- TheoryDocument2 pagesTheoryNasir Mehmood AryaniNo ratings yet

- Fire and Life Safety Evacuation OSHADocument31 pagesFire and Life Safety Evacuation OSHAWaseem SiddiqueNo ratings yet

- Risk Assessment FormDocument1 pageRisk Assessment FormNasir Mehmood AryaniNo ratings yet

- Refunds Policy v2 041010510201031035Document7 pagesRefunds Policy v2 041010510201031035Nasir Mehmood AryaniNo ratings yet

- Kaia ImageDocument9 pagesKaia ImageNasir Mehmood AryaniNo ratings yet

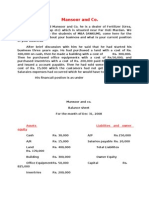

- Mansoor and CoDocument2 pagesMansoor and CoNasir Mehmood AryaniNo ratings yet

- ID July 08 Syllabus Summary 080109912009121546Document22 pagesID July 08 Syllabus Summary 080109912009121546Nasir Mehmood AryaniNo ratings yet

- Working Capital NasirDocument2 pagesWorking Capital NasirNasir Mehmood AryaniNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 3.3 Kantian Theory - Kantian Ethics TheoryDocument14 pages3.3 Kantian Theory - Kantian Ethics TheoryAbdulwhhab Al-ShehriNo ratings yet

- Cover Letter For Apprenticeship ApplicationDocument6 pagesCover Letter For Apprenticeship Applicationbdg8b37x100% (2)

- (1996) 2 CLJ 49 Set Out The Four Conditions As FollowsDocument3 pages(1996) 2 CLJ 49 Set Out The Four Conditions As FollowsevasopheaNo ratings yet

- Improve Workplace Safety with Committees and MeetingsDocument6 pagesImprove Workplace Safety with Committees and MeetingsOws AnishNo ratings yet

- Minsola vs. New CityDocument12 pagesMinsola vs. New CityruelNo ratings yet

- Components of Total CompensationDocument43 pagesComponents of Total Compensationsanathchamp100% (1)

- 95051060-BRC-Food6-Checklist GDFGDocument27 pages95051060-BRC-Food6-Checklist GDFGAsep RNo ratings yet

- Dessler hrm16 PPT 05 3Document38 pagesDessler hrm16 PPT 05 3Janice KeeNo ratings yet

- MWC-East Zone Union vs. Manila WaterDocument3 pagesMWC-East Zone Union vs. Manila WaterDO SOLNo ratings yet

- Stress Management PolicyDocument12 pagesStress Management PolicyBAla100% (1)

- Adkar ModelDocument6 pagesAdkar ModelDRUVA KIRANNo ratings yet

- Energized Electrical PermitDocument3 pagesEnergized Electrical PermitMohd AzharNo ratings yet

- YAS Clinic Group Employee Clearance FormDocument1 pageYAS Clinic Group Employee Clearance FormMahra AlMazroueiNo ratings yet

- Performance Review FormDocument12 pagesPerformance Review FormTarannum Yogesh DobriyalNo ratings yet

- 24-7 Intouch India Private LimitedDocument1 page24-7 Intouch India Private LimitedMohammed JunaidNo ratings yet

- Research ArticleDocument7 pagesResearch Articleayushir654No ratings yet

- Economics of Minimum WageDocument20 pagesEconomics of Minimum WagePranav Tirunagiri100% (1)

- Sample Records Request LetterDocument1 pageSample Records Request LetterFermin James ErosidoNo ratings yet

- Seasonal UnemploymentDocument1 pageSeasonal UnemploymentOana PuiuNo ratings yet

- QuestionnaireDocument4 pagesQuestionnaireSharadha Devi100% (1)

- Performance Measures QuestionsDocument7 pagesPerformance Measures QuestionsMohammad EssamNo ratings yet

- DR HANS Human Resource Planning - 1-2 ModulesDocument70 pagesDR HANS Human Resource Planning - 1-2 ModulesAakash KrNo ratings yet

- Starbucks Ethical CoffeeDocument4 pagesStarbucks Ethical CoffeerynmodulationNo ratings yet

- LinkedinDocument11 pagesLinkedinChitra SingarajuNo ratings yet

- PRINCIPLES OF MANAGEMENTDocument1 pagePRINCIPLES OF MANAGEMENTJothiEeshwarNo ratings yet

- INATEK Student Guide eBookDocument44 pagesINATEK Student Guide eBooksun9kyuNo ratings yet

- Education Act of 1982 key provisionsDocument88 pagesEducation Act of 1982 key provisionsRiza Mae Bayo100% (3)

- BCR CompilerDocument171 pagesBCR Compilershethdipati2No ratings yet

- Strategy Mapping ToolDocument15 pagesStrategy Mapping ToolXuan Hung100% (2)

- Shouldice Hospital - A Case StudyDocument44 pagesShouldice Hospital - A Case StudyPimkhwan_Bunji_2272100% (1)