Professional Documents

Culture Documents

No.29 MMC Standard-Zinc Electroplating Standard. MS82-3701

Uploaded by

Alejandro TiqueCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

No.29 MMC Standard-Zinc Electroplating Standard. MS82-3701

Uploaded by

Alejandro TiqueCopyright:

Available Formats

MMC STANDARD

SCOPE

CLASSIF1CATI0N :

Engineering

STANDARES NO.:

O F APPUCATION:

Standard

MS 82-3701

(Rev. 5)

CORPORATE - WIDE

TITLE:

BY:Technical

A d m i n i s t r a t i o n Dept.

ISSUED

ZINC ELECTROPLATING STANDARD

{estuoso)

Scope

This standard s p e c i f i e s the e l e c t r o p l a t e d c o a t i n g of z i n c ( h e r e i n a f t e r

c a l l e d " p l a t i n g " ) a p p l i e d to b a s i s metis o f automobile parts ( h e r e i n a f t e r c a l l e d " p a r t s " ) c h i e f l y f o r the purpose of preventing corrosin

or r u s t and of ornament.

D e f i n i t i o n of Terms

The terms i n t h i s standard are defined as f o l l o w s .

The other terms

s h a l l conform to the d e f i n i t i o n i n J I S H 0400 (Glossary of Terms Used

in Electroplating).

(1) B r i g h t Chromate Treatment

The chromate treatment

produces corrosin p r e v e n t i v e coatings on

z i n c and at the same time e x e r c i s e s chemical p o l i s h i n g .

chromate treatment

Bright

i s imtended f o r g i v i n g b r i g h t n e s s to the p l a t i n g

making use of the chemiaal p o l i s h i n g .

There are two methods; one

by use of chromate treatmet s o l u t i o n that mainly gives chemical

p o l i s h i n g w h i l e contrlling the formation of corrosin preventive

c o a t i n g and another by se of a l k a l i n e s o l u t i o n , a f t e r

forming

corrosin preventive cating, t o o b t a i n the b r i g h t f i n i d h .

(2) Color Chromate, Greea Chromate, and B l a c k Chromate Treatment

The coatings of chrmate f o r corrosin p r e v e n t i o n are t h i c k and

colored.

Therefore te corrosin p r e v e n t i v e coatings are c a l l e d

" c o l o r chromate".

Tke c o l o r tone v a r i e s w i t h the composition

percentage of chrmium chromates ( x C r 0 - y C r 0 z H 0 ) that i s the

2

main component the c o a t i n g ; green c o l o r tone i s c a l l e d "green

chromate" and blak c o l o r tone i s c a l l e d "black chromate'.'., .

- ->v?>,

(3) I n t e r f e r e n c e Frige

In r e l a t i v e l y t h i n chrmate c o a t i n g s , t r a n s p a f e h t a n d . i n y i s i b l e Vt h i n coatings smetimes remain on the p l a t i n g W

l i g h t s t r i k e s n t h i s s u r f a c e , the r e f l e c t e d

Mo.

>

When the wnite ,-._/

49'

the coating.'

and the p l a t i m g surface, i n t e r f e r i n g w i t h each o t * ^ y ^ s m > ^ ^ \ r a i n b owEFTECnVE:

ESTABUSHMENT:

R

E

V

I

I

0

N

REV. 1

REY 2

REV. 3

REV.

REV S

June 20 ,'84

Feb. 13 '68

REFERENCE

Mar. 20 ,'69

Apr. 2 ,'70

Mar. 22 ,'76

9 ,'84

Feb.

June 20 .'84

ENCLOSURES

JIS H 8610.

JIS D 0201

JIS Z 2248

ORIGINAL

FILED

AT :

Technical Administra

t i o n Deot.

APPROVALl

MS 82-3701

MMC STANDARD

l i k e color.

REV.

2

/7

The f r i n g e pattern caused by t h i s phenomenon i s c a l l e d

"interference fringe".

(4) Dispersin of Surface Color

The c o l o r tone of c o l o r chromate v a r i e s w i t h the composition of

coating.

The composition of coating i s l i a b l e " t o vary depending

upon the composition of chromate treatment bath and the operating

conditions.

Therefore, even i n a l o t of one p a r t , color tone,

d i f f e r e n c e w i l l p o s s i b l y happen i n i n d i v i d u a l p a r t s and even on

one surface i t i s d i f f i c u l t to o b t a i n uniform c o l o r tone and leading

to uneven c o l o r .

(5) White Corrosin Product

The corrosin products of zinc c o s i s t s , i n most cases, of white

chemical compounds such as basic z i n c carbonate and so on.

Such

c o r r o s i v e products (zinc r u s t ) are produced when the chromate

coatings are destroyed and z i n c i s exposed to c o r r o s i v e enviromnent.

Class

and Symbol

P l a t i n g s s h a l l be d i v i d e d i n t o 19 groups w i t h i t s symbol as shown i n

Table 1.

TABLE

^lass

Symbol

Location

Applicable

Parts

Screws, washers, small

cases, e t c .

Chiefly i n interior requiring for

identification.

MFZn5-B

C h i e f l y i n i n t e r i o r r e q u i r i n g f o r ] Screws, washers, small

beauty and i d e n t i f i c a t i o n .

i cases, e t c .

MFZn8-B

Chiefly i n interior requiring for

beauty.

MFZnl3-B

C h i e f l y i n s i d e of p a r t s , mounted Case, r e t a i n e r , lamp body,

i n e x t e r i o r , r e q u i r i n g f o r b r i g h t - j general s t r u c t u r a l p a r t s ,

mechanical f u n c t i o n p a r t s .

ness.

MFZn3-C

C h i e f l y i n i n t e r i o r r e q u i r i n g f o r Screws, washers, small

identification.

i shafts.

MFZn5-C

Chiefly i n interior requiring for

corrosin r e s i s t a n c e .

MFZn8-C

Case, r e t a i n e r , lamp body,

C h i e f l y i n i n t e r i o r and i n s i d e of

general s t r u c t u r a l p a r t s ,

p a r t s , mounted i n e x t e r i o r , r e q u i r - mechanical function p a r t s ,

ing f o r corrosin r e s i s t a n c e .

brake pipe.

0)

Applicable

SYMBOL

MFZn3-B

X

en

Kt

Screws, washers, small

cases, e t c .

Screws, washers, small

s h a f t s , grease n i p p l e s ,

s m a l l cases, general

s t r u c t u r a l parts.

(continued)

MMC STANDARD

/

/

Class

Symbol

Applicable

(continued)

Locatlon

Applicable

Parts

MFZnl3-C

Chiefly i n exterior especially

r e q u i r i n g f o r corrosin r e s i s t a n c e .

Case, r e t a i n e r , lamp body,

general s t r u c t u r a l p a r t s ,

mechanical function p a r t s ,

i n s t a l l i n g parts.

MFZn25-C

Chiefly i n exterior requiring for

s p e c i a l corrosin prevention.

Brake tubes, e t c . ,

MFZn5-G

C h i e f l y i n i n t e r i o r of green.

Screws, washers, e t c .

MFZn8-G

C h i e f l y i n i n t e r i o r and i n s i d e of

p a r t s , mounted i n e x t e r i o r , green

and r e q u i r i n g f o r corrosin r e sistance.

Screws, washers, small

s h a f t s , cases, r e t a i n e r ,

lamp body, general s t r u c t u r a l p a r t s , mechanical

function parts, i n s t a l l i n g

parts.

MFZnl3-G

C h i e f l y i n e x t e r i o r , green and

especially requiring for corrotion

resistance.

Case, r e t a i n e r , lamp body,

general s t r u c t u r a l p a r t s ,

i n s t a l l i n g p a r t s , mechanic a l function parts.

MFZn5-K

Chiefly i n interior requiring f o r

b l a c k i n respect of s t y l i n g .

Screws, washers, e t c .

J)

MFZn8-K

C h i e f l y i n i n t e r i o r and i n s i d e of

p a r t s , mounted i e x t e r i o r , r e q u i r i n g f o r black i n respect of

s t y l i n g and f o r corrosin r e s i s t ance.

Screws, washers, samll

s h a f t s , case, r e t a i n e r ,

lamp body, general s t r u c t u r a l p a r t s , mechanical

function parts, i n s t a l l i n g

parts.

MFZnl3-K

Chiefly i n exterior requiring f o r

b l a c k i n respect of s t y l i n g and

e s p e c i a l l y f o r corrosin r e s i s t ance.

Case, r e t a i n e r , lamp body,

general s t r u c t u r a l p a r t s ,

i n s t a l l i n g p a r t s , mechani c a l f u n c t i o n parts.

MFZnl3

Chiefly i n interior specifically

not subjected to chromate t r e a t ment i n respect of s t y l i n g , e t c .

Case, r e t a i n e r , lamp body,

i n s t a l l i n g p a r t s , general

s t r u c t u r a l p a r t s , mechanic a l f u n c t i o n parts.

MFZn20

Chiefly i n exterior s p e c i f i c a l l y

not subjected to chromate t r e a t ment i n respect of s t y l i n g , e t c .

Case, r e t a i n e r , lamp body,

i n s t a l l i n g p a r t s , general

s t r u c t u r a l p a r t s , mechanic a l function parts.

MBZn2

C h i e f l y i n i n t e r i o r and e x t e r i o r

not r e q u i r i n g f o r beauty. .

Screws, small machine

parts.

MBZn2-B

C h i e f l y i n i n t e r i o r and e x t e r i o r

not r e q u i r i n g f o r beauty.

Screws, small machine

parts.

MS 82-3701

Kt.V.

MIC STANDARD

Remarks:

1. At the end of symbols, B means " b r i g h t chromate treatment", C means

" c o l o r chromate treatment", G means "green chromate treatment"

(commonly c a l l e d " o l i v e drab treatment"), and K means "black chromate

treatment".

2. I n t e r i o r i s intended f o r l o c a t i o n s i n s i d e the carbody and not subj e c t to r a i n d i r e c t l y or i n d i r e c t l y .

3. E x t e r i o r i s intended f o r l o c a t i o n s other than i n t e r i o r .

However,

a l o c a t i o n , though w i t h i n i n t e r i o r , subject p a r t i a l l y to weathering

s h a l l be considered as e x t e r i o r .

Quality

4.1

...

Appearance

P l a t i n g i n appearance s h a l l be smooth and f r e e from burning, b l i s t e r ,

bare b a s i s metis, and other d e f e c t s t h a t might a f f e c t s e r v i c e a bility.

For b r i g h t chromate and c o l o r chromate treatments the i n t e r -

ference f r i n g e or dispersin of c o l o r on the s u r f a c e s h a l l be acceptable.

However, f o r green chromate and b l a c k chromate treatments,

uneven c o l o r s h a l

not be permitted.

Note ( 1 ) : Defects of b a s i s metis, though not recognized by normal

methods, sometimes appear, a f t e r p l a t i n g , as i f . t h e y were

plating defects.

4.2

Thickness

P l a t i n g thickness s h a l l conform to Table 2.

The thickness means the

minimum p l a t i n g t h i c k n e s s except that of chromate treatment c o a t i n g .

TABLE 2

Symbol

MINIMUM PLATING THICKNESS

Minimum P l a t i n g Thickness (pm)

MFZn3

MFZn5

MFZn8

MFZnl3

13

MFZn20

20

MFZn25

25

MBZn2

Test Method

Paragraph

5.2

LjMC

na

STANDARD

4.3

O-J/U

Corrosin Resistance

Conduct s a l t spray t e s t i n accordance w i t h 5.3.

White corrosin or

red r u s t s h a l l not form before the time s p e c i f i e d i n Table 3.

TABLE 3

Symbol

SALT SPRAY TIME REQUIREMENT

Time f o r White Corrosin

Time f o r Red Rust

(Iron Rust)

MFZn3-B

4.4

MFZn5-B

56

MFZn8-B

96

MFZnl3-B

144

MFZn3-C

72

MFZn5-C

72

132

MFZn8-C

72

152

MFZnl3-C

72

192

MTZn25-C

72

400

MFZn5-G

72

132

MFZn'8-G

72

152

MFZnl3-G

72

192

MFZn5-K

72

132

MFZn8-K

72

152

MFZnl3-K

72

192

MFZnl3

96

MTZn20

152

Removal of Hydrogen Embrittlement

(1) S t e e l products, f o r example b o l t s , screws, s p r i n g washers, spring

c l i p s , p i n s , and other mechanical f u n c t i o n p a r t s or equivalent,

which are heat treated to hardness HRC 35 min by quenching and

tempering, s h a l l be subjected to removal of.hydrogen embrittlement

as a r u l e w i t h i n 8 hr a f t e r p l a t i n g .

"*

The operating c o n d i t i o n s h a l l be as f o l l o w s :

Heating Temperature: 190 5C

Time

: 3 hr min

: '

MMC

STANDARD

(2) When removal of hydrogen embrittlement and chromate treatment

are r e q u i r e d , a f t e r removal of hydrogen embrittlement conduct

a c t i v a t i o n treatment and then chromate treatment.

(Remarles) The c o n d i t i o n s of a c t i v a t i o n treatment are given f o r

reference as f o l l o w s .

Treatment

solution:

N i t r i c a c i d 0.5 to 2.0 1 (by volume) or s u l f u r i c a c i d

1.0 to 2.0 Z (by volume).

' Temperature

4.5

: Room temperature

Inmersin time

: 5 to 10 sec

Rinse

: S u f f i c i e n t l y r i n s e by fresh water.

Bending

When p a r t i c u l a r l y s p e c i f i e d , conduct bend t e s t i n accordance w i t h

5.4.

5.

P l a t i n g s h a l l be free from p e e l i n g .

Methods of Test

5.1

Surface P r e p a r a t i o n of Test

(2)

Test specimens

s h a l l be degreased and cleaned on the surface

using a s u i t a b l e s o l v e n t .

F u r t h e r , f o r t h i c k n e s s t e s t , the chromate

coating i n the t e s t l o c a t i o n s h a l l be removed immediately before

t e s t by a s u i t a b l e method of rubbing w i t h paste of magnesium oxide

or p r e c i p i t a t e d calcium carbonate.

The

t e s t specimen s h a l l then

be r i n s e d and allowed to dry.

Note ( 2 ) : P a i n t coatings and so f o r t h , i f so a p p l i e d , s h a l l be

p e r f e c t l y removed before t e s t .

5.2

P l a t i n g Thickness Test

Use microscopio t e s t , as a r u l e , f o r t h i c k n e s s t e s t .

E i t h e r of

magnetic t e s t , coulometric t e s t , and dropping t e s t may be used under

agreement between the p a r t i e s .

5.2.1 Microscopic Thickness Test

Prepare a cross s e c t i o n perpendicular to the p l a t i n g surface to be

(3)

measured,

Polish

the cross s e c t i o n and measure the p l a t i n g

thickness by a microscope.

In order to make the boundary of

(4)

the p l a t i n g l a y e r easy to see, i t i s recommended to etch

adequately f o r o b s e r v a t i o n .

Note ( 3 ) : Sag of p l a t i n g layer makes l a r g e e r r o r s i n measurement,

therefore i t i s recommended to s e f ' t h e t e s t specimen i n t o

a support block or plstic f o r p o l i s h i n g .

(A): Use a chromate treatment s o l u t i o n of adequate concentrat i o n or a s o l u t i o n of 95 m water and 5 m concentrated

hydrochloric acid.

1 A I I U A R U

5.2.2 Magnetic Thickness Test

Use a magnetic t h i c k n e s s t e s t e r c a l i b r a t e d by standard test s p e c i mens of known p l a t i n g thickness.

Measurement s h a l l be conducted

at l e a s t three times per one l o c a t i o n on the s i g n i f i c a n t surface.

The average s h a l l be considered as the r e s u l t .

5.2.3 Coulometric Thickness Test

Measure i n accordance w i t h Appendix 1 to JIS H 8610

(Electroplated

Coatings of Zinc on Iron and S t e e l ) .

5.2.4 Dropping Test

Measure i n accordance w i t h Appendix 2 to J I S H 8610.

5.3

S a l t Spray Test

Conduct t e s t i n accordance w i t h Appendix 3 to J I S H 8610.

Use t e s t specimens at l e a s t 24 hr a f t e r chromate treatment.

5.4

Bend Test

Bend a t e s t specimen 25 mm wide, 100 mm l o n g , 1.0 mm t h i c k through

an angle of 180 i n accordance w i t h JIS Z 2248 (Method of Bend Test

for M e t a l l i c Materials).

Designation

(1) P l a t i n g s s h a l l be designated w i t h the symbols i n Table 1 as follows

Example: MFZn8-B

(2) Removal of hydrogen embrittlement, i f so r e q u i r e d , s h a l l be

designated w i t h "-H" f o l l o w i n g the end of symbols as shown above.

Example: MFZn8-B-H

'

'

You might also like

- WV - TL245Document9 pagesWV - TL245Juan José Viñas MéndezNo ratings yet

- Harmonized "Cluster" Document: For Electrical Connectors Conductive Plated CoatingsDocument22 pagesHarmonized "Cluster" Document: For Electrical Connectors Conductive Plated CoatingsFrederico CésarNo ratings yet

- Material Specifications: Zinc Plating 1. ScopeDocument12 pagesMaterial Specifications: Zinc Plating 1. ScopeHaroldo Hubner NetoNo ratings yet

- Hes D2003 05 Rev6Document15 pagesHes D2003 05 Rev6FABRICIO100% (1)

- WSS M1P87 BXDocument6 pagesWSS M1P87 BXShu Fu100% (1)

- GMW16215Document7 pagesGMW16215JOECOOL67100% (1)

- TM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)Document5 pagesTM-0028M-F (Property Requirements of Internally-Threaded Fasteners, Steel)方綵樺No ratings yet

- Engineering Material SpecificationDocument10 pagesEngineering Material SpecificationMike FiorenNo ratings yet

- WX100 Fastener Finish Speecification PDFDocument16 pagesWX100 Fastener Finish Speecification PDFJulion2009No ratings yet

- TSH7702GDocument8 pagesTSH7702GEmir AkçayNo ratings yet

- Plating Specification ListDocument11 pagesPlating Specification Listsursh60% (5)

- Jis B0209 1997Document13 pagesJis B0209 1997fatimahNo ratings yet

- N67F CM-ZN-2 - 5001.110.016 - NormDocument22 pagesN67F CM-ZN-2 - 5001.110.016 - Normgokul100% (1)

- GMW 8-2008Document9 pagesGMW 8-2008Clauco Tiago Seno RoqueNo ratings yet

- GM Approved Finishers - ApplicatorsDocument3 pagesGM Approved Finishers - ApplicatorsScott Kramer0% (1)

- Danh Sách Tiêu Chuẩn YgkDocument2 pagesDanh Sách Tiêu Chuẩn YgkanhthoNo ratings yet

- TSZ2207G: Toyota Engineering StandardDocument6 pagesTSZ2207G: Toyota Engineering StandardGuilherme DurãesNo ratings yet

- DIN 9830 Burr Heights On Stamped PartsDocument6 pagesDIN 9830 Burr Heights On Stamped Partssumit_saraf_5100% (2)

- Jed-739 008 GDocument5 pagesJed-739 008 GPaulo Henrique NascimentoNo ratings yet

- JIS Steel Wires StandardDocument7 pagesJIS Steel Wires StandardPS NguyễnNo ratings yet

- Hes B008-03 Hexagon NutsDocument5 pagesHes B008-03 Hexagon NutsPreetam KumarNo ratings yet

- HONDA D2021 E Coating SpecificationDocument5 pagesHONDA D2021 E Coating SpecificationDavid Martínez100% (1)

- Standard VCS 5737,: Volvo Car CorporationDocument9 pagesStandard VCS 5737,: Volvo Car CorporationWei Yue ZhuanNo ratings yet

- Ford Worldwide Fastener Standard: Printed Copies Are UncontrolledDocument7 pagesFord Worldwide Fastener Standard: Printed Copies Are Uncontrolledferhat aydoganNo ratings yet

- General Dimensional Tolerance For Parts Formed by Press Working From Sheet MetalDocument2 pagesGeneral Dimensional Tolerance For Parts Formed by Press Working From Sheet MetalRicardo F.A.100% (3)

- Jed-257 008 en LDocument4 pagesJed-257 008 en LcroplaninecNo ratings yet

- FORD WX200 Rev2014Document4 pagesFORD WX200 Rev2014Amandeep SinghNo ratings yet

- E M5083 2016-NDocument7 pagesE M5083 2016-NPongsan57% (7)

- TL245 English 2004Document8 pagesTL245 English 2004Elliott RussellNo ratings yet

- JDV 21Document15 pagesJDV 21Juan Cogolludo100% (2)

- NES M 2020 2009-N Cold Rolled C & Steel & StripsDocument13 pagesNES M 2020 2009-N Cold Rolled C & Steel & Stripssalvador hernandezNo ratings yet

- Geomet 321Document2 pagesGeomet 321Satnam Rachna FastenersNo ratings yet

- JDM F17 Pintura IJDDocument14 pagesJDM F17 Pintura IJDcharssx100% (1)

- WX 100Document17 pagesWX 100anon_967426204100% (1)

- Jdma17 2Document8 pagesJdma17 2qualidadesider0% (1)

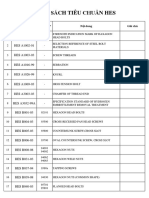

- Danh Sách Tiêu Chuẩn HesDocument2 pagesDanh Sách Tiêu Chuẩn HesanhthoNo ratings yet

- EN1A - Mild SteelDocument2 pagesEN1A - Mild SteelSuyash TambeNo ratings yet

- Din 50942-96Document13 pagesDin 50942-96RONALD100% (2)

- GMW - 4707-2002 Corrosion Protective Coating Zinc Plating OrganicDocument3 pagesGMW - 4707-2002 Corrosion Protective Coating Zinc Plating Organichorse888No ratings yet

- Sae J496 1972 (En)Document5 pagesSae J496 1972 (En)Oh No PotatoNo ratings yet

- Hes d2003 05 - Galvanoplastia (Para A Corrosão Prevenção, A OxidaçãoDocument14 pagesHes d2003 05 - Galvanoplastia (Para A Corrosão Prevenção, A Oxidaçãohkatzer100% (1)

- Fiat 9.57409 - 2007-04 - ZINC - NICKEL ALLOY ELECTROLYTICDocument13 pagesFiat 9.57409 - 2007-04 - ZINC - NICKEL ALLOY ELECTROLYTICMiguel QueirosNo ratings yet

- DIN 1681 Chemical CompositionDocument12 pagesDIN 1681 Chemical CompositionAshish Kesharwani100% (1)

- Ford Wa950Document2 pagesFord Wa950amanNo ratings yet

- TSB1503G 9 P 1Document18 pagesTSB1503G 9 P 1kk_pammu_915176926No ratings yet

- Zinc Electroplated Coatings: Process Standard Page: 1/22Document22 pagesZinc Electroplated Coatings: Process Standard Page: 1/22IBRNo ratings yet

- Mat1140 PDFDocument4 pagesMat1140 PDFGustavo C. FerreiraNo ratings yet

- Zinc Flake Vs Zinc-Nickel ComparisonDocument7 pagesZinc Flake Vs Zinc-Nickel ComparisonSon NguyenNo ratings yet

- Mil L 0046010eDocument21 pagesMil L 0046010eGoogle User100% (1)

- GMW 3044-0405Document5 pagesGMW 3044-0405GilmarasanNo ratings yet

- STD Finish CodesDocument4 pagesSTD Finish CodesEmre TekinNo ratings yet

- 9.57405-Eng - Plating Std.Document20 pages9.57405-Eng - Plating Std.Baravkar Auto Parts100% (1)

- DBL 8451pDocument16 pagesDBL 8451pSimone CorrêaNo ratings yet

- WX100 World Wide Fastener Standard PDFDocument16 pagesWX100 World Wide Fastener Standard PDFRico Malibiran100% (1)

- JDM F20Document8 pagesJDM F20X800XLNo ratings yet

- Phosphor Bronze To Bs 1400: Pb2Document1 pagePhosphor Bronze To Bs 1400: Pb2Santanu Chakraborty100% (1)

- Knotek 1991Document6 pagesKnotek 1991FSNo ratings yet

- 110 Semiconductor Projects for the Home ConstructorFrom Everand110 Semiconductor Projects for the Home ConstructorRating: 4 out of 5 stars4/5 (1)

- Adobe Scan Apr 11, 2023Document17 pagesAdobe Scan Apr 11, 2023Girish RoyNo ratings yet

- Adobe Scan Apr 11, 2023Document11 pagesAdobe Scan Apr 11, 2023Girish RoyNo ratings yet

- No.8 Federal Specification-Silver Plating, Electrodeposited General Requirements For. QQ-S-365D (Año 2001)Document13 pagesNo.8 Federal Specification-Silver Plating, Electrodeposited General Requirements For. QQ-S-365D (Año 2001)Alejandro TiqueNo ratings yet

- The Application of Wi-Fi RTLS in Automatic WarehouseDocument6 pagesThe Application of Wi-Fi RTLS in Automatic WarehouseAlejandro TiqueNo ratings yet

- Geofencing For Fleet & Freight ManagementDocument4 pagesGeofencing For Fleet & Freight ManagementAlejandro TiqueNo ratings yet

- An Assessment of Location Data Requirements in LogisticsDocument40 pagesAn Assessment of Location Data Requirements in LogisticsAlejandro TiqueNo ratings yet

- 4 Heat TreatmentokDocument22 pages4 Heat TreatmentokPramod AthiyarathuNo ratings yet

- X45NiCrMo4 - 1.2767Document34 pagesX45NiCrMo4 - 1.2767patiltushar79No ratings yet

- Material Technology IInd SemDocument262 pagesMaterial Technology IInd SemvinayakNo ratings yet

- Acero A11Document2 pagesAcero A11Jose LuisNo ratings yet

- A 290 - 95 R99Document4 pagesA 290 - 95 R99GenXY07No ratings yet

- Martensitic-Austenitic Stainless Steel EN 1.4418, QT 900Document2 pagesMartensitic-Austenitic Stainless Steel EN 1.4418, QT 900LebasNo ratings yet

- HeattreatmentDocument21 pagesHeattreatmentroyalmechnoNo ratings yet

- 605m36 SteelDocument2 pages605m36 Steelhimanshudhol25No ratings yet

- Bolting - Selection Guide For Bolting MaterialDocument5 pagesBolting - Selection Guide For Bolting MaterialLatif RadwanNo ratings yet

- 3-Piece Tinplate Aerosol CansDocument38 pages3-Piece Tinplate Aerosol CansGinanjar Wahyu JayaningratNo ratings yet

- ANSI-AGMA 2004-B89-Gear Materials and Heat Treatment ManualDocument79 pagesANSI-AGMA 2004-B89-Gear Materials and Heat Treatment ManualMarcelo Crestani100% (3)

- Heat Treatment ProcessesDocument44 pagesHeat Treatment Processesmesa142No ratings yet

- Standard Test Method For Determination of Reference Temperature, To, For Ferritic Steels in The Transition RangeDocument39 pagesStandard Test Method For Determination of Reference Temperature, To, For Ferritic Steels in The Transition Rangeggsachary100% (2)

- A266A266M-13 Standard Specification For Carbon Steel Forgings For Pressure Vessel ComponentsDocument5 pagesA266A266M-13 Standard Specification For Carbon Steel Forgings For Pressure Vessel ComponentsLorena JimenezNo ratings yet

- ASTM5Document1,227 pagesASTM5Guatavo91No ratings yet

- 42 CR Mo 4Document4 pages42 CR Mo 4kazdanoNo ratings yet

- Uddeholm Pocket Book PDFDocument80 pagesUddeholm Pocket Book PDFPeter NomikosNo ratings yet

- Property Improvement of Subzero/Cryogenic Heat Treated Camshafts Made of 8620H, 16Mncr5 and 100Cr6 SteelsDocument4 pagesProperty Improvement of Subzero/Cryogenic Heat Treated Camshafts Made of 8620H, 16Mncr5 and 100Cr6 SteelsSama UmateNo ratings yet

- Aluminum-Alloy Sand Castings: Standard Specification ForDocument12 pagesAluminum-Alloy Sand Castings: Standard Specification ForOdyzeus PingolNo ratings yet

- Steel Handbook IntroDocument4 pagesSteel Handbook IntroMuhammed Ali PisuwalaNo ratings yet

- Chapter 12 Aluminium and Magnesium Casting Alloys PDFDocument41 pagesChapter 12 Aluminium and Magnesium Casting Alloys PDFDANIEL ALEJANDRO FERNANDEZ GARCIANo ratings yet

- Metal Colouring TechniquesDocument1 pageMetal Colouring TechniquestobiNo ratings yet

- Lathe Machine AssignmentDocument23 pagesLathe Machine AssignmentChristopher Rohrer100% (1)

- On The Changes in The Low Cycle Fatigue Life and Cracking Mechanism of P91 Cross Weld Specimens at Elevated TemperaturesDocument19 pagesOn The Changes in The Low Cycle Fatigue Life and Cracking Mechanism of P91 Cross Weld Specimens at Elevated TemperaturessscNo ratings yet

- International Standard: Iteh Standard Preview (Standards - Iteh.ai)Document9 pagesInternational Standard: Iteh Standard Preview (Standards - Iteh.ai)idanfriNo ratings yet

- Surface Vehicle Recommended Practice: Issued OCT1999Document19 pagesSurface Vehicle Recommended Practice: Issued OCT1999Paco LMNo ratings yet

- Astm 389Document3 pagesAstm 389JOSEPH REFUERZONo ratings yet

- Quenching and Tempering Check Sheet - Issue 1Document8 pagesQuenching and Tempering Check Sheet - Issue 1Sakthi VelNo ratings yet

- Investmech (Design of Aluminium Alloys Structures) TR R0.0Document35 pagesInvestmech (Design of Aluminium Alloys Structures) TR R0.0romalan govenderNo ratings yet

- Welding TermsDocument9 pagesWelding Termssanjibkrjana100% (1)