Professional Documents

Culture Documents

20 Fuel Supply

Uploaded by

brechtfestjens0 ratings0% found this document useful (0 votes)

9 views34 pagesVW T3 Bentley

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentVW T3 Bentley

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views34 pages20 Fuel Supply

Uploaded by

brechtfestjensVW T3 Bentley

Copyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 34

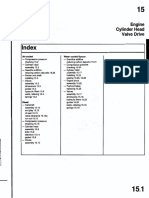

Index

‘Aircooled AFC

Accelerator linkage/cable

‘auto. trans. 20.8, 20.9

manual trans. 20,6, 20.7

Fuel fter 20.4

—Fuel gauge sending unit 20.4

—Fuel pump 20.7

—Fuel systom 20.2, 20.3

leak checking 20.5,

—Fuel tank 20.4, 20.5

Diesel

Accelerator linkagefcable 20.14

—Fuel gauge sending unit 20.13

—Fuel system 20.10, 20.11

leak checking 20.13,

Fuel tank 20.12

Water-cooled Digijet

Accelerator linkagelcable

‘auto, trans, 20.23, 20.24

rmanwal trans. 20.22

Charcoal fiter valve 20.20

—Fuel fter 20.18,

—Fuel gauge sending unit 20:18,

—Fuol pump 20:19

—Fuel system 20.16, 20.17

leak checking 20.21

—Fuel tank 20:18, 20.19

Water-cooled Digifant

Accelerator linkage/cable

adjusting 20.32

auto trans, 20.31

‘manual trans, 20.30

Charcoal fiter 20.33

—Fuel gauge sending unit 20.29

—Fuel pump 20.29

—Fuel system 20.26, 20.27

leak checking 20.21

—Foel tank 20.28

20

Fuel

Supply

20.1

20 Fuel Supply

Note

California models, rom 198}, have a:

= new fuel-tank filter that i self

cleaning and requices NO

SERVICING

= now an etre finemeth ting acareebenn

{ca fe which requlee NO romero 2

i SERVICING foot 6 3

Fuel supply system components, ‘aide

Removing and installing oS

SO Bele

hoon marin ngson

Pe

et

—

elvery rate page 207

crecking, elactical page 20.7

roomate

heck system for leaks using a soap solution at

SbOIs marked with ait". Seal if necessary,

Air-cooled ‘|

20.2 sacyson

Fuel Supply 20

ap

teplace gasket it camaged

Gravity vont valve

‘checking: when tilted 180°,

vaive must close

WARNING

Charcot titer

Disconnect battery when working on fuel

system, Never smoke when working with

fue oF have anying in area bt can ignite

Se ‘Aways pace tea and uel note clamps

ome

Air-cooled AFC Fuel system 20.3

20 Fuel Supply

Fig. 1

Fuol titer, installing

Fuel tank, removing

Work sequence

WARNING

Fire hazard! Do not smoke or have anything

in area that can ignite fuel

= disconnect battery ground cable

= drain fuel tank

— install with arrow pointing tawarg fuel

pump

Fig.2 Fuel gauge sending unit, removing

— frat remove fuel tank

loosen hose clamp 2

= remaye filer neck 1

— remove vent hose $

= remove vent hoses 1, 2 and 3

Fuel gauge sending unit, installing

= coat seal with araphite powder and

Position caretully

— install sending unit with electrical

connector as shown (ar

front of vehicle)

Ww points to.

20.4

Fuel fitter

Ful gauige sending unit

remaving

Fuel fan

Air-cooled AFC

Fuel Supply 20

= remove vent hoses 4 and §

= remove fuel supply hose 1 and fuel ceturn

hose 2 trom fuel tank

loosen bolts on fuel tank mounting rails

white arrows) and remove rails from rear

channel

— lower fuel tank and disconnect electrical

Connector on uel gauge sending unit

— remove fue! tank

Fuel system, leak checking

Refer to illustration on pages 20.2 and 20.3 for

location of vent line indicated below

_Aftor removal/epairs on fuo! tank, alvays check

fuol system for loaks as follows:

— romave small hose A from activated charcoal

filter and eannoct to leek tester US 4487,

~ bet leak testor sale ta “0”

= pressurize system with hand pump to 1.3 i.

cof mercury.

© systersOK if press

after B minutes

i 1.0 in or greater

1 syste leaking if pressure drops below 1.0 in.

atter 8 minutes,

Note

Check system for leaks using so9p solution ot

spots marked with an *, Seal if neces.

Air-cooled AFC | Fuel tank, removing 20. 5

Fuel system leak checking

20 Fuel Supply

Accelerator linkage/cable

Manual transmission

Posh rod

UUoncate anon inataling Accalaretor peda

rele

sways epics,

a

iho °

Aatey vor ——_——_

bnate wen = oP

‘tamping bot

Boot

check for ora

°

\.

‘Accelerator euble

‘dusting Fig. t

?

el

20 6 Air-cooled AFC Manual Trans.

. ‘Accelerator linkage eable

Fuel Supply 20

Fig.1 Accelerator cable, adjusting

~ adjust cable so that clearance is.

‘obtained batwaen throttle valve lever

{and stop on throttle valve housing

1.0-1.5mmm (©:040-0.060 in.)

Fuel pump delivery rate, checking

Work sequence

WARNING

Fire hazard! Never smoke or have anything

Inarea that can ignite fuel

— disconnect tue! retum line at pressure cegulator

= attach hose to return line fitting on pressure

Tegulator A and place other end ot nose in

‘one quart messuring container

— tum on ignition and open air sensor (or

bridge air sensor plug terminals 98 and 39)

Fun pump exactly 80 seconds

* delivery quantity should be at least 500 co

(approx. 1/2 quart)

HINO, check fue! filter Is not blocked, ground

‘connections are O.K. and voltage at pump Is.

at least 115 volts before replacing pump

Fuel pump, checking (electrical)

Note

Battery must be fully charged

— connect ammeter at fuel pump in series with

pump and current supply

‘CAUTION.

Do not touch positive connection to ground

— turn on ignition ang open air sensor flap

(or bridge air sensor plug terminals 36 and 39)

+ ammeter should reac 65-8, amps

‘+ loner reading may indicate pocr ground

connections

* higher reading usually indicates dragging

pump motor and unit must be replaced

Air-cooled AFC

Manual Trans. ‘Accelerator linkage/cable 2 0 av

Fuel pump

20 Fuel Supply

Accelerator linkage/cable

Automatic transmission

Push rod

lubricate when instating

on

sa A

lubricate when ina

Accelerator pod

cretip

Bae

Tube

must engage in fever

Hove Wire te ‘on transmission

2 0. 8 Accelerator tnkagevcabie |_Aif-c00Ked AFC Auto. Trans.

Fuel Supply 20

Accelerator linkage/cable adjustment,

checking

{automatic ransmission)

Work sequence

— depress accelerator pedal to full throttle

position

* throttle valve lever must contact stop, but

kickdown lever on transmission must nat be

in kickdown position

— press accelerator pedal beyond full throttle to

tloor

* override spring must be tensioned and

kickdown fever on trangmisgion must be in

kickdown position

INO, adjust as tollows:

Accelerator linkage/cable, adjusting

{automatic transmission)

Work sequence

loosen nut t

— remove override spring 2

—slart engine and let idle

— adjust idle speed at screw 5

(a9e Repair Group 24)

= shut engine OFF

~ press accelerator rod in direction of arrow

to stop

— turn adjusting rod 9 with screwdriver until

shoulder of adjusting rod just contacts pivot

of throttle lever 4

reinstall override spring 2

— start engine and check idle speed

* adjust if necessary by turning rod 3

= lock adjusting rod 3 in position with nut 1

= press accelerator pedal to floor

* Jeyer B must be in kickdown position (arrow),

wath approx, 1-2mm (1/32-3/32 in} free

play belween lever and stop

— release accelerator pedal

lever must be in idle position (out of kickdown}

=f necessary, adjusi accelerator cable at

clamping bolt (arrow)

Air-cooled AFC] [Automatic Trans

ico rare] gecantarinagoenns 20D

20 Fuel Supply

WARNING:

Disconnect battery when working on fuel

system. Never smoke when working with

fuel or have anything in area that can

Ignite nt,

‘Always replace seals and fuel hose clamps.

Atways clean tual tines before loosening

Removing and

conte ete

checking: valve must

lose when tuened 180"

stem components,

installing

=|

Fuel return ine

‘hom Injection puin

Seat

ast with

‘graphite powder

Before instaling

1 Injection pump

Vent screw

‘open when draining

‘water from titer

Fual titer Naage.

Fut titer

removing: use US 4462 or

equivatent

nstaling: tighten by nan

CAUTION

Use only angroved fuel filters for

maintenance servies or repairs

Not al aftermarket filters meet

the filtering, fuel flow, or woter

separation requirements of the

injeetian system.

Fuel tenk

vert ines

35 Nm (att)

i

Fuel gauge sending unit

removing Fig, 1

Installing Fig. 2

ving:

‘eplace

Wamaged

28 Nm (18 fe 1b)

7

Seal

‘molston with Diese! Yue!

‘tore installing fer

-— Water drain plug

loosen and drain

approx. 100 en» (#102)! fuet

20.10 esnten

Fue! Supply 20

WARNING.

Disconnect battery when warking on fuel

system. Never smoke when working with

fuol or have anything in area that can

‘ignite it,

Always replace seals and fuel hose clamps.

Always cloan fuel lines before loosening

Fuel tank vant fines, .

Filler ep

replace gasket

imjige it damaged

Filer neck

removing: two 19

ralease from ide

15 Nm (11M)

"Fe een

25m (18 1810} Sst

ual tank

removing page 20.4

Note

Check system for leaks using a soap solution at spots

marked with an * Seal if necessary.

[8] pen 20.11

20 Fuel Supply

Fuel tank, removing

Work sequence

WARNING

Fire hazard! Do not smoke or have anything in

area that can ignite fuel

—disconnect battery ground cable

—srain fuel tank

Fi

—remova vent noses 4 and 5

—pull fue! suction ting to (uel filter en right side)

{and fuel retura tine (rom Injection pump, teft

side) off fuel tank

Fa

loosen bolts on fue! tank mounting rails (white

arrows) and remove rails {rom rear channel

lower fue! tank and gisconnect electricat

‘eannecior on fuel gauge sending unit

—remove fuel tank

-

‘emove vent hoses 1, 2and 3

20.12 rertan snore

Fuel Supply 20

1. Fuel gauge sending unit, removing

—first remove fuel tank

Fig. 2 Fuel gauge sending unit, installing

—coat seal with graphite powder and

position carefully

install sending unit with electrical con:

nector as shown (arrow roints to front

ot vehicle)

Fuel system, leak checking

Refer 0 illustration on pages 20.10 and 20,11 for

lacation af vent lines indicated botow.

After repaits/removal of fuel tank, always check fuel

system for leaks as Fallows:

= pinch off all 3 vent hoses & with clamp.

~ remove vent host B from eanister and connect to

feak tester US A437,

~ set leak tester tt

— pressurize bush system with hand pump te 1.31in.

fof mercury.

‘system OK if pressure remains et 1.0 in, Ha oF

greater after § minutes,

«+ system not OK if pressure drops below 1.0 in. Ha

afterS minutes.

Now

(Check system For laaks using 2 soap solution at spots

marked with an *, Seal if necessary,

Diesel

Felorveccencnent, 20.13

20 Fuel Supply

Accelerator linkage/cable

Manual transmission

Push od

ivbvicate when

instating

re

sways Acolarator paca

replace

‘

Pin

Laver

lubricate when

natating

‘Clamping bolt

adjust cable so mat

Injection pump lever

contacts stop without

tension

‘Accelerator eabia

__ Pe

porter &

Dh injection Bump y

20.14 seceerncriniageraic .

Fuel Supply 20

THIS PAGE INTENTIONALLY

LEFT BLANK

as 20.15

20 Fuet Supply

Fuel supply system components,

Removing and installing

Fuel system

checking fr inks, soe

page 20721

uel gauge sending unt

40 Nm (7H ty —_ stating Fig. 4

Fuel expansion tank a

‘coat with graphite powder

before instating

wo”

Fuel tank

‘esmowng, pags 20.18

~

/ Cn a

USAuCanada:instaling FIG. 1

Caitornia only: installing Fig. 2

\

roost retire

SRT

/

ttt eum

/ eal ‘ /

(< Roster

To ttt vave

housing

To intake air cietetoutor ™t

jet

20.16 nme

Fuel Supply 20

WARNING.

Disconnect battery when working on fuel

system. Never smoks when working with

fuel or have anything in area that can ignite

it

‘Always replace seals and fuel hose clamps

Gravity vent valve

checking: valve must close

‘whan titted 180"

- go

Fue! expansion tank

Water-cooled Digijet

racism 20017

20 Fuel Supply

Fact fies instlting

(USA and Canada)

‘+ arrow on titer faces toward tuel pump Fig. 4 Fuel gauge sending unit, installing

— Soa seal with graphite powder and

position carefully

— Install sending unit so that electrical

connector {s aligned with dotted line

* arrow points to front of vehicle

Fuel tank, removing

Werk sequence

— disconnect battery ground strap

= drain fuel tank

Fig. 2 Fuel filter, installing

(California only)

+ arrow on filter faces toward engine

2A

loosen clip 2 0n filler elbow:

ller pipe f and pull out breather

99 to next page

(35)

Fig. 3 Fuel gauge sending unt, removing

— before removing unit, remove fuel tank

Fuet rier

Fuel gauge sending unit -

20.1 Fuel gauge sending Water-cooled Digijet

Fuel Supply 20

— remove fuel supply hose 1 and fuel return

hose 2 from fuel tank

— loosen Eoits an fuel tank mounting rails

(white arrows} and remove ralls trom ro

channel

— lower fuel tank and disconnect electrical

‘connector on fuel gauge sending unit

— remove fuel tank

Fuel pump delivery rate, checking

Work sequence

WARNING

Fire hazard! Never smoke or have anything

{In arga that can ignite fut

disconnect fuel return line al pressure

regulator and block tine

attach hose to return ‘ine fitting on pressure

regulator and place other end of hose in one

quar measuring container

remove relay ©

— connect terminals 30 and 87 with tester

us 4480/3

— switeh on for 30 seconds

‘+ minimum fuel delivery rate should be

500. em?

me Water-cooled |

Ful tank

Raster LOAD

Digijet

20 Fuel Supply

Charcoal filter valve, checking

= disconnect hose 4 from charcoal filter valve 2

connect vacuum pump to filter valve

connection instead of hose 1

— disconnect hose 3 from Tplece 4

— operate vacuum pump and suck with mouth

fon hose 3

+ filter valve must be open

— without operating vacuumn'pump suck with

mouth on nose 3

‘filter valve must be closed

IWNOT, replace charcoal filter valve

20.20 crac ate vie

Water-cooted

Digijet

Fuel Supply 20

Fuel system, checking for leaks

(Vehicles with rear wheel drive ONLY)

WARNING

Disconnect battery when working on fuel

system, Never smoke when working with fuel

‘or have anything in area that can ignite i.

Note

‘ter performing repairs on fuel tank, always check

‘uel system for leaks as follows:

—

US 4487

nA

i

Work sequence

— Remove small hose A at charcoal fiter and

connect to leak tester US 4487

— Set leak tester scale to “0°

— Pressurize system with hand pump to

3.3 om (1.3 in) of mercury

«© system OK if pressure is 2.54 cm (1.0 in) oF

greater aftor 5 minutes

‘© system leaking if pressure drops below

254 om (1.0 in) after 5 minutes

Note

‘Check system for leaks using soap solution at spots.

marked with Seal If necessary.

Water-cooled | [_Digitant | [ digiet | .,,.,cereem 20,21

20 Fuel Supply

Accelerator linkage/cable

Manual transmission

Accelerator pods

Boot:

{hock for cracks

Accelerator cabla

‘adjust cable 50 that

clearance of about 1.0 mm (0,040 In

lg obtained cetwaen thottio

valve lever end stop on throttle

rousing

‘clamping bolts

=a)

20 2 Accelerator cable/ | Water-cooled Manual Trans.

5 Hokage

Fuel Supply 20

Aczelerator linkage/cable

Automatic transmission

Push rod

‘ubcate when inataling

wil ‘Accslorator pede!

Clamping bots

linkage/cabie,

-thecking adjusting page 209

Boot

‘cheek for cxache

Accelerator eabla

Tube

Ralay lver

lubrleate when instaling

‘must engage in lever

(on transmission

Hose.

Wire sie

Aahusting res

‘aqusing page 20.9

As Water-cooled

Auto, Trans. | Accelerator cabler 20. 23

20 Fuel Supply

Accelerator linkage/ca

checking

{automatle transmission)

‘Work sequence

—dopress accelerator pedal fo full throttle

position

* trroitle valve lever must contact stop, but

kickdown lever on transmission must not be

In kickdown position

— press accelerator pedal beyond full throttle to

tloor

* override spring must be tensioned and

kickdown lever on transmission must be in

kickeiown position — press accelerator pedal to floor

HNO, adjust as follows: ‘lever 4 must be on stop in kickdown

position (arrow A)

release accelerator pedal

Accelerator linkage/cable, adjusting aver must be in idle position (out of

jautomatic transmission) Kickdown) (arrow B)

‘Work sequence

— remove override spring 2

— start engine and let idle

— adjust idle speed at screw

(see Repair Group 24)

— shut engine OFF

~ press accelerator rad in direction of arrow to

stop

j — turn adjusting rod 8 with screwdriver until

shoulder of adjusting rod just contacts pivot

of throttle lever

= reinstall override spring 2

— start engine and check idle speed

‘ adjust If necessary by turning fod 3

— lock adjusting rod 3 in position with nut 1

20.24 sccicserenes [water-cooled Digijet Auto, Trans,

. linkage

Fuel Supply 20

THIS PAGE INTENTIONALLY

LEFT BLANK

Fuel supply system components,

Removing and installing

WARNING

Disconnect vattery ground strap when working

(on fuel system. Never smoke wien working

wit ust or have anything in area that can

igeie i

Alwaye replace seals and fuel hose clamps.

Alwaya cloan fuel fines botore loosening

Fuel pume

1 hacking — page 20.29

ft og —— ce

o rataton

sow poets

Iaretan of ow

going to engine

. Sram deny

tte 300 a0

Torin oe —

Fuel Supply 20

'¢ Rules of cleantiness, 20.28

(© Checking for toaks, 20.21

Fler esp.

| replace gasket

damaged

Fal tani

vert lines

. Gravity vont valve

ee neo

Ss

180° (connection

25m (18 fib)

ranaurousere 20.27

20 Fuel Supply

Rules of cleanliness:

CAUTION

wen working on the fuel syetam, the folowing

rules of cleaniness must be carefully followed.

— Thoroughly elean tonnecting points and

‘surrounding areas before loosening,

— Lay pieces tat nave bean removed on &

‘lean surface and cover thert with plaste

‘im or paper — de not uge:cioths with it.

Carefully wrap of close parts that have been

‘opened i repair will not be completed,

— Use only lean pars

‘© Do not unwrap replacement parts Until

immediately betore instalina.

'¢ Do not use parts that have been stored

‘unwrapped (i.e. in t20\ boxes).

—With system open:

' Avoid the use of compressed air as much

85 possible,

‘© Avoid moving vehicle as much as

possible.

Fuel tank, removing

Vehicles with rear wheel drive only

— Disconnect batlery ground strap

— Empty fuel tank

~ Remove filler pipe

Remove vent jines

— Remove feed and return lines fram fuel tani

= Unsere splash plate from body anc take out of

brackets

— Lower tue! tank and remove electieal connector

Irom fuel gauge sender

Remove fue} tank

Syncro vehicles

Note

Removing and instalng the fuel tank is possibie

afler removing the tansmission,

For transmission removal and installation: see Flepair

Group 34

— Disconnect battery ground strap

= Drain fut tare

~— Remove titer pipe

~ Remove vent and tua! ines

— Remove restraining straps

— When taking out fue! tank, caretully push oF

secure coolant pipes and hoses to one side

20.28 Fuel tank, removing Digifant

Fuel Supply 20

Fuel gauge sender, removing and

installing

Vehicles with rear wneet drive only

= remove fuel tank — page 20.28

— remove and Install Sender with toot 2012 A

Note

lrstating: electrical connector must fine up with

dotted Tne, Ascaw points In driving direction.

Synero vehicloe

— ctsconniect battery ground strap

— empty tuel tank until float fies below level of

sender opening

— remove sender behind rear whee! house

— when instating the sender, make sure that return

line is insert into expansion tank inside ot fue!

lank (see Fig, 20-549, Page 20.24)

Note

Aor instalation of sender:

Rocker arm must be able to be swung downwards,

Fuel pump delivery rate, checking

WARNING

Fre razard! Never smoke of have anything in

‘ea that can ignite fe!

— disconnect fuel ratur tine at pressure regulator

and block ting

— attach hose to retum line fting on pressure

regulator and place other end of hose in one

{quart measuring container

— remove relay ©

— connect ferminals 30 and 87 with tester US 4490/3

= switch on far 30 seconds

‘© minimum fuel delivery rate should be $00 em?

a7

Digifant

Fuel gauge sender,

raroratirss 20.29

20 Fuel Supply

Accelerator linkage/cable

Manual transmission

a

‘Clamping bots

«© adjust accelerator cable in

‘5uch way that the throttle

vale lvor lies against the

Sop on tattle housing

with eppcoximatoly 1.0 mm

(0.039 ny pay

20.30 saves Losten

Fuel Supply 20

Accelerator linkage/cable

transmission:

Puah rod Gs pecat

BR tt nate

check an

‘ual supply — Page 2032

on

oS (=)

“ [_Digtart ] Anveer at toaae sacs 20.31

20 Fuel Supply

Accelerator linkage/cable, adjusting

The accelerator inkage’cable should be adjusted in

such a way that with Ihrotla valve closed, (le), the.

lever on transmission is against stop in ro-gas,

position: otherwise, siting occurs 100 late in middle

sooed ranges.

‘The accelerator linkage/cable should be adjusted as

follows at ide speed (engine at operating

temperature, with throttle vaive closed)

— Press gas pedal to floor. Laver ($) must be on

slop in kickdewn postion (arrow A)

— Release gas pedal. Lever musi be in icle position

(ut of kickdown) (arrow B)

—Loosen’nut (1)

— Remove spring (2)

= Pull accelerator rod in rection of arrow

— Tum adjusting rod (3) with screwdriver until

shoulder of adjusting rod just contacts pivot of

throte lover

— install spring (2)

Start engine and check to 866 i idle rpm Is — It necessary, adjust eecolerator cable at clamping

reached. I! necessary, re-adjust by tuming ott

adjusting cod (3)

lock adjusting rod with nut ¢t) Check gmalustment

— Push gas pedal down to ful throtte point. Throttle

valve lever must lo against stop (without

kickdown)

— Push gas pedal past fll thratle point to stop.

Spring tmust be compressed. Laver on

transmission must be in kicksown position (A.

20.32 rcaieacrinaseeie soning [Pitan

Fuel Supply 20

Charcoal filter assembly

on comune sony 20233

20 Fuel Supply

Fuel supply system, components

Synero vehicles

Fuel tank

ent fee

Notes,

© Rules of Civaniiness — page 20.28

«© replace seals and spring clamps

Feed tne

(trom tuo itor to

engine ring tine

Fuel tank

tank (internally located) Ny

wih sano, k

Fusl ther % A

‘Insialaton locaton: %

fron point now econ

twergne 9 and

Insaing — page 20.29

20 Nim (1518) racket tor

20m fut lines

rons)

20.34 Samm | diatom

You might also like

- DoodleDocument3 pagesDoodlebrechtfestjensNo ratings yet

- Tech-Rider-St - James-2015.xlsx - Blad1Document1 pageTech-Rider-St - James-2015.xlsx - Blad1brechtfestjensNo ratings yet

- Flours Herbs and SpicesDocument1 pageFlours Herbs and SpicesbrechtfestjensNo ratings yet

- Instrumentalists: Performing Arts TipsDocument2 pagesInstrumentalists: Performing Arts Tipsbrechtfestjens100% (1)

- C033407 enDocument3 pagesC033407 enmelgarcia829No ratings yet

- Con Tech Resident Ail Lighting GuideDocument20 pagesCon Tech Resident Ail Lighting GuidegtgreatNo ratings yet

- Event Production Health and SafetyDocument38 pagesEvent Production Health and SafetyCarlo Cliff LeeNo ratings yet

- 35-Manual Transmission-Case, Gears, ShaftsDocument136 pages35-Manual Transmission-Case, Gears, ShaftsbrechtfestjensNo ratings yet

- 27 Electrical Battery, Starter, AlternatorDocument33 pages27 Electrical Battery, Starter, AlternatorbrechtfestjensNo ratings yet

- 34-Manual Transmission - Controls, AssemblyDocument30 pages34-Manual Transmission - Controls, AssemblybrechtfestjensNo ratings yet

- 39 DifferentialDocument62 pages39 DifferentialbrechtfestjensNo ratings yet

- 26-Exhaust System:Emission ControlDocument11 pages26-Exhaust System:Emission ControlbrechtfestjensNo ratings yet

- 28 Ignition SystemDocument46 pages28 Ignition SystembrechtfestjensNo ratings yet

- 30 Clutch, ControlsDocument12 pages30 Clutch, ControlsbrechtfestjensNo ratings yet

- 28 Ignition SystemDocument46 pages28 Ignition SystembrechtfestjensNo ratings yet

- 15-Cylinder Heads:Valve DriveDocument32 pages15-Cylinder Heads:Valve DrivebrechtfestjensNo ratings yet

- 26-Exhaust System:Emission ControlDocument11 pages26-Exhaust System:Emission ControlbrechtfestjensNo ratings yet

- 23-Fuel Injection-Diesel System PDFDocument11 pages23-Fuel Injection-Diesel System PDFbrechtfestjensNo ratings yet

- 1983 Westfalia Vanagon Camper ManualWMDocument26 pages1983 Westfalia Vanagon Camper ManualWMbrechtfestjens100% (2)

- 19 Cooling SystemDocument24 pages19 Cooling SystembrechtfestjensNo ratings yet

- 17 Lubrication SystemDocument10 pages17 Lubrication SystembrechtfestjensNo ratings yet

- 10 Engine AssemblyDocument10 pages10 Engine AssemblybrechtfestjensNo ratings yet

- 10 Engine Assembly PDFDocument10 pages10 Engine Assembly PDFbrechtfestjensNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)