Professional Documents

Culture Documents

B31.3 Process Piping Course - 08 Flexibility

Uploaded by

dalianbouriCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

B31.3 Process Piping Course - 08 Flexibility

Uploaded by

dalianbouriCopyright:

Available Formats

ASME B31.

3 Process Piping Course

8. Flexibility

ASME B31.3 Process Piping

Charles Becht IV, PhD, PE

Don Frikken, PE

Instructors

BECHT ENGINEERING COMPANY, INC.

Flexibility -

Piping Development Process

1. Establish applicable system standard(s)

2. Establish design conditions

3. Make overall piping material decisions

Pressure Class

Reliability

Materials of construction

4. Fine tune piping material decisions

Materials

Determine wall thicknesses

Valves

5. Establish preliminary piping system layout & support

configuration

6. Perform flexibility analysis

7. Finalize layout and bill of materials

8. Fabricate and install

9. Examine and test

BECHT ENGINEERING COMPANY, INC.

Flexibility -

ASME B31.3 Process Piping Course

8. Flexibility

8. Flexibility

General Considerations

Friction

Stress Intensification

Thermal Expansion

Spring Hangers

The Displacement Load Analysis

BECHT ENGINEERING COMPANY, INC.

Flexibility -

The Material in This Section is

Addressed by B31.3 in:

Chapter II - Design

Appendix D - Flexibility & Stress

Intensification Factors

BECHT ENGINEERING COMPANY, INC.

Flexibility -

ASME B31.3 Process Piping Course

8. Flexibility

General Considerations

Main purpose is to provide sufficient flexibility to

safely accommodate changes in length

resulting from temperature variations, avoiding

failure caused by

Fatigue

Creep-fatigue

Ratchet

Another purpose is to keep movement of piping

within a manageable range

Avoiding interference with other stuff

Supports designed to handle displacements

BECHT ENGINEERING COMPANY, INC.

Flexibility -

General Considerations

Loads are actions that cause one end of a pipe

segment to move relative to the other end and

actions that have an equivalent effect

Thermal expansion of attached equipment

Temperature changes in the piping

Peak stresses are accounted for using stress

intensification factors

Acceptance criterion is based on the stress

range

BECHT ENGINEERING COMPANY, INC.

Flexibility -

ASME B31.3 Process Piping Course

8. Flexibility

Friction

Displacement causes piping to move over

sliding supports

Friction forces are in one direction when

the pipe is heating and in the opposite

direction when cooling

The coefficient of friction used for steel on

steel ranges from 0.3 to 0.5.

N

F = N

BECHT ENGINEERING COMPANY, INC.

Flexibility -

Flexibility -

Friction

The coefficient of friction can

be reduced to 0.1 by using

PTFE or graphite impregnated

plates

Using roller supports can

further reduce the coefficient of

friction to 0.02

BECHT ENGINEERING COMPANY, INC.

ASME B31.3 Process Piping Course

8. Flexibility

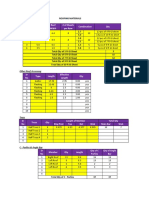

Friction Workshop

Calculate the east-west reactions at the anchors

caused by friction.

Assume steel on steel

Line is NPS 6, std WT steel, uninsulated and full of water

BECHT ENGINEERING COMPANY, INC.

Flexibility -

Stress Intensification

Stress intensification factors (SIFs) are

used to account for higher stresses that

may exist at discontinuities in the piping at

fittings and joints

The calculated stresses at a fitting or joint

are taken as the stress calculated for a

perfect circular cylinder times the SIF

SIFs are given in Appendix D of B31.3

BECHT ENGINEERING COMPANY, INC.

Flexibility -

10

ASME B31.3 Process Piping Course

8. Flexibility

Stress Intensification

SIFs are based on Markl testing of piping

components

Primarily A106 Gr B pipe, with some types

316 and 347 stainless steel

NPS 4 Sch 40

Fully reversed bending

Displacement controlled tests

Markl started with a fatigue curve

generated by fatigue tests on pipe with

circumferential welds

BECHT ENGINEERING COMPANY, INC.

Flexibility -

11

Stress Intensification

Pipe with Circumferential Welds

Stress Range

1,000,000

Average

Fatigue

Failure

100,000

Design

Fatigue

Curve (1/2

Average)

10,000

1,000

1000

10000

100000

1000000 10000000

Number of Cycles

BECHT ENGINEERING COMPANY, INC.

Flexibility -

12

ASME B31.3 Process Piping Course

8. Flexibility

Stress Intensification

Components such as tees and elbows

were similarly fatigue tested

The SIF for a component is the ratio of

the nominal stress in the circumferentially

welded pipe divided by the nominal stress

in the component at failure for the same

number of cycles

Even though the component may have

thicker walls, the evaluation is based on

the dimensions of the pipe

BECHT ENGINEERING COMPANY, INC.

Flexibility -

13

Stress Intensification

NPS 4 STD WT Fittings

100,000

Stress Range

Buttwelded

Pipe

Elbow = 1.1

Tee = 1.5

Elbow

10,000

Tee

1,000

1000

10000

100000

1000000 10000000

Number of Cycles

BECHT ENGINEERING COMPANY, INC.

Flexibility -

14

ASME B31.3 Process Piping Course

8. Flexibility

Thermal Expansion

Thermal Expansion of metals can be

calculated by

L = T L

Where:

L

L

T

=

=

=

=

Coefficient of thermal expansion

Length of piping

Change in length of piping

Change in temperature, usually

temperature range

BECHT ENGINEERING COMPANY, INC.

Flexibility -

15

Thermal Expansion

Thermal Expansion of metals can also be

calculated by

L = Exp L

Where:

Exp = Total thermal expansion, in/100 ft

(mm/m)

L

= Length of piping, 100 ft (m)

L = Change in length of piping, in (mm)

BECHT ENGINEERING COMPANY, INC.

Flexibility -

16

ASME B31.3 Process Piping Course

8. Flexibility

Thermal Expansion

What is the change in length of a carbon

steel line that has

An original length of 60 ft (18.3 m)

Has a minimum expected temperature of

-29F (-34C), and

Has a maximum expected temperature of

300F (150C)

See pages 41-44 of the supplement.

BECHT ENGINEERING COMPANY, INC.

Flexibility -

17

Flexibility -

18

Spring Hangers

Spring hangers are used

to provide support for

piping while allowing

vertical movement of the

piping caused by

displacement loads.

Variable Type

BECHT ENGINEERING COMPANY, INC.

ASME B31.3 Process Piping Course

8. Flexibility

Force

Spring Hangers

Displacement

BECHT ENGINEERING COMPANY, INC.

Flexibility -

19

Spring Hangers

Selection Process

Calculate weight to be supported

Calculate movement of the line at the support

location

Select hanger size based on the load

Decide allowable load variation

Usually less than 25%

Less if needed to meet stress or reaction

requirements

Select hanger from manufacturers table

BECHT ENGINEERING COMPANY, INC.

Flexibility -

20

ASME B31.3 Process Piping Course

8. Flexibility

Spring Hanger Workshop

Select a spring hanger that will minimize the

weight reaction on the pump.

BECHT ENGINEERING COMPANY, INC.

Flexibility -

21

Spring Hangers

Variable Spring Hanger Installation (Anvil International)

[Note that springs are always in compression.]

BECHT ENGINEERING COMPANY, INC.

Flexibility -

22

ASME B31.3 Process Piping Course

8. Flexibility

Spring Hangers

Constant type spring hangers are used when the

load variation on a variable type spring hanger

would be too high.

Constant Type

BECHT ENGINEERING COMPANY, INC.

Flexibility -

23

Spring Hangers

Constant Support Hanger Installation (Anvil International)

BECHT ENGINEERING COMPANY, INC.

Flexibility -

24

ASME B31.3 Process Piping Course

8. Flexibility

The Displacement Load Analysis

Temperature Range

Displacement Stress Calculation

Calculation Methods

BECHT ENGINEERING COMPANY, INC.

Flexibility -

25

Temperature Range

B31.3 requires that we consider the

algebraic difference between strains in

the extreme displacement condition and

the original (as-installed) condition (or any

anticipated condition with a greater

differential effect)(319.2.3(b))

The minimum and maximum

temperatures used dont necessarily

correspond to the design temperature and

the design minimum temperature

BECHT ENGINEERING COMPANY, INC.

Flexibility -

26

ASME B31.3 Process Piping Course

8. Flexibility

Temperature Range

design temperature: the temperature at

which, under the coincident pressure, the

greatest thickness or highest component

rating is required (301.3).

design minimum temperature: the lowest

component temperature expected in

service (301.3.1)

BECHT ENGINEERING COMPANY, INC.

Flexibility -

27

Temperature Range

Minimum temperature may be due to

Normal operation

Excursion operation

Expected winter temperature

Maximum temperature may be due to

Normal operation

Excursion operation

Piping exposed to hot summer sun [120F,

50C]

Empty piping exposed to heat tracing

Steam cleaning

BECHT ENGINEERING COMPANY, INC.

Flexibility -

28

ASME B31.3 Process Piping Course

8. Flexibility

Temperature Range Examples

Outdoor cooling tower water line:

Minimum water temperature is 45F (7C)

Maximum water temperature is 90F (32C)

The piping is installed during February,

which has an average daily temperature of

53F (12C)

Minimum average daily temperature is 30F

(-1C)

Temperature range is _______ to ________

BECHT ENGINEERING COMPANY, INC.

Flexibility -

29

Temperature Range Examples

Outdoor compressed air piping

Minimum compressed air temperature is

ambient

Maximum compressed air temperature is

150F (65C)

The piping is installed during July, which has

an average daily temperature of 64F (18C)

Minimum average daily temperature is -30F

(-35C)

Temperature range is _______ to ________

BECHT ENGINEERING COMPANY, INC.

Flexibility -

30

ASME B31.3 Process Piping Course

8. Flexibility

Temperature Range Examples

Outdoor steam traced water line:

Minimum water temperature is 40F (4C)

Maximum water temperature is 60F (16C)

The piping is installed during September,

which has an average daily temperature of

76F (24C)

Minimum average daily temperature is 30F

(-1C)

Calculated maximum temperature for no flow

condition with steam tracing on is 280F

(140C)

Temperature range is _______ to ________

BECHT ENGINEERING COMPANY, INC.

Flexibility -

31

Displacement Stress Calculation

L

= EL / L

L = TL

= E T

1. What is for carbon steel and T = 330F (185C)?

E for carbon steel = 29E6 psi (200 GPa)

2. What is for stainless steel under the same condition?

E for stainless steel = 28.3E6 psi (195 GPa)

BECHT ENGINEERING COMPANY, INC.

Flexibility -

32

ASME B31.3 Process Piping Course

8. Flexibility

Calculation Methods

The Code describes four acceptable

methods to demonstrate adequate flexibility

1. Formal analysis

2. Duplicate of a successful system

3. System that can be judged adequate by

comparison

4. Empirical equation for piping that meets

certain requirements

BECHT ENGINEERING COMPANY, INC.

Flexibility -

33

Calculation Methods

The empirical equation is:

Dy/(L U)2 30SA/Ea (in/ft)2

Dy/(L U)2 208,000SA/Ea (mm/m)2

Where:

D

L

U

Y

=

=

=

=

Pipe outside diameter (in) (mm)

Developed length of piping between anchors (ft) (m)

Distance between anchors (ft) (m)

Total displacement strain to be absorbed by the

piping (in) (mm)

SA = Allowable stress range

Ea = Elastic modulus at room temperature

BECHT ENGINEERING COMPANY, INC.

Flexibility -

34

ASME B31.3 Process Piping Course

8. Flexibility

Calculation Methods

L1

L2

L = L1 + L2

y = UT

BECHT ENGINEERING COMPANY, INC.

Flexibility -

35

Calculation Methods

The empirical equation can be used if the

piping system:

Is of uniform size

Has no more than two points of fixation

Has no intermediate restraints

The equation is not applicable to systems

subject to severe cyclic conditions.

The equation may not be accurate for

certain geometries.

BECHT ENGINEERING COMPANY, INC.

Flexibility -

36

ASME B31.3 Process Piping Course

8. Flexibility

Calculation Methods

The Code describes four acceptable

methods to demonstrate adequate flexibility

1. Formal analysis

2. Duplicate of a successful system

3. System that can be judged adequate by

comparison

4. Empirical equation for piping that meets

certain requirements

BECHT ENGINEERING COMPANY, INC.

Flexibility -

37

Calculation Methods

Formal analyses can be simple or complex.

The complex analyses are done using

computer programs such as

Autopipe, Siber Technology,

http://www.siber.co.uk/rebis/autopipe.shtml

CAEPIPE, SST Systems, Inc., http://www.sstusa.com/

Caesar, Coade, Inc., http://www.caesarii.com/

PipePak, Algor,

http://www.pipepak.com/products/Profes1504/default.asp

SIMFLEX, Peng Engineering, http://www.pipestress.com/

TRIFLEX, Nor-Par a.s, http://www.norpar.com/triflex.htm

BECHT ENGINEERING COMPANY, INC.

Flexibility -

38

ASME B31.3 Process Piping Course

8. Flexibility

Calculation Methods

The simple analyses are done using

equations, charts and graphs such as

described in

Design of Piping Systems, The M.W. Kellogg

Company, John Wiley & Sons, Inc., First Edition

1941

Piping Design and Engineering, Grinnell

Corporation, First Edition 1963

One of the simplest methods is the guided

cantilever method described in the Kellogg

book.

BECHT ENGINEERING COMPANY, INC.

Flexibility -

39

Guided Cantilever Method

= 48L2SA/EaD

Where = maximum permissible displacement

BECHT ENGINEERING COMPANY, INC.

Flexibility -

40

ASME B31.3 Process Piping Course

8. Flexibility

Guided Cantilever Method

See page 49 of the Supplement.

BECHT ENGINEERING COMPANY, INC.

Flexibility -

41

Calculation Methods

The Code describes four acceptable

methods to demonstrate adequate flexibility

1. Formal analysis

2. Duplicate of a successful system

3. System that can be judged adequate by

comparison

4. Empirical equation for piping that meets

certain requirements

BECHT ENGINEERING COMPANY, INC.

Flexibility -

42

ASME B31.3 Process Piping Course

8. Flexibility

Calculation Methods

Judging by comparison

20 (6 m)

NPS 6

13 (4 m)

If this line is OK,

20 (6 m)

what can we say about this line,

which is in the same fluid service?

BECHT ENGINEERING COMPANY, INC.

13 (4 m)

NPS 4

Flexibility -

43

Calculation Methods

Judging by comparison

20 (6 m)

NPS 6

13 (4 m)

If this line is OK,

20 (6 m)

what can we say about this line,

which has the same pipe material

at a lower temperature range?

BECHT ENGINEERING COMPANY, INC.

13 (4 m)

NPS 6

Flexibility -

44

ASME B31.3 Process Piping Course

8. Flexibility

Calculation Methods

Judging by comparison

20 (6 m)

13 (4 m)

NPS 6

If this line is OK,

20 (6 m)

what can we say about this line,

which is in the same fluid service?

BECHT ENGINEERING COMPANY, INC.

16 (5 m)

NPS 6

Flexibility -

45

Calculation Methods

Judging by comparison

NPS 6, carbon steel

13 (4 m)

If this line is OK,

20 (6 m)

20 (6 m)

what can we say about this line,

which is in the same fluid service?

BECHT ENGINEERING COMPANY, INC.

13 (4 m)

NPS 6, stainless steel

Flexibility -

46

You might also like

- B31.3 Process Piping Course - 06 Flexibility Analysis For IntroDocument10 pagesB31.3 Process Piping Course - 06 Flexibility Analysis For IntroJose BijoyNo ratings yet

- B31.3 Process Piping Course - 17 High Pressure PipingDocument12 pagesB31.3 Process Piping Course - 17 High Pressure PipingpfpmatosNo ratings yet

- ASME B31.3 Process Piping Reactions CourseDocument0 pagesASME B31.3 Process Piping Reactions CourseCarlos Del ToroNo ratings yet

- ASME B31.3 Nonmetallic Piping Design and FabricationDocument0 pagesASME B31.3 Nonmetallic Piping Design and FabricationAxel MoorNo ratings yet

- B31.3 Process Piping Course - 04 Pressure Design of MetalsDocument22 pagesB31.3 Process Piping Course - 04 Pressure Design of MetalsEryl YeongNo ratings yet

- B31.3 Process Piping Course - 07 Layout and SupportDocument15 pagesB31.3 Process Piping Course - 07 Layout and SupportgerrydimayugaNo ratings yet

- B31.3 Process Piping Course - 11 Designing With Expansion Joints PDFDocument15 pagesB31.3 Process Piping Course - 11 Designing With Expansion Joints PDFSulist N WahyudieNo ratings yet

- ASME Piping Stress Analysis RequirementsDocument8 pagesASME Piping Stress Analysis RequirementsjjirwinNo ratings yet

- B31.3 Process Piping Course - 12 Fabrication and InstallationDocument21 pagesB31.3 Process Piping Course - 12 Fabrication and InstallationLuong AnhNo ratings yet

- ASME B31.3 Category M Fluid Service Design RequirementsDocument8 pagesASME B31.3 Category M Fluid Service Design RequirementsRomner CordovaNo ratings yet

- ASME B31.3 Process Piping Fabrication InstallationDocument21 pagesASME B31.3 Process Piping Fabrication InstallationMuhammed SulfeekNo ratings yet

- Unlock-B31.3 Process Piping Course - 10 Flexibility Analysis MethodsDocument5 pagesUnlock-B31.3 Process Piping Course - 10 Flexibility Analysis MethodsProkopNo ratings yet

- B31.3 Process Piping Course - 03 Materials PDFDocument19 pagesB31.3 Process Piping Course - 03 Materials PDFNguyen Anh TungNo ratings yet

- B31.3 Process Piping Course - 03 Materials-LibreDocument45 pagesB31.3 Process Piping Course - 03 Materials-LibrejacquesmayolNo ratings yet

- Whats Different in B31.1 PDFDocument30 pagesWhats Different in B31.1 PDFhirenkumar patel100% (2)

- History b16 34Document5 pagesHistory b16 34qazi12100% (1)

- Piping CodesDocument47 pagesPiping CodesSankar MukaNo ratings yet

- ASME B31.3 Process Piping InspectionDocument20 pagesASME B31.3 Process Piping InspectionPedro DiazNo ratings yet

- Spiral Wound GasketsDocument7 pagesSpiral Wound GasketsYap HSNo ratings yet

- Piping TechniquesDocument8 pagesPiping TechniquespiglitNo ratings yet

- PipeDocument47 pagesPipemohanNo ratings yet

- Piping MaterialDocument125 pagesPiping MaterialSargunam SankaravadivelNo ratings yet

- BR 170 1Document7 pagesBR 170 1Himanshu ChaturvediNo ratings yet

- TH10 - Pipe Loop or Expansion JointsDocument3 pagesTH10 - Pipe Loop or Expansion JointsloukatsNo ratings yet

- Brittle Fracture of Carbon Steel Piping During Hydrostatic TestingDocument4 pagesBrittle Fracture of Carbon Steel Piping During Hydrostatic TestingSH1961No ratings yet

- 4.1 Rerating Piping and Pressure Vessels: Major Piping Inspection CodesDocument23 pages4.1 Rerating Piping and Pressure Vessels: Major Piping Inspection CodesMahmoud samahaNo ratings yet

- MSS SP 6Document6 pagesMSS SP 6d1a9v8i3d100% (1)

- Ower Iping: Charles Becht IVDocument52 pagesOwer Iping: Charles Becht IVmiguel medina100% (1)

- API 660 Vs TEMADocument2 pagesAPI 660 Vs TEMAloqNo ratings yet

- ABSA PipingDocument1 pageABSA Pipingcorreen100% (1)

- Piping CodesDocument32 pagesPiping Codesengrabrar100% (3)

- Inspection of Heat ExchangerDocument83 pagesInspection of Heat ExchangerRaghavanNo ratings yet

- Fittings TrainingDocument61 pagesFittings TrainingsbmmlaNo ratings yet

- FuturePipe Installation Manual 18-7-05 PDFDocument25 pagesFuturePipe Installation Manual 18-7-05 PDFPaul WoworNo ratings yet

- Why Insulate Pipes: 3 Key Benefits of InsulationDocument13 pagesWhy Insulate Pipes: 3 Key Benefits of InsulationnguyenNo ratings yet

- In Servicepressurevesselinspectionaccordingtoapi 51010theditionoverview 180328042225 PDFDocument33 pagesIn Servicepressurevesselinspectionaccordingtoapi 51010theditionoverview 180328042225 PDFKrishna Vacha100% (2)

- Pressure Vessel Inspection PDF FreeDocument44 pagesPressure Vessel Inspection PDF FreemabroukNo ratings yet

- Asmepcc 2repairleaks Article 4Document23 pagesAsmepcc 2repairleaks Article 4amalhaj2013No ratings yet

- API-570 SAMPLE Closed Book ExamDocument12 pagesAPI-570 SAMPLE Closed Book ExamuttamNo ratings yet

- PetroSync - ASME B31.3 Process Piping Code Design Requirements 2017Document5 pagesPetroSync - ASME B31.3 Process Piping Code Design Requirements 2017Engr Khurram Jaan RamayNo ratings yet

- 1 PipelineDocument69 pages1 PipelineEhab MohammedNo ratings yet

- Inspect New PipingDocument126 pagesInspect New Pipingmohd qamarNo ratings yet

- Shell Corrosion Under InsulationDocument16 pagesShell Corrosion Under InsulationDavide CongiuNo ratings yet

- Hydrostatic TestingDocument18 pagesHydrostatic TestingRicardoNo ratings yet

- Pipe Thickness Calculation Internal Pressure Design Thickness As Per ASME B313Document7 pagesPipe Thickness Calculation Internal Pressure Design Thickness As Per ASME B313mohamed samyNo ratings yet

- 650-680 Rev 4 - Hydrostatic Test ExemptionsDocument3 pages650-680 Rev 4 - Hydrostatic Test ExemptionsAnonymous 6S9tcbhNo ratings yet

- Flex Spiral Wound GasketsDocument49 pagesFlex Spiral Wound GasketsJomer J Simpson100% (1)

- ASME B31.3 Piping Inspection GuideDocument19 pagesASME B31.3 Piping Inspection GuideferooxidanNo ratings yet

- ASME B31.1 CourseDocument1 pageASME B31.1 Coursejeffcall50% (2)

- Proceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988From EverandProceedings of the Twelfth International Cryogenic Engineering Conference Southampton, UK, 12–15 July 1988R. G. ScurlockNo ratings yet

- Technical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionFrom EverandTechnical Writing A-Z: A Commonsense Guide to Engineering Reports and Theses, Second Edition, British English: A Commonsense Guide to Engineering Reports and Theses, U.S. English Second EditionNo ratings yet

- Stress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsFrom EverandStress in ASME Pressure Vessels, Boilers, and Nuclear ComponentsNo ratings yet

- Chemical Engineering - June 1997 - Pipe Design For Robust SystemsDocument9 pagesChemical Engineering - June 1997 - Pipe Design For Robust Systemshtaboada2008100% (1)

- Module 05 Piping Stress Analysis Pravin JedheDocument15 pagesModule 05 Piping Stress Analysis Pravin JedheAbdul Tayyeb100% (2)

- Better Piping and Expansion Joint DesignDocument3 pagesBetter Piping and Expansion Joint DesignSeungmin PaekNo ratings yet

- C-27 Piping Flexibility AnalysisDocument32 pagesC-27 Piping Flexibility AnalysisChuy Lee100% (1)

- Basics of Pipe Stress AnalysisDocument90 pagesBasics of Pipe Stress AnalysisMohamed Al-Odat0% (1)

- Offshore Corrosion Control SolutionsDocument2 pagesOffshore Corrosion Control SolutionsdalianbouriNo ratings yet

- Solar Power-101 PDFDocument86 pagesSolar Power-101 PDFKishore Krishna100% (1)

- Wind Turbine TypesDocument7 pagesWind Turbine TypessupersempronioNo ratings yet

- Cathelco ICCP Hull Protection SystemsDocument8 pagesCathelco ICCP Hull Protection SystemsdalianbouriNo ratings yet

- Wind Energy PDFDocument42 pagesWind Energy PDFAnonymous oUoJ4A8xNo ratings yet

- Asme B16.34Document16 pagesAsme B16.34Thomas Martin100% (1)

- MW Kellogg TrunnionDesign PDFDocument31 pagesMW Kellogg TrunnionDesign PDFtilsidNo ratings yet

- The Basics of Solar Power For Producing ElectricityDocument5 pagesThe Basics of Solar Power For Producing ElectricityJason HallNo ratings yet

- GuidanceDocument58 pagesGuidancedalianbouriNo ratings yet

- 0jUJNnYWQR21CTZ2FrEdQw 211120 PE M4 Modeling-in-RevitDocument4 pages0jUJNnYWQR21CTZ2FrEdQw 211120 PE M4 Modeling-in-RevitAr AbhiNo ratings yet

- Roofing Materials EstimateDocument1 pageRoofing Materials Estimatejhomel garciaNo ratings yet

- Lec-1-Introduction ACI 318-19 - ACI 214r-11Document48 pagesLec-1-Introduction ACI 318-19 - ACI 214r-11Muhammad AdilNo ratings yet

- Propped Cantilever Wall Design As A SlabDocument4 pagesPropped Cantilever Wall Design As A SlabmudithaNo ratings yet

- Evaluation of Joints Influence On Segmental Tunnel Lining BehaviorDocument11 pagesEvaluation of Joints Influence On Segmental Tunnel Lining BehaviorFoolad GharbNo ratings yet

- BS 5950-1 1990Document126 pagesBS 5950-1 1990Anoy100% (4)

- SUBMERGENCE REQUIREMENTS FOR PUMP STORAGE POWER PLANT TURBINESDocument4 pagesSUBMERGENCE REQUIREMENTS FOR PUMP STORAGE POWER PLANT TURBINESSunil MaharjanNo ratings yet

- M. Sc. Steel Structures: Lecture # 6Document61 pagesM. Sc. Steel Structures: Lecture # 6SSNo ratings yet

- Piping Thickness Calculation for Steam LinesDocument21 pagesPiping Thickness Calculation for Steam LinesAmit BansalNo ratings yet

- Complete Quality Manual Vol 2 Rev. 2010Document277 pagesComplete Quality Manual Vol 2 Rev. 2010Percy Ruiz Feril100% (1)

- Orchid BrowcherDocument8 pagesOrchid Browcherramesh410No ratings yet

- 2022 Buildcrete Product Installation ManualDocument13 pages2022 Buildcrete Product Installation ManualIan Patrick WijayaNo ratings yet

- Use of Falling Weight Deflectometer Data To Determine The Effective Structural Number of Full-Depth Asphalt Pavements For Structural Condition AssessmDocument16 pagesUse of Falling Weight Deflectometer Data To Determine The Effective Structural Number of Full-Depth Asphalt Pavements For Structural Condition AssessmVINEESHA CHUNDINo ratings yet

- ECP201-2008 Earthquake Lateral Forces - Protected-09!06!2012Document23 pagesECP201-2008 Earthquake Lateral Forces - Protected-09!06!2012magdyamdbNo ratings yet

- Definition and Types of Bridges PDFDocument34 pagesDefinition and Types of Bridges PDFHivet Jurieta Mamani100% (1)

- 9A01601 Design & Drawing of Steel StructuresDocument5 pages9A01601 Design & Drawing of Steel StructuressivabharathamurthyNo ratings yet

- Computer Programming Project ReportDocument8 pagesComputer Programming Project ReportAmir IqmalNo ratings yet

- Hot Weather Concreting: Dr. Khaldoun RahalDocument32 pagesHot Weather Concreting: Dr. Khaldoun Rahalabdul khaderNo ratings yet

- New Aluminium FormworkDocument34 pagesNew Aluminium FormworkSandip Jagdale0% (1)

- FM Practice Questions 1682618846111Document38 pagesFM Practice Questions 1682618846111Hasan javedNo ratings yet

- Sohail Ahmed - ResumeDocument5 pagesSohail Ahmed - ResumenomNo ratings yet

- Japan ReportDocument98 pagesJapan ReportGerardo Arotoma VelizNo ratings yet

- Physical Modeling of Local Scour Around Complex Bridge PiersDocument293 pagesPhysical Modeling of Local Scour Around Complex Bridge PiersJoko NugrohoNo ratings yet

- Report 310 2Document2 pagesReport 310 2sujupsNo ratings yet

- How To Calculate Septic Tank Size and Design of Septic TankDocument3 pagesHow To Calculate Septic Tank Size and Design of Septic TankBongga Ka DayNo ratings yet

- Cold Room Refrigeration EquipmentsDocument4 pagesCold Room Refrigeration EquipmentsLorena PertierraNo ratings yet

- MivanDocument19 pagesMivanshamkumavatNo ratings yet

- TNU-MT-50-001-A4 R0 Material Take OffDocument37 pagesTNU-MT-50-001-A4 R0 Material Take OffaerfansNo ratings yet