Professional Documents

Culture Documents

23-Fuel Injection-Diesel System PDF

Uploaded by

brechtfestjens0 ratings0% found this document useful (0 votes)

16 views11 pagesOriginal Title

23-Fuel_Injection-Diesel_System.pdf

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views11 pages23-Fuel Injection-Diesel System PDF

Uploaded by

brechtfestjensCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 11

pan

23

Diesel Injection System

Quick Data

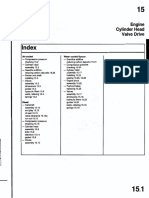

Index

Diesel Injection System

—Coid start cable 23.5

—Engine speed 23.5,

—Fue! cut-of solenoid 23.5

—Fue! delivery valve/

housing 23.7, 23.8

Fuel fiter water ingicator

kit instaling 23.10, 23.11

—Fuelinjoctors 23.8-23.10

injection pump 23.6, 23.7

—Injection pump/valve timing

23.3, 23.4

injection system 23.2

—Injection timing 23.4

23 Diesel Injection System

Accelerator cable

adjusting, 698

Repair Group 20,

WARNING

Disconnect battery when warking on fuel

system. Never smoke wien working with tual

for have anything in area that can ignite it

‘Always replace seats and fuel hose clamps

Injector pipes.

25 Nm (181 1b)

Injectors

70 Nm (51 ft 1b)

removinglintalting page 23.0

Cleaning page 239

‘checking page 20.10

old start eabie

‘aajusting page 23.5

aot dolivery valvos

45 Nm (9 Ith)

checkingieplacing

Engine speed

checsing/agjusting

page 205 Injection pump

removing page 238

Som ce Installing page 23.7

‘adjusting page 23.4

Fepair Group 28 ‘hooking page 23.3

Tensioner

use too! US 4499)

46 Non (23116)

Drive belt

ramovingninetalling

atte

S8 Repair Group 13, 25 Nm (18 1 10)

Injection pump sprocket

tn (14 11)

An ‘moving page 23.7

Intormesiate shaft putty

48. (951819)

(81) CAUTION |

= 1 Grankahett sprocket | To avoid damage, keep injection parts clean

when removing, installing, disassembling

and assembling. Da not spill diesel fuel on

any rwaber hoses

Grankshatt sprocket bolt

10Nm (80 1),

129 not use locking compound

Double Vbelt pulley

23.2 wectonyam [Diese]

Diesel Injection System 23

jection pumpiValve timing, checking

Wark sequence

eta

Drive beft must be checked for proper tension and

‘te centered in sprockets before checking Injec-

on purraivatve timing

—remove eytinder head coveridrive belt cover

rotate engine until lobes of camishatt on

cylinder No. 1 point upward (TDG position)

install setting bar 2065A on cylinder head

luin camshaft until one end of setting bar

touches cylinder head

measure gap at other end with feeler gauge

take half of measurement and insert feeler of

this thickness between bar and cylinder head

ata

—tuin camshaft so bar rests on fevier gauge

insart second feeier gauge of same thickness

botwoen other end of bar and cylinder head

1B

“~eeok that marks on sprocket, pump and

‘mounting plate (black arrow) are approximately

aligned

YES, pump in correct position, continue with

work sequence

INKO, pump incorrectly positioned, adjust

iming (see page 23.4)

{engine removed)

—altach tool 2068 to crankcase

set scafe to 100 mm (arrow A)

—tip of scale must align with TDC mark on

clutch pressure plate (arrow B)

{engine Instatied}

—check that TD€ mark on clutch pressure plate

is In fine with boss on bell housing

If YES, valve timing OK; next check injection

timing (see page 23.4)

INO, valve timing incorrect, proceed as follows:

loosen camshaft spfecket bolt # turn

—tap back of camshaft sprocket with rubber

hammer nti itis loose

—hand tighten sprocket bott until end play is

eliminated but sprocket still urns freely on

camshatt

—rotate engine until TDC marks aliga on flywheel

torque camsnatt bolt 10 45 Nm (33 ft lb)

recheck marks

—check injection timing (see page 23.4)

wists pmpnabetining 2D

You might also like

- DoodleDocument3 pagesDoodlebrechtfestjensNo ratings yet

- Flours Herbs and SpicesDocument1 pageFlours Herbs and SpicesbrechtfestjensNo ratings yet

- Event Production Health and SafetyDocument38 pagesEvent Production Health and SafetyCarlo Cliff LeeNo ratings yet

- 35-Manual Transmission-Case, Gears, ShaftsDocument136 pages35-Manual Transmission-Case, Gears, ShaftsbrechtfestjensNo ratings yet

- Con Tech Resident Ail Lighting GuideDocument20 pagesCon Tech Resident Ail Lighting GuidegtgreatNo ratings yet

- 34-Manual Transmission - Controls, AssemblyDocument30 pages34-Manual Transmission - Controls, AssemblybrechtfestjensNo ratings yet

- C033407 enDocument3 pagesC033407 enmelgarcia829No ratings yet

- Tech-Rider-St - James-2015.xlsx - Blad1Document1 pageTech-Rider-St - James-2015.xlsx - Blad1brechtfestjensNo ratings yet

- Instrumentalists: Performing Arts TipsDocument2 pagesInstrumentalists: Performing Arts Tipsbrechtfestjens100% (1)

- 39 DifferentialDocument62 pages39 DifferentialbrechtfestjensNo ratings yet

- 28 Ignition SystemDocument46 pages28 Ignition SystembrechtfestjensNo ratings yet

- 30 Clutch, ControlsDocument12 pages30 Clutch, ControlsbrechtfestjensNo ratings yet

- 27 Electrical Battery, Starter, AlternatorDocument33 pages27 Electrical Battery, Starter, AlternatorbrechtfestjensNo ratings yet

- 28 Ignition SystemDocument46 pages28 Ignition SystembrechtfestjensNo ratings yet

- 20 Fuel SupplyDocument34 pages20 Fuel SupplybrechtfestjensNo ratings yet

- 26-Exhaust System:Emission ControlDocument11 pages26-Exhaust System:Emission ControlbrechtfestjensNo ratings yet

- 26-Exhaust System:Emission ControlDocument11 pages26-Exhaust System:Emission ControlbrechtfestjensNo ratings yet

- 17 Lubrication SystemDocument10 pages17 Lubrication SystembrechtfestjensNo ratings yet

- 19 Cooling SystemDocument24 pages19 Cooling SystembrechtfestjensNo ratings yet

- 15-Cylinder Heads:Valve DriveDocument32 pages15-Cylinder Heads:Valve DrivebrechtfestjensNo ratings yet

- 10 Engine AssemblyDocument10 pages10 Engine AssemblybrechtfestjensNo ratings yet

- 10 Engine Assembly PDFDocument10 pages10 Engine Assembly PDFbrechtfestjensNo ratings yet

- 1983 Westfalia Vanagon Camper ManualWMDocument26 pages1983 Westfalia Vanagon Camper ManualWMbrechtfestjens100% (2)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)