Professional Documents

Culture Documents

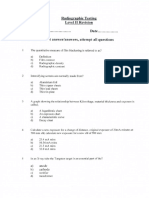

Addressing Corrosion Under Pipe Supports (CUPS) (PRS200a)

Uploaded by

Trajko GorgievskiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Addressing Corrosion Under Pipe Supports (CUPS) (PRS200a)

Uploaded by

Trajko GorgievskiCopyright:

Available Formats

General Factsheet

Addressing Corrosion Under

Pipe Supports (CUPS)

Corrosion Under Pipe Supports

(CUPS) is a growing problem

- a particular threat to the

integrity of ageing pipework.

Poor pipework integrity can lead to incidents impacting

safety and production. These incidents can become very

costly. Process Industry facilities with miles of pipework must

continue to strive for, and improve, safety, environmental,

production and cost goals at a time when many asset are

extending their period of operation beyond their original

design life.

The Energy Institute, in conjunction with ABB, have produced

guidance for managing CUPS. Complying with this guidance

is expected to become an area of focus for the industry.

The greatest concern is that corrosion develops in areas

that are difficult to inspect so this could go undetected.

The design of the support, its material of construction,

and a number of other factors affect the type and rate of

deterioration. The main contributory factors include:

Moisture (rain, fire water, deluge testing etc.) and

contaminants (e.g. chlorides from sea water)

The pipe operating temperature

Thermal expansion and contraction of the piping - this can

damage the coating by fretting, or cause it to crack and

disbond

Internal and external corrosion

Inability to inspect / maintain

Pipe support design

Breakdown of protective coating

What we offer

ABB offers a 3 stage approach to managing CUPS, involving

a combination of inspections, assessments, remediation and

repair.

Assess

Review of the current condition of piping systems and an

assessment of the risk posed by CUPS

Plan

Remediation planning - the objective is to plan and

undertake the work effectively and safely. The outcome is

to establish the known condition of piping systems and to

plan necessary actions

Develop an effective inspection and maintenance strategy

for managing CUPS into the future

Execute

Implement an effective and safe remediation strategy for

piping affected by CUPS, including both on-line and offline remediation

We can support by implementing complete programmes

of remediation or carrying out discrete services such as

inspection or design

All the advice that we give is in line with the EI guidance.

Typical areas of work for managing CUPS.

Condition

review

Plan

Agree goals

Standards

Cost and

schedule

Execute

Inspection

Design,

repair or

remediate

Remediation

and repair

Work

management

procedures

Typical areas of work for managing CUPS

Assess

We have extensive knowledge of all aspects necessary to

manage corrosion under pipe supports. We have inspection

guidelines, working procedures, risk assessment processes,

estimating methods, data management expertise etc. as well

as the project management and piping functional expertise.

Our team of specialists with operational heritage will use their

experience to make pragmatic technical judgements and

offer solutions that are cost effective.

Our experience of such programmes will enable you to get

started on this significant area with confidence. ABB can

be with you each step of the way to ensure the benefits are

realised.

For further information please contact:

ABB Consulting

Daresbury Park

Daresbury

Warrington

Cheshire

WA4 4BT

United Kingdom

Phone: +44 (0)1925 741111

Fax: +44 (0)1925 741212

E-Mail: contact@gb.abb.com

www.abb.com/consulting

ABB Consulting provides technical and engineering services

to improve performance in the areas of compliance,

operations and engineering to customers in the chemical,

petrochemical, oil & gas, power, pharmaceuticals, metals

and consumer industries worldwide.

PRS200a/06/14

ABB Limited 2014

Why ABB?

ABB Consulting has many years experience in the design,

inspection and maintenance of pipework, based on this

experience, the Energy Institute commissioned us to produce

their industry guidance.

Integrity management

Benefits

Improved plant safety and reliability through minimising

pipework failures

Long term cost benefits through efficient work planning

Pipework life extended, therefore potential plant life

extension

Minimised loss of production, by carrying out remediation

online

Costed improvement plan for budgeting purposes

Increased confidence in understanding the risks presented

by CUPS and in the pipework integrity

Demonstrable management of CUPS issues

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Non-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2Document242 pagesNon-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2darqm589% (18)

- Non-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2Document242 pagesNon-Destructive Testing: Sample Questions For Conduct of Examinations at Levels 1 and 2darqm589% (18)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- NDT Screening MethodDocument180 pagesNDT Screening MethodAjith Kumar100% (2)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- ET ArrayDocument30 pagesET ArrayTrajko Gorgievski100% (1)

- Spa Business PlanDocument23 pagesSpa Business Planfahad sarwar100% (3)

- Ancient Indian Medicine Systems OverviewDocument11 pagesAncient Indian Medicine Systems OverviewAmrutha AyinavoluNo ratings yet

- Radiographic Testing: Compiled For ASNT by Bahman Zoofan The Ohio State UniversityDocument293 pagesRadiographic Testing: Compiled For ASNT by Bahman Zoofan The Ohio State UniversityTrajko GorgievskiNo ratings yet

- Radiographic Testing: Compiled For ASNT by Bahman Zoofan The Ohio State UniversityDocument293 pagesRadiographic Testing: Compiled For ASNT by Bahman Zoofan The Ohio State UniversityTrajko GorgievskiNo ratings yet

- Ae0 PDFDocument14 pagesAe0 PDFMartinus PutraNo ratings yet

- Nonrelevant and False Indications 2 (Ebook)Document60 pagesNonrelevant and False Indications 2 (Ebook)Trajko Gorgievski100% (1)

- Section 3 Capabilities and Limitations of Guided Wave Tests.Document16 pagesSection 3 Capabilities and Limitations of Guided Wave Tests.Trajko GorgievskiNo ratings yet

- Buch 15 Corrosion Under Pipe SupportsDocument8 pagesBuch 15 Corrosion Under Pipe SupportsTrajko GorgievskiNo ratings yet

- Crisis ManagementDocument23 pagesCrisis ManagementLauren Gail75% (4)

- Project WorkPlan Budget Matrix ENROLMENT RATE SAMPLEDocument3 pagesProject WorkPlan Budget Matrix ENROLMENT RATE SAMPLEJon Graniada60% (5)

- Efndt GuidelinesDocument50 pagesEfndt GuidelineszirimiaNo ratings yet

- Ae01 PDFDocument34 pagesAe01 PDFTrajko GorgievskiNo ratings yet

- Relevant Discontinuities Electromagnetic Testing (ET), (Ebook)Document78 pagesRelevant Discontinuities Electromagnetic Testing (ET), (Ebook)Trajko GorgievskiNo ratings yet

- Evaluation of Precision Performance of Quantitative Measurement Methods Approved Guideline-Second EditionDocument56 pagesEvaluation of Precision Performance of Quantitative Measurement Methods Approved Guideline-Second EditionHassab Saeed100% (1)

- Cip PrasanjaDocument1 pageCip PrasanjaTrajko GorgievskiNo ratings yet

- T-And L-Types of Long-Range Guided Waves For Defect DetectionDocument16 pagesT-And L-Types of Long-Range Guided Waves For Defect DetectionTrajko GorgievskiNo ratings yet

- RT - SNT ReviewerDocument7 pagesRT - SNT ReviewerTrajko GorgievskiNo ratings yet

- En Manual GA 4 - 01 Rev1 - 00Document15 pagesEn Manual GA 4 - 01 Rev1 - 00Trajko GorgievskiNo ratings yet

- 2 GinzelDocument13 pages2 GinzelDurgamadhaba MishraNo ratings yet

- Asnt-Level II RTDocument21 pagesAsnt-Level II RTTrajko GorgievskiNo ratings yet

- 2002 Corrosion at Pipe Supports Causes and Solutions J Britton PDFDocument16 pages2002 Corrosion at Pipe Supports Causes and Solutions J Britton PDFTrajko GorgievskiNo ratings yet

- En Manual GA 4 - 01 Rev1 - 00Document15 pagesEn Manual GA 4 - 01 Rev1 - 00Trajko GorgievskiNo ratings yet

- VI - B - Surface Wave Ultrasonic InspectionDocument6 pagesVI - B - Surface Wave Ultrasonic InspectionTrajko GorgievskiNo ratings yet

- 2 GinzelDocument13 pages2 GinzelDurgamadhaba MishraNo ratings yet

- Usm 35x Data SheetDocument2 pagesUsm 35x Data SheetAsif HameedNo ratings yet

- How To Write An SOP PDFDocument3 pagesHow To Write An SOP PDFMohammad Abd Alrahim ShaarNo ratings yet

- En Manual GA 4 - 01 Rev1 - 00Document15 pagesEn Manual GA 4 - 01 Rev1 - 00Trajko GorgievskiNo ratings yet

- Info ALP 201101 GB FullDocument26 pagesInfo ALP 201101 GB FullSaqib KhanNo ratings yet

- 021 002 935 - Phasec 3 PDFDocument185 pages021 002 935 - Phasec 3 PDFvrapciudorian0% (1)

- 021 002 935 - Phasec 3 PDFDocument185 pages021 002 935 - Phasec 3 PDFvrapciudorian0% (1)

- 9 Facebook BmiDocument29 pages9 Facebook BmiDin Flores MacawiliNo ratings yet

- Senior Counsel or Associate General Counsel or Assistant GeneralDocument3 pagesSenior Counsel or Associate General Counsel or Assistant Generalapi-76922317No ratings yet

- English in Nursing 1: Novi Noverawati, M.PDDocument11 pagesEnglish in Nursing 1: Novi Noverawati, M.PDTiara MahardikaNo ratings yet

- Beddtiot ORTHO / Orthodontic Courses by Indian Dental AcademyDocument60 pagesBeddtiot ORTHO / Orthodontic Courses by Indian Dental Academyindian dental academyNo ratings yet

- Kasaj2018 Definition of Gingival Recession and Anaromical ConsiderationsDocument10 pagesKasaj2018 Definition of Gingival Recession and Anaromical ConsiderationsAna Maria Montoya GomezNo ratings yet

- Comet Assay: From Wikipedia, The Free EncyclopediaDocument11 pagesComet Assay: From Wikipedia, The Free EncyclopediasuryasivNo ratings yet

- Moosa Amandio PDFDocument12 pagesMoosa Amandio PDFMussa AmândioNo ratings yet

- UntitledDocument19 pagesUntitledAnna S. LatipNo ratings yet

- En Anerkennung Abschluesse FinalDocument2 pagesEn Anerkennung Abschluesse FinalKasim ButkovicNo ratings yet

- The Premier University in Zamboanga Del Norte: Jose Rizal Memorial State UniversityDocument1 pageThe Premier University in Zamboanga Del Norte: Jose Rizal Memorial State UniversityCHARLEES BRAVONo ratings yet

- Pediatric Nutrition and Nutritional Disorders: PediatricsDocument4 pagesPediatric Nutrition and Nutritional Disorders: Pediatricsapi-3829364No ratings yet

- 2022-03-15 Board of Supervisors - Full Agenda-2940Document546 pages2022-03-15 Board of Supervisors - Full Agenda-2940ShannanAdamsNo ratings yet

- Immunization WHODocument17 pagesImmunization WHOMuhammad Hardhantyo PuspowardoyoNo ratings yet

- PVMC FormDocument3 pagesPVMC FormAhsanAnjumNo ratings yet

- Taking Blood Pressure CorrectlyDocument7 pagesTaking Blood Pressure CorrectlySamue100% (1)

- Botany (Virus)Document48 pagesBotany (Virus)Madhuri DeviNo ratings yet

- HRFuture Sept 2020 MJLKJDocument59 pagesHRFuture Sept 2020 MJLKJGlecy KimNo ratings yet

- DMDFDocument22 pagesDMDFsujal177402100% (1)

- Siddhant Fortis HealthCareDocument4 pagesSiddhant Fortis HealthCaresiddhant jainNo ratings yet

- HIV Prevention: HSCI 225 BY Mutua Moses MuluDocument23 pagesHIV Prevention: HSCI 225 BY Mutua Moses MuluJibril MohamudNo ratings yet

- Functional Electrical StimulationDocument11 pagesFunctional Electrical StimulationMohd Khairul Ikhwan AhmadNo ratings yet

- Chapter 14 Pharmacy Law and Ethics Notes Complete Notes by Noteskarts Acc To ER20Document4 pagesChapter 14 Pharmacy Law and Ethics Notes Complete Notes by Noteskarts Acc To ER20Shamant TNo ratings yet

- Addressing The Impact of Foster Care On Biological Children and Their FamiliesDocument21 pagesAddressing The Impact of Foster Care On Biological Children and Their Familiesapi-274766448No ratings yet

- Mixed Connective Tissue DZ (SLE + Scleroderma)Document7 pagesMixed Connective Tissue DZ (SLE + Scleroderma)AshbirZammeriNo ratings yet

- PM - IntelliVue MP2 Patient MonitorDocument30 pagesPM - IntelliVue MP2 Patient MonitorpilarNo ratings yet