Professional Documents

Culture Documents

Job#5 Unconfined Compressive Strength Using Cemnt

Uploaded by

MazharYasinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Job#5 Unconfined Compressive Strength Using Cemnt

Uploaded by

MazharYasinCopyright:

Available Formats

Geotechnical and Foundation Engineering October 19, 2016

EXPERIMENT # 5

DETERMINATION OF UNCONFINED COMPRESSIVE

STRENGTH OF COHESIVE SOILS STABILIZED WITH CEMENT

5.1 OBJECTIVES

The basic purpose of the unconfined compression test is to quickly obtain a

measure of compressive strength for those soils that possess sufficient

cohesion to permit testing in the unconfined state

To perform unconfined compression test on cement stabilized cohesive soils to

determine their unconfined compressive strength (qu) and undrained shear

strength (su).

The determination of the unconfined compressive strength of cohesive soil in

the intact, remoulded, or reconstituted condition, using strain-controlled

application of the axial load.

Provides an approximate value of the strength of cohesive soils in terms of total

stresses.

5.2 APPARATUS:

Unconfined Compression Device (Electrically driven strain controlled)

Re-molding Device

Deformation Dial Gage

Balance (L.C. = 0.01 gm)

Spatula

Moisture tins

5.3 RELATED THEORY:

The geotechnical process of improvement the required characteristics of soil are

known as ground improvement. It has two types

i. Surface Stabilization

ii. Deep ground improvement

5.3.1 SURFACE STABILIZATION

This method for stabilization can be grouped into:

The University of Lahore 29

Geotechnical and Foundation Engineering October 19, 2016

Mechanical Stabilization

Physical Stabilization

Chemical stabilization

Physio-Chemical Stabilization

5.3.1.1 MECHANICAL STABILIZATION:

In this method, mechanical energy is used to improve the soil mass and the method

is known as compaction. For the embankments for roads, railways, dams, levees, etc.

generally rollers, vibratory plates, and tampers are used compaction. Choice of roller

or tamper usually depends on the degree of improvement required and the type of soil

being compacted.

5.3.1.2 PHYSICAL STABILIZATION:

In this method, the physical properties of the material (soil) are improved by blending

two or three soils, together so as to improve the grading of mixture to well graded

material. This technique is mostly used in road construction when more than one type

of soils is readily available at or near the site. In physical method, some additive like

cement, lime and bitumen is added in the soil.

5.3.1.3 CHEMICAL STABILIZATION

Chemical stabilizer also known as soil binders or soil palliatives provides temporary

soil stabilization. Materials made of vinyl, asphalt or rubbers are sprayed onto the

surface of exposed soils to hold the soil in place and protect against erosion from

runoff and wind. Chemical used for stabilization are easily applied to the surface of the

soil, can be effective in stabilizing area where vegetative practice cannot be

established, and provide immediate protection.

5.3.1.4 PHYSIO-CHEMICAL STABILIZATION

In this method of soil stabilization, a combination of both physical and chemical

methods such as lime stabilization are used.

The University of Lahore 30

Geotechnical and Foundation Engineering October 19, 2016

5.4 PROCEDURE

If density and moisture content of the soil is known, calculate the weight of the

dry soil needed for preparation of soil sample of 1.5 diameter and 3 height.

5.4.1 PREPARATION OF SAMPLE

We have pressure at sample

= 18 /

= 11 %

Volume =

.

Volume = 3 = 5.3014

=0.0000868 m3

.

W o =180.0000868 = 1.56 = .

= 160

Moisture content 3% 6% 9%

Cement (g) 4.8 9.6 14.4

Water Content (g) 17.6 17.6 17.6

Soil (g) 137.6 132.8 128

Add specified amount of water and percentage of cement (3%, 6%, 9%) and

mix them thoroughly.

Put the sample in mold and prepare soil column.

Cure the sample at least 7 days in desiccator to cure the sample.

After 7 days carefully align the specimen in the compression machine.

The University of Lahore 31

Geotechnical and Foundation Engineering October 19, 2016

Set the load dial gage to zero and set the deformation dial to zero. At this time

a very small load should be on the sample.

Turn on machine and take load and deformation dial readings as follows 10,

20, 30, 40, dial divisions thereafter, until of the following:

Load decreases on sample significantly.

Load holds constant for 4 readings.

Deformation is significantly past 20% strain.

Compute the unit strain, corrected area, and the unit stress, for enough of the

reading to define the stress-strain curve adequately. Plot the results on the

graph paper from the test results, show qu as the peak stress of each test and

show the average value of qu for three tests. Be sure to plot strain as the

abscissa.

5.5 OBSERVATIONS& CALCULATIONS

Height of specimen= = 3" = 76.2

Diameter of specimen= = 1.5" = 38.1

Area of specimen

38.1

=

4

= 1140

Volume of Specimen=AreaHeight= 114076.2 = 86875

Proving Ring Constant= PRC = 2.43 lb/div.

Deformation dial gage constant=0.01 mm

Weight of soil sample= 160 gram

Initial Moisture Content= 11 %

The University of Lahore 32

Geotechnical and Foundation Engineering October 19, 2016

5.5.1 FOR 3% CEMENT CONTENT

Load

Deformation

Dial Sample Unit Axial Corrected Axial

Sr# Dial Gauge Axial Load

Gauge Deformation Strain Strain Area Stress

Reading

Reading

- lb./Div. mm mm/mm % mm2 lb. kN kPa

1 0.00 0.00 0.00 0.00 0.00 1140.00 0.00 0.00 0.00

2 10.00 4.00 0.10 0.00 0.13 1141.50 9.72 0.04 37.88

3 20.00 5.00 0.20 0.00 0.26 1143.00 12.15 0.05 47.28

4 30.00 6.00 0.30 0.00 0.39 1144.51 14.58 0.06 56.67

5 40.00 6.00 0.40 0.01 0.52 1146.02 14.58 0.06 56.59

6 50.00 6.50 0.50 0.01 0.66 1147.53 15.80 0.07 61.23

7 60.00 4.00 0.60 0.01 0.79 1149.05 9.72 0.04 37.63

8 70.00 3.00 0.70 0.01 0.92 1150.57 7.29 0.03 28.18

9 80.00 2.00 0.80 0.01 1.05 1152.10 4.86 0.02 18.76

5.5.2 FOR 6% CEMENT CONTENT

Load

Deformation

Dial Sample Unit Axial Corrected Axial

Sr# Dial Gauge Axial Load

Gauge Deformation Strain Strain Area Stress

Reading

Reading

- lb./Div. mm mm/mm % mm2 lb. kN kPa

1 0.00 0.00 0.00 0.00 0.00 1140.00 0.00 0.00 0.00

2 10.00 10.00 0.10 0.00 0.13 1141.50 24.30 0.11 94.69

3 20.00 15.00 0.20 0.00 0.26 1143.00 36.45 0.16 141.85

4 30.00 18.00 0.30 0.00 0.39 1144.51 43.74 0.19 170.00

5 40.00 20.00 0.40 0.01 0.52 1146.02 48.60 0.22 188.64

6 50.00 25.00 0.50 0.01 0.66 1147.53 60.75 0.27 235.49

7 60.00 21.00 0.60 0.01 0.79 1149.05 51.03 0.23 197.55

8 70.00 20.00 0.70 0.01 0.92 1150.57 48.60 0.22 187.89

9 80.00 18.00 0.80 0.01 1.05 1152.10 43.74 0.19 168.88

The University of Lahore 33

Geotechnical and Foundation Engineering October 19, 2016

5.5.3 FOR 9 % CEMENT CONTENT

Load

Deformation

Dial Sample Unit Axial Corrected Axial

Sr# Dial Gauge Axial Load

Gauge Deformation Strain Strain Area Stress

Reading

Reading

- lb./Div. mm mm/mm % mm2 lb. kN kPa

1 0.00 0.00 0.00 0.00 0.00 1140.00 0.00 0.00 0.00

2 10.00 10.00 0.10 0.00 0.13 1141.50 24.30 0.11 94.69

3 20.00 15.00 0.20 0.00 0.26 1143.00 36.45 0.16 141.85

4 30.00 20.00 0.30 0.00 0.39 1144.51 48.60 0.22 188.89

5 40.00 23.00 0.40 0.01 0.52 1146.02 55.89 0.25 216.94

6 50.00 22.00 0.50 0.01 0.66 1147.53 53.46 0.24 207.23

7 60.00 15.00 0.60 0.01 0.79 1149.05 36.45 0.16 141.11

8 70.00 14.00 0.70 0.01 0.92 1150.57 34.02 0.15 131.52

9 80.00 13.00 0.80 0.01 1.05 1152.10 31.59 0.14 121.97

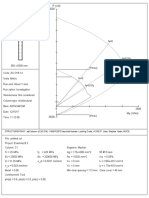

5.5.4 Graphs

GRAPH BETWEEN AXIAL STRESS VS AXIAL STRAIN

250.00

200.00

AXIAL STRESS

150.00

3% Cement

6% Cement

100.00

9% Cement

50.00

0.00

0.00 0.20 0.40 0.60 0.80 1.00 1.20

AXIAL STRAIN

The University of Lahore 34

Geotechnical and Foundation Engineering October 19, 2016

5.6 RESULTS

( ) =

2

Group # % Cement % Strain

KPa KPa

1 3 61.23 0.66 30.61

2 6 235.49 0.66 117.74

3 9 216.94 0.52 108.47

5.7 REFERENCE

ASTM D2166-06

Standard Test Method for Unconfined Compressive Strength of Cohesive Soil

5.8 COMMENTS

This test is basically a comparison b/w unconfined compression test by using simple

soil and by using soil and cement together. Form the graph we observed that the axial

stress of the 9% cement content sample shows less strength which may be due to the

errors in the apparatus or the error in the proper preparation of the sample.

This graph shows that the strength increases up to certain limit and then decreases.

We performed this test on 18kN/m3 dry density and 11% optimum moisture content.

This test can be performed on both types of sample i.e. (Disturbed and Undisturbed)

the strength of the material can be determined. This method of determining strength

is suitable only for soils that can retain a stable specimen shape in the remoulded

state. For soils that will not retain a stable shape, a vane shear test is performed

The University of Lahore 35

You might also like

- Construction Project StakeholdersDocument19 pagesConstruction Project StakeholdersMazharYasinNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

- SBR LatexDocument2 pagesSBR LatexMazharYasinNo ratings yet

- "Dear Students, Due Dates For Fall-2018 Semester Fee Are Mentioned BelowDocument1 page"Dear Students, Due Dates For Fall-2018 Semester Fee Are Mentioned BelowAlauddin Ahmad KHAN KHANNo ratings yet

- Uol HRD EdifDocument1 pageUol HRD EdifMazharYasinNo ratings yet

- GGBFSDocument2 pagesGGBFSMazharYasinNo ratings yet

- Burned Clay Pozzolana-Used PDFDocument9 pagesBurned Clay Pozzolana-Used PDFMazharYasinNo ratings yet

- Construction and Building MaterialsDocument9 pagesConstruction and Building MaterialsMazharYasinNo ratings yet

- Drawing Lecture-1Document28 pagesDrawing Lecture-1MazharYasinNo ratings yet

- Const.P. 2 2011Document42 pagesConst.P. 2 2011MazharYasinNo ratings yet

- Cement: The Binding Building MaterialDocument12 pagesCement: The Binding Building MaterialMazharYasinNo ratings yet

- 3Document4 pages3MazharYasinNo ratings yet

- Light Weight ConcreteDocument23 pagesLight Weight ConcreteMazharYasinNo ratings yet

- HOT WEATHER CONCRETING TIPSDocument6 pagesHOT WEATHER CONCRETING TIPSMazharYasinNo ratings yet

- CM 425 - Properties of Fresh Concrete PDFDocument14 pagesCM 425 - Properties of Fresh Concrete PDFTran Huynh NamNo ratings yet

- Citation 222245843Document1 pageCitation 222245843MazharYasinNo ratings yet

- Experiment No. 10: To Determine The Effect of Rate of Loading On The Compressive Strength of P.C.C Cube and CylinderDocument3 pagesExperiment No. 10: To Determine The Effect of Rate of Loading On The Compressive Strength of P.C.C Cube and CylinderMazharYasinNo ratings yet

- Citation 222245843Document36 pagesCitation 222245843MazharYasinNo ratings yet

- Untitled MapDocument1 pageUntitled MapMazharYasinNo ratings yet

- Brick BondsDocument4 pagesBrick BondsMazharYasinNo ratings yet

- Slab DesignDocument78 pagesSlab DesignMazharYasinNo ratings yet

- Public Notice CE 2019 EnglishDocument4 pagesPublic Notice CE 2019 EnglishMazharYasinNo ratings yet

- Table: Assembled Joint Masses Joint Masssource U1 U2 U3 R1 R2 R3 CenterxDocument80 pagesTable: Assembled Joint Masses Joint Masssource U1 U2 U3 R1 R2 R3 CenterxMazharYasinNo ratings yet

- Public Notice CE 2019 English PDFDocument1 pagePublic Notice CE 2019 English PDFMazharYasinNo ratings yet

- Structurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceDocument1 pageStructurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceMazharYasinNo ratings yet

- Structurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceDocument1 pageStructurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceMazharYasinNo ratings yet

- ReactionsDocument2 pagesReactionsMazharYasinNo ratings yet

- PlanDocument1 pagePlanMazharYasinNo ratings yet

- SP ColumnDocument2 pagesSP ColumnMazharYasinNo ratings yet

- Structurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceDocument1 pageStructurepoint - Spcolumn V5.50 (TM) - 1869762670 Day Trial License. Locking Code: 4-31D37. User: Mazhar Yasin, MsceMazharYasinNo ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Chapter 6 DryingDocument34 pagesChapter 6 DryingPMNo ratings yet

- Design of FRP-Profiles & All-FRP-Structures (2009) - Presentation PDFDocument67 pagesDesign of FRP-Profiles & All-FRP-Structures (2009) - Presentation PDFJulio Humberto Díaz RondánNo ratings yet

- Electrochemistry PresentationDocument36 pagesElectrochemistry PresentationMuhammad HaziqNo ratings yet

- Coaching Plan Sub. Code & Name: AE6403 AIRCRAFT STRUCTURES - I Sem: Staff Name: Department: DayDocument3 pagesCoaching Plan Sub. Code & Name: AE6403 AIRCRAFT STRUCTURES - I Sem: Staff Name: Department: DayPradharsan ChelvanayagamNo ratings yet

- En1995 ManualDocument32 pagesEn1995 ManualMarian DragosNo ratings yet

- Operator's Manual New Wave Research, Inc. Tempest and Gemini PIV ND: YAG LasersDocument72 pagesOperator's Manual New Wave Research, Inc. Tempest and Gemini PIV ND: YAG LasersLeonardo PantojaNo ratings yet

- Manual For Design and Detailing of Reinforced Concrete 2013 HK GuideDocument301 pagesManual For Design and Detailing of Reinforced Concrete 2013 HK GuideLau Kim HwaNo ratings yet

- A Comparative Study of Omrf & SMRF Structural System Using Different SoftwaresDocument6 pagesA Comparative Study of Omrf & SMRF Structural System Using Different SoftwaresIJIRAE- International Journal of Innovative Research in Advanced EngineeringNo ratings yet

- 10th MG Cup 2022 Physics English ProblemsDocument12 pages10th MG Cup 2022 Physics English Problemsmilos9444No ratings yet

- IISER Aptitude Test 2013: Syllabus ForDocument1 pageIISER Aptitude Test 2013: Syllabus ForSanthoshkumar RayavarapuNo ratings yet

- PM1610 - Leaflet (2023.04)Document2 pagesPM1610 - Leaflet (2023.04)Роман РакусовNo ratings yet

- Chemical Engineering and Processing- Process Intensification Volume 48 Issue 5 2009 [Doi 10.1016_j.cep.2009.03.001] Christina B. Dirk-Faitakis; Weizhu an; Tzong-Bin Lin; Karl T. Ch -- Catalytic Distillation for SimulDocument8 pagesChemical Engineering and Processing- Process Intensification Volume 48 Issue 5 2009 [Doi 10.1016_j.cep.2009.03.001] Christina B. Dirk-Faitakis; Weizhu an; Tzong-Bin Lin; Karl T. Ch -- Catalytic Distillation for SimulAdi Prima RizkiNo ratings yet

- Chemistry Exam Study Guide ContentsDocument2 pagesChemistry Exam Study Guide ContentsAnna ScamardellaNo ratings yet

- HW 2 - ChemDocument14 pagesHW 2 - ChemStephanieNo ratings yet

- Ideal GasDocument60 pagesIdeal Gas68zrvtr9bfNo ratings yet

- Laser Diode: Product Specification Sheet L658P040Document1 pageLaser Diode: Product Specification Sheet L658P040Jorge GuerreroNo ratings yet

- Li 2016Document10 pagesLi 2016baihaqiNo ratings yet

- Axial Piston Variable Pump A10V (S) O Series 31 AmericasDocument56 pagesAxial Piston Variable Pump A10V (S) O Series 31 AmericasFawzi AlzubairyNo ratings yet

- Car Cooling SystemDocument5 pagesCar Cooling SystemInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Shell Momentum Balances for Pipe and Annular FlowDocument15 pagesShell Momentum Balances for Pipe and Annular FlowPatricia de LeonNo ratings yet

- Heat Transfer Lab ManualDocument77 pagesHeat Transfer Lab ManualJoe AfendiNo ratings yet

- Parth PosterDocument1 pageParth Posteranubhav thakurNo ratings yet

- Combustion Physics by C K LawDocument11 pagesCombustion Physics by C K LawSuvendu Kumar SethyNo ratings yet

- D 3032 - 98 - RdmwmzitotgDocument42 pagesD 3032 - 98 - RdmwmzitotgPrakash MakadiaNo ratings yet

- Chap 5Document31 pagesChap 5Kali DasNo ratings yet

- TGT-P-H01-RP-0002 Rev.0 PDFDocument41 pagesTGT-P-H01-RP-0002 Rev.0 PDFThái Xuân QuangNo ratings yet

- Problems of Geodesy and Its Place Among Other Disciplines. Basic Concepts of Geodesy. Coordinate and Height Systems Used in GeodesyDocument13 pagesProblems of Geodesy and Its Place Among Other Disciplines. Basic Concepts of Geodesy. Coordinate and Height Systems Used in GeodesyMasooma HashemiNo ratings yet

- Scintillation Material For Neutrn Imaging DetectorsDocument6 pagesScintillation Material For Neutrn Imaging Detectors송한결100% (1)

- Chemistry Test Chapter 7 ElectrolysisDocument3 pagesChemistry Test Chapter 7 ElectrolysisamirNo ratings yet

- Conjugation Part 1Document32 pagesConjugation Part 1Syed Ali100% (1)

![Chemical Engineering and Processing- Process Intensification Volume 48 Issue 5 2009 [Doi 10.1016_j.cep.2009.03.001] Christina B. Dirk-Faitakis; Weizhu an; Tzong-Bin Lin; Karl T. Ch -- Catalytic Distillation for Simul](https://imgv2-2-f.scribdassets.com/img/document/212683560/149x198/61db6a310c/1439890498?v=1)