Professional Documents

Culture Documents

Bubble Size and Bubble Size Determination

Uploaded by

James MarinCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bubble Size and Bubble Size Determination

Uploaded by

James MarinCopyright:

Available Formats

RICHARD C. CHANG, HERBERT M. SCHOEN, and C. S. GROVE, JR.

Syracuse University, Syracuse, N. Y.

Bubble Size and Bubble Size Determination

Quick Freezing of Foam

b Stabilizes fresh foam as it i s generated

1 Holds bubble size and bubble size distribution

unchanged

h Provides data on relation between dispersity and other

physical properties

A L T H O U G H a large amount of work meters of the gas-liquid interface in 1 ml. persity under flow conditions. He com-

has been done on foams in general, in- of foam. pared the light transmission to the ex-

vestigations of dispersity of foams and However, when Clark and Blackmans pansion ratio and to actual photomicro-

the relationships between dispersity of light transmission method is applied to a graphs of the flowing foam.

foam and other physical properties are foam system, which changes during Another method of obviating the insta-

rather scarce. standing, errors may be introduced be- bility of foam, used by Sovitskaya ( 5 ) ,

Distribution of bubble sizes in a very cause time is required to take the photo- was the quick-freezing technique with

stable froth was studied by Sibree (4, micrographs and the light transmission liquid oxygen. Photomicrographs were

who used a photomicrographic tech- readings. taken after the foam was frozen, and the

nique. Clark and Blackman (7), using Stenuf (6,7) modified Clark and Black- bubble sizes were determined from them.

a similar technique to study foams, mans technique and studied foam dis- She found that freezing and thawing

found that the larger bubbles grow and did not affect the dispersity and that the

the smaller bubbles shrink as a function frequency distribution of the bubbles

of time.

During their study of foam structure

Clark and Blackman ( 2 ) observed a rela-

p.-I was nearly the same in the surface layer

as in any other section of the foam mass.

71

tionship between foam dispersity and the 0.4w.

Experimental Apparatus and

opacity of the dispersed system, caused

by the scattering of incident light by

multiple reflections and refractions.

Later they found that the loss of light on

transmission through a layer of foam can

be expressed as a function of the degree

of dispersion of the air. They made

photomicrographs of foam at various

degrees of dispersion under static con-

A-

B-

BM5bF&rpR

7 r5ci.W.

Techniques

Freezing Apparatus. Because foams

are usually unstable, bubble sizes and

bubble size distribution change on

standing. I n order to study these prop-

erties, fresh foam was stabilized by quick

freezing as it was generated. The rate

of freezing is important, because bubble

ditions at atmospheric pressure and then size and bubble size distribution may

calibrated light transmission data with change while the foam is being frozen.

these photomicrographs as standards. Several freezing chamber designs were

They claimed that this method can be /.oCM tested, the final design, shown in Figure

used to measure specific surface of

foam. Specific surface was defined as

the total surface area in square centi- Figure 1.

I

/-

Freezing apparatus

1, being a modification of Sovitskayas

apparatus. The freezing chamber, A , is

a 1.9 X 1.0 X 0.4 cm. brass sheet. B is a

VOL. 48, NO. 11 NOVEMBER 1956 2035

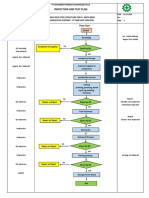

of the chamber to prevent evaporation dispersity. A flowsheet showing this

and condensation of moisture during the method used for generating foam of

freezing process. The freezing chamber variable expansion ratio is presented in

is constructed with only two sides, in- Figure 3. Foam liquid (6y0 Mearl-

stead of four, to allow any excess foam to foam), preheated to a desired tempera-

flow out when the chamber is covered. ture, was pumped from the solution

The time required for complete freezing tank by pump A at a constant rate of

is 15 to 30 seconds (average of 16 ob- 11.4 gallons per minute, as measured by

servations). a rotameter. iVhen the foam liquid was

Photomicrographic Apparatus and delivered into a tee, air was also sucked

Techniques. The photomicrographs into the tube by the adjustable speed of

were taken with a photomicrographic the Blackmer sliding vane pump, B, and

camera at magnifications of 20 and 40 thus foam was generated. ,4s the speed

diameters. Foam in the freezing cham- of pump B was varied, the amount of

ber was placed directly under the camera, feed air differed accordingly. Thus,

as shown in Figure 2, and a picture was foams of different expansion ratios were

taken within a few seconds to represent obtained. The foam was then passed

the unfrozen foam. Another picture of through a column packed with Berl

the same foam was taken about 1 minute saddles to a height of 40 inches. The

later, when complete freezing was as- packed column served as a homogenizer.

sured. The bubble sizes were computed Foam samples obtained were frozen

from the negatives with the aid of a com- immediately, and a photomicrograph of

parator. Averages were calculated for each sample was taken.

a number of plates before and after This study was also carried out using a

Figure 2. Photomicrographic camera freezing. Statistical analysis was applied centrifugal pump instead of the Blackmer

and freezing apparatus to evaluate the difference between aver- sliding vane pump, to generate the foam.

ages of the tw-o groups. A flowsheet of this generating equip-

To photograph the bubble distribution ment is shown in Figure 4.

solid brass bar, attached to the bottom of within the foam mass, the frozen foam Foam liquid was pumped from the

A , which serves as the cooling conductor. was sliced with a razor blade at several solution tank by means of the two cen-

The freezing apparatus is precooled by different depths. trifugal pumps. The flow rate of the solu-

dipping the brass bar in liquid oxygen; Expansion Ratio and Foam Dis- tion was measured by means of a rotam-

then the freshly generated foam is de- persity. A Blackmer sliding vane pump eter. The liquid feed rate was controlled

livered into the freezing chamber. A was employed in studying the relation- by means of the valve located between

small glass plate is quickly placed on top ship between expansion ratio and foam the pump and rotameter. The foam

solution and air were mixed in a tee and

the foam formed was passed through one

of the two packed columns. Both

I I columns were constructed of l1/z-inch

standard iron pipe packed with Berl

saddles. One column was 9 inches high

(homogenizer I), the other 36 inches high

(homogenizer 11). The foam generated

was delivered to a reservoir tank. Two

/ pressure gages were used to measure the

pressure drop across the column, AP =

PI - Pz,in Figures 3 and 4.

Foam formed during each test was

photomicrographed and the developed

plates \vere enlarged twice on paper

prints. Bubble sizes and bubble size

distribution \vere evaluated from these

positive prints.

Foam Agents Used

Ultravon '\I' Heptadecyl benzini-

midazol compound

(Ciba Co.)

Saponin AK 500 Plant glucosides (A. K.

Peters Go.)

Unox Phf-1000 Mixture of sodium hep-

tadecyl sulfate. butyl

Carbitol, monoeth-

1 anolamine, morpho-

line, and sodium ni-

trate (Union Car-

PZD bide and Carbon)

PE*d?///vg.

PUMP

4 PUMP Sodium lauryl

8 sulfate

Mearlfoam

(Raymond Labs.)

Protein hydrolyzate

Figure 3. Flowsheet of Blackmer vane pump foam-generating system (Mearl Corp.)

2036 INDUSTRIAL AND ENGINEERING CHEMISTRY

AQUEOUS FOAMS

Figure 5. Outer surface of drained

foam of 3% sodium laurylsulfate( X 4 0 )

Figure 6. Cut surface of foam of

&PA.

Figure 5 (X40)

Figure 4. Flowhseet of centrifugal pump foam-generating system

Results and Discussion rather than bv any real difference is

roughly about 94 oui of 100.

Effect of Freezing on Bubble Size

Results obtained with Ultravon W a t

and Bubble Size Distribution. Table

other concentrations, and with 4%

I lists the bubble size groups of five Mearlfoam, are summarized in Table

samples of foam generated with 0.5%

11. One pair showed identical average

Ultravon W, before and after freezing.

bubble size, while the other three pairs

When the plates taken before freez-

ing were compared with those taken after varied slightly. Again, the differences

freezing, three out of five gave identical were not statistically significant.

Figure 7. Second cut surface of foam

values for the average bubble sizes. The Bubble Size Distribution in Outer

Surface and in Foam Mass. In this

of Figure 5 (X40)

other two samples showed slight varia-

tions in bubble size during freezing, but series, after a photomicrograph of the

the differences were too small to be outer surface of each sample was taken,

statistically significant. The t value (3) two inner surfaces were obtained by

of the difference between the two groups cutting with a razor blade. Bubble sizes

was calculated to be 0.064, indicating and bubble size distribution were meas-

that the probability of producing such a ured on these pictures (Table 111).

difference in these samples by chance Photomicrographs of outer and inner

Table 1. Effect of Freezing

[Material. 0.5% Ultravon W concentration (by weight)] . Figure 8. Outer surface of freshly

Grouped Bubble S i z e , Microns prepared foam of 0.3% Saponin

26- 76- 125- 176- 225- 275- 516- 576- Av. Diarn , AK500 ( X 4 0 )

26 76 125 176 126 276 516 576 426 LNa P

N o . of Bubbles

Beforeb 210 85 25 12 14 13 12 11 2 274 92.5

After 100 85 25 12 14 13 12 11 2 274 92.5

Before 148 34 16 20 21 17 14 3 ,. 273 87

After 139

Before 232

31 21 25 20 18 13 2 .. 269 88

32 23 25 26 20 4 5 1 368 73.5

After 232 32 23 25 26 20 4 5 1 368 73.5

Before 67 99 14 6 15 19 16 7 1 244 102.5

After 67 99 14 6 15 19 16 7 1 244 102.5

Before 84 31 4 9 17 16 15 2 3 181 107.5

After 67 40 2 7 16 23 6 3 1 165 104.0

a Total number of bubbles.

Before and after freezing. Figure 9. Cut surface of foam of

Figure 8 (X40)

VOL. 48, NO. 11 NOVEMBER 1956 2037

Table II. Effect of Freezing on Difference Surfactants

Grouped Bubble S i z e , Microns

Av. t

Material 25-76 76-1?25 126-176 175-2$26 226-275 276-526 325-376 376-426 425-475 ZN D i a m . , p Value

iVo. of Bubbles -

Beforea 0 . 1 % Ultravon W 49 34 37 19 20 16 6 5 3 189 161.0 0.2

After 0.1% Ultravon W 44 39 33 21 21 16 7 2 2 185 159.0 0.2

Before 4% Mearlfoam 54 49 47 24 9 .. .. .. .. 183 119.0 1.04

After

Before

4% Mearlfoam

1% Ultravon W

78

11

91

6

62

5

32

5

5

3

..2 ..

2

..

2

. e

4

268

40

112.0

189.0

1.04

0.07

After 1% Ultravon W 10 10 4 6 6 3 3 4 a 47 1187.0 0.07

a Before and after freezing.

Table 111. Bubble Size Distribution o f Outer Surface and of Inner Surface after Cut

Grouped Bubble S i z e , Microns Av.

Surface 25-50 60-100 100-160 160-200 200-260 250-300 300-350 560--400 400-450 460-500 BN Diam., p

No. of Bubble8

3% Sodium Lauryl Sulfate

Outer .. 2 2 7 6 9 6 6 3 44 284

Inner .. ..1 1

.. 5

1

6

2

8

6

2

2

2 3 29 283.8

3 1 19 309.8

..

I .

Outer 2 5 3 2 5 5 5

Inner ..

..

..

1

4

2

2

4

3

5

4

5

5

5

5

4

3

1

3

37

29

31

295.8

300.2

286

Outer

Inner

12

..

17

7

8

11

12

7

6

2

1

1

.

.. ..

e . ..

..

56

28

115

106.4

0.37, Saponin AI( 500

Outer .. 18 39 18 9 1 1 .. .. 86 140.8

Inner

Outer

1

4

26

26

45

34

50

27

6

5

* *

1

..

..

.... *.

.. .. .... 129

96

139.2

127.2

.. ..

m .

Inner 4 16 30 29 9 *. e . 88 138.8

surfaces of two samples are presented in made using the light transmission when the pressure was increased to 29

Figures 5 to 9 as examples. These method. The change of average bubble pounds per square inch gage.

samples were statistically analyzed for size was less noticeable when the expan- When the 4.5 and 3y0Unox PM--1000

significance. The t values obtained in- sion ratio increased from 9.7 to 11.0 as solutions were studied, slug flow was ob-

dicated that the deviations of average compared to the increase from 7.6 to tained only within the pressure range of

bubble size were not significant. 9.7. This seems to indicate that there is a 11 to 21 pounds per square inch gage.

Relationship between Expansion Ra- maximum limit in the ability of a given With this slug-flow type of foam, the re-

tio and Foam Dispersity. The relation- foam system to reduce bubble sizes. lationship between expansion ratio and

ship between the expansion ratio and Photomicrographs of the resulting foam dispersity, as $hewn in Table V,

bubble size distribution, as studied with was very different from that obtained

foam produced by the three different

the Blackmer sliding vane pump using with steady flow. Contrary to the re-

expansion ratios are presented in Figures

670 Mearlfoam, is presented in Table sults obtained with 670 Unox PiM-1000

10 to 12.

IV. Results obtained with the centrifu- solution, a high inlet air pressure re-

gal pump, using 670 Unox PM-1000 Using the centrifugal pump, B, Figure

sulted in a low expansion ratio, which

and Mearlfoam solutions a t several con- 4, the 670 Unox PM-1000 solutions gave smaller average bubble sizes with

centrations, are summarized in Tables V showed results similar to the 670 Mearl- Unox PM-1000 at lower concentrations.

and VI, respectively. foam solution (using the Blackmer sliding This apparent anomaly can be explained

In Table IV, the average bubble sizes vane pump) when the pressure range as follows: When the foam is generated

obtained with 6% Mearlfoam were was held between 10 and 20 pounds per in a steady flow condition, most of the

found to be inversely proportional to the square inch gage. Within this pressure air forced into the pump is trapped by

expansion ratios. This fact is in agree- range the foam was produced in a steady the foam solution. When a foam solu-

ment with Stenufs (7) investigation stream, but slug flow was observed tion of lower concentration is used, the

Figure 10. Foam made with 6% Figure 11. Foam made with 6% Figure 12. Foam made with 6%

Mearlfoam solution ( X 2 0 ) Mearlfoam solution ( X 2 0 ) Mearlfoam solution (X20)

Expansion ratio 7.6 Expansion ratio 9.7 Expansion ratio 1 1 .O

2038 INDUSTRIAL AND ENGINEERING CHEMISTRY

AQUEOUS FOAMS

~~~ ~~~

Table VI. Average Bubble Size, Expansion Ratio, and Pressure Drop

Material. Mearlfoam

Packing column height. 9 inches

Packing column diameter. Il/pinch std. pipe

Packing material. Berl saddle

Solution rate. 1.5 gallons per minute

6% Concn. 4.6% Concn. 3% Concn. 1.5% Concn.

Photo No. 187.00 192.00 193.00 194.00 195.00 197.00 202.00 198.00 199.00 204.00 205.00 207.00

Expansion ratio 14.2 35.5 10.35 15.00 21.7 32.00 11.75 23.2 42.0 12.0 17.0 32.0

Av. diameter, fi 167.00 88.00 231.00 215.00 196.00 56.8 275.00 105.00 90.4 280.00 154.5 90.6

Inlet air pressure, P 10.00 28.00 11.00 15.00 21.00 37.00 12.00 12.00 37.00 12.00 16.00 28.00

Pressure drop ( A P ) , lb./

sq. inch 2.00 12.00 4.00 4.00 6.00 21.00 4.00 7.00 11.00 4.00 5.00 9.00

Temp., O C. 28.00 30.00 28.00 28.00 28.5 28.5 28.00 27.6 28.00 29.5 30.00 30.00

solution can no longer trap all of the air; Results of the tests with 1.5, 3.0, 4.5, also by the type of generating system, in-

hence slug flow is obtained. The higher and 6.0% Mearlfoam, using the centrif- let air pressure, and height and/or na-

the inlet air pressure, the more the air ugal pump, showed a relationship be- ture of the packed column.

escapes trapping by the foam solution, tween expansion ratio and foam dis-

resulting in a lower expansion ratio. O n persity similar to those obtained using Conclusions

the other hand, a reduction of bubble the Blackmer sliding vane pump. The

sizes is caused by the mixing action of air pressure range used was between 1 0 The quick-freezing of foam does not

the air in the packed column. The and 37 pounds per square inch gage. significantly change the structure of the

higher the air pressure, the greater the A steady flow was produced in all cases; foam with respect to bubble sizes and

mixing action; therefore, in spite of the hence the results agree with those ob- bubble size distribution.

low expansion ratio, a smaller average tained with the 60/, Unox PM-1000 Bubble sizes and bubble size distribu-

bubble size is produced. solutions. tion of the outer surface of a foam mass

A steady-flow foam was again ob- A decrease in average bubble size was, and those within the foam mass are

tained with 3% Unox PM-1000 solution in all cases, accompanied by an increase almost the same. The occasional small

when the height of the homogenizing in the pressure drop across the homogen- differences are not statistically significant.

column was increased from 9 to 38 izing column, whether the foam was in Expansion ratio, bubble sizes, and

inches. This , was attributed to the steady or slug flow. Presumably the bubble size distribution are related.

greater resistance offered by the longer smaller bubble sizes caused an increase However, the type of generating system,

packing column, which made steady in the apparent foam viscosity and hence nature of the foaming agent, concentra-

flow possible. Under this condition the an increase in the pressure drop. These tion of the solution, inlet air pressure, and

results were similar to those obtained results were in agreement with the find- height and/or nature of the refining

with 6% Mearlfoam solutions and Unox ings of Stenuf (6). section are also important in determining

P-1 000 solutions at higher concentra- It is apparent from the above three the foam dispersity.

tions. These foams were produced a t series of tests that the bubble sizes and The pressure drop across the homogen-

expansions of 7.33, 12.7, and 18.8; here bubble size distribution were affected izer (packed column) is directly affected

again smaller average bubble sizes were not only by the expansion ratio, nature by the bubble sizes and bubble size dis-

produced a t the higher expansion ratios. of foaming agent, and concentration, but tribution of the foam.

Acknowledgment

Table IV. Relationship between Expansion Ratio and Bubble Size The authors wish to thank the Engi-

neer Research and Development Labora-

(Material. 6% Mearlfoam. Liquid rate, 11.4 gallons per minute) tories of the United States Army, the

Figure Grouped Bubble Size, Microns Av. Naval Research Laboratories, and the

No. APO ab 85-75 76-125 126-176 176-236 225-275 Diam., I.( Office of Naval Research, under whose

10 11.9 7.6 46 23 22 18 12 120 sponsorship this research was carried

11 15.5 9.7 108 82 49 10 5 95.5 out.

12 18.0 11.0 136 70 72 15 e . 94

a Pressure drop, across homogenizer lb./sq. inch. literature Cited

Expansion ratio.

(1) Clark, N. O., Blackman, M., Trans.

Faraday SOC.44, 1 (1948).

Table V. Average Bubble Size, Expansion Ratio, and Pressure Drop ( 2 ) Ibid., p. 7.

( 3 ) Davies, 0. L., Statistical Methods in

(Material. Unox PM - 1000) Research and Production, p. 58,

Homogenizer I Homogenizer 11 Imperial Chemical Industries, Lon-

6% Concn. 4.6% Concn. 8% Concn. 3% Concn.

don, 1947.

(4) Sibree, J. V., Trans. Faraday SOC.

30,325

Photo No. 215.0 217.0 224a 223 22ga 227 233.0 234.0 235.0 (1 934).

01 8.38 9.45 9.67 10.45 9.0 15.8 7.33 12.7 18.8 ( 5 ) Sovitskaya, E. M., Kolloid. Zhur. 13,

D av., p 47.6 31.85 46.9 67.3 34.0 61.4 66.3 52.9 47.1 309 (1951).

PI, lb./sq. inch

gage 10.0 20.0 21.0 15.0 21.0 11.0 11.0 16.0 22.0

.,

( 6 ) Stenuf, T. J.. unmblshed M.Ch.E.

thesis, Syracuse Qniversity, 1951.

AP = Pi - Pa 3.5 8.0 9.0 6.0 9.0 4.0 6.0 9.0 12.0 ( 7 ) Stenuf, T. J., unpublished Ph.D. thesis,

Temp., O C. 26.0 26.0 26.0 26.0 24.8 24.0 26.0 26.4 26.0 Syracuse University, 1953.

Slugging flow. RE~EIVED

for review November 25, 1955

ACCEPTEDJuly 3, 1956

VOL. 48, NO. 11 NOVEMBER 1956 2039

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- The Pentester BlueprintDocument27 pagesThe Pentester Blueprintjames smith100% (1)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- 6.water Treatment and Make-Up Water SystemDocument18 pages6.water Treatment and Make-Up Water Systempepenapao1217100% (1)

- Customer Advisory For Fire Suppression Systems - V4 - ENDocument18 pagesCustomer Advisory For Fire Suppression Systems - V4 - ENsak100% (1)

- Supplier Assessment Report-Shenzhen Illuman Photoelectronic Co., LTDDocument29 pagesSupplier Assessment Report-Shenzhen Illuman Photoelectronic Co., LTDAdam Andrew OngNo ratings yet

- Inspection and Test Plan: Flow Chart Start IncomingDocument1 pageInspection and Test Plan: Flow Chart Start IncomingSinden AyuNo ratings yet

- 8021b Aromatic and Halogenated Volatiles by Gas Chromatography UsingDocument21 pages8021b Aromatic and Halogenated Volatiles by Gas Chromatography UsingJames MarinNo ratings yet

- English Final Exam Level III - CadocentesdocxDocument4 pagesEnglish Final Exam Level III - CadocentesdocxJames MarinNo ratings yet

- Simulated Distillation TgaDocument7 pagesSimulated Distillation TgaJames MarinNo ratings yet

- Rye Columna Snyder 3 Bolas 2158 3coDocument1 pageRye Columna Snyder 3 Bolas 2158 3coJames MarinNo ratings yet

- El Recetario Industrial Hiscox-HopkinsDocument1,348 pagesEl Recetario Industrial Hiscox-HopkinsfolskanNo ratings yet

- SK Accessories - ENYAQ - Unpriced - JAN 2023 ART V2Document30 pagesSK Accessories - ENYAQ - Unpriced - JAN 2023 ART V2Viktor RégerNo ratings yet

- Health Programs Activities Timeframe Expected Output Child CareDocument3 pagesHealth Programs Activities Timeframe Expected Output Child CareC SamNo ratings yet

- CWK-IDD-009-CC-2020: Reference Checking Consent and Authorization Form Candidate's Full NameDocument1 pageCWK-IDD-009-CC-2020: Reference Checking Consent and Authorization Form Candidate's Full NamePopa Alina-ManuelaNo ratings yet

- Variable Displacement Engines: The Magic of Cylinder DeactivationDocument3 pagesVariable Displacement Engines: The Magic of Cylinder DeactivationdinuNo ratings yet

- EXPERIMENT 5 - Chroamtorgraphy GRP9 RevDocument2 pagesEXPERIMENT 5 - Chroamtorgraphy GRP9 RevMic100% (2)

- The Congressional Committee and Philippine Policymaking: The Case of The Anti-Rape Law - Myrna LavidesDocument29 pagesThe Congressional Committee and Philippine Policymaking: The Case of The Anti-Rape Law - Myrna LavidesmarielkuaNo ratings yet

- Cd6352 Lee Swee LeongDocument24 pagesCd6352 Lee Swee LeongFrea Marie SarabiaNo ratings yet

- Generate Profits from Bottled Water Using Atmospheric Water GeneratorsDocument20 pagesGenerate Profits from Bottled Water Using Atmospheric Water GeneratorsJose AndradeNo ratings yet

- Reading 1Document2 pagesReading 1Marcelo BorsiniNo ratings yet

- SmithfieldDocument11 pagesSmithfieldandreea143No ratings yet

- Assessing Inclusive Ed-PhilDocument18 pagesAssessing Inclusive Ed-PhilElla MaglunobNo ratings yet

- Sunflower Herbicide ChartDocument2 pagesSunflower Herbicide ChartpapucicaNo ratings yet

- Test Units and Accessories: Sinteso™Document22 pagesTest Units and Accessories: Sinteso™Imad QsnNo ratings yet

- SafewayDocument70 pagesSafewayhampshireiiiNo ratings yet

- 3.SAFA AOCS 4th Ed Ce 2-66 1994Document6 pages3.SAFA AOCS 4th Ed Ce 2-66 1994Rofiyanti WibowoNo ratings yet

- 6V Plush Ride-On: Owner'S ManualDocument26 pages6V Plush Ride-On: Owner'S ManualVisas LaredoNo ratings yet

- Chemistry CHM 1311C 2012 Test 1 BlankDocument6 pagesChemistry CHM 1311C 2012 Test 1 BlankSimon HagosNo ratings yet

- VERALLIA WHITE-BOOK EN March2022 PDFDocument48 pagesVERALLIA WHITE-BOOK EN March2022 PDFEugenio94No ratings yet

- Kidde Ads Fm200 Design Maintenance Manual Sept 2004Document142 pagesKidde Ads Fm200 Design Maintenance Manual Sept 2004José AravenaNo ratings yet

- Biosafety FH Guidance Guide Good Manufacturing Practice enDocument40 pagesBiosafety FH Guidance Guide Good Manufacturing Practice enMaritsa PerHerNo ratings yet

- GDCR Final PDFDocument311 pagesGDCR Final PDFHrushikesh PatelNo ratings yet

- Notes Lecture No 3 Cell Injury and MechanismDocument5 pagesNotes Lecture No 3 Cell Injury and MechanismDr-Rukhshanda RamzanNo ratings yet

- Mola SubseaDocument10 pagesMola Subseashahbaz akramNo ratings yet

- Vacuum Conveyin 5.0Document56 pagesVacuum Conveyin 5.0Mostafa AtwaNo ratings yet

- Environmental Science OEdDocument9 pagesEnvironmental Science OEdGenevieve AlcantaraNo ratings yet