Professional Documents

Culture Documents

Risk Assessment - Placing of Transformer - TTS

Uploaded by

nsadnanOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Risk Assessment - Placing of Transformer - TTS

Uploaded by

nsadnanCopyright:

Available Formats

T

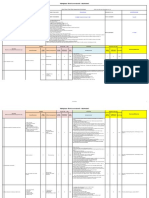

EHS RISK ASSESSMENT T International

S

ACTIVITY: REMOVING AND RE-INSTALLATION OF TRANSFORMER

Current Risk Final Risk

Task (Steps) Potential Hazard Existing Control Additional Control

Cons. Prob. Risk Cons. Prob. Risk

Lifting area must be

Hit by moving object cordoned off.

Trip hazards Supervisors, riggers and

helpers to be properly

trained and competent.

Head injuries

General operations on Wearing of proper PPE

site Fatal injury including hard hat, safety

4 1 4

shoes, safety goggles and

Falling hi-vis vest.

Bodyparts caught/crushed All lifting and jacking

equipment and

accessories to be third

party certified.

Wearing of proper PPE

Bodyparts getting caught Trained and experienced

Place supports personnel

underneath of transformer 2 1 2

Incorrect positioning of

supports underneath load Visual checking of

positioning vs drawings

and actual support points

Wearing of proper PPE

Bodyparts getting caught Trained and experienced

Placing of beams for

personnel

transformer rest on 2 1 2

supports Incorrect positioning of

beams underneath load Visual checking of

positioning vs drawings

and actual support points

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 1 of 6

T

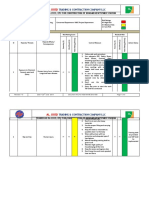

EHS RISK ASSESSMENT T International

S

ACTIVITY: REMOVING AND RE-INSTALLATION OF TRANSFORMER

Wearing of proper PPE

Trained and experienced

personnel

Ensuring bodyparts are clear

prior to setting down of jacks

Offloading transformer on Failure of hydraulic

supports system Visual checking of positioning 3 1 3

vs drawings and actual

support point

Ensuring the jacks are of

sufficient capacity for the

transformer.

Wearing of proper PPE

Bodyparts getting caught Trained and experienced

personnel

Placing beams & rollers 4 1 4

Incorrect positioning of

rollers underneath load Visual checking of positioning

vs drawings and actual

support points

Wearing of proper PPE

Trained and experienced

personnel

Ensuring bodyparts are clear

prior to setting down of jacks

Offloading transformer on Failure of hydraulic

rollers system Visual checking of positioning 3 1 3

vs drawings and actual

support points

Ensuring the jacks are of

sufficient capacity for the

transformer.

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 2 of 6

T

EHS RISK ASSESSMENT T International

S

ACTIVITY: REMOVING AND RE-INSTALLATION OF TRANSFORMER

No unauthorised personnel in

the area

Roller slipping from Experienced and qualified

underneath skid

riggers and operators

Hit by moving object Wearing of proper PPE

Pulling of transformer Ensuring all in the working

Pulling wire breaking area are aware of the moving 4 1 4

through the loading area

objects and the wires

Trip hazard over pulling

wire Keeping close observation of

roller movement

Overload of rollers

Ensuring all equipment is

tested, certified and of

sufficient capacity

Experienced personnel.

Wearing of PPE.

Bodyparts caught Use of taglines.

Offload the load on between load and landing Ensuring all bodyparts clear

Foundation surface 4 1 4

from any potential jamming

area.

Failure of landing area

Ensuring the landing area is

strong enough to carry the

imposed load.

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 3 of 6

T

EHS RISK ASSESSMENT T International

S

ACTIVITY: REMOVING AND RE-INSTALLATION OF TRANSFORMER

Operator must pass third

party competency test for

crane operation and secure

competency certificate.

Operator should attend

induction course for crane

operation.

Obtain lift authorization.

Loading and offloading of Crane must have:

transformer by using Unauthorized 1. Valid registration 4 3 12

crane operation of crane from RTA to Travel.

2. Valid certificate of

conformity or

through crane

3. inspection from

approved

certification

agencies.

4. Statement of

insurance policy.

Crane must be certified by

approved third party

certification agencies.

Ensure crane has valid EMAL

inspection sticker

Gears, chains, and belts

Mechanical Failure should be inspected, third 4 3 12

party certified and colour

coded to use.

Avoid overloading of

transport equipment.

Lift load for its specific load

limit or safe working load.

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 4 of 6

T

EHS RISK ASSESSMENT T International

S

ACTIVITY: REMOVING AND RE-INSTALLATION OF TRANSFORMER

Use tag lines or tag ropes to

guide the load towards its

destination.

Having no control of Supervisor to advice workers

4 3 12

the load not to walk, come close or

stand under the load.

Assign a certified

rigger/banksman.

Operator can be Only certified

confused if more rigger/banksman is

than one person authorized to give signal 3 4 12

giving instruction or during lifting operation.

signal.

Lifting job to be

stopped or postponed at

Adverse weather wind speed of 35kph or

condition (High wind more.

velocity, Sand storm Lifting job to be 4 3 12

etc.) postponed at high velocity

wind resulting to sandstorm

or poor visibility

NOTE: All Current Risk ranked above C-15 must have additional control measures: Risk = Consequence x Probability (R = C x P)

Tolerable Risk (Low) = 1-6, Medium = 8 -12, (Methods statement), Intolerable Risks (High) = 15 25 (Method Statement plus additional Control Measures in place)

Consequence

Consequence ( Severity) Rating Factors (5) Probability Rating Factors (5) Frequency/Probability

(Severity)

No Safety Health Environ. Financial No Frequency A B C D E

1 First Aid Immediate Minor <AED 1k <1 hr A (1) Practically impossible or Once in 10 years 5 5 10 15 20 25

2 Medical Temporary Short term <AED50K 1-2 hrs B (2) Not likely or Once per year 4 4 8 12 16 20

3 Lost Time Short term Long term >AED300k 2-4 hrs C (3) Could happen or Monthly 3 3 6 9 12 15

4 Disability Long term Serious >AED500k 4-8 hrs D (4) Has happened or Weekly 2 2 4 6 8 10

5 Fatality Fatal Catastrophic >AED1m >1 shift E (5) Common or Daily 1 1 2 3 4 5

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 5 of 6

T

EHS RISK ASSESSMENT T International

S

ACTIVITY: REMOVING AND RE-INSTALLATION OF TRANSFORMER

503406-AD0000-68AF-12303_R01 (2012-01-30) Page 6 of 6

You might also like

- Risk Assessment - Pre-Internal Wiring of Patch PanelDocument3 pagesRisk Assessment - Pre-Internal Wiring of Patch Panelnsadnan100% (1)

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Document3 pagesRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- Risk Assessment For Installation of Cable Tray and TruckingDocument1 pageRisk Assessment For Installation of Cable Tray and Truckingazer33% (3)

- Hazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (DueDocument5 pagesHazard Identification Risk Assessment Risk Control (HIRARC) : K Additional Risk K PIC (Duetana83% (6)

- 5.19 JSP Electrical Power InstallationDocument4 pages5.19 JSP Electrical Power InstallationDarius DsouzaNo ratings yet

- Jha RebarsDocument7 pagesJha RebarsJaycee QuinNo ratings yet

- RA Risk Assessment for 33kVA Transformer MaintenanceDocument4 pagesRA Risk Assessment for 33kVA Transformer MaintenancePandu BirumakovelaNo ratings yet

- Risk Assessment For Earthing Work-R1Document3 pagesRisk Assessment For Earthing Work-R1Azhar Mushtaq75% (4)

- JSA FOR Fixing of Light FittingsDocument1 pageJSA FOR Fixing of Light Fittingswahyu nugroho100% (1)

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Ehs Risk AssessmentDocument2 pagesEhs Risk AssessmentRohit Singh100% (1)

- 2 - Pulling CablesDocument5 pages2 - Pulling CablesAhmed KhaledNo ratings yet

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- (Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)Document3 pages(Potential/existing) (Permits, Safety Precautions, Equipment, PPE, Recommended Actions)krisNo ratings yet

- Installation of Earthing SystemDocument9 pagesInstallation of Earthing SystemamalNo ratings yet

- JSA Electrical Maintenance LCSDocument8 pagesJSA Electrical Maintenance LCSmohamed yasinNo ratings yet

- RISK ASESSMENT For MAST CLIMBERDocument16 pagesRISK ASESSMENT For MAST CLIMBERadeoye Adeyemi100% (4)

- JSA Transformer InstallationDocument1 pageJSA Transformer Installationpushpanath reddyNo ratings yet

- Risk Assessment - Distribution Board (DB) & Junction Box (JB) InstallationDocument6 pagesRisk Assessment - Distribution Board (DB) & Junction Box (JB) Installationnsadnan91% (11)

- 5-Pole Erection & Stringing PDFDocument2 pages5-Pole Erection & Stringing PDFAhmed Zai50% (4)

- 001 - JHA Survey Setting Out - REV000Document5 pages001 - JHA Survey Setting Out - REV000Venkadesh Periathambi100% (2)

- Installing Cladding Risk AssessmentDocument3 pagesInstalling Cladding Risk AssessmentAhmed Tarek67% (3)

- Concrete WorkDocument1 pageConcrete WorkChandruNo ratings yet

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocument6 pagesRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- HIRA - Fixed Scaffold and Wall BreakingDocument6 pagesHIRA - Fixed Scaffold and Wall BreakingSujan Augustin100% (2)

- EHS risk assessment for transformer erectionDocument2 pagesEHS risk assessment for transformer erectionshamshu123No ratings yet

- Installation of Diesel GeneratorDocument12 pagesInstallation of Diesel Generatoramal100% (1)

- Risk Assessment Distribution Board DB Junction Box Junction Box InstallationDocument6 pagesRisk Assessment Distribution Board DB Junction Box Junction Box InstallationAnonymous HeA9HEbtDmNo ratings yet

- 012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1Document6 pages012 - Risk Ass. - CG 4760 - Earthing Sysytem Installation - S - Rev. 1nsadnan100% (11)

- Workplace Risk AssessmentDocument8 pagesWorkplace Risk AssessmentAsad Raza100% (3)

- Risk Assessment For Hot WorksDocument4 pagesRisk Assessment For Hot Workseldho100% (1)

- Risk Assessment Form: 1 Biophysical HazardsDocument5 pagesRisk Assessment Form: 1 Biophysical HazardsGajendran Sriram33% (3)

- Drilling Work by MCDocument1 pageDrilling Work by MCChandruNo ratings yet

- Risk Assessment - Installation and Testing of Motorized Fire & Smoke DamperDocument10 pagesRisk Assessment - Installation and Testing of Motorized Fire & Smoke Dampernsadnan50% (2)

- Transformer Oil Regeneration Issue Based Risk AssessmentDocument2 pagesTransformer Oil Regeneration Issue Based Risk AssessmentMoses Muchakaviri100% (4)

- 012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Document5 pages012 Risk Ass CG 4760 Earthing Sysytem Installation S Rev 1Em Niax50% (2)

- 004 Annexure D Job Safety SAnalysis JSADocument3 pages004 Annexure D Job Safety SAnalysis JSAAvoor Khan75% (4)

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 pagesRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanNo ratings yet

- DLF PCC HiraDocument6 pagesDLF PCC HiraskfahimuddinNo ratings yet

- Area Hard Barrication JsaDocument7 pagesArea Hard Barrication JsaJanakiramanNo ratings yet

- HIRA For Pre-Commissionong Testing of Over Head Equipment (OHE)Document8 pagesHIRA For Pre-Commissionong Testing of Over Head Equipment (OHE)DEBASISH KHADANGA50% (2)

- Risk Assessment For Repair of ManholeDocument5 pagesRisk Assessment For Repair of Manholeflmm09No ratings yet

- 4-Cable Laying PDFDocument6 pages4-Cable Laying PDFAhmed ZaiNo ratings yet

- Format for JHA WorksheetDocument4 pagesFormat for JHA WorksheetWaseem Ahmad100% (1)

- Changing Faulty Flood Light JSA (BoomLift)Document2 pagesChanging Faulty Flood Light JSA (BoomLift)black_3289No ratings yet

- Power Distribution HIRARC Risk AssessmentsDocument76 pagesPower Distribution HIRARC Risk AssessmentsNazri100% (1)

- PTW272 - Asphalt Paving 17-01-2023Document22 pagesPTW272 - Asphalt Paving 17-01-2023Shah Muzzamil0% (1)

- Cable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentDocument23 pagesCable Pulling / Laying, Glanding and Termination SOP: Task Risk AssessmentMon Trang Nguyễn100% (2)

- DewateringDocument1 pageDewateringChandruNo ratings yet

- Risk Assessment LoaderDocument3 pagesRisk Assessment Loadermohamed ghalyNo ratings yet

- jsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiDocument6 pagesjsa-for-electrical-conduit-installationdocx - compress-đã chuyển đổiMon Trang NguyễnNo ratings yet

- Electrical Risk AssessmentDocument6 pagesElectrical Risk AssessmentEman Fawzy100% (1)

- 012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2Document11 pages012 - Risk Ass - CG 4760 - Earthing Sysytem Installation - S - Rev 2nsadnanNo ratings yet

- AL JOOD TRADING RISK RATINGSDocument5 pagesAL JOOD TRADING RISK RATINGSghada gattouch100% (1)

- RISK ASSESSMENT AND ANALYSISDocument6 pagesRISK ASSESSMENT AND ANALYSISabhinav dj50% (2)

- Risk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in OmbDocument9 pagesRisk Assessment - Ad-456 - Installation and Testing Vav Boxes & Controls in Ombnsadnan100% (1)

- TRA of Lifting of EquipmentsDocument3 pagesTRA of Lifting of EquipmentsandreNo ratings yet

- HVAC Risk AssessmentDocument6 pagesHVAC Risk AssessmentpragyaadanaNo ratings yet

- Pipe Fabrication and Erection JSADocument8 pagesPipe Fabrication and Erection JSAjithin shankarNo ratings yet

- JOB SAFETY ANALYSIS FOR WORKOVER OPERATIONSDocument5 pagesJOB SAFETY ANALYSIS FOR WORKOVER OPERATIONSAshok SureshNo ratings yet

- ONVIF Profile Feature Overview v2-2Document6 pagesONVIF Profile Feature Overview v2-2nsadnanNo ratings yet

- Exc Installation GuideDocument1 pageExc Installation GuidensadnanNo ratings yet

- ONVIF Profile T Specification v1-0Document77 pagesONVIF Profile T Specification v1-0nsadnanNo ratings yet

- ONVIF Profile - S Specification v1-2Document42 pagesONVIF Profile - S Specification v1-2nsadnan0% (1)

- Sensor Line Cable InstallationDocument6 pagesSensor Line Cable InstallationnsadnanNo ratings yet

- Checklist For Access Control System InstallationDocument6 pagesChecklist For Access Control System Installationnsadnan71% (7)

- DDC Systems2Document28 pagesDDC Systems2nsadnan100% (1)

- BSIA Cyber Secure It January 2019Document16 pagesBSIA Cyber Secure It January 2019nsadnanNo ratings yet

- HVAC ManualDocument107 pagesHVAC ManualWissam JarmakNo ratings yet

- Testing and Commissioning Pre-Check List (ID 1506)Document1 pageTesting and Commissioning Pre-Check List (ID 1506)nsadnan0% (2)

- Peer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GageDocument5 pagesPeer Communications Protocol Communications Media: Twisted Pair Copper Conductors Ranging From 16 To 24 GagensadnanNo ratings yet

- Checklist For Commissioning of CCTV SystemDocument2 pagesChecklist For Commissioning of CCTV Systemnsadnan70% (10)

- 1 45Document3 pages1 45nsadnan0% (1)

- Excel Intelligent PduDocument21 pagesExcel Intelligent PdunsadnanNo ratings yet

- Exc Fibre Installation GuideDocument38 pagesExc Fibre Installation GuidensadnanNo ratings yet

- Excel Intelligent Pdu User InstructionsDocument2 pagesExcel Intelligent Pdu User InstructionsnsadnanNo ratings yet

- 109 Installation CCTV Systems PDFDocument60 pages109 Installation CCTV Systems PDFRodelDavidNo ratings yet

- Exc Fibre Installation GuideDocument16 pagesExc Fibre Installation GuideMohamad FaifNo ratings yet

- RISK ASSESSMENT - TK-4742-Operation Training For Overhead CraneDocument6 pagesRISK ASSESSMENT - TK-4742-Operation Training For Overhead CranensadnanNo ratings yet

- Risk Assessment - Tk-4741-Removal Works For Site Office FacilitiesDocument14 pagesRisk Assessment - Tk-4741-Removal Works For Site Office FacilitiesnsadnanNo ratings yet

- Checklist For Pre Commissioning of CCTV SystemDocument1 pageChecklist For Pre Commissioning of CCTV Systemnsadnan67% (6)

- CCTV Testing and Commissioning Pre-Check List (ID 1506)Document1 pageCCTV Testing and Commissioning Pre-Check List (ID 1506)nsadnan67% (3)

- ADDC Electricity Wiring Regulations - Mar.2014Document276 pagesADDC Electricity Wiring Regulations - Mar.2014hajimak89% (18)

- Risk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3Document4 pagesRisk Assessment - Aux. Relay Mounting & Pre-Internal Wiring of RT LCP-3nsadnanNo ratings yet

- Risk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)Document3 pagesRisk Assessment - Repairing The Damaged LV Cable at Sea Water Intake Area (Back Side of BLDG 2221)nsadnan100% (1)

- Risk Assessment - Installation of Ventilation FanDocument6 pagesRisk Assessment - Installation of Ventilation Fannsadnan100% (5)

- RISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolerDocument5 pagesRISK ASSESSMENT - Load Current Measurement and Cleaning of Oil CoolernsadnanNo ratings yet

- RISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling FanDocument6 pagesRISK ASSESSMENT - CG-4750 Phase 1 Upgrade-Inspection and Testing of Bus Bar Cooling Fannsadnan100% (2)

- ISCA Chapter 1 Notes 1Document34 pagesISCA Chapter 1 Notes 1Kumar SwamyNo ratings yet

- 4Q Resource Guide 2016Document52 pages4Q Resource Guide 2016jaimegarcia20No ratings yet

- Equipment Rental Action PlanDocument3 pagesEquipment Rental Action PlanKenneth MedinaNo ratings yet

- Chapter 4 - Organizational and Managerial Issues in Logistics PDFDocument65 pagesChapter 4 - Organizational and Managerial Issues in Logistics PDFTrey HoltonNo ratings yet

- Trading Mistakes PDFDocument6 pagesTrading Mistakes PDFVrushabh SahareNo ratings yet

- NHBC GasDocument132 pagesNHBC GasBart kaczynskiNo ratings yet

- Melvis Group HSE-MSDocument12 pagesMelvis Group HSE-MSAndi NurbayantoNo ratings yet

- Encyclopedia ENVIRONMENTALSECURITYDocument9 pagesEncyclopedia ENVIRONMENTALSECURITYJonas George S. SorianoNo ratings yet

- Portfolio ManagementDocument35 pagesPortfolio Managementhemant vermaNo ratings yet

- Berkshire HathawayDocument4 pagesBerkshire HathawayHasna Nurul Fitri100% (1)

- Professional Standards in Risk Management, IRMDocument28 pagesProfessional Standards in Risk Management, IRMMTNo ratings yet

- DhoneDocument3 pagesDhoneA NaveenNo ratings yet

- PMP Exam 5Document46 pagesPMP Exam 5ibnumoqlaNo ratings yet

- Wind Turbine Fire ProtectionDocument26 pagesWind Turbine Fire ProtectionAsif MohammedNo ratings yet

- Reshaping Retail Banking For Next Normal PDFDocument13 pagesReshaping Retail Banking For Next Normal PDFarisbudimanNo ratings yet

- Diploma: in Treasury ManagementDocument45 pagesDiploma: in Treasury ManagementJewelyn C. Espares-Ciocon100% (1)

- Risk Assessment: Health and SafetycDocument10 pagesRisk Assessment: Health and SafetycNoormal SaidyNo ratings yet

- CHAPTER 1 N 2Document16 pagesCHAPTER 1 N 2Maria Erika GarcesNo ratings yet

- Operational Risk ManagementDocument46 pagesOperational Risk ManagementUnited States Militia100% (2)

- Department of Defense: Standard Practice For System SafetyDocument31 pagesDepartment of Defense: Standard Practice For System SafetyBoris EngelmanNo ratings yet

- Suicide Thesis Statement ExamplesDocument7 pagesSuicide Thesis Statement Examplesafkngwxvn100% (1)

- Risk management techniques for Birzeit UniversityDocument3 pagesRisk management techniques for Birzeit UniversityAya alawiNo ratings yet

- Guidebook On Life InsuranceDocument105 pagesGuidebook On Life InsuranceElearnmarketsNo ratings yet

- ISACA Certification IT Audit - Security - Governance and RiskDocument33 pagesISACA Certification IT Audit - Security - Governance and Riskakbisoi1No ratings yet

- OHS-PR-09-03-F02 HIRA - 011 Excavation Work Using Equipment Rev. 2021Document6 pagesOHS-PR-09-03-F02 HIRA - 011 Excavation Work Using Equipment Rev. 2021MUHAMMAD AHMADNo ratings yet

- TutorialDocument231 pagesTutorialsuryanathNo ratings yet

- EPR ALARP AssessmentDocument5 pagesEPR ALARP AssessmentShaik MushtaqNo ratings yet

- EPWired Magazine February IssueDocument41 pagesEPWired Magazine February IssueBorbála Heléna (Macika)No ratings yet

- Technical Services CatalogueDocument57 pagesTechnical Services CatalogueElson EgidioNo ratings yet

- Ohsas180012007 Hsms ManualDocument36 pagesOhsas180012007 Hsms ManualPrem Shanker RawatNo ratings yet